Patents

Literature

49results about How to "Flexible printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

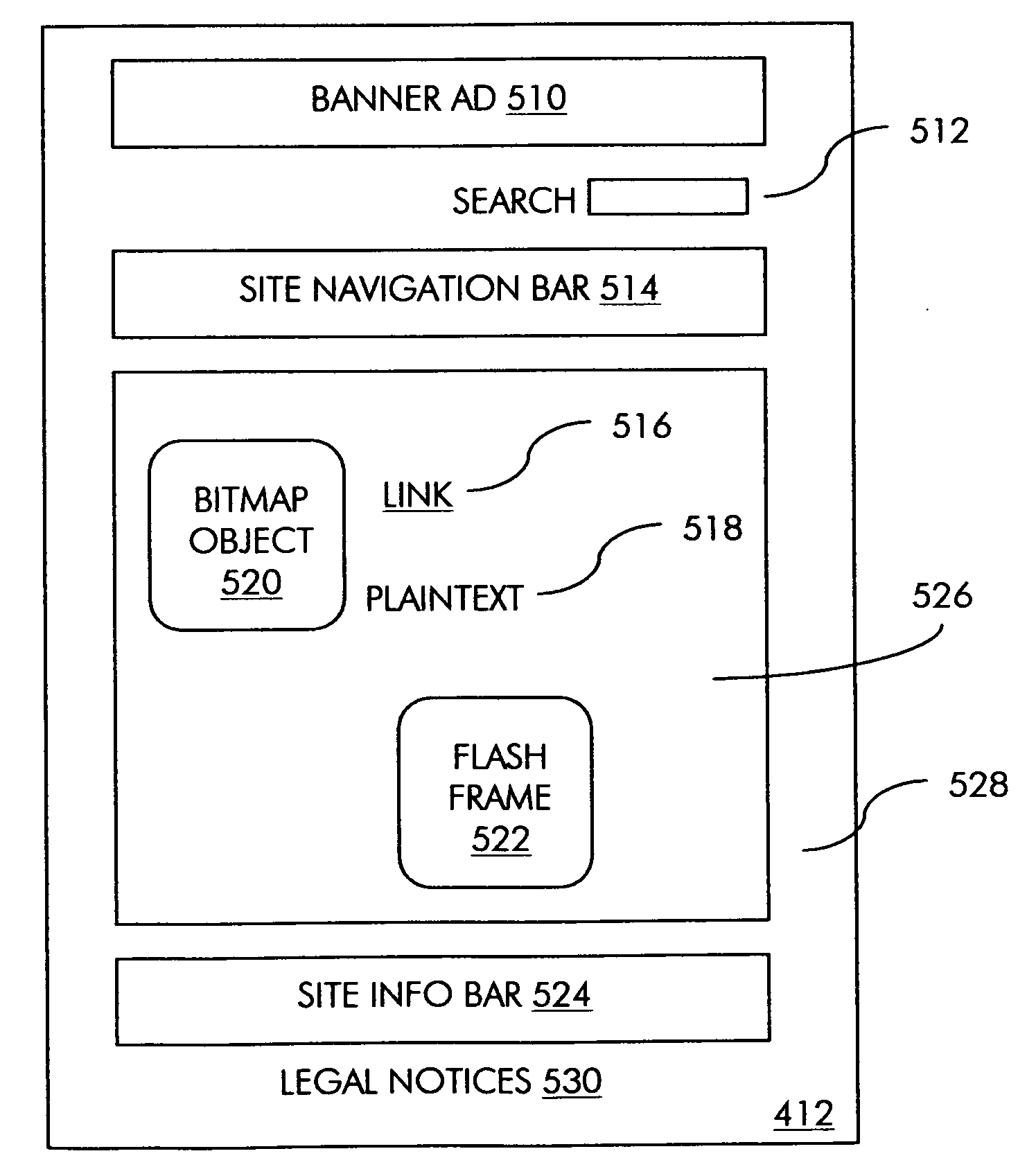

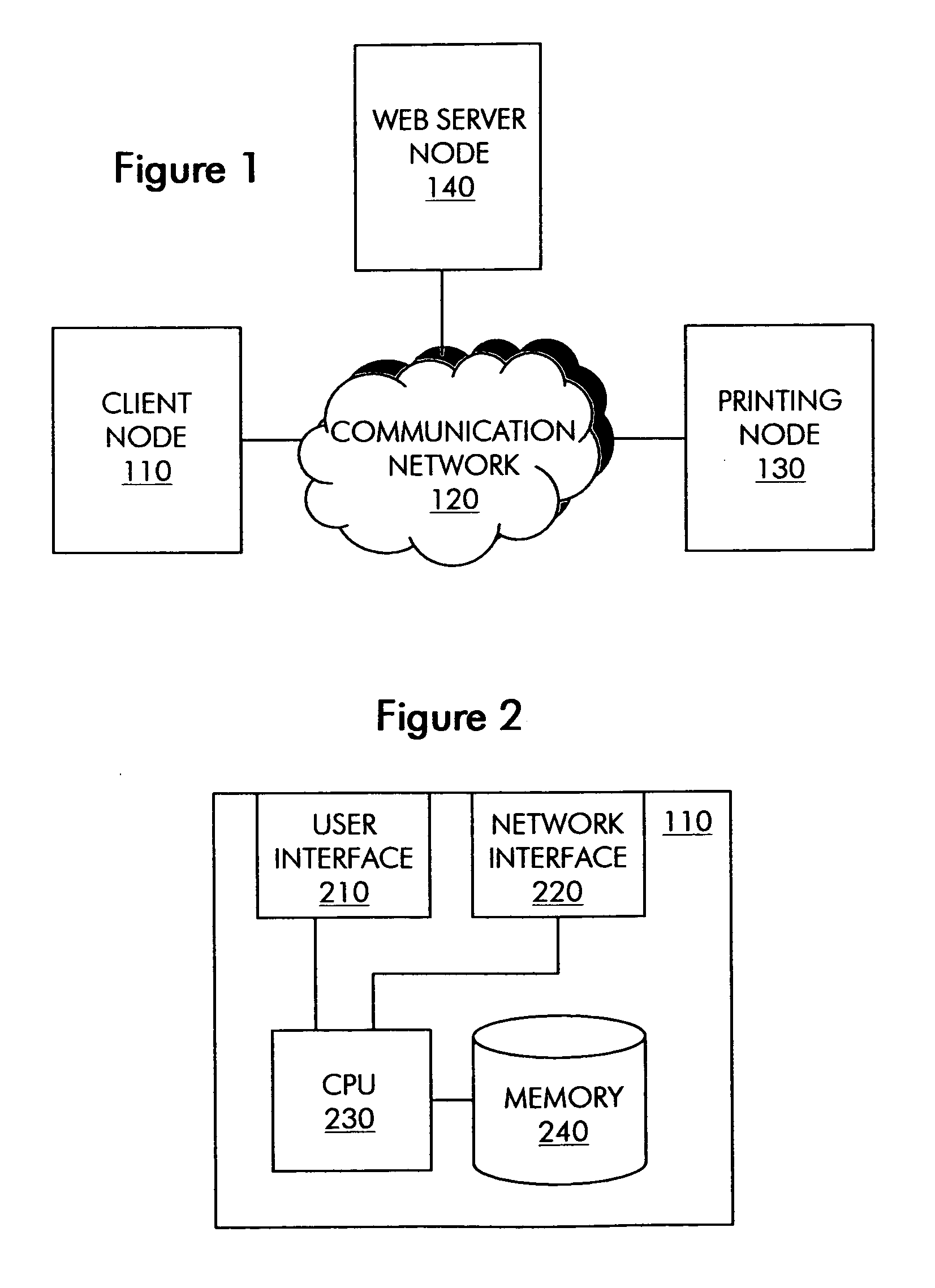

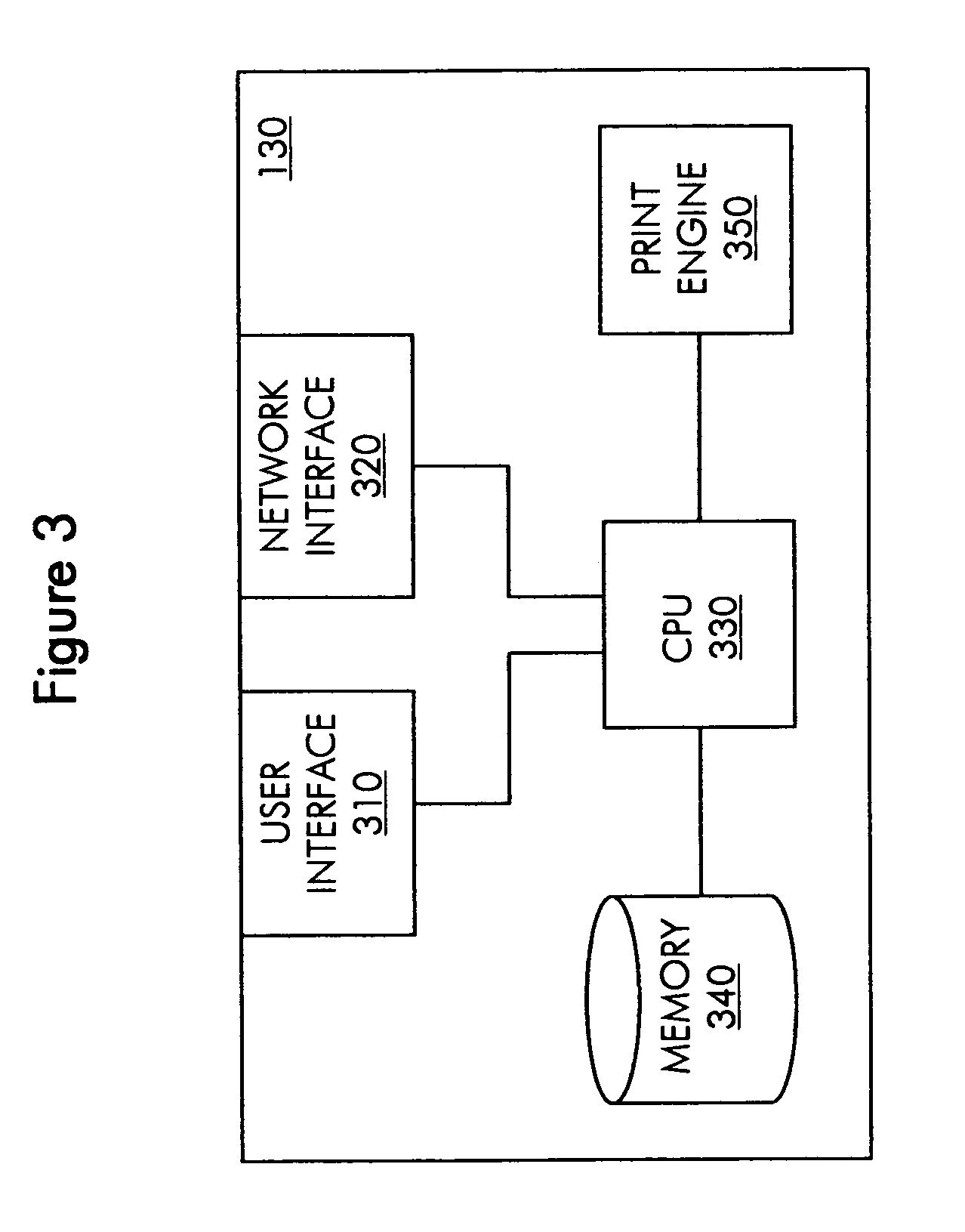

Context-aware printing method and system

InactiveUS20100214614A1Flexible printingIncrease flexibilityVisual presentation using printersDocument preparationContext based

A context-aware printing method and system invoke contextual rendering tags to realize more flexible printing. The contextual rendering tags provide information about the nature or purpose of print elements in a document and are used to identify and selectively modify print elements in a given print instance of the document at the discretion of the user. The contextual rendering tags provide added flexibility in printing by enabling a user to make a broad array of purpose-driven modifications and enabling a document to be printed in multiple instances and in any sequence with modifications indicated by all contextual rendering tags, modifications indicated by a subset of contextual rendering tags or no context-based modifications. For example, print elements that are designated nonessential by contextual rendering tags can be excluded from a printed document in a first print instance to reduce ink consumption and included in a printed document in a second print instance where an unaltered document is required.

Owner:SHARP LAB OF AMERICA

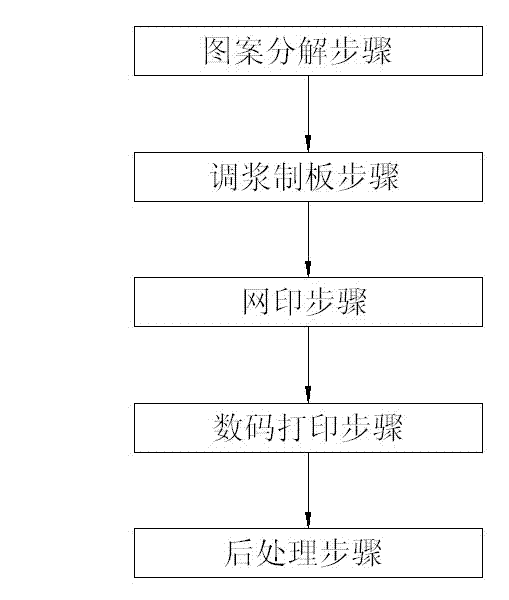

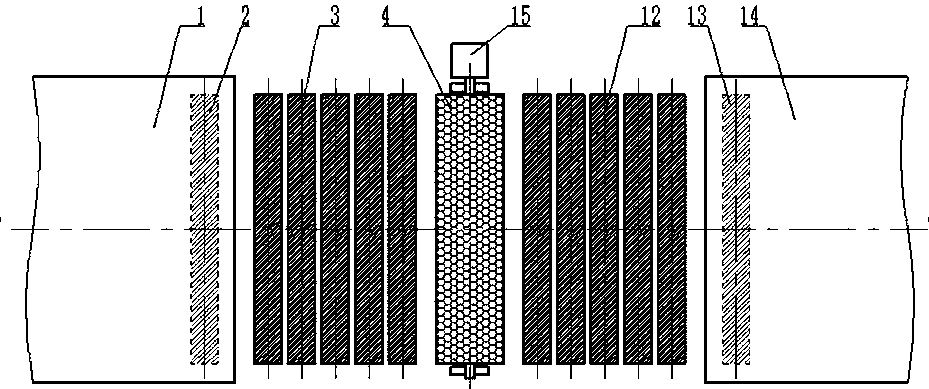

Printing method of combining conventional printing with digital printing

ActiveCN103171319AFlexible printingRich in colorDuplicating/marking methodsTypewritersDigital printingEngineering

The invention relates to a printing method of combining conventional printing with digital printing. At present, no printing method is capable of really and effectively combining conventional printing with digital printing. The printing method sequentially comprises the following steps of:1. decomposing a pattern, namely, decomposing a pattern needing being printed into a conventional printing pattern and a digital printing pattern; 2. mixing size and making plate, namely, carrying out dye blending and making a digital printing screen; 3. carrying out screen printing, namely, carrying out conventional printing and digital printing pretreatment; 4. carrying out digital printing, namely, carrying out digital jet printing on a printing medium by adopting a digital jet printing system with a pre-detection device according to the digital printing pattern, determining a digital printing position on the printing medium, printing the digital printing pattern on the printing medium to ensure that the digital printing pattern is coincident with the conventional printing pattern; and 5. carrying out post-treatment to prepare a finished product. The printing method is good in printing effect and low in production cost, and is capable of really and effectively combining the conventional printing with the digital printing.

Owner:HANGZHOU HONGHUA DIGITAL TECH

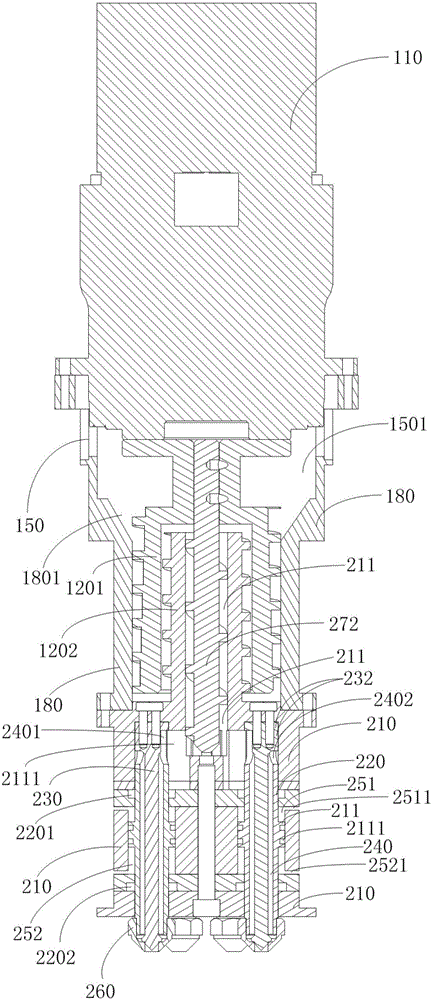

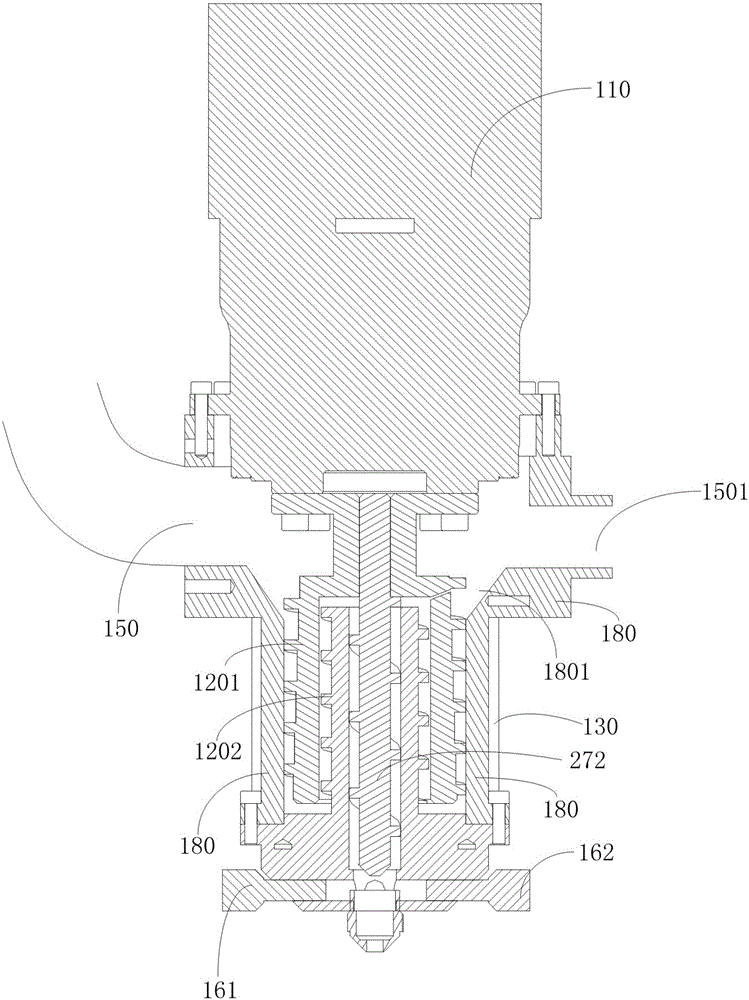

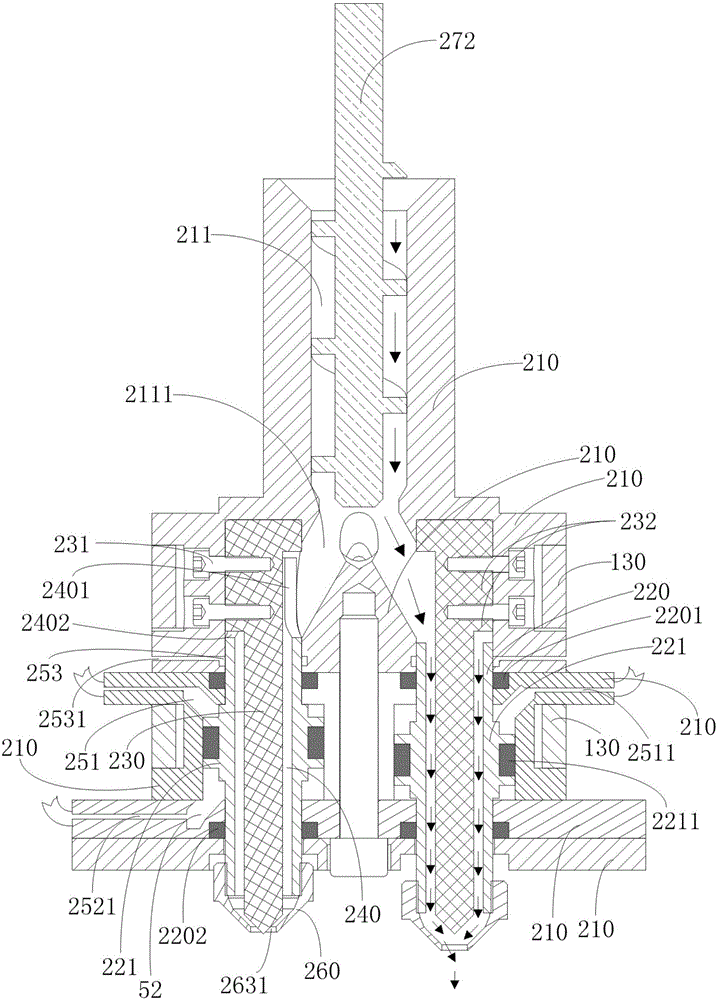

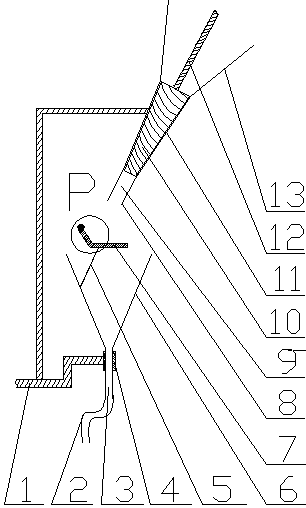

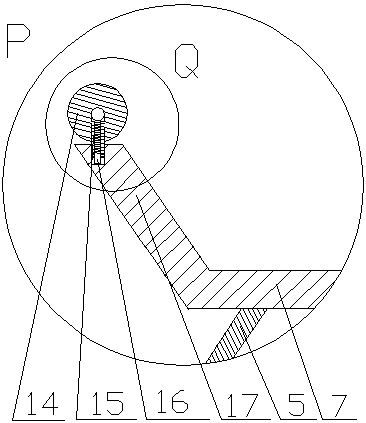

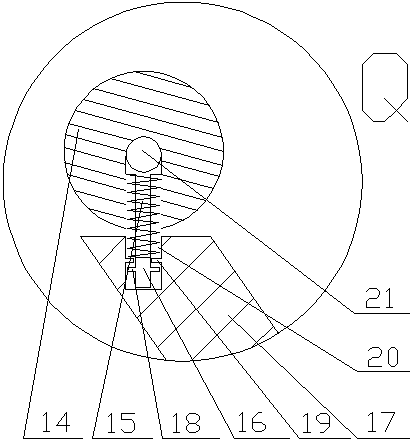

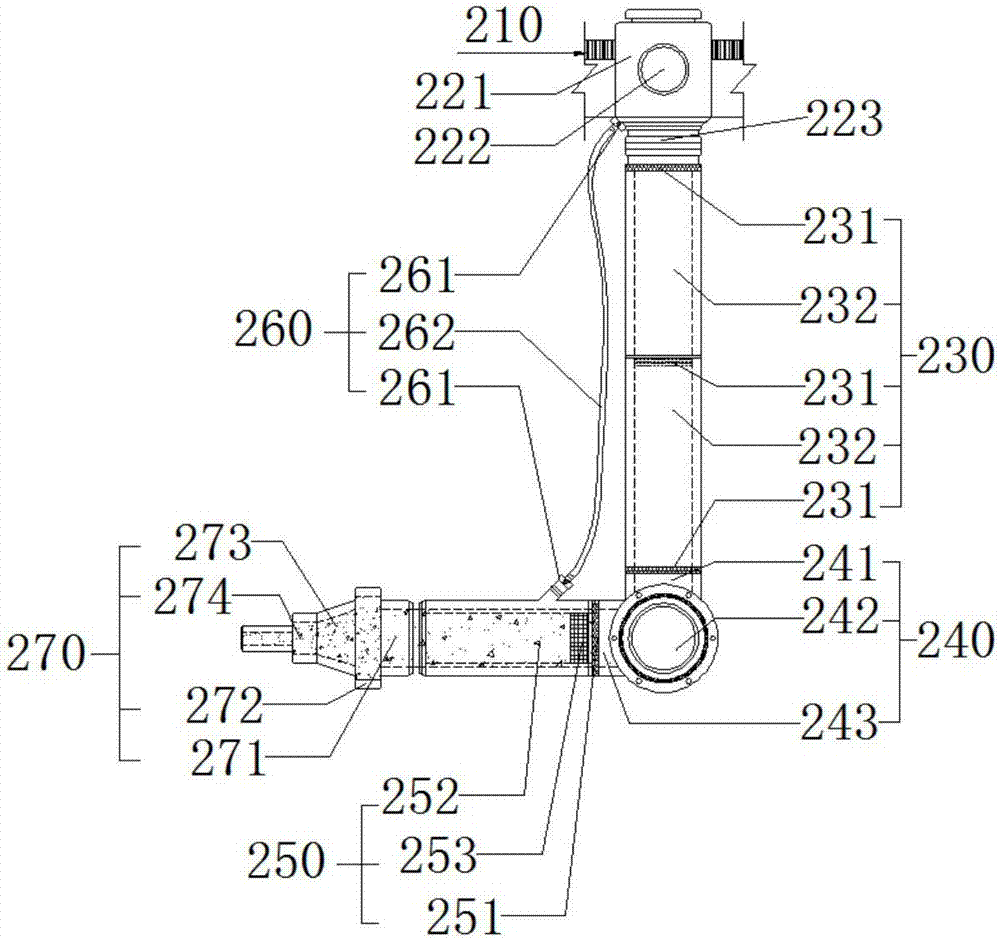

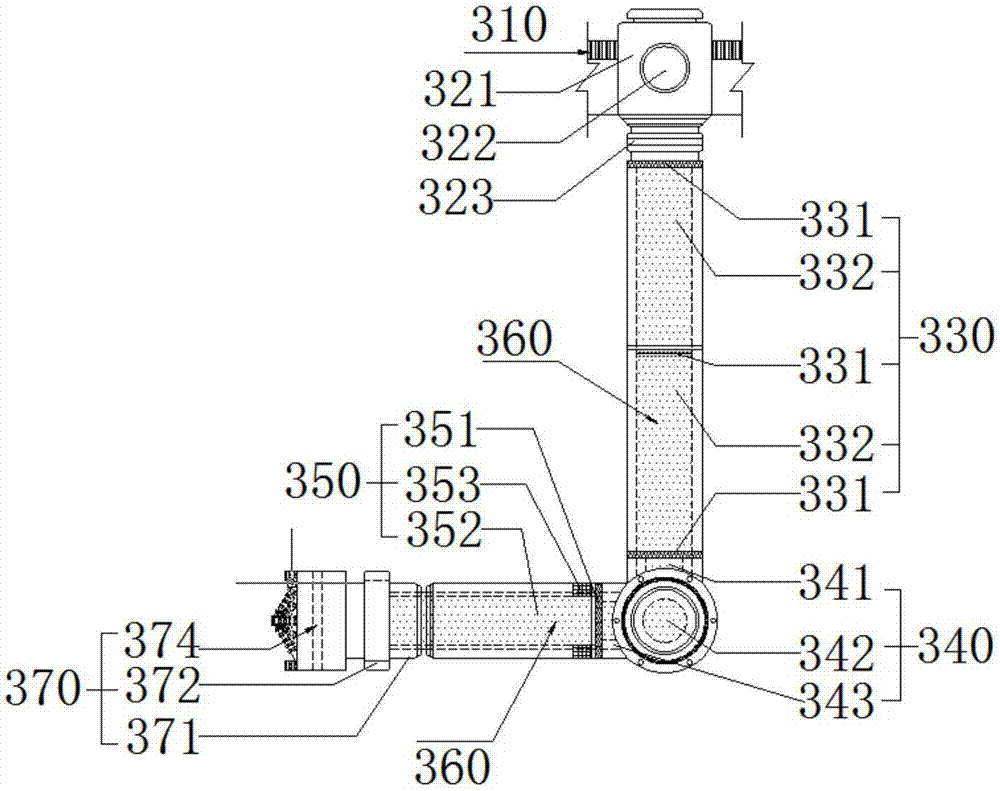

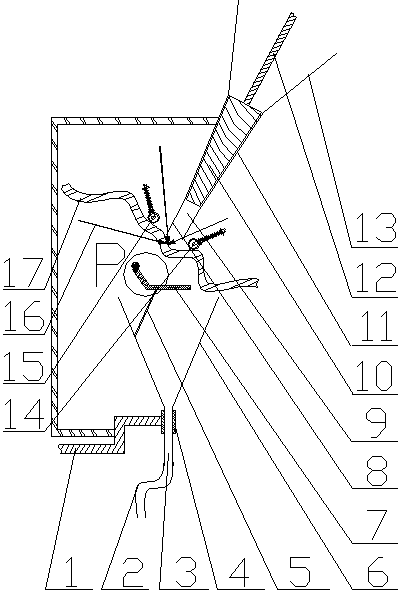

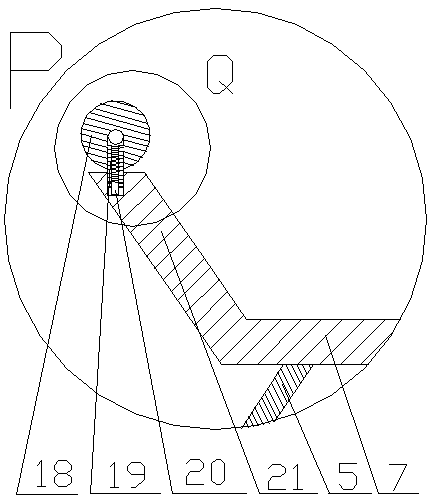

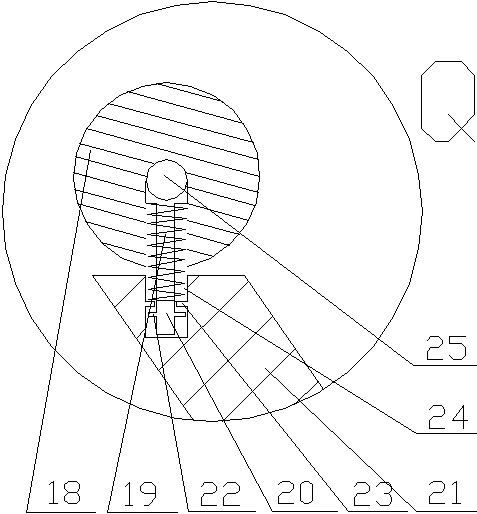

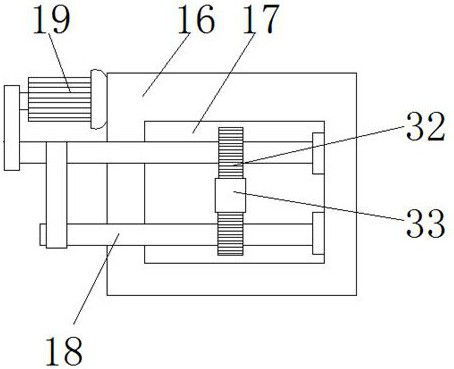

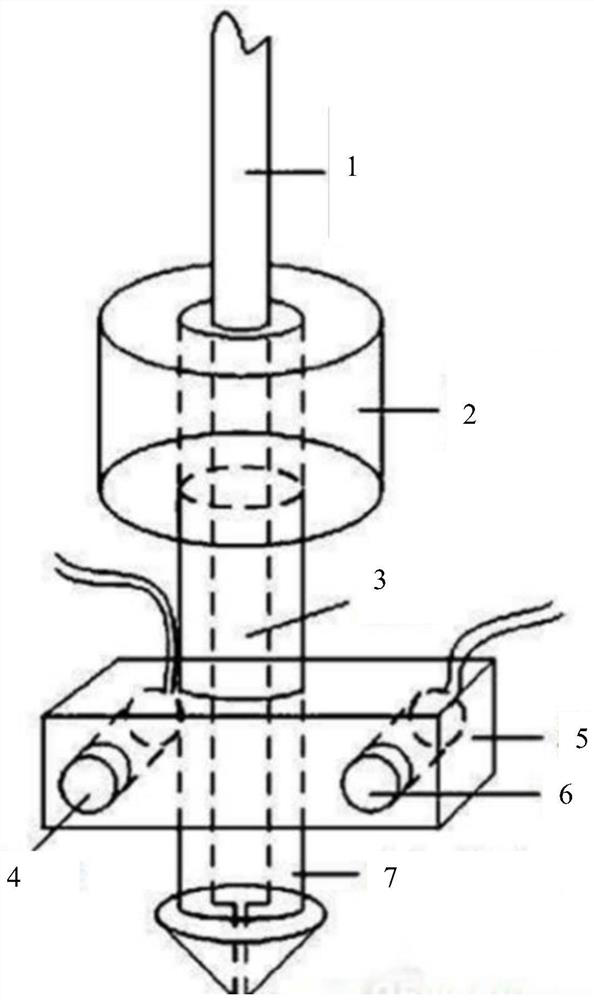

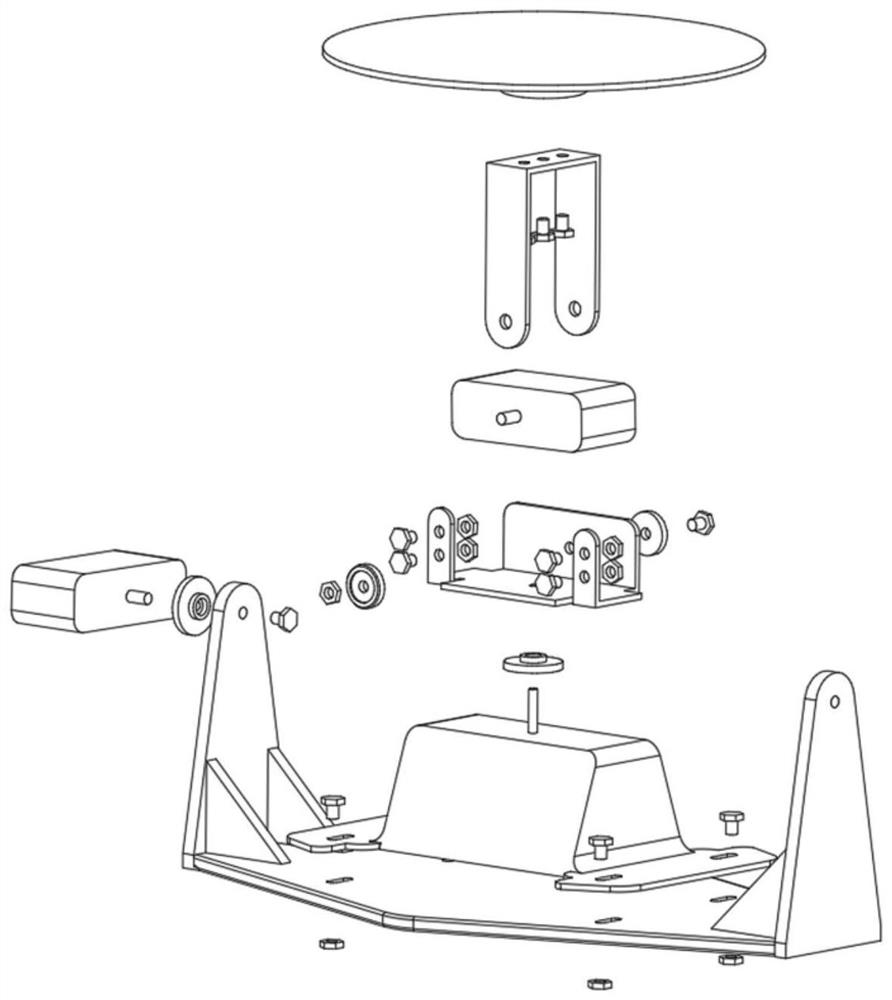

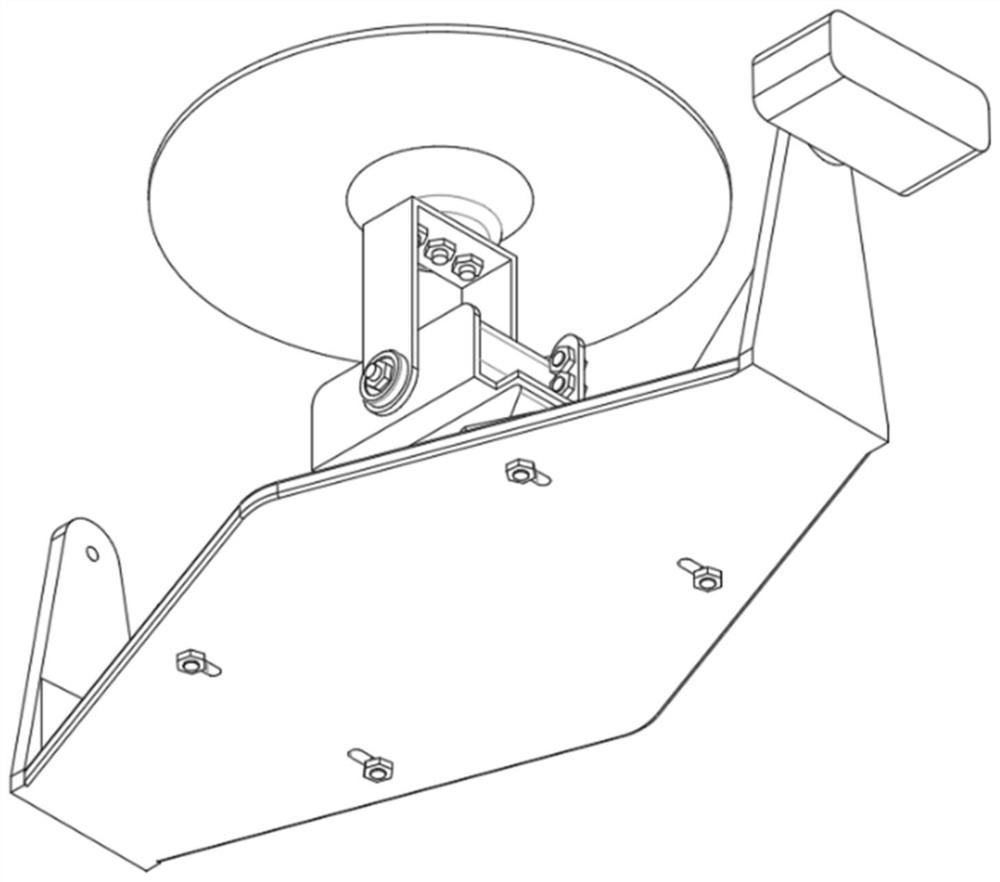

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

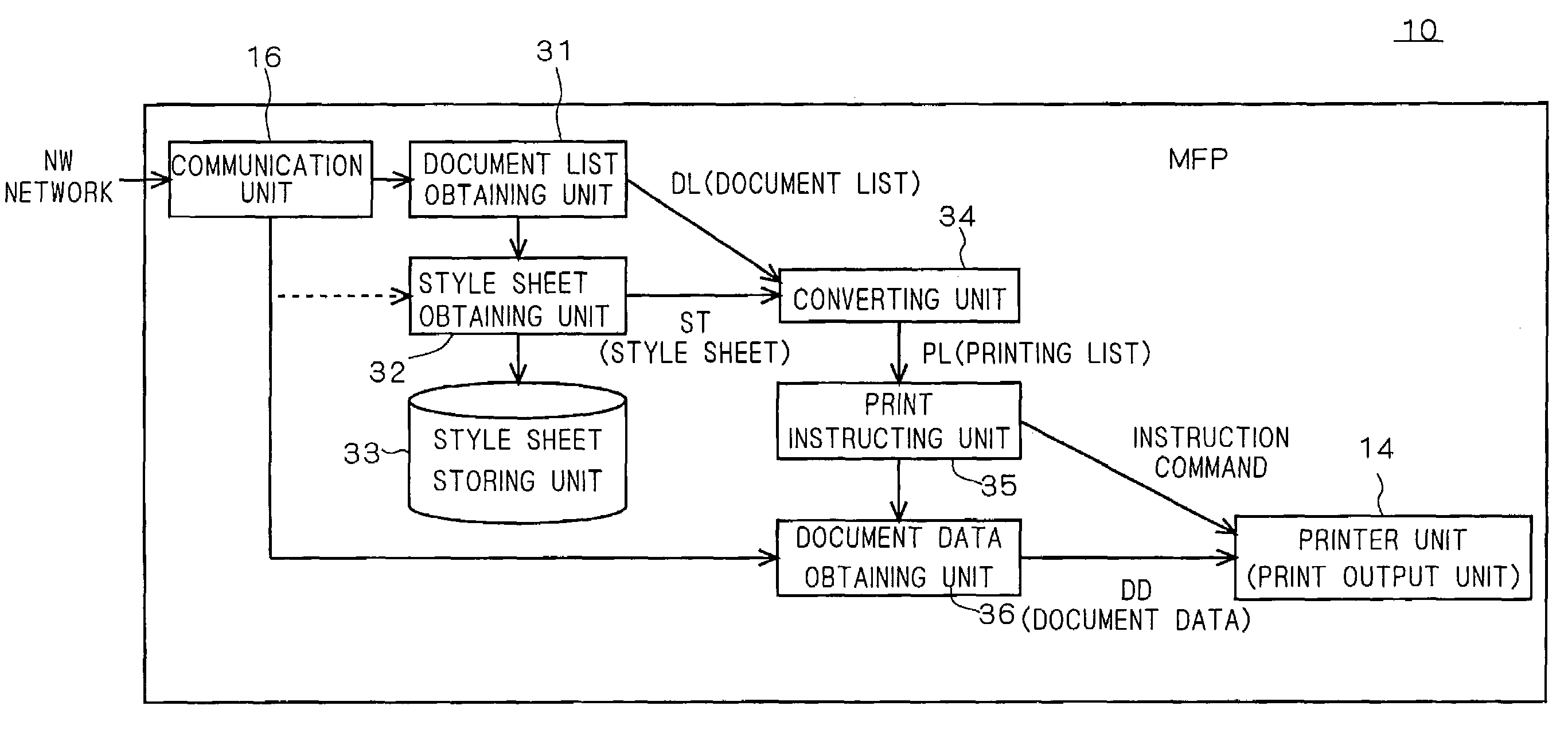

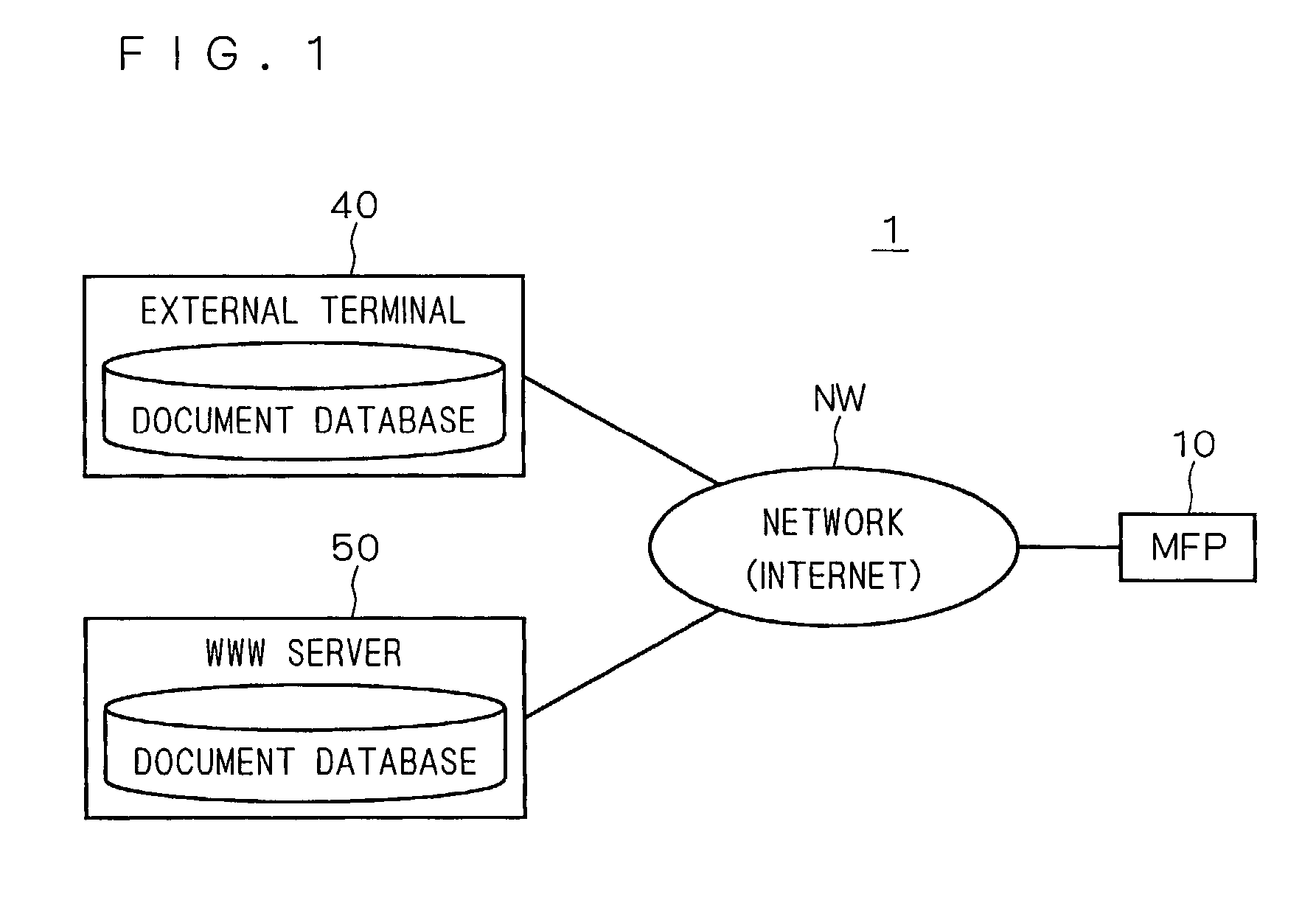

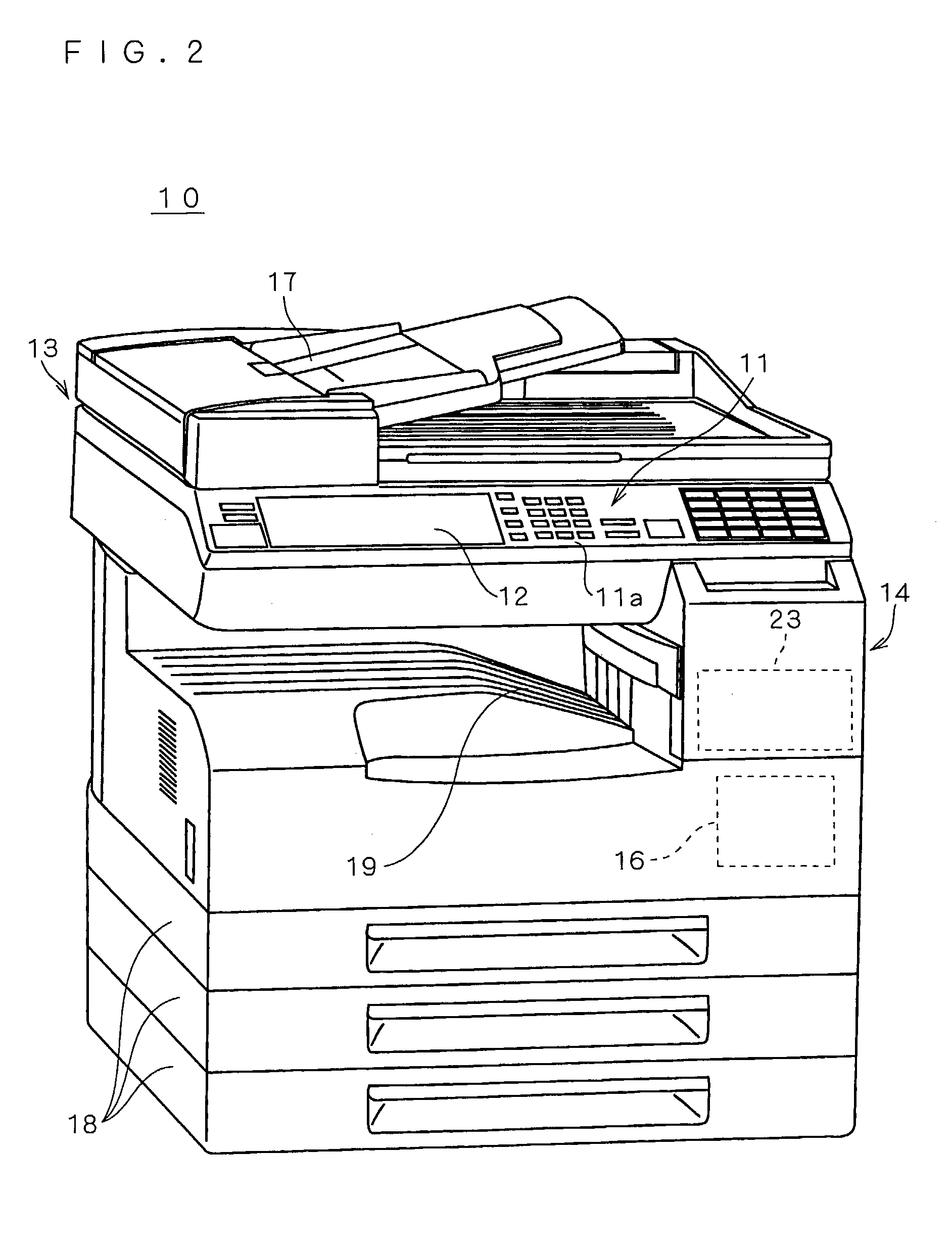

Print control apparatus, method and program using a tag of a document list for printing a plurality of documents in various formats

ActiveUS7414743B2Flexible printingMultiple digital computer combinationsHand compositionDocumentation procedureInstruction unit

The present invention provides a print control technique for printing a plurality of documents more flexibly. A document list obtaining unit in an MFP (Multi Function Peripheral) obtains a document list DL of a plurality of documents to be printed. The document list DL is described by, for example, the XML (extensible Markup Language) or the like. A style sheet obtaining unit obtains a style sheet ST corresponding to the document list DL from a style sheet storing unit or the like. A converting unit converts the document list DL to a printing list PL of a predetermined format by using the tag in the document list DL on the basis of the style sheet ST. On the basis of the printing list PL, a printing instruction unit uses the document data obtained by a document data obtaining unit and outputs a printing instruction to a printer unit. The printer unit continuously prints the plurality of documents onto sheets on the basis of the printing instruction.

Owner:MINOLTA CO LTD

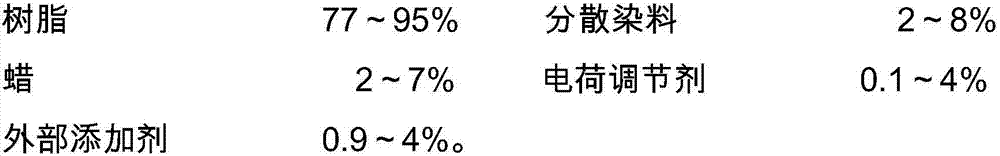

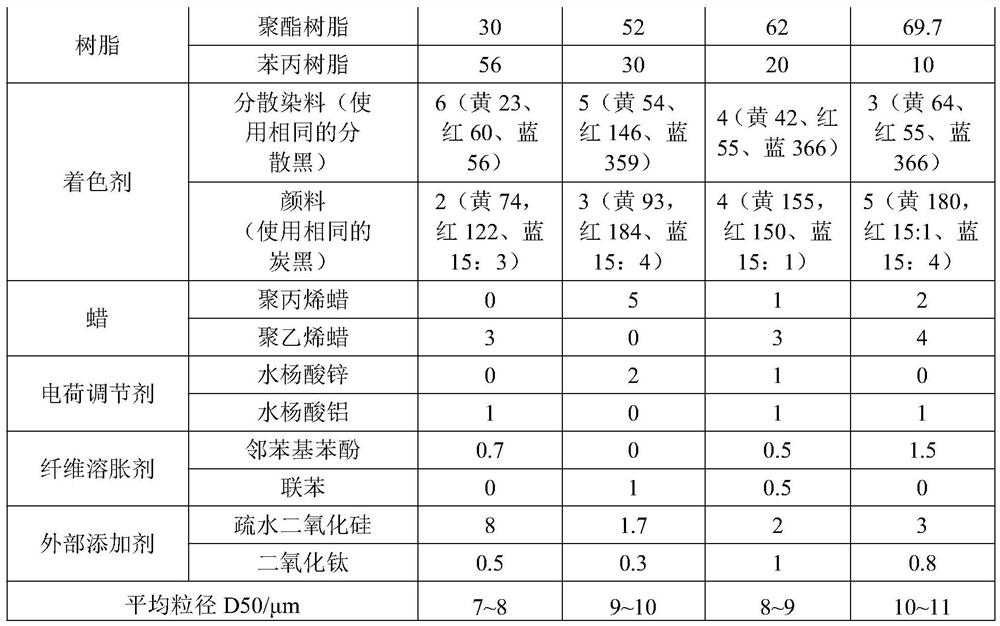

Colorful powdered ink, preparation method thereof and method for digital thermal transfer printing

InactiveCN107329381ASuitable for thermal transfer printingLow costDevelopersDisperse dyeCharge control

The invention discloses colorful powdered ink, a preparation method thereof and a method for digital thermal transfer printing. The colorful powdered ink is composed of, by mass, 77-95% of resin, 2-8% of disperse dye, 2-7% of paraffin, 0.1-4% of charge control agent and 0.9-4% of external addition agent. The colorful powdered ink, with disperse printing dye, prepared through a dry-type physical method has the function of thermal transfer printing. After patterns are printed through a laser printing machine, the patterns can be subjected to transfer printing on substrates of textile products, ceramic, metal, glass, plastic and others through transfer printing equipment by the adoption of a thermal transfer technology of 180-230 DEG C and 10-120 s. Compared with a current ink-spraying thermal transfer technology, the method for digital thermal transfer printing has the advantages that printing speed is high, the production technology is mature, the production process is safer and environmentally friendlier, cost is low, the substrates are wide in application range, the firmness of the patterns after transfer printing is good, and the method is suitable for large-scale printing and personalized customization.

Owner:邯郸汉光办公自动化耗材有限公司

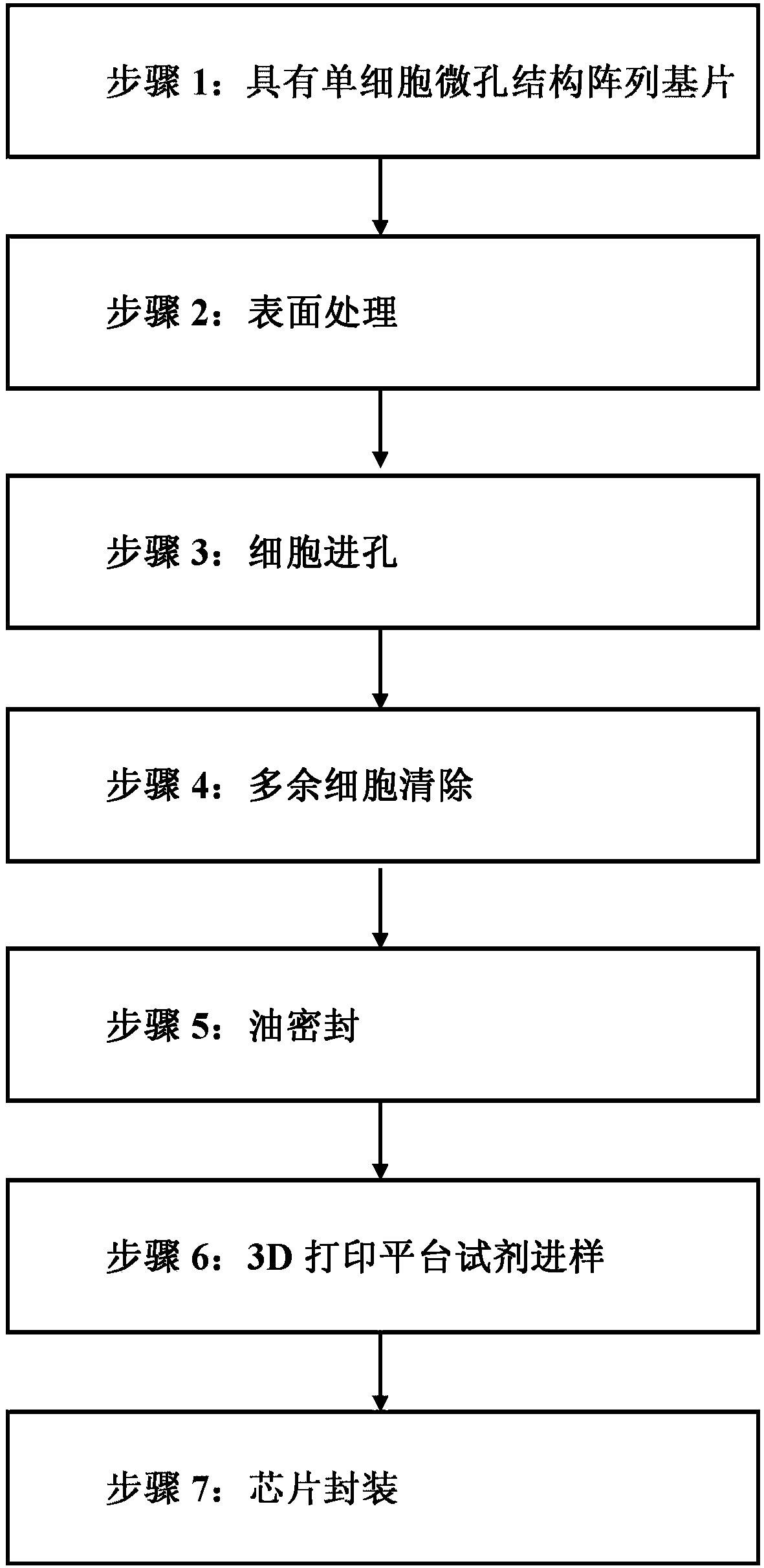

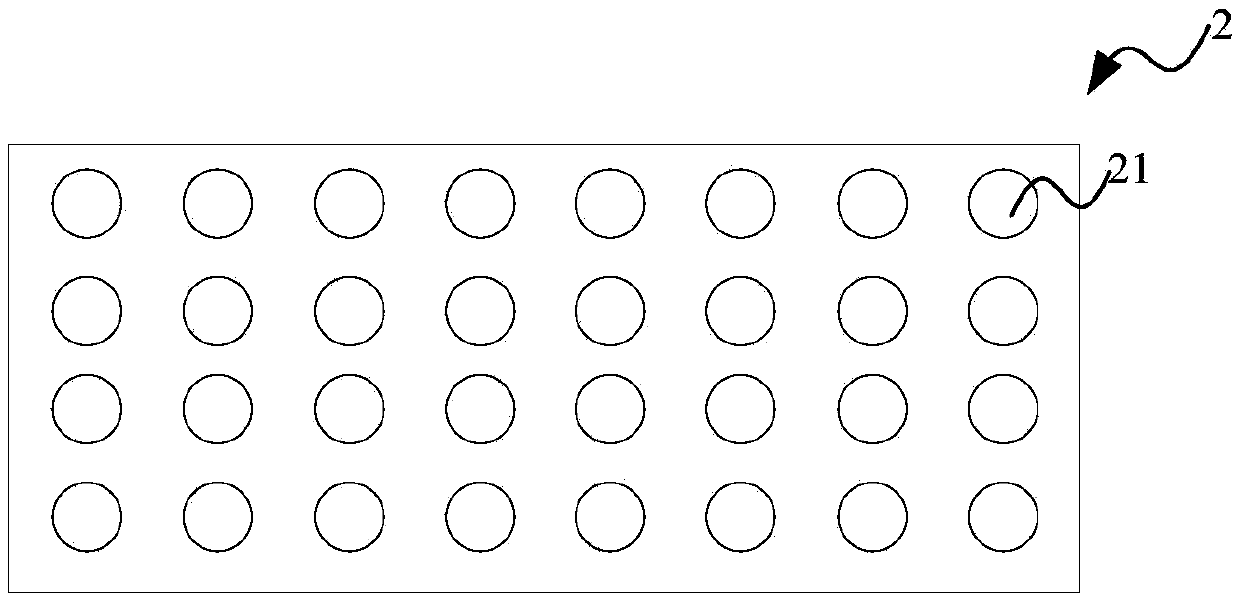

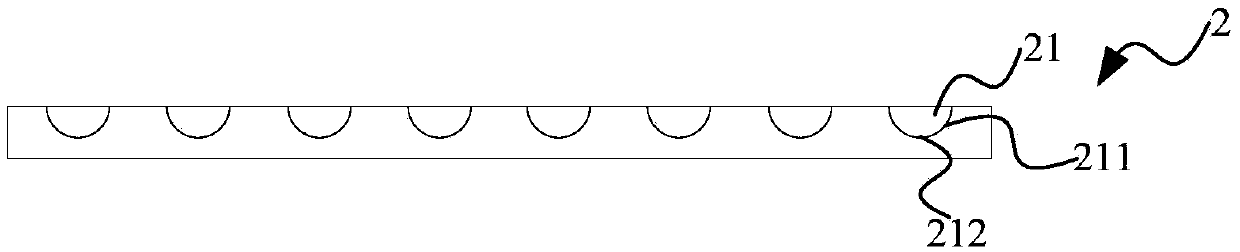

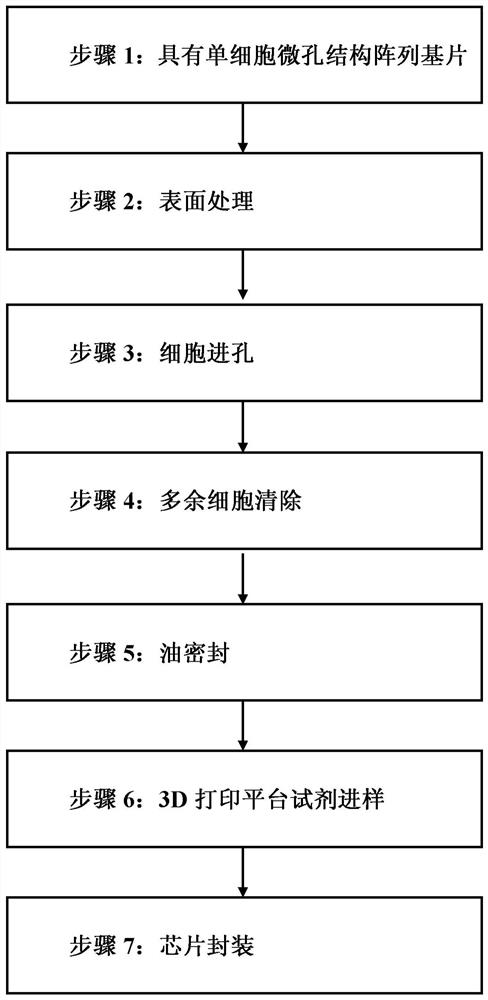

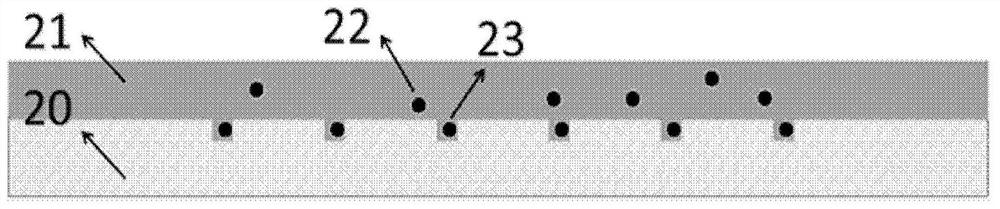

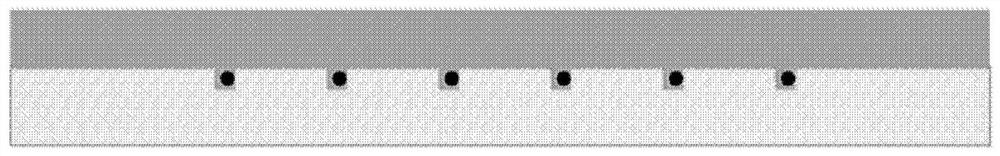

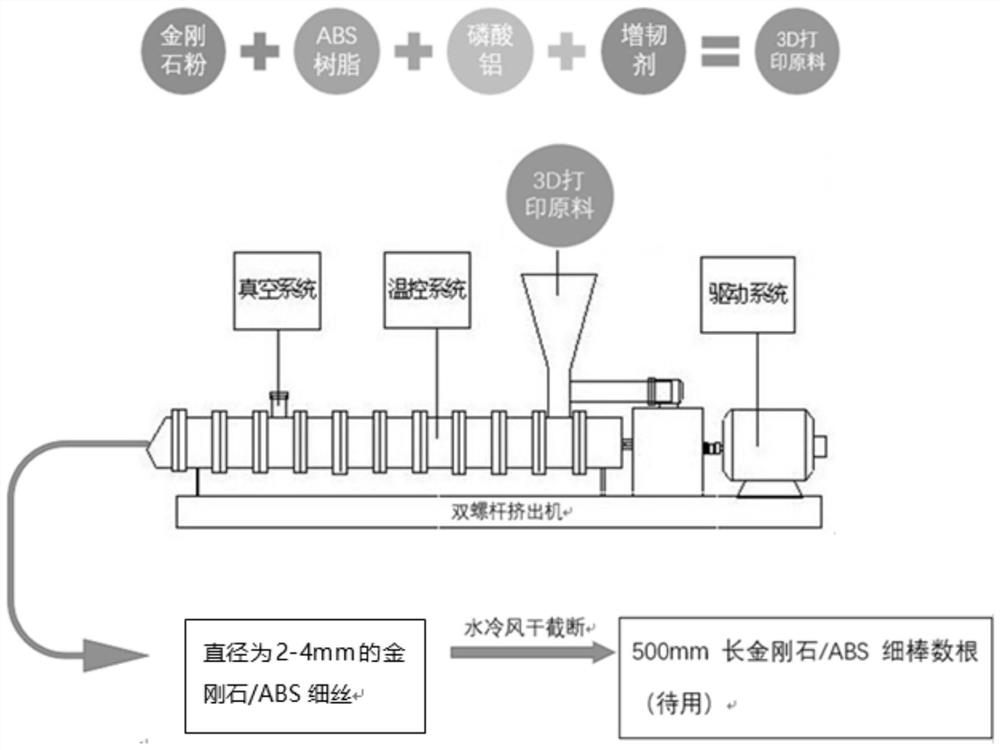

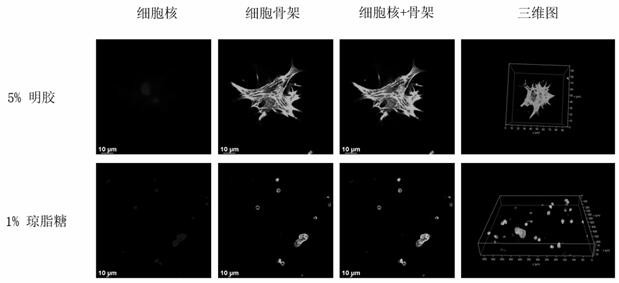

Open chip for single cell research, and preparation method thereof

ActiveCN107828653AEasy to shareEasy to makeBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOpen structure

The invention discloses an open chip for single cell research, and a preparation method thereof. The chip comprises a packaging structure formed by a substrate, a retaining wall and a transparent cover sheet, the substrate has a micro-pore array structure at the inner side of the packaging structure, single cells are accommodated in a plurality of micro-pores of the micro-pore array structure, droplets of reagents for the single cell research are respectively added to the micro-pores in a 3D printing manner from the top, and the remaining space in the packaging structure is filled with sealingoil. The invention further provides the preparation method of the chip. A 3D printing technology is perfectly combined with the single cell micro-pore array to efficiently and fast realize the research at the single cell level, establish a single cell research system with a simple structure, a wide application range and complete functions and realize the high-occupancy single cell capture, the chip can achieve diversified and accurate multi-step liquid feeding treatment of single cells, the above open structure can be applied to various research systems.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Air 3D printing material extruding and holding apparatus

An air 3D printing material extruding and holding apparatus comprises a material extruding device and a material holding device, the material extruding device is composed of a conical tube, a tapered material extruding screw, a feeding hopper, a square tube and a connecting shaft, and the material holding device is composed of a material holding plate, a powder scraping rotating wheel, a material receiving hopper and a material receiving straight tube; the tapered larger opening end of the tapered tube is upward and is connected with the feeding hopper, the tapered material extruding screw is arranged in the tapered tube, the connecting shaft and a motor are arranged at the upper end of the tapered material extruding screw, the small opening end of the tapered tube is downward and is connected with the square tube, an oblique square opening is arranged at one end of the square tube far away from the tapered tube, and the material holding plate is arranged in a position having a preset distance to the oblique square opening and just below the oblique square opening; and the material receiving hopper is arranged below the material holding plate, the lower end port of the material receiving hopper is connected with the material receiving straight tube, the lower end of the material receiving straight tube is connected with a flexible tube, the body of the material receiving hopper is connected with a support arm, and the support arm is connected with the tapered tube and supports the tapered tube and the feeding hopper.

Owner:CHANGSHU INTELLIGENT LASER EQUIP RES INST CO LTD

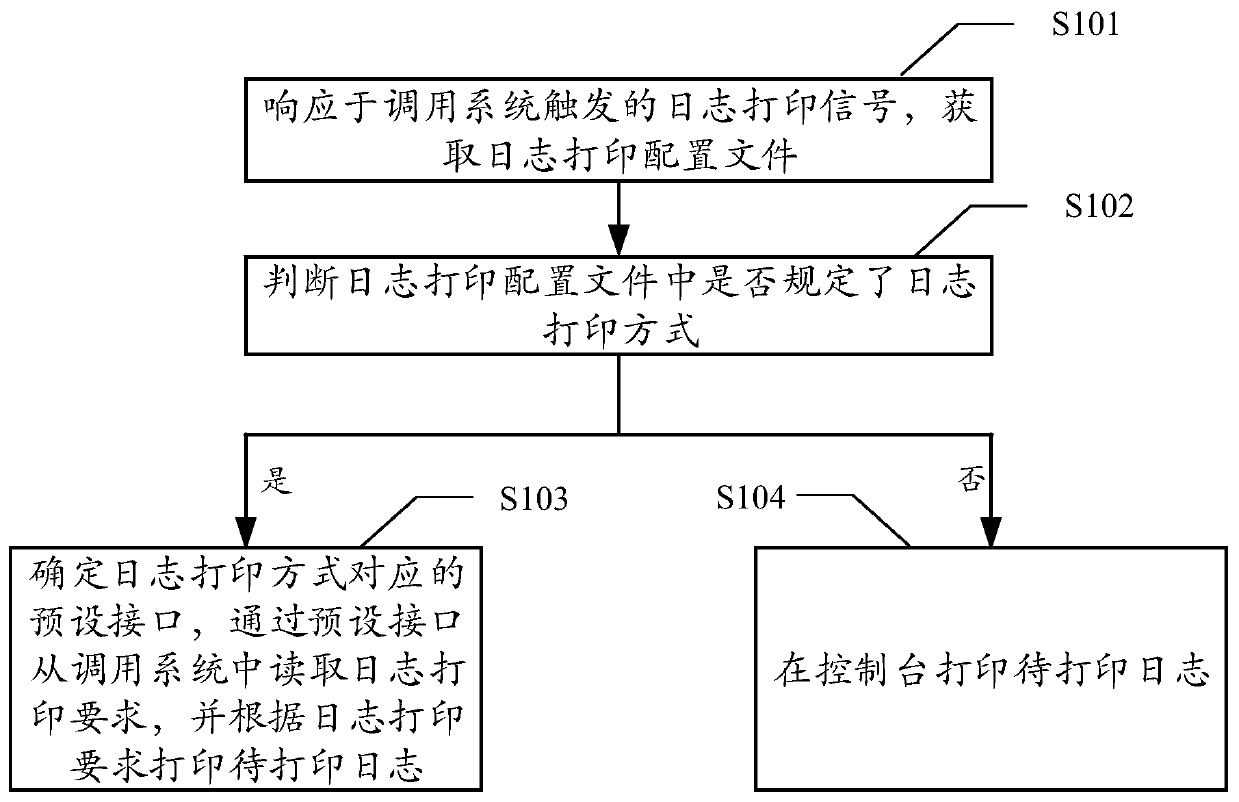

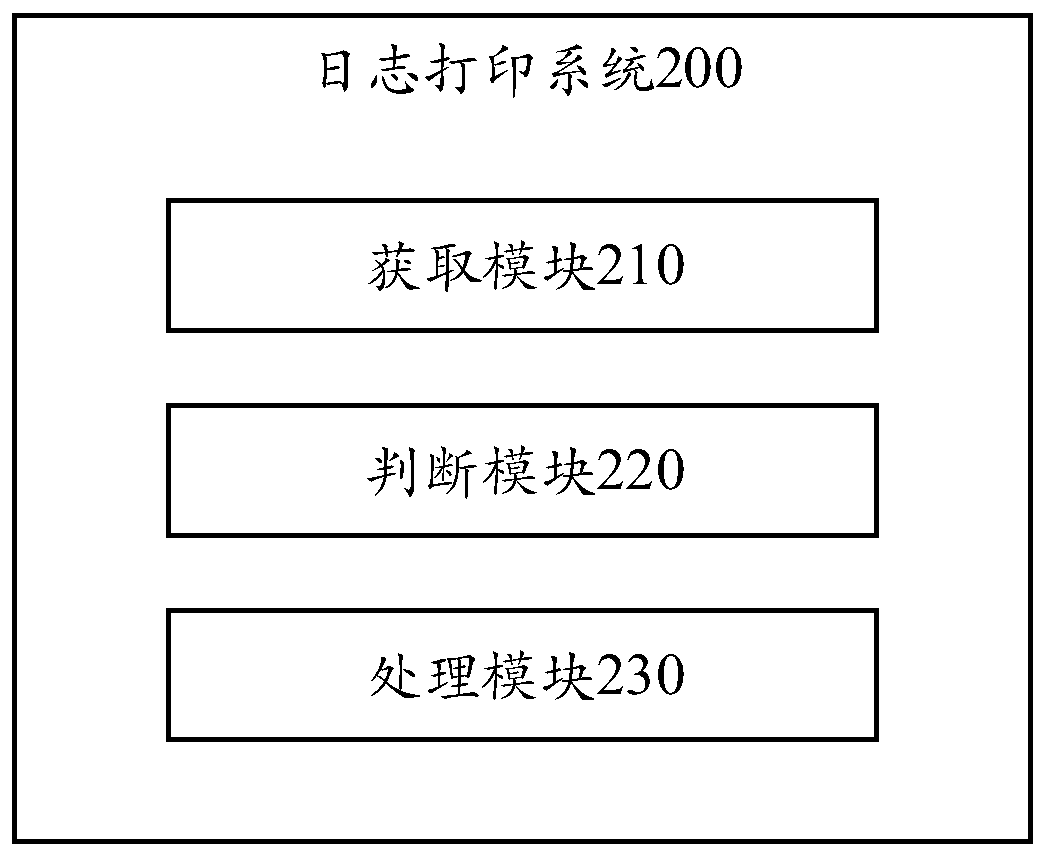

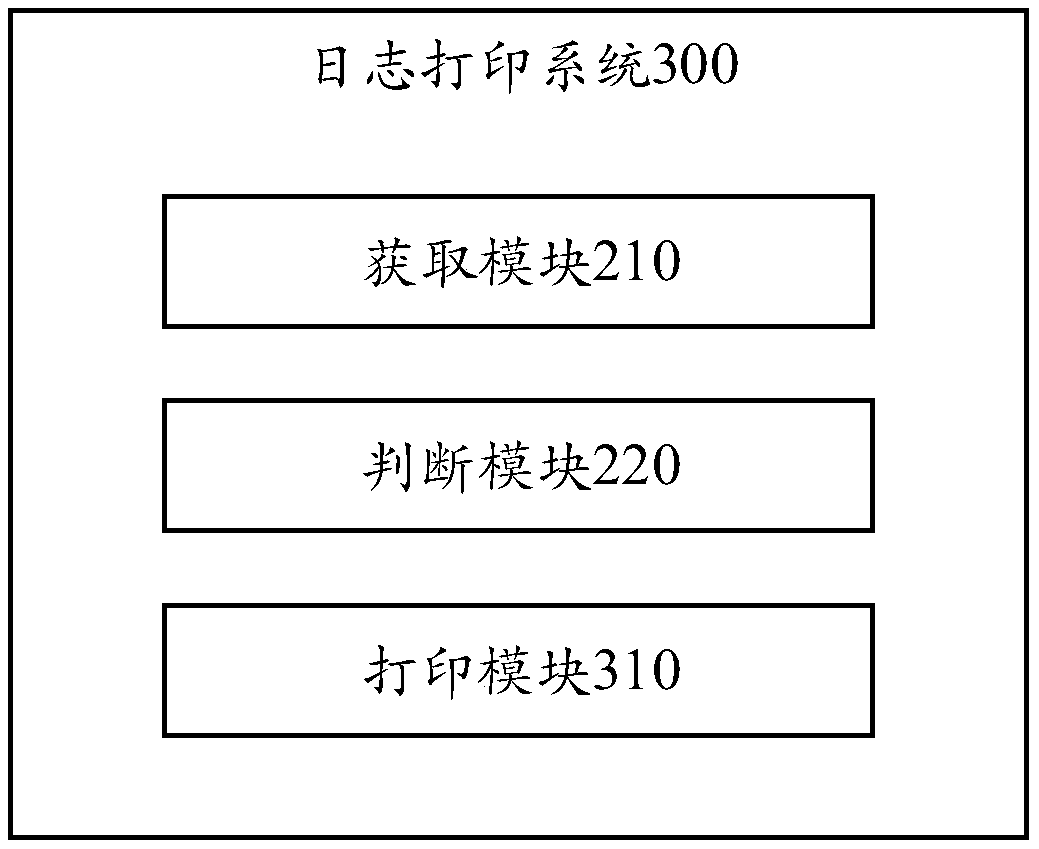

Log printing method and system, computer equipment and computer readable storage medium

ActiveCN110308880AFlexible printing of logsFlexible printingDigital output to print unitsComputer equipmentComputer engineering

The invention relates to the technical field of computers, in particular to a log printing method, which comprises the steps: obtaining a log printing configuration file in response to a log printingsignal triggered by calling a system; judging whether a log printing mode is specified in the log printing configuration file or not; and if it is judged that the log printing mode is specified in thelog printing configuration file, determining a preset interface corresponding to the log printing mode, reading the log printing requirement from the calling system through the preset interface, andprinting the to-be-printed log according to the log printing requirement. The invention further provides a log printing system, computer equipment and a computer readable storage medium.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

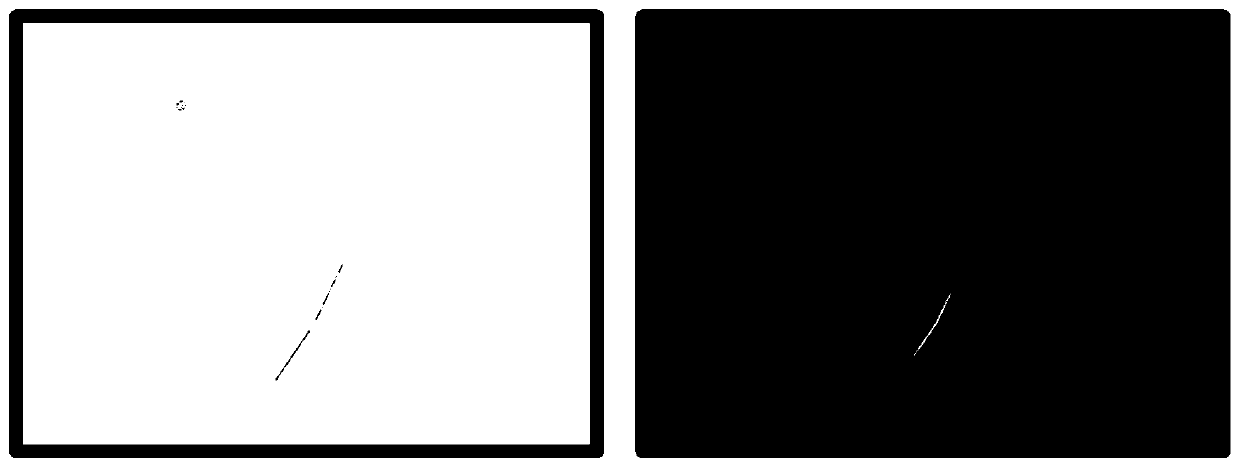

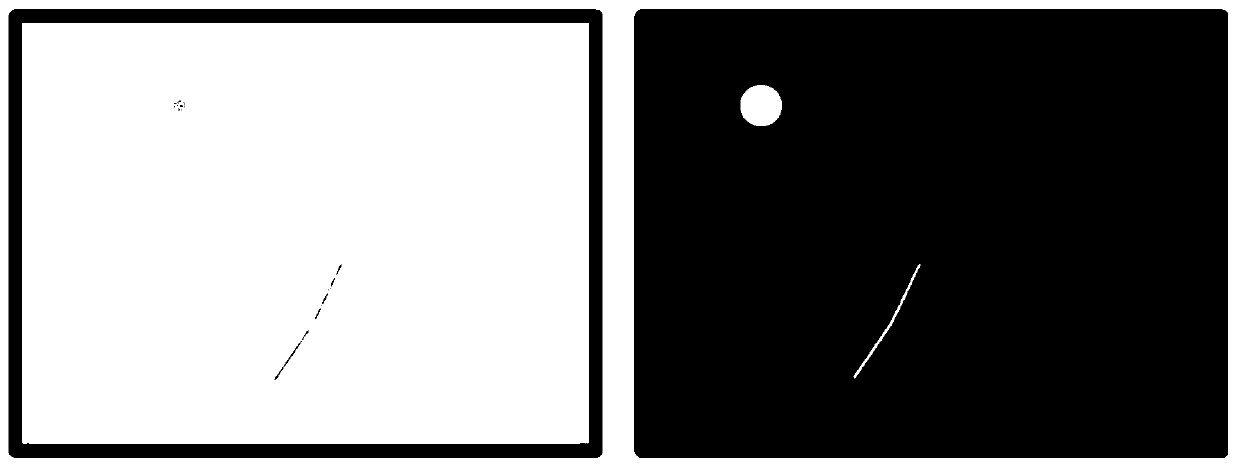

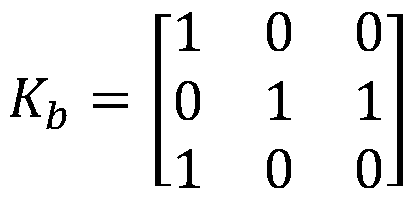

A paper defect detection method based on local brightness invariance priori

ActiveCN109886914AImprove accuracySolve the problem of strobeImage analysisOptically investigating flaws/contaminationColor imageGray level

The invention relates to a paper defect detection method based on the local brightness invariance priori, which comprises the following steps of 1, photographing the surface of paper to be detected byusing a color area array camera, and capturing a frame of color image with a pixel format of RGB components; 2, carrying out nonlinear graying operation on all pixels of the color image in the mask of the convolution template by using a convolution template with local brightness invariance priori, and finally obtaining pixels corresponding to the convolution window; according to the 1*1 convolution operation and the 3 * 3 convolution operation, obtaining two gray level images respectively; 3, carrying out corresponding position pixel division on the two grayscale images to obtain a grayscaleimage; 4, performing 3 * 3 Fourier convolution operation on the grayscale image; 5, performing gradient morphological operation on an operation result; 6, performing thresholding processing to obtaina paper defect detection result. According to the present invention, a common light source and an area array camera can be used for detecting paper defects, and a detection system is low in complexity, high in accuracy and low in cost.

Owner:浙江企银印务科技有限公司

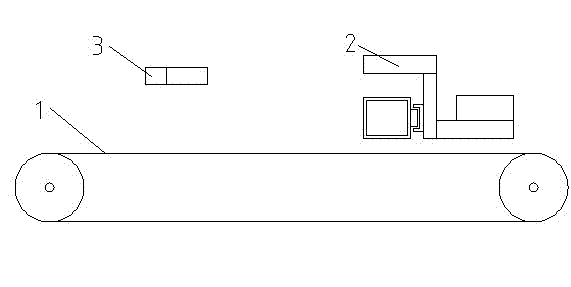

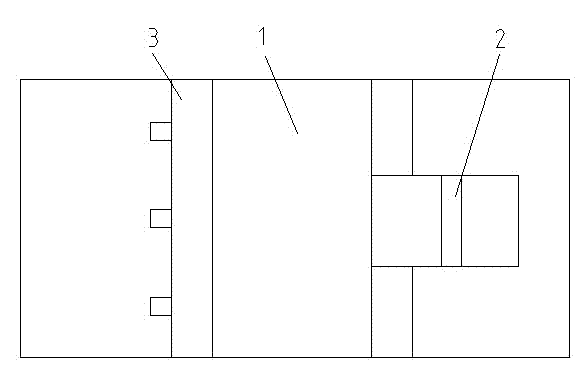

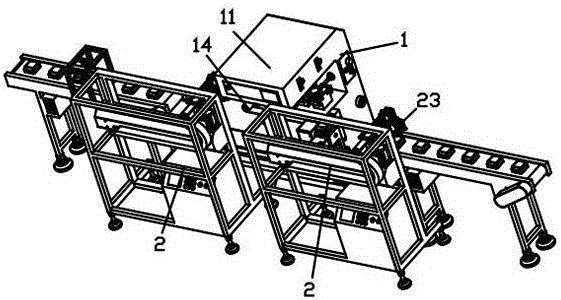

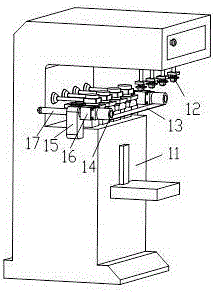

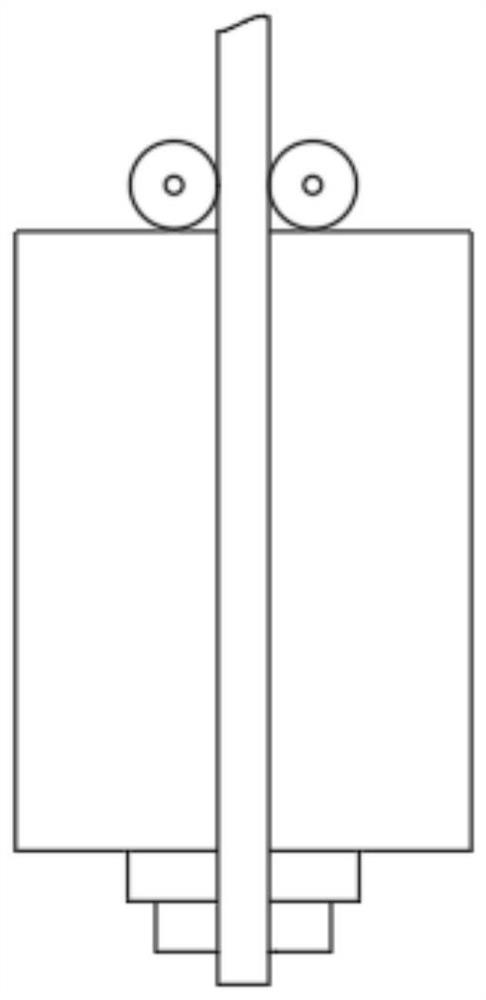

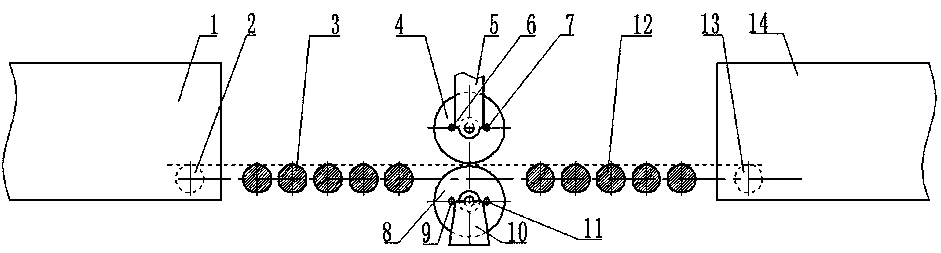

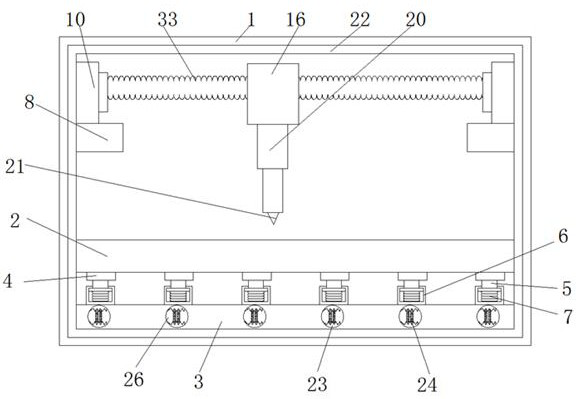

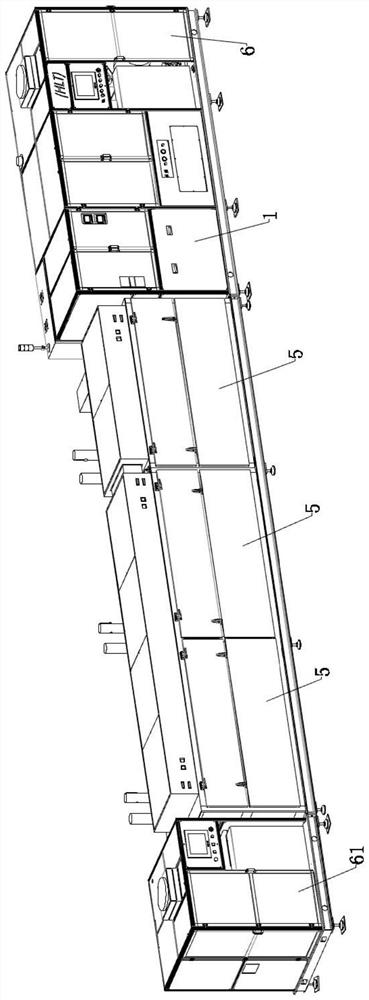

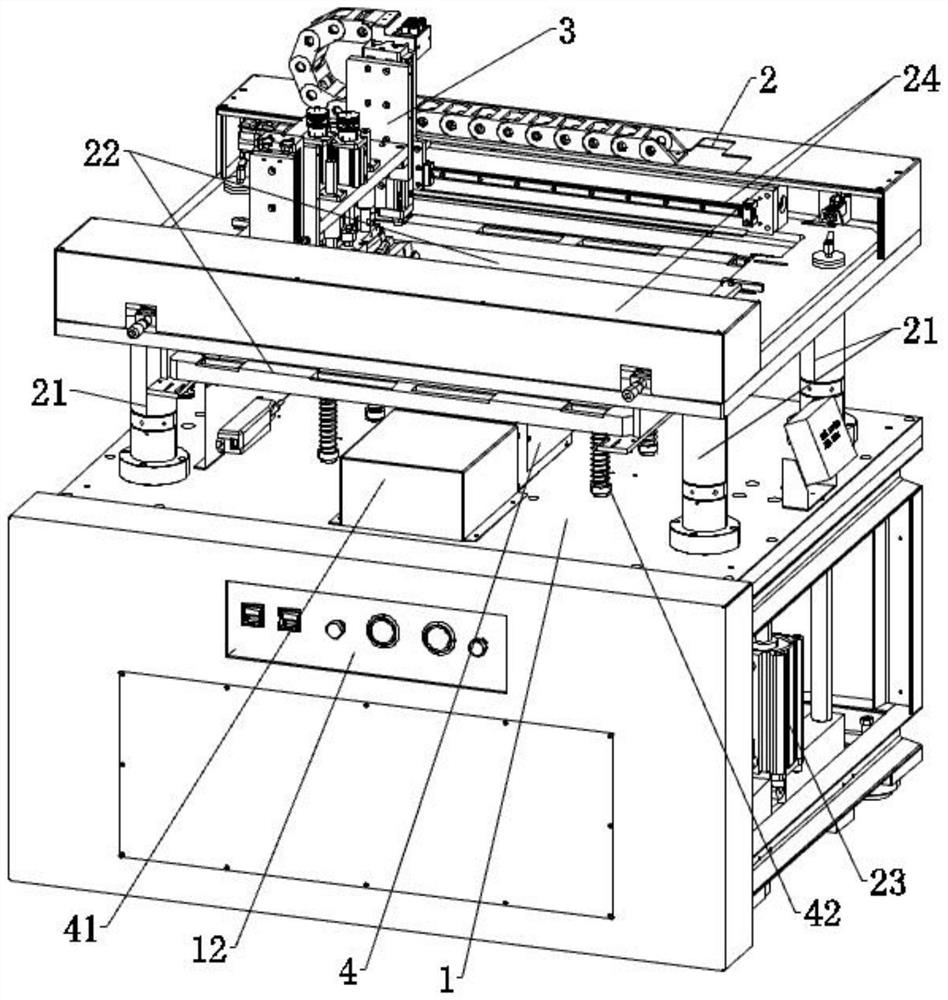

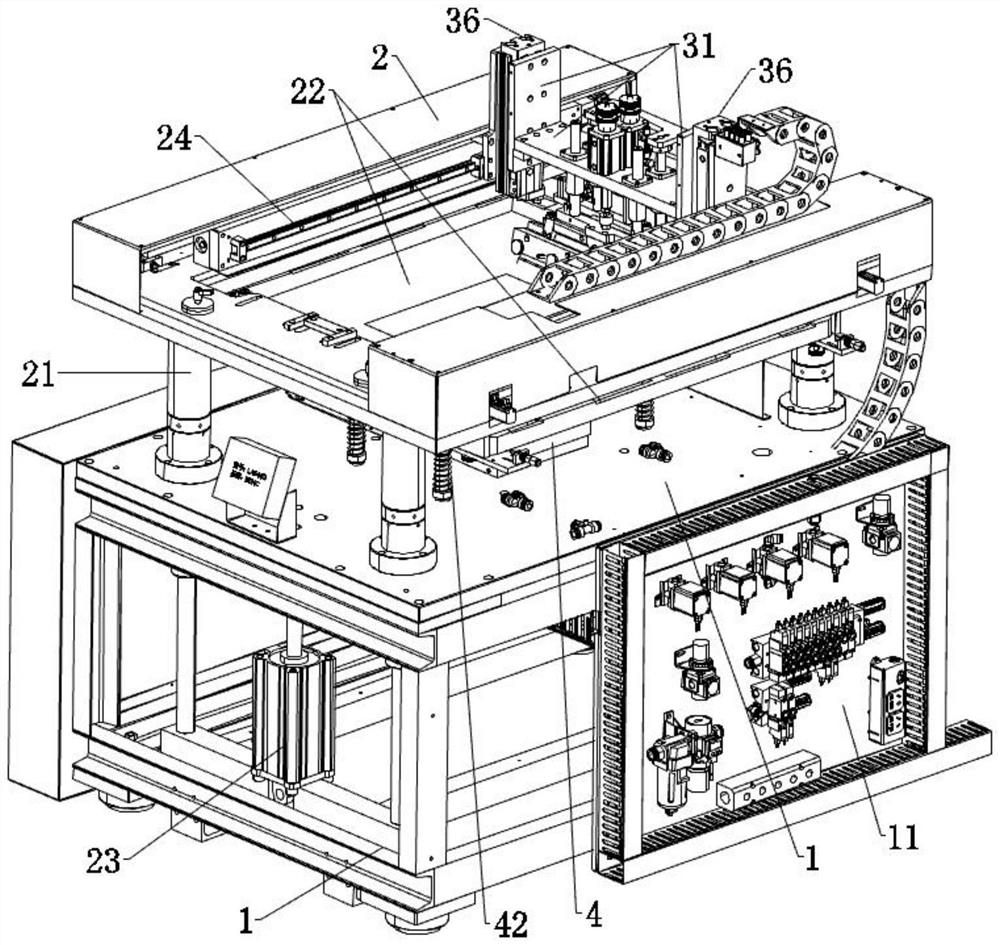

Automatic pad printing machine

ActiveCN106739453AFlexible printingGuaranteed stabilityRotary pressesPrinting press partsEngineeringMotor drive

The invention discloses an automatic pad printing machine. The automatic pad printing machine comprises a transfer platform and a printing mechanism. An extending-retracting roller wheel, a rotating motor and a horizontal adjusting rod are arranged at the two ends of cleaning adhesive tape of the printing mechanism. The extending-retracting roller wheel is driven to rotate through the rotating motor. The transfer platform comprises a horizontal movement mechanism, a movable motor, a movable platform and a workpiece fixture. The workpiece fixture is driven to horizontally move through the horizontal movement mechanism. The movable motor drives the horizontal movement mechanism to move below a pad printing rubber head. The horizontal movement mechanism comprises a rotating motor and a multifunctional rotating disc, and the multifunctional rotating disc is driven to rotate through the rotating motor so that the direction can be adjusted. The automatic pad printing machine is divided into the transfer platform and the printing mechanism; the transfer platform can rotate in a plurality of directions so as to drive a workpiece, and flexible printing is achieved; and the printing mechanism uses the horizontal adjusting rod to adjust the position of the cleaning adhesive tape, so that the cleaning adhesive tape corresponds to the position of the above pad printing rubber head, and direct cleaning is convenient.

Owner:东莞市众泰自动化设备有限公司

Luminous anti-counterfeiting element, and detection method and detection system thereof

ActiveCN108956549AGood chemical stabilityImprove thermal stabilityInksAnalysis by material excitationOptoelectronicsInvisibility

The invention provides a luminous anti-counterfeiting element, and a detection method and a detection system thereof. The luminous anti-counterfeiting element has the following luminous characteristics: the luminous anti-counterfeiting element is irradiated with a first excitation light, then the first excitation light is removed, and the luminous the second excitation light anti-counterfeiting element is further irradiated with a second excitation light to generate a second emission light visible to naked eyes; and the luminous anti-counterfeiting element is not irradiated with the first excitation light in advance, and is irradiated with the second excitation light to generate a third emission light invisible to the naked eyes, wherein the wavelength of the second excitation light is greater than the wavelength of the first excitation light, and the wavelength of the second excitation light is greater than the wavelength of the second emission light. The luminous anti-counterfeitingelement has the unique luminous effect, so the luminous anti-counterfeiting element has the characteristics of convenience in detection, and high invisibility. The invention also provides the detection method and the detection system for the luminous anti-counterfeiting element.

Owner:CHINA BANKNOTE PRINTING & MINTING +1

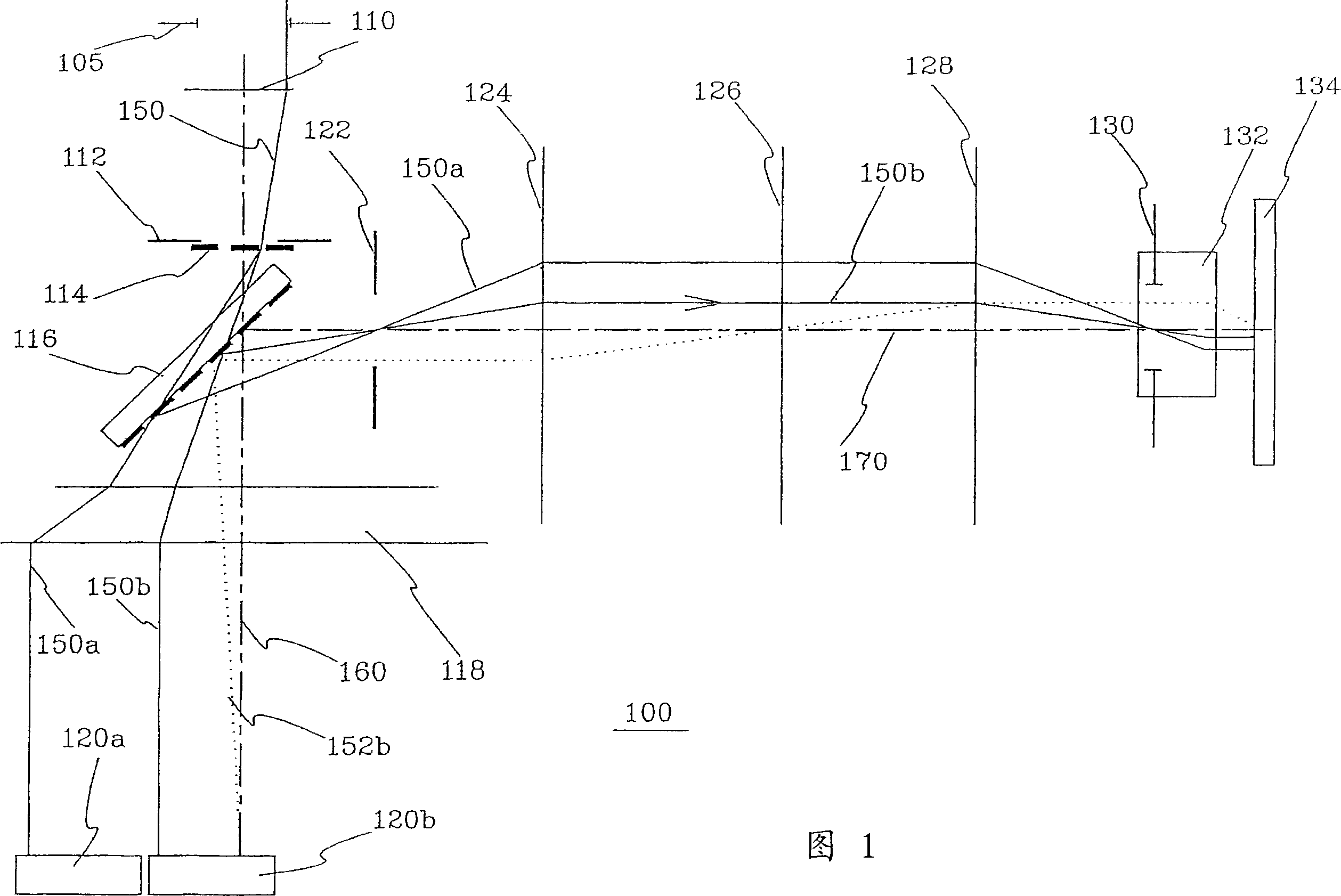

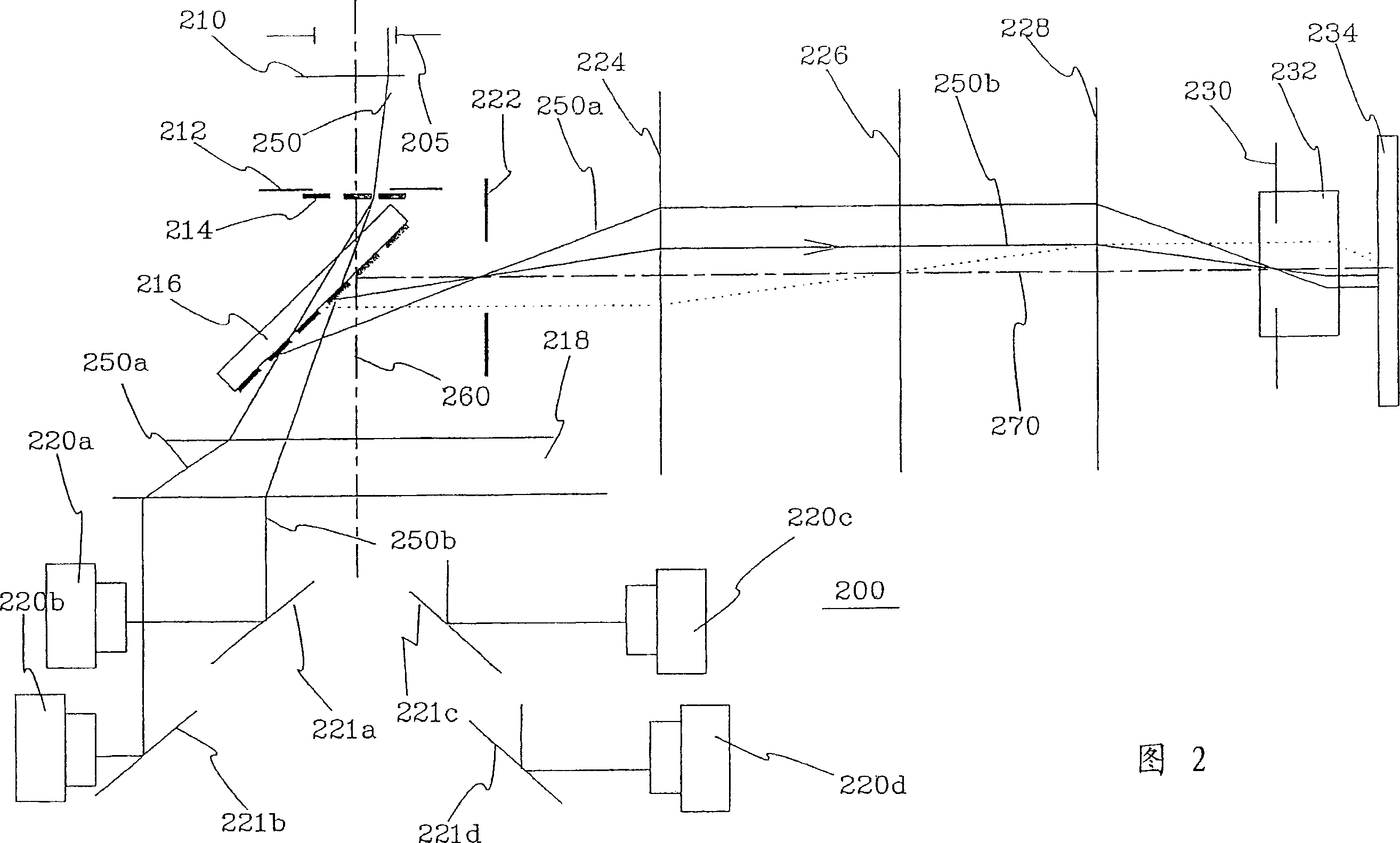

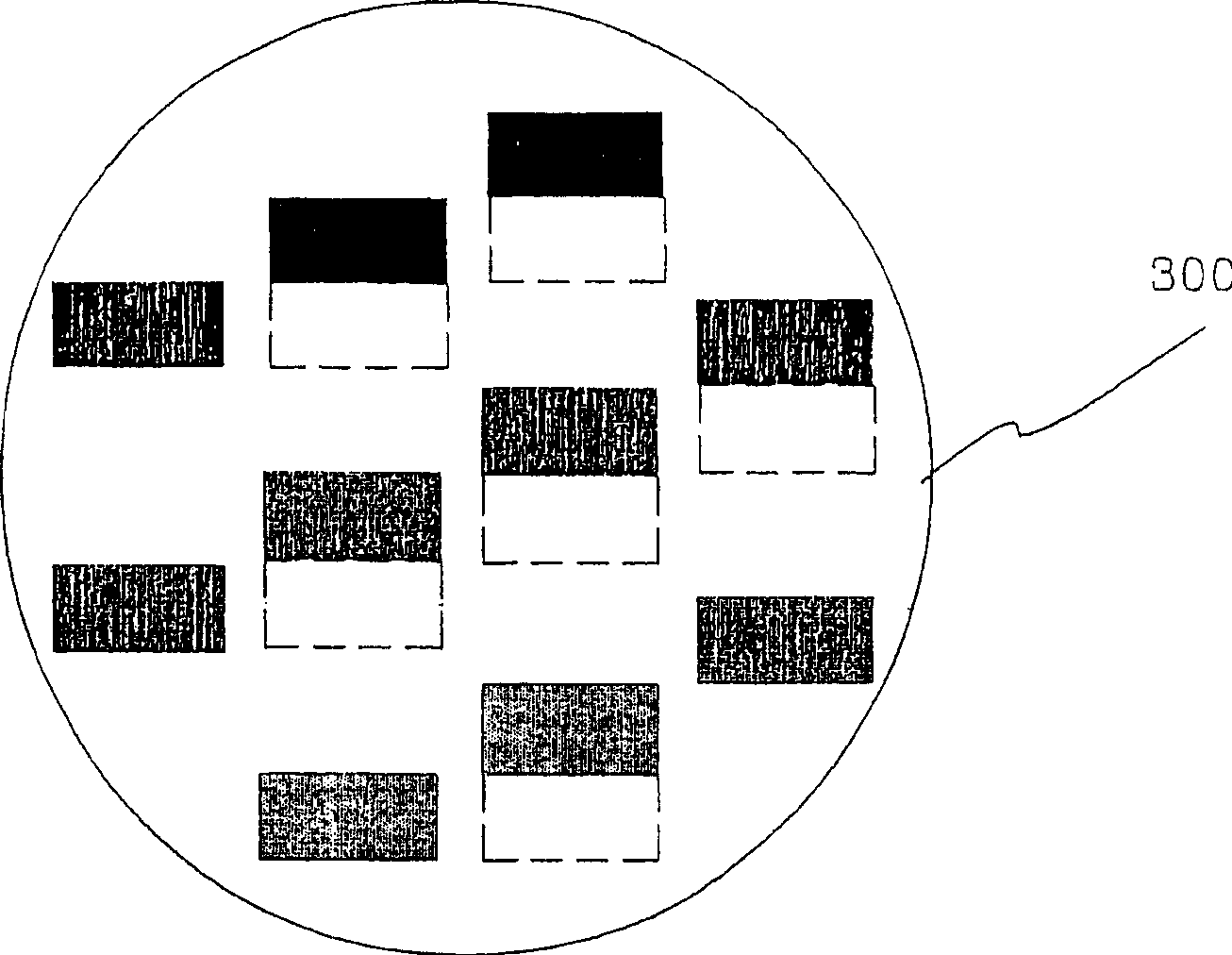

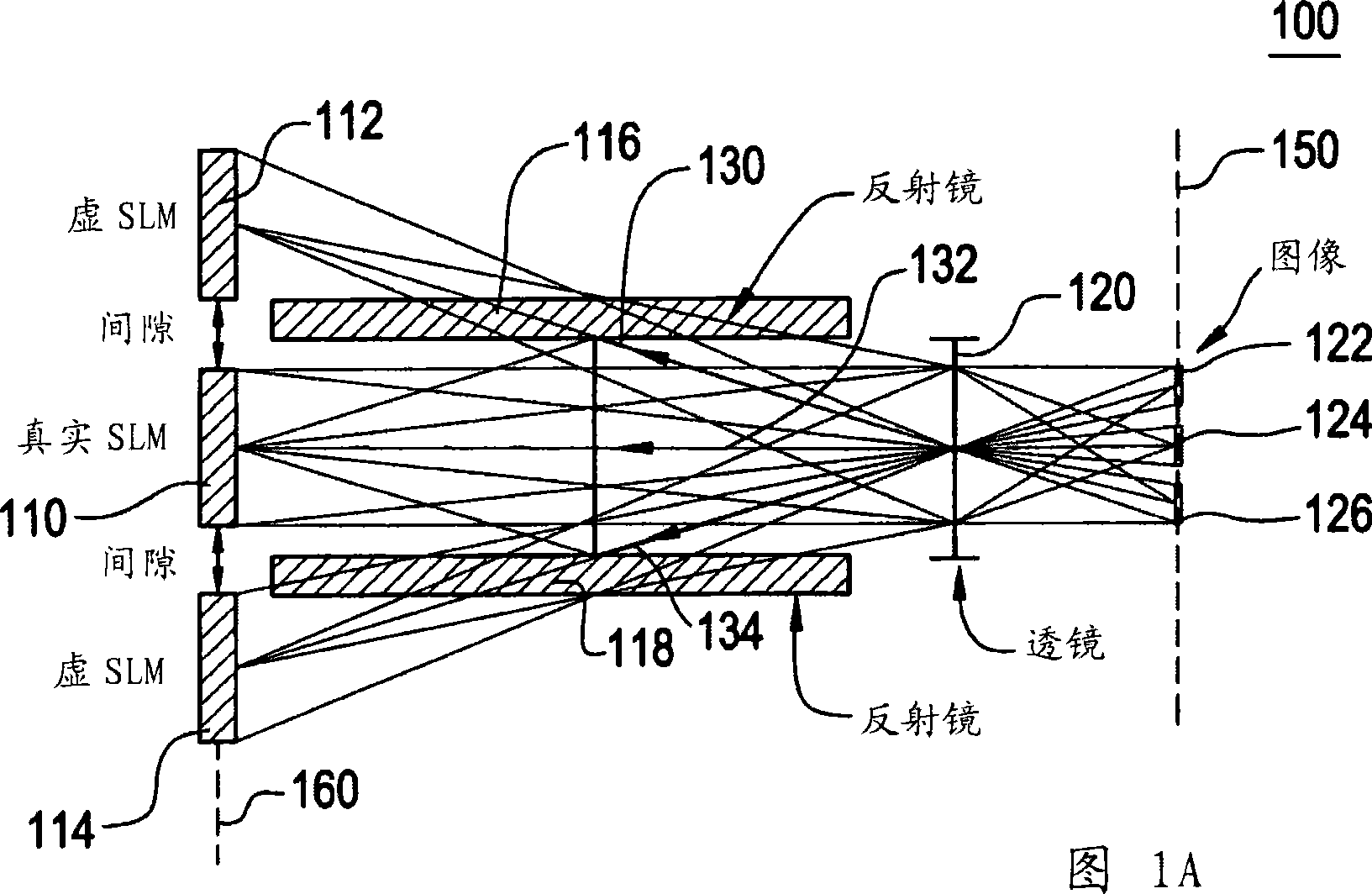

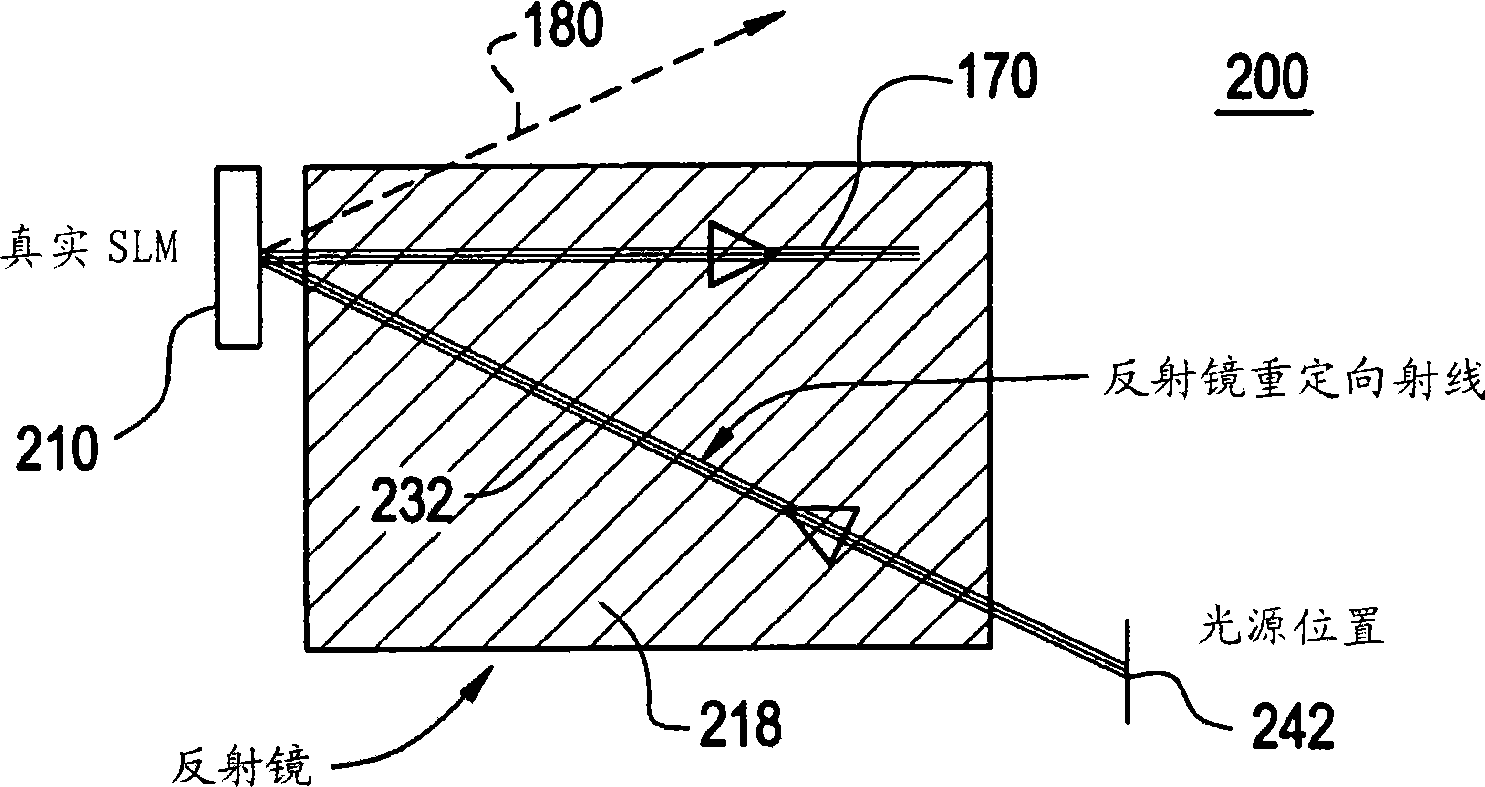

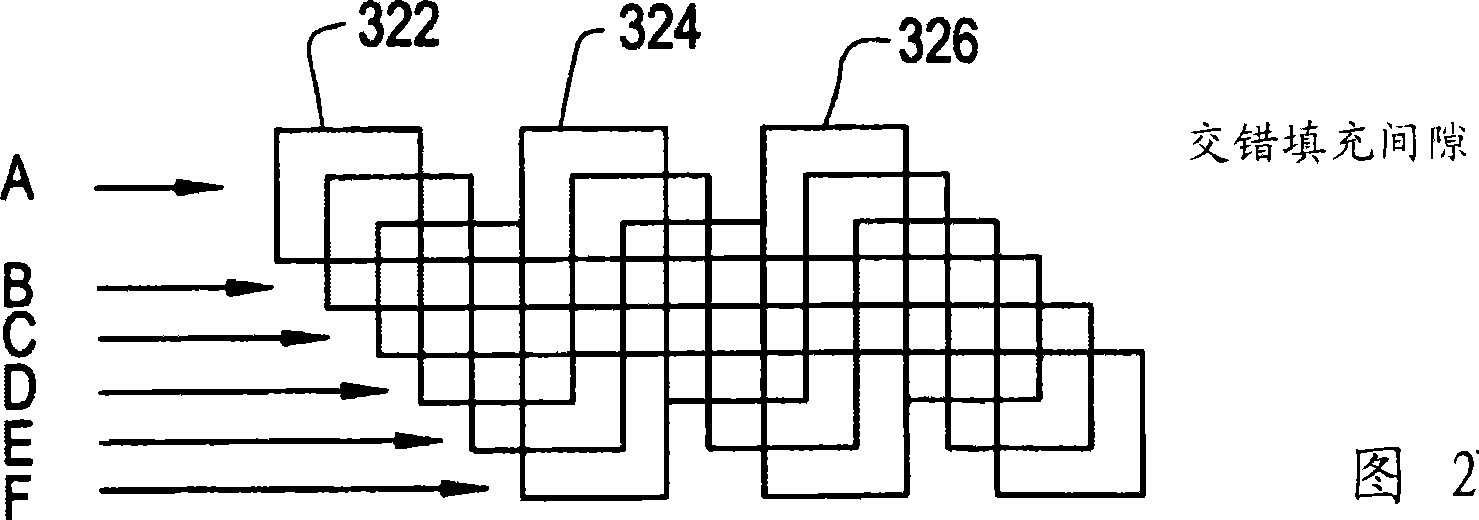

Slm direct writer

ActiveCN1754130AFast printFlexible printingPhotomechanical exposure apparatusMicrolithography exposure apparatusSpatial light modulatorBeam splitting

The present invention relates to an apparatus (100) for patterning a workpiece arranged at an image plane and sensitive to electromagnetic radiation, comprising a source emitting electromagnetic radiation onto an object plane and at least two spatial light modulators each comprising numerous of object pixels, adapted to receive said electromagnetic radiation at said object plane and to relay said electromagnetic radiation toward said workpiece, wherein said electromagnetic radiation is split into at least two beams, which beams will impinge on different spatial light modulators, by a beam splitting device arranged at an optical plane between said spatial light modulators and an illuminator pupil or a conjugate optical plane. The invention also relates to a method for patterning a workpiece with a plurality of spatial ight modulators.

Owner:MICRONIC LASER SYST AB

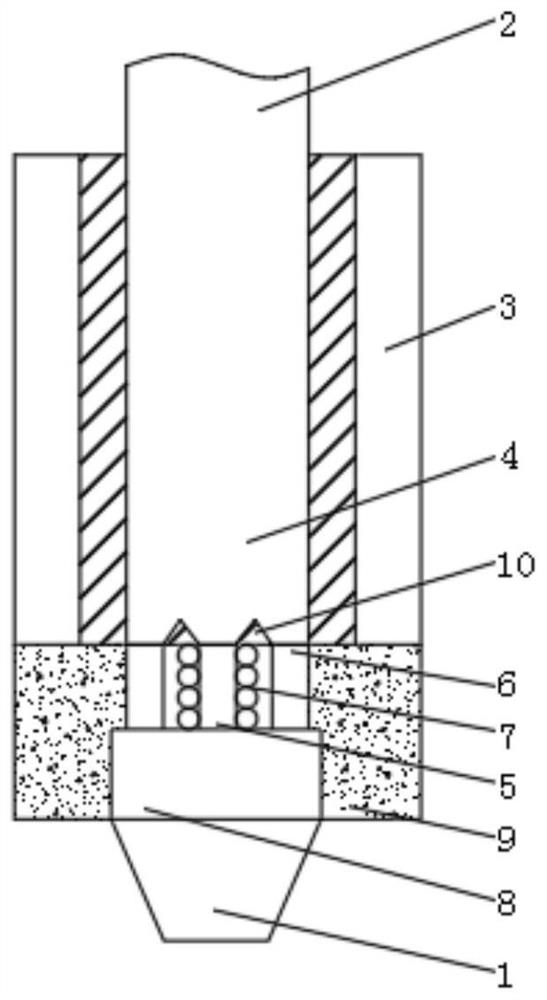

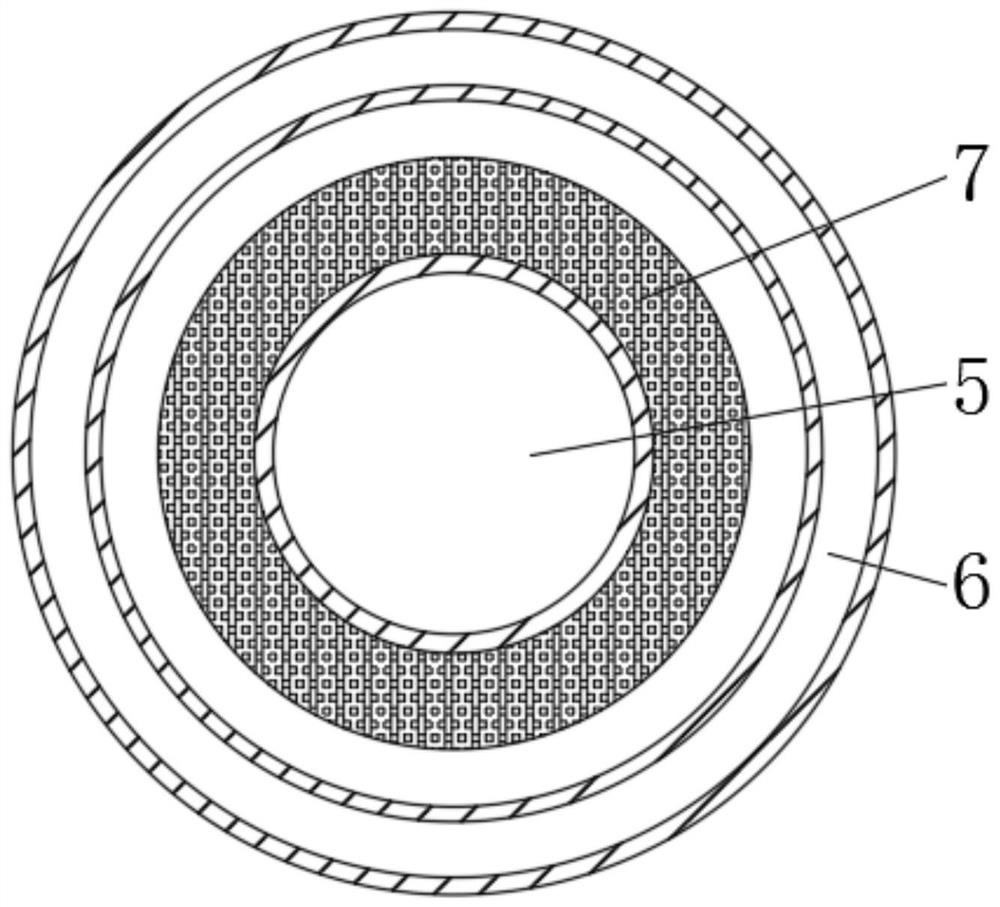

A temperature control structure of fdm nozzle

ActiveCN110561743BUniform temperature distributionImprove printing qualityManufacturing heating elements3D object support structuresTemperature controlProcess engineering

Owner:浙江春分智创科技有限公司

Device for producing tempered embossed plate glass by using float plate glass

PendingCN111116028AFlexible printingEasy to use and maintainGlass transportation apparatusGlass tempering apparatusFlat glassElectric machine

The invention discloses a device for producing tempered embossed plate glass by using float plate glass. The device comprises a heating furnace, a toughening furnace, and an embossing roller and a driving motor which are arranged between the heating furnace and the toughening furnace. A glass conveying roller is arranged on the inner side of the discharge hole of the heating furnace; a front transition roller is arranged between the glass conveying roller and the embossing roller, a rear transition roller is arranged between the embossing roller and the toughening furnace, the embossing rollercomprises an upper roller, an upper roller pressing rod, a lower roller and a lower roller supporting frame, the lower roller is fixed on the lower roller supporting frame, the upper roller is pressed above the lower roller through the upper roller pressing rod, and the upper roller is connected with an output shaft of a driving motor. According to the invention, a traditional flat glass toughening furnace is divided into two parts from the middle, the front half part serves as a heating furnace, the rear half part serves as a toughening furnace, and a conveying and embossing roller is additionally arranged between the front half part and the rear half part, so that after the plate glass is heated in the heating furnace, required patterns are pressed on the surface of the glass through atransition roller supply embossing roller, and then the plate glass enters the toughening furnace to be toughened.

Owner:HENAN ANCAI HI-TECH

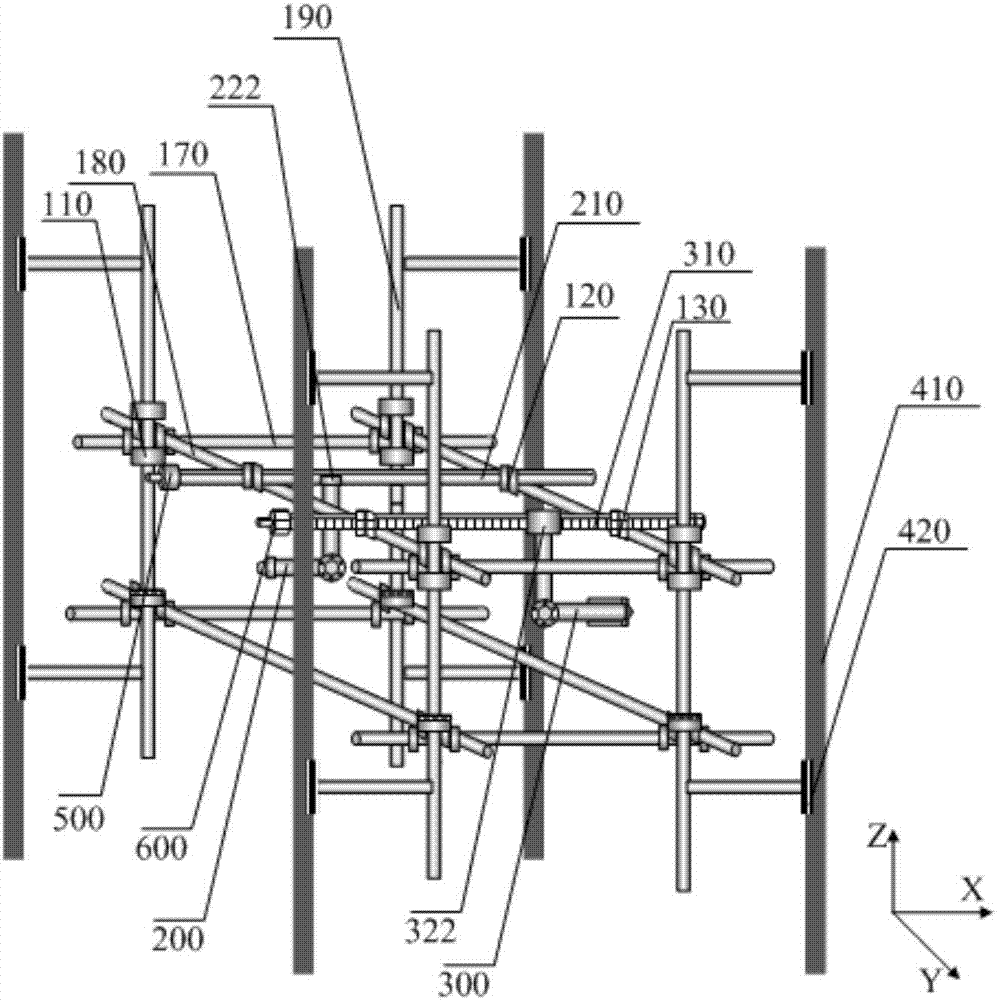

Construction engineering integrated 3D printing and building system and use method thereof

ActiveCN107419901ASolve the problem that the construction of deep foundation cannot be carried outSolve, unable to achieve foundation foundationBuilding material handlingBuilding construction3D printing

In order to solve the problems that an existing 3D printing device cannot conduct construction on a deep foundation basis, and integrated printing and building of the foundation basis and the upper structure cannot be achieved, the invention provides a construction engineering integrated 3D printing and building system and a use method thereof. Due to the fact that a lifting device is arranged, when construction is conducted on the deep foundation basis, the lifting device can be installed in the deep foundation basis; according to the system, the deep construction position is moved through the lifting device, and construction is conducted on the deep foundation basis; after the foundation basis is completed, the system can be moved to the portion above the ground through the lifting device, construction is conducted on the upper structure, the upper structure and the foundation basis are integrally formed, and then the problems that the existing 3D printing device cannot conduct construction on the deep foundation basis, and integrated printing and building of the foundation basis and the upper structure cannot be achieved are solved.

Owner:SHANGHAI CONSTRUCTION GROUP

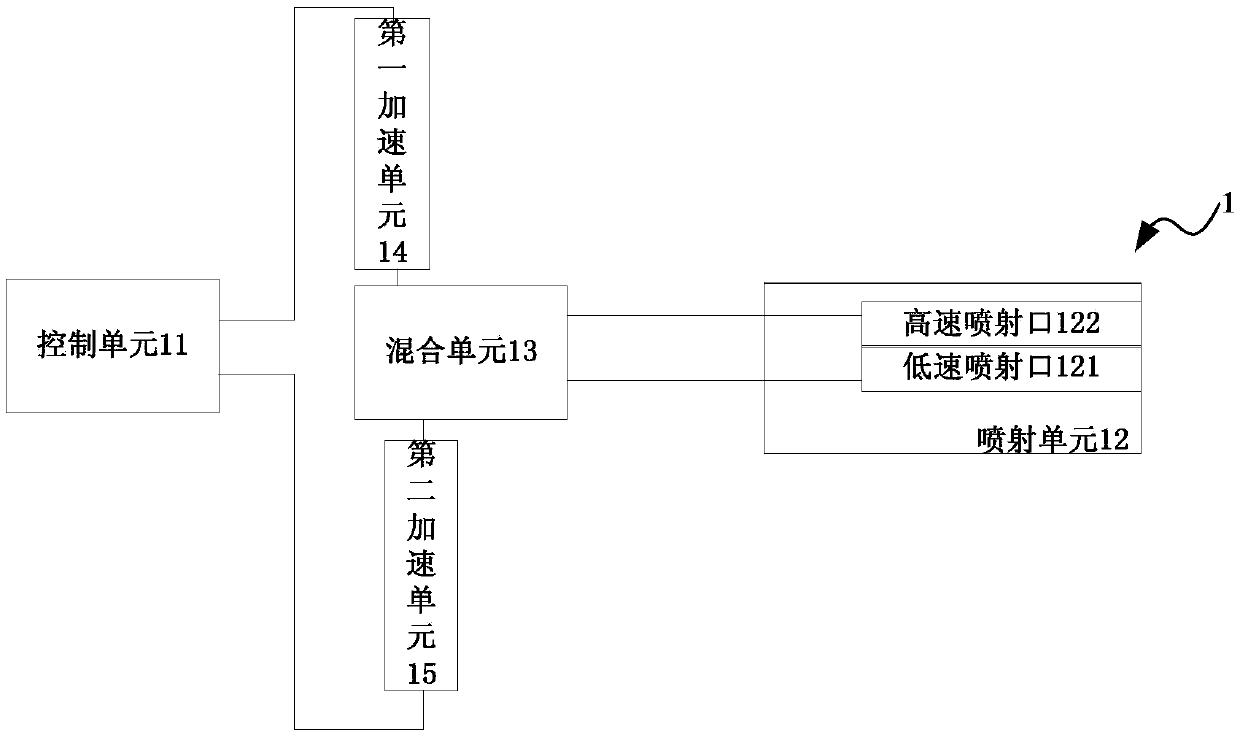

Printed circuit board (PCB) printing device and method

ActiveCN105365405AFlexible printingControl precisionTypewritersOther printing apparatusElectricityLow speed

The invention provides a printed circuit board (PCB) printing device and method. The PCB printing device comprises a control unit, an injection unit electrically connected with the control unit, a mixing unit, a first accelerating unit and a second accelerating unit. The injection unit is provided with a low-speed injection opening corresponding to the first accelerating unit and a high-speed injection opening corresponding to the second accelerating unit. The control unit is used for sending a control command to the first accelerating unit and making the first accelerating unit increase the speed of mixed materials in the mixing unit, and the mixed materials are injected on a PCB substrate through the low-speed injection opening, or sending the control command to the second accelerating unit and making the second accelerating unit increase the speed of the mixed materials in the mixing unit, and the mixed materials are injected on the PCB substrate through the high-speed injection opening. The precision of PCB printing can be accurately controlled; in addition, the low-speed injection opening and the high-speed injection opening are adopted for the injection unit, and thus the PCB printing can be conducted flexibly by effectively using different properties of the two injection openings.

Owner:台州市吉吉知识产权运营有限公司

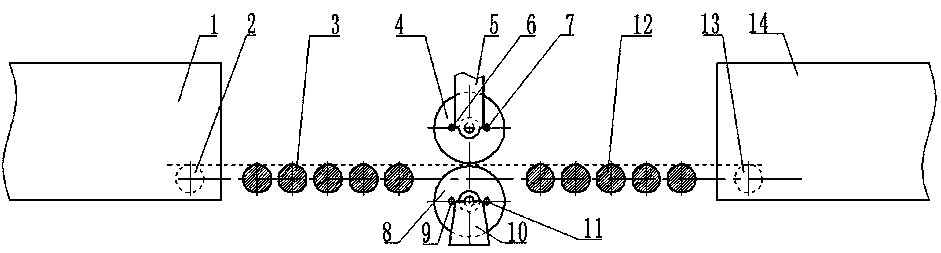

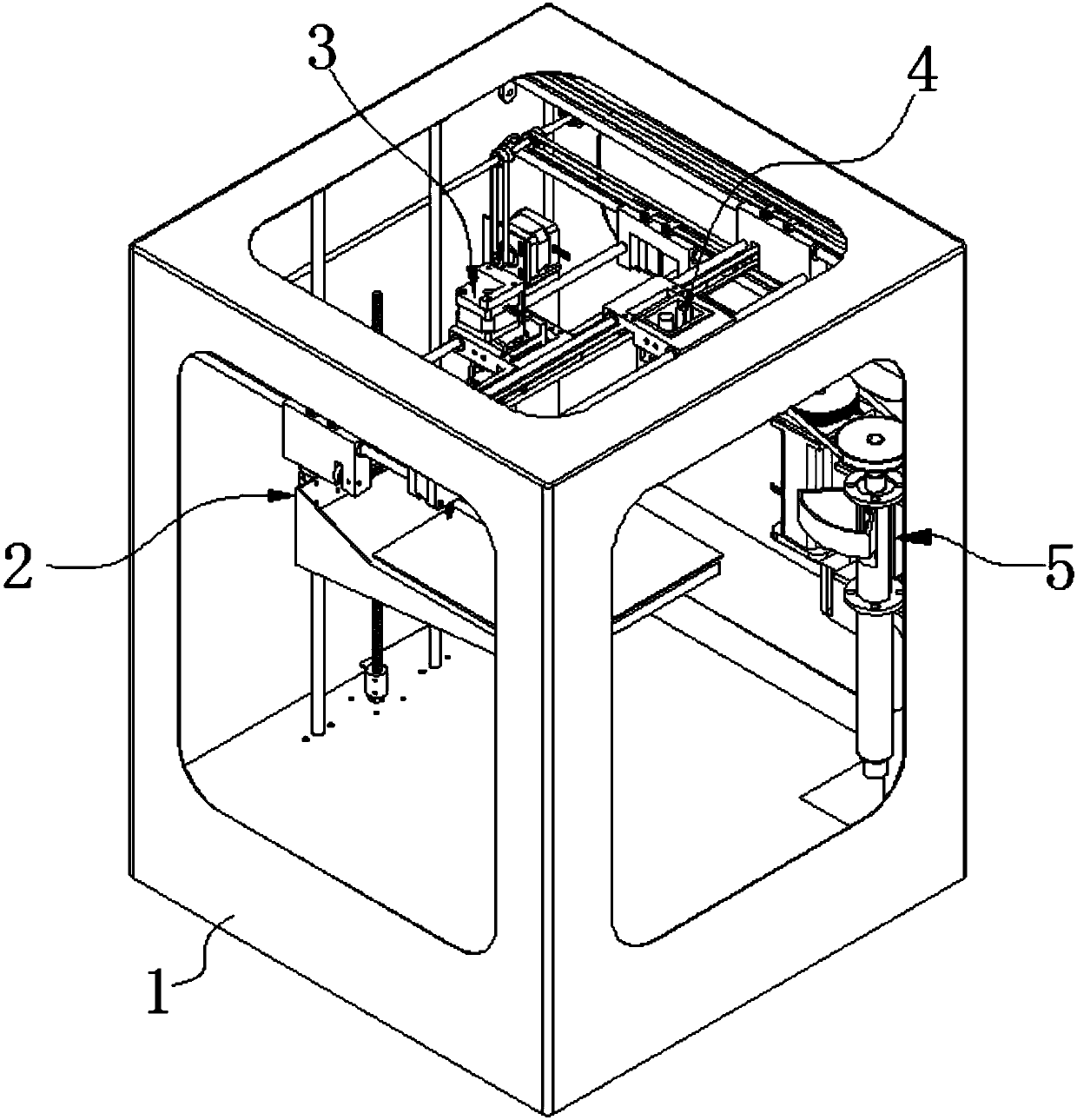

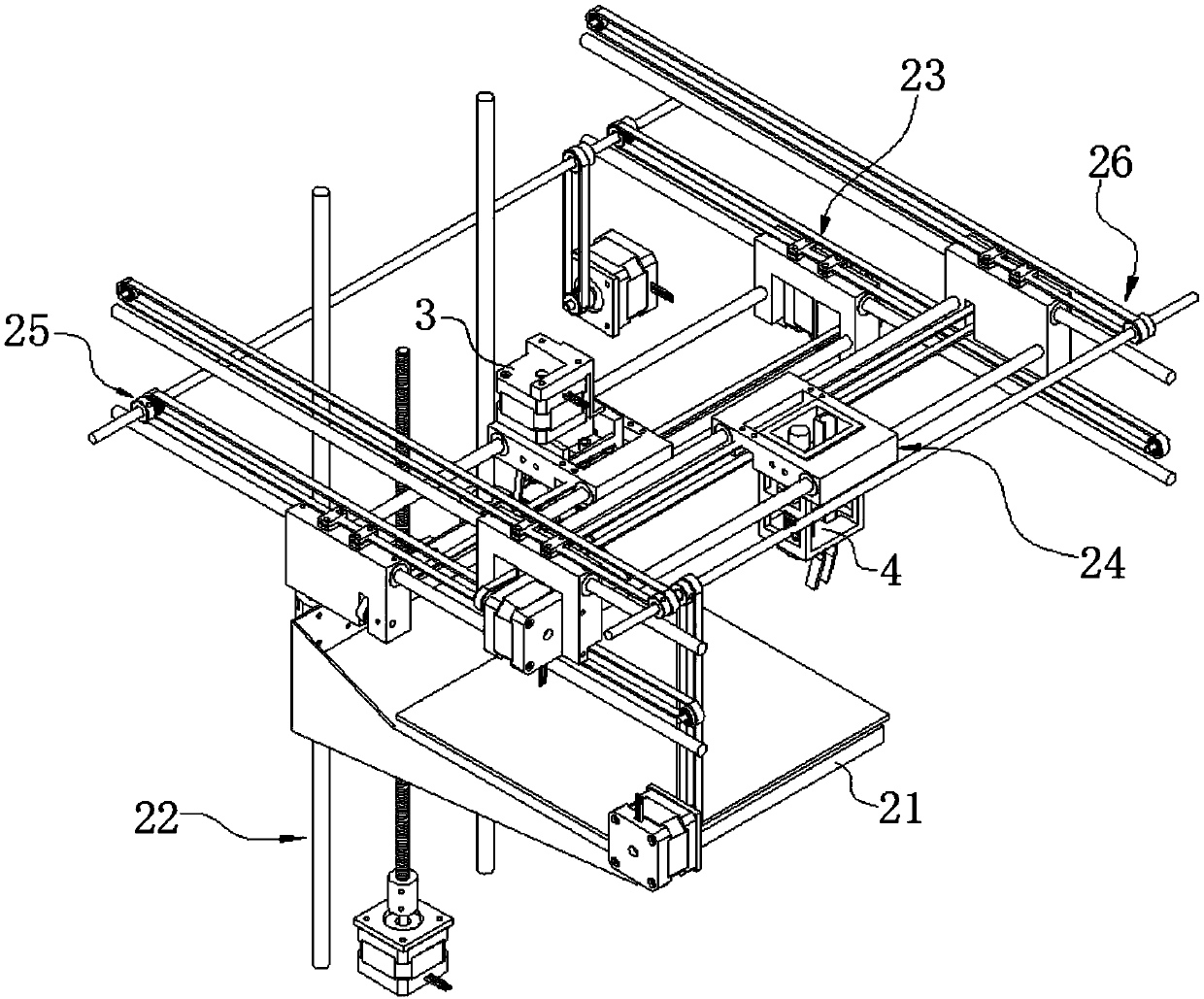

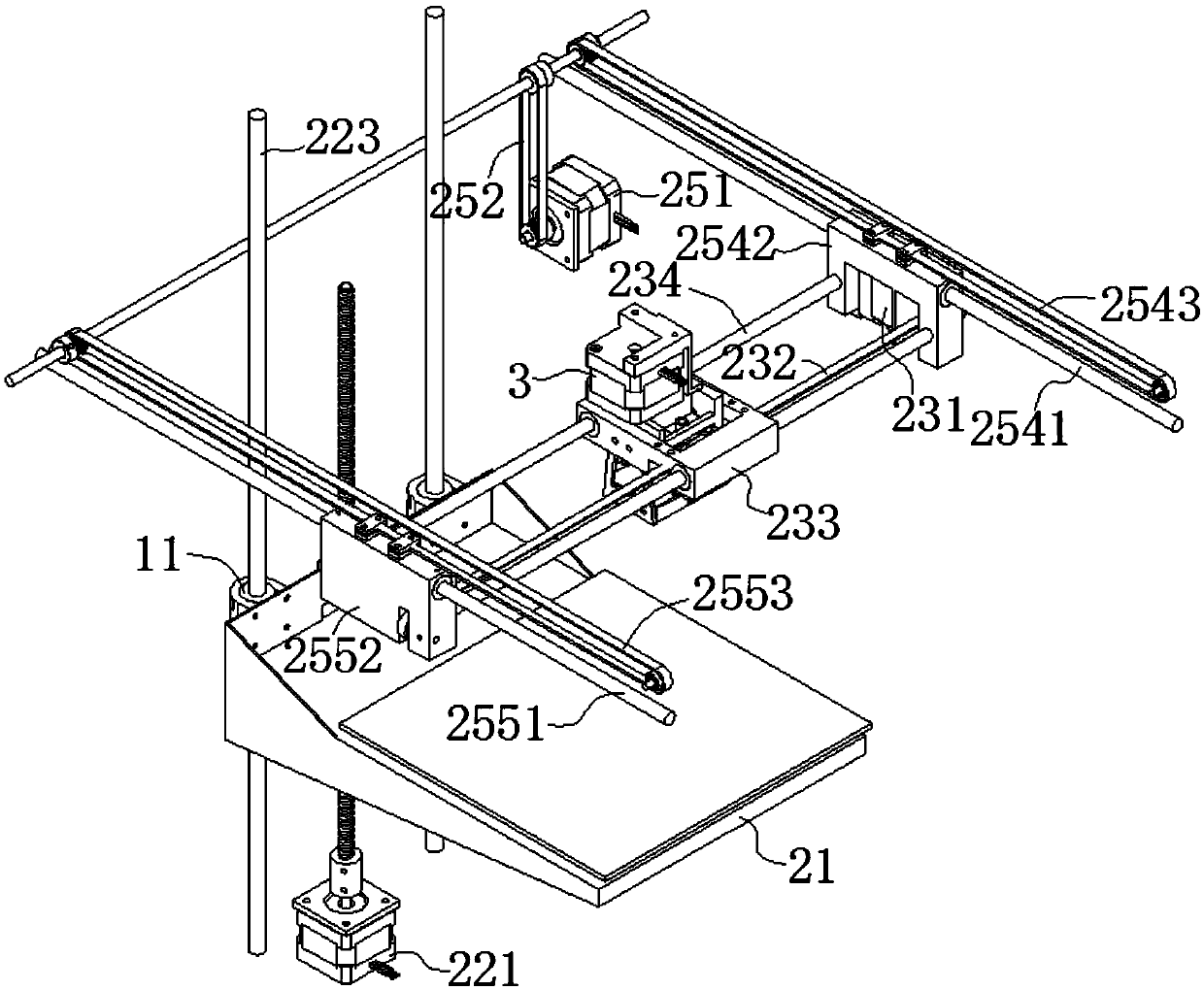

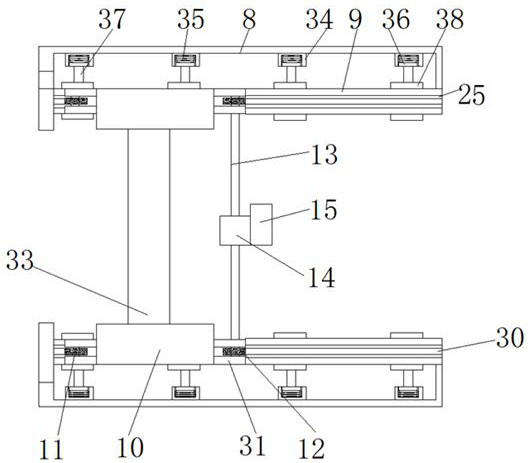

Double-axis 3D printing device of cement handicraft

PendingCN109605538AImprove qualityGuaranteed heightAdditive manufacturing apparatusCeramic shaping apparatusFiberThree-dimensional space

The invention provides a double-axis 3D printing device of cement handicraft, which meets the requirements of multi-nozzle cooperated printing and 3D printing positioning. The double-axis 3D printingdevice is characterized by comprising a c, a multi-axis movement mechanism, a TPU fiber double-nozzle assembly, a cement nozzle assembly and a material squeezing mechanism; and the multi-axis movementmechanism is arranged on the machine base, the TPU fiber double-nozzle assembly and the cement nozzle assembly are driven by the multi-axis movement mechanism, the material squeezing mechanism is used for feeding the cement nozzle assembly, the multi-axis movement mechanism comprises a bottom bed, a Z-axis assembly, an XI-axis assembly, an XII-axis assembly, a YI-axis assembly and a YII-axis assembly, the Z-axis assembly, the XI-axis assembly and the YI-axis assembly form a three-dimensional space coordinate system which corresponds to the TPU fiber double-nozzle assembly, the Z-axis assembly, the XII-axis assembly and the YII-axis assembly form a three-dimensional space coordinate system which corresponds to the cement nozzle assembly, and the bottom bed is arranged above the Z-axis assembly and is driven to do a Z-axis motion by the Z-axis assembly.

Owner:ZHONGSHAN ADVANCED ENG & TECH RES INST WUHAN UNIV OF TECH +1

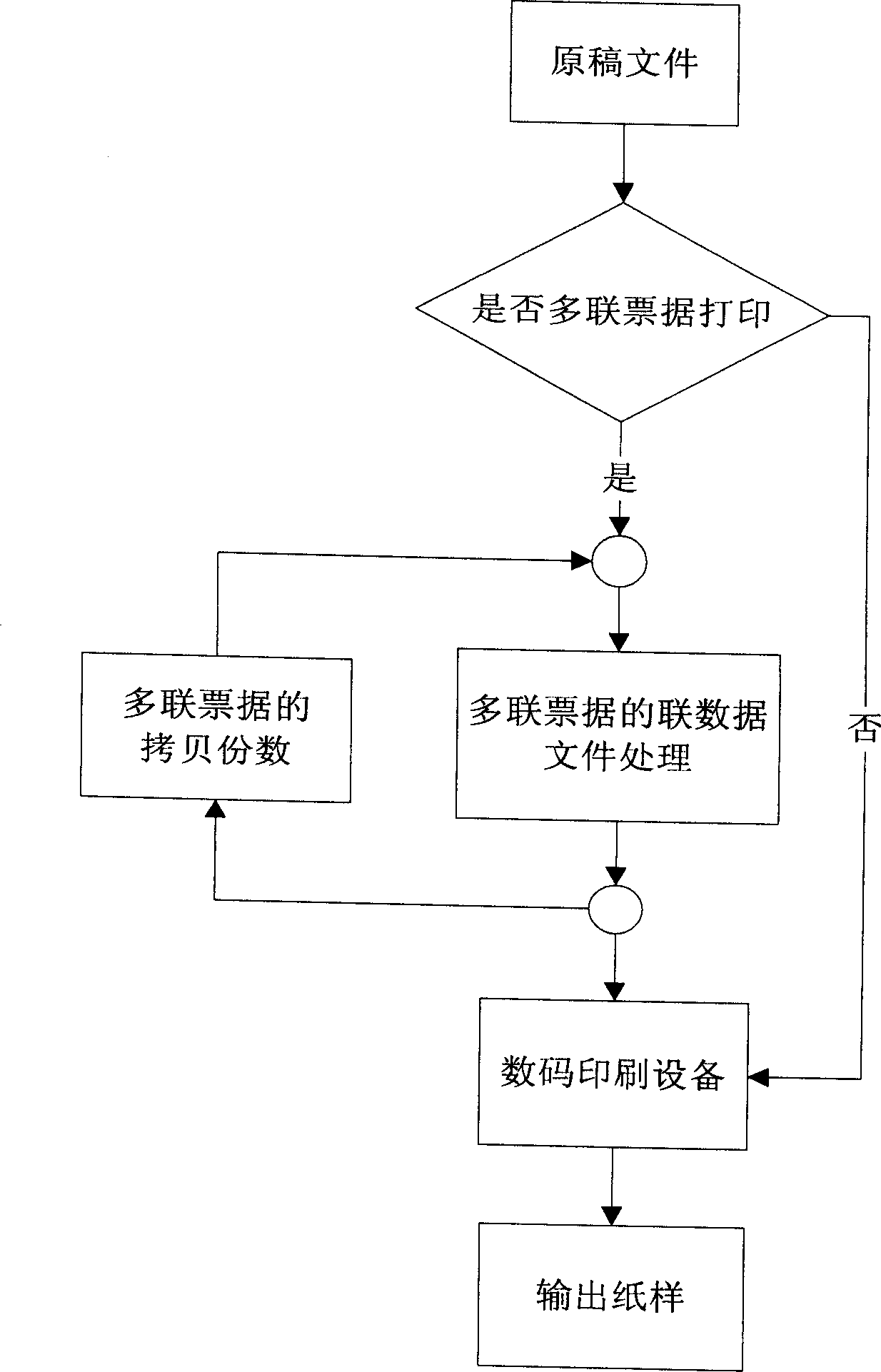

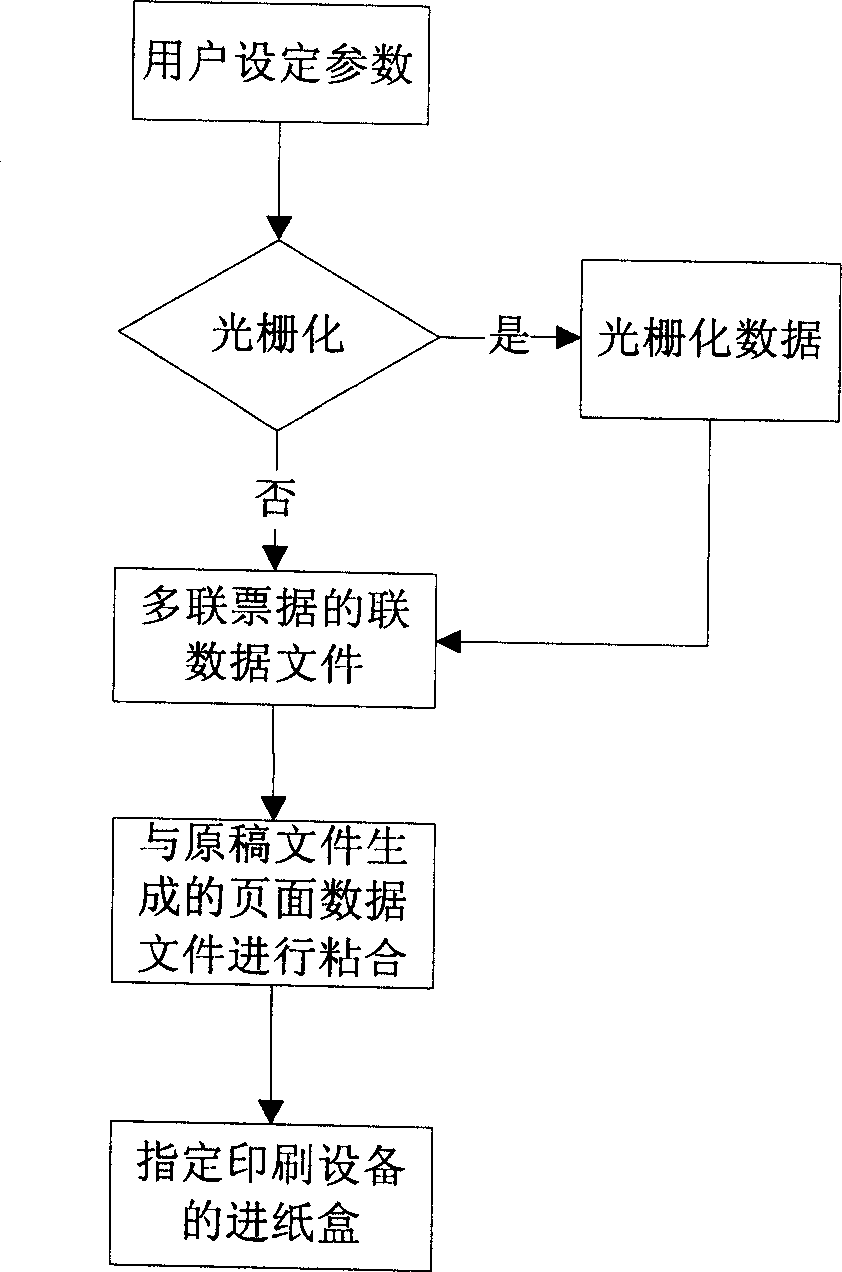

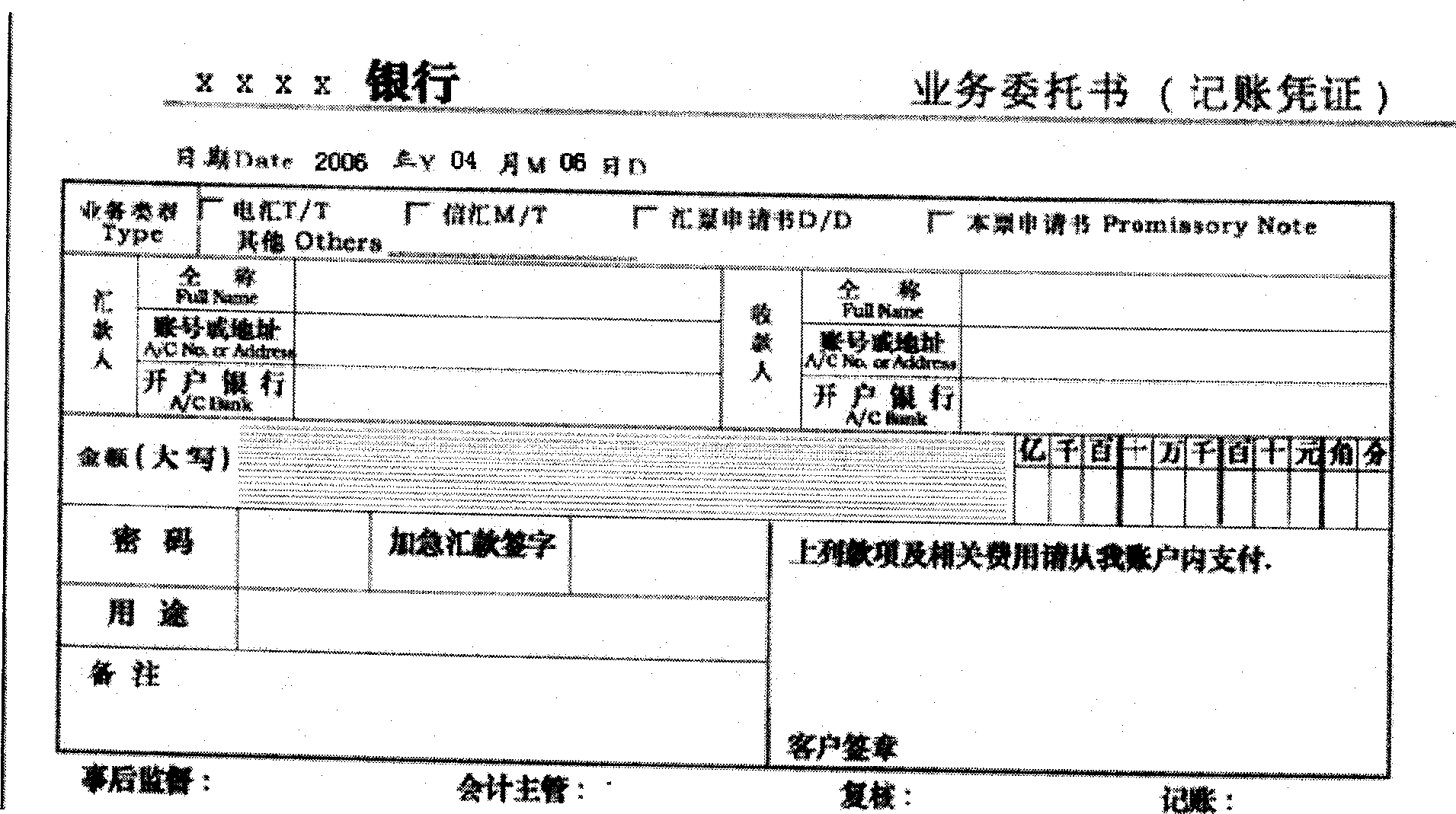

Method and system for continuously printing multiple part bills

InactiveCN1908887ALow costImprove work efficiencyVisual presentation using printersDigital output to print unitsDigital printingData file

The related continual printing method for multiple-bill comprises: unlike to current technology, generating every data file for multiple-bill according to user selected control parameters, bonding the data file with original page data file to generate new complete data file; outputting the whole bill file for one time by digital printing device. This invention reduces cost and improves efficiency.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

Huge three-dimensional (3D) printer in the air

The invention relates to a huge three-dimensional (3D) printer in the air, which comprises a material extruding device, a material supporting device and induction brush electric wheels, wherein the material extruding device is composed of a cone-shaped tube, a cone-shaped material extruding screw, a feed hopper, a square tube, a connecting shaft and the like; the supporting device is composed of a material supporting plate, a powder scraping rotary wheel, a material receiving hopper, a material receiving straight tube and the like; the induction brush electric wheels are divided into a front induction brush electric wheel and a rear induction brush electric wheel, the front induction brush electric wheel can not be too far away from the rear induction brush electric wheel, and points where the front induction brush electric wheel and the rear induction brush electric wheel are contacted with a printed object are located at the periphery of the printed object near a thermal curing area. The huge 3D printer in the air is characterized in that a supporting arm is connected with and supports the material extruding device and the material supporting device simultaneously, and the material extruding device and the material supporting device move along with the supporting arm synchronously in the same direction; and the front induction brush electric wheel and the rear induction brush electric wheel move along with the supporting arm synchronously in the same direction.

Owner:CHANGSHU INTELLIGENT LASER EQUIP RES INST CO LTD

Slm direct writer

InactiveCN101384965AFlexible printingFlexible printing featuresPhotomechanical exposure apparatusMicrolithography exposure apparatusSpatial light modulatorBeam splitting

The present invention relates to an apparatus ( 100 ) for patterning a workpiece arranged at an image plane and sensitive to electromagnetic radiation, comprising a source (142)emitting electromagnetic radiation onto an object plane (160) and at least two spatial light modulators each comprising numerous of object pixels adapted to receive said electromagnetic radiation at said object plane and to relay said electromagnetic radiation toward said workpiece, wherein said electromagnetic radiation is split into at least two beams which will impinge on different spatial light modulators, by a beam splitting device arranged at an optical plane between said spatial light modulators and an illuminator pupil or a conjugate optical plane. The invention also relates to a method for patterning a workpiece with a plurality of spatial light modulators.

Owner:MICRONIC LASER SYST AB

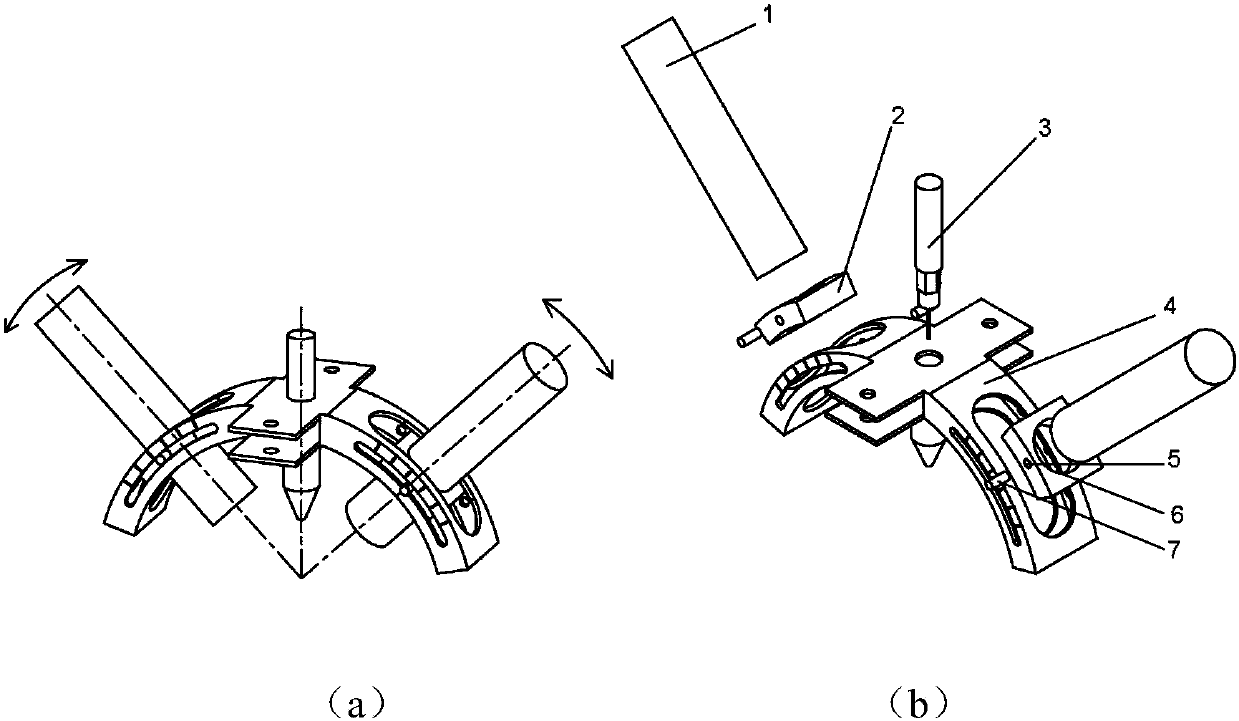

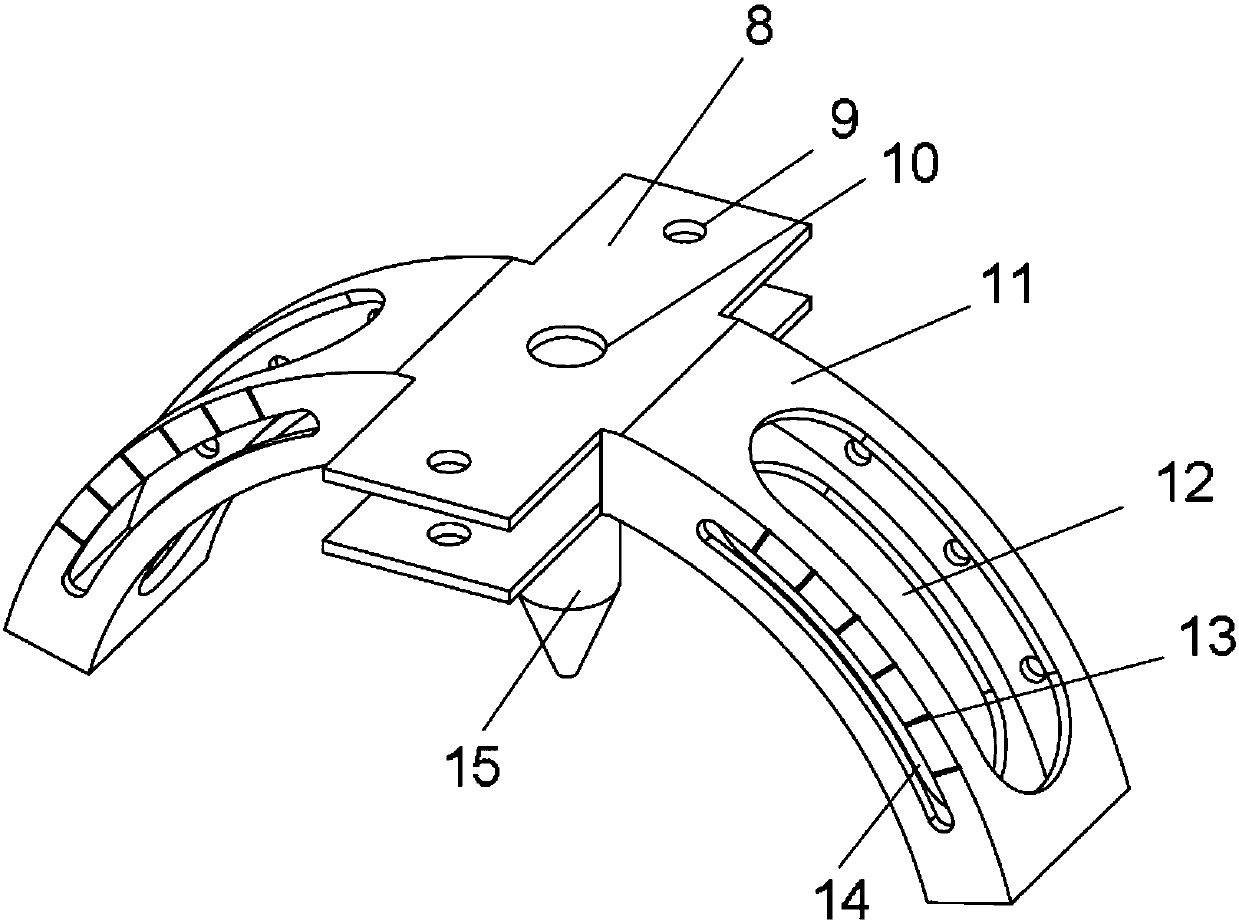

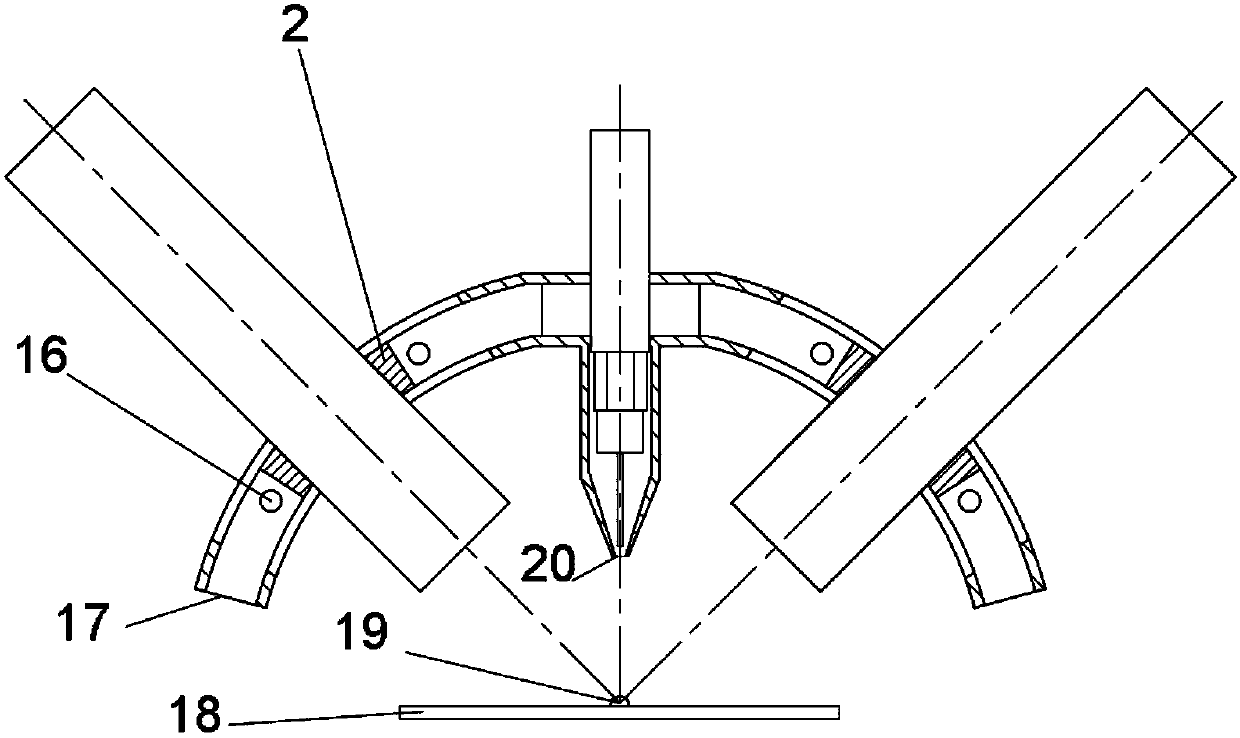

An Angle Adjustable Dual Light Source Inkjet Printing Nozzle

The invention discloses a double-light-source ink jetting type printing sprayer with the adjustable angle. The double-light-source ink jetting type printing sprayer comprises an ink jetting type sprayer body, two light sources, two light source clamps, four set screws and an integral sprayer frame. The integral sprayer frame is integrally in an arc shape and comprises an installing plate, two arc slide ways and a sprayer light shield. An opening of the ink jetting type sprayer body faces downwards, the ink jetting type sprayer body can jet light curing materials, the two light sources are symmetrically arranged on the two sides of the ink jetting type sprayer body, light rays are gathered to a light source focus point under the sprayer body, and the materials jetted by the ink jetting type sprayer body fall to the position of the light source focus point to be cured and formed. The incidence angle of the two light sources can be independently adjusted and ranges from 30 degrees to 60 degrees, the angle of the light sources is adjusted, and the position of the light source focus point is not changed. The flexibility of the technology is improved through the adjustable light source incidence angle; the forming technology performance and the printing efficiency are improved through the two light sources symmetrically arranged; and by means of the sprayer light shield, the probability of the blockage of the sprayer can be greatly reduced.

Owner:XI AN JIAOTONG UNIV

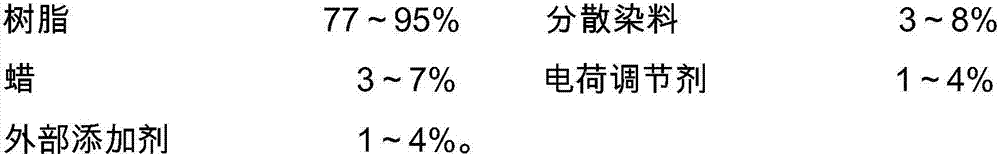

Multifunctional colored toner and preparation method thereof and thermal transfer printing method

PendingCN113031411AAchieve normal printing effectImprove performanceDevelopersTextile printerDisperse dye

The invention discloses a multifunctional color toner and a preparation method thereof, and a thermal transfer printing method thereof. The multifunctional color toner is composed of the following components in percentage by mass: 67-96% of a resin, 1-8% of a disperse dye, 1-8% of a pigment, 1-7% of wax, 0.1-4% of a charge control agent, 0.05-2% of a fiber swelling agent and 0.2-4% of an external additive. According to the invention, the colored toner prepared by a dry physical method has the normal color office function on paper, further has the thermal transfer digital printing function, can transfer patterns on base materials such as textiles, ceramics, metals, glass, plastics and the like, and widen the application range of laser printing and copying technologies; compared with the existing ink-jet thermal transfer printing technology, the method has the advantages of high printing speed, mature production technology, safe and environment-friendly production process and wide substrate application range; and the output on the paper can meet the requirements of common color office printing, and meanwhile, the transfer printing pattern is good in fastness and suitable for the requirements of large-scale printing and personalized customization.

Owner:邯郸汉光办公自动化耗材有限公司

Small part 3D printer

PendingCN111805903AReduce noiseImprove securityAdditive manufacturing apparatusSound producing devicesLow noiseComputer printing

The invention provides a small part 3D printer. The small part 3D printer comprises a case, a printing table is installed inside the case, a sound collecting plate is installed at the bottom of an inner cavity of the case, fixing blocks are installed at the bottom of the printing table, a vibration rod is fixedly connected with the bottom of each fixing block, and the end, away from the fixing block, of each vibration rod is sleeved with an outer sleeve; and a damping spring is arranged inside each outer sleeve. According to the small part 3D printer, a sound adsorption plate is arranged, noise of the printer is adsorbed into a sound adsorption sponge through sound adsorption holes, the density of the sound adsorption sponge is adjusted through sound adsorption springs, the noise is buffered, and harm of the noise to the human body is reduced; and the arranged outer sleeves, the damping springs and the vibration rods are used in a cooperative mode, vibration generated in the operationprocess of the printer can be effectively adsorbed by extruding and damping the damping springs through the vibration rods, the strength of vibration generated by the printer and transmitted to the ground is reduced, and noise generated by operation of the printer is reduced.

Owner:杨进

Chip for open single cell research and preparation method thereof

ActiveCN107828653BEasy to shareEasy to makeBioreactor/fermenter combinationsBiological substance pretreatmentsCell trappingEngineering

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for preparing diamond/copper thermally conductive composite parts by 3D printing near net shape

The invention discloses a near-net forming method for preparing a diamond / copper heat-conducting composite material part through 3D printing, and belongs to the field of metal-based composite materials. According to the method, diamond powder and a binder are mixed into uniform gel-like sizing agent, a diamond / cooper composite material prefabricated body is prepared by using a 3D printing technology, a porous diamond prefabricated part is formed through processes such as curing, pyrolysis and carbonization, and then copper infiltration compounding is conducted on the prefabricated part by adopting a pressure infiltration technology so as to obtain the diamond / copper composite material with good performance. The method is particularly suitable for near-net forming of complex shapes, designability and processability of the diamond / copper composite material are greatly improved, the cost is reduced, and the application field of diamond / copper is expanded.

Owner:GRIMAT ENG INST CO LTD

High-stability automatic screen printing machine

PendingCN114701243AEasy to replaceSmooth liftScreen printersPrinting press partsScreen printingEngineering

The invention discloses a high-stability automatic screen printing machine in the technical field of screen printing machines. The high-stability automatic screen printing machine comprises a workbench, a printing platform, a printing mechanism and a sorption plate. The workbench is a horizontal reference platform, and a controller and an operation panel are further arranged on the workbench; the printing platform is of an integral gantry type structure with two rails, the printing mechanism can be erected between the two gantry type structures in an up-and-down moving mode, a glue scraping plate and a glue returning plate are arranged below the printing mechanism, the glue scraping plate and the glue returning plate can be attached to the top face of a printing template in a lifting and separating mode, ink scraping glue can be better attached to a film for printing, and the printing efficiency is improved. By means of the structure, the film can be stabilized during printing, the printing stability is ensured, the film cannot be driven during ink glue scraping, clear printing is ensured, the printed film can keep tension all the time, follow-up advancing of the film is not affected, the stability is higher, and automatic silk-screen printing is achieved.

Owner:厦门海力拓自动化科技有限公司

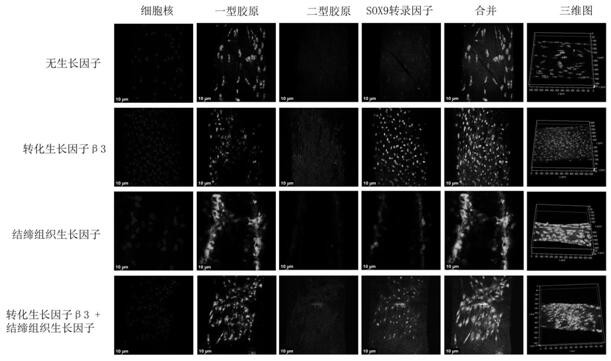

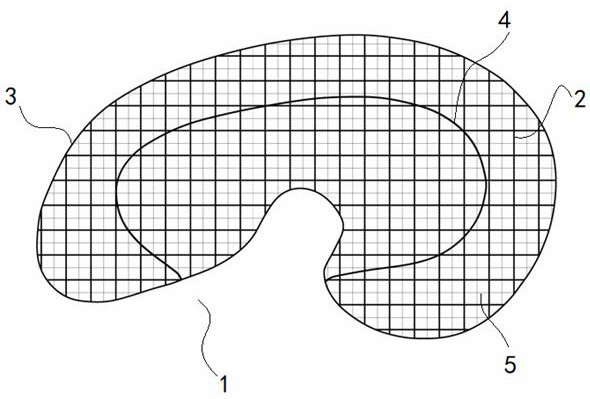

Personalized 3D printing meniscus regeneration stent and preparation method thereof

ActiveCN113995557ABuild personalizationImprove repair functionJoint implantsTissue regeneration3d printComputer printing

The invention provides a preparation method of a personalized 3D printing meniscus regeneration stent. The preparation method comprises the following steps: S1, a stent model is prepared, and a support structure model for support the stent model is set; s2, working parameters of a high-temperature printing head, a low-temperature printing head and internal structure printing design are set on a biological 3D printer; and S3, the extruded material in the high-temperature printing head and the extruded material in the low-temperature printing head are subjected to mixed printing, and the meniscus regeneration stent is constructed in a partition printing mode that the 2 / 3 area of the inner side of the meniscus regeneration stent is set as a white area, and the 1 / 3 area of the outer side of the meniscus regeneration stent is set as a red area. The personalized 3D printing meniscus regeneration stent has the advantages that the bottom of the personalized 3D printing meniscus regeneration stent can be matched with the tibial plateau; and the regeneration and repair functions after implantation can be effectively enhanced.

Owner:PEKING UNIV THIRD HOSPITAL

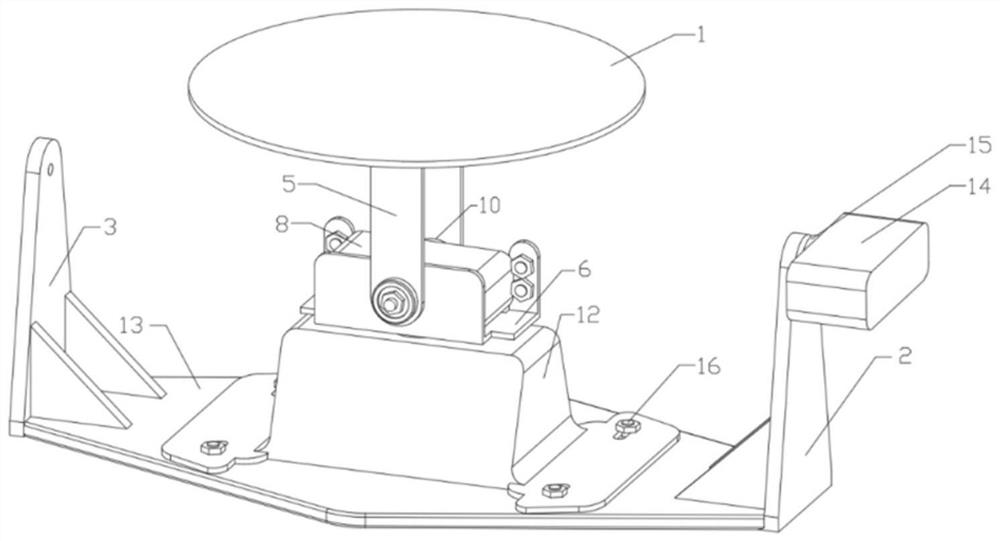

Six-axis 3D printer three-dimensional rotary table device for additive manufacturing of elastic wave metamaterial

PendingCN114311669AExtended service lifeHigh control precisionManufacturing platforms/substratesManufacturing driving meansRotational axisSteering wheel

The invention discloses a six-axis 3D printer three-dimensional rotary table device for additive manufacturing of elastic wave metamaterials. The six-axis 3D printer three-dimensional rotary table device comprises a B-direction cradle type swing assembly, a C-direction objective table rotating assembly, an A-direction objective table swing assembly and an objective table. The B-direction cradle type swing assembly is fixed to a z-direction moving shaft of the 3D printer, and a rotating shaft of the B-direction cradle type swing assembly is perpendicular to the mounting plane. A U-shaped base is fixed in the middle of the B-direction cradle type swing assembly, a C-direction steering engine is assembled and driven in the base, a metal main steering wheel is assembled at the output end of the C-direction steering engine, and a rotating shaft of the C-direction steering engine is perpendicular to the upper plane of the U-shaped base. A threaded hole coaxial with the C-direction steering engine is formed in the bottom of the multifunctional support, and the C-direction objective table rotating assembly is connected with the A-direction objective table swinging assembly through threaded connection. An A-direction steering engine for driving the objective table to swing is fixed in the multifunctional support, the output end of the A-direction steering engine is in threaded connection with a metal main steering wheel, and the other end is connected with a bearing. The metal main steering wheel is in threaded connection with the U-shaped support to output transmission of the motor.

Owner:TIANJIN UNIV

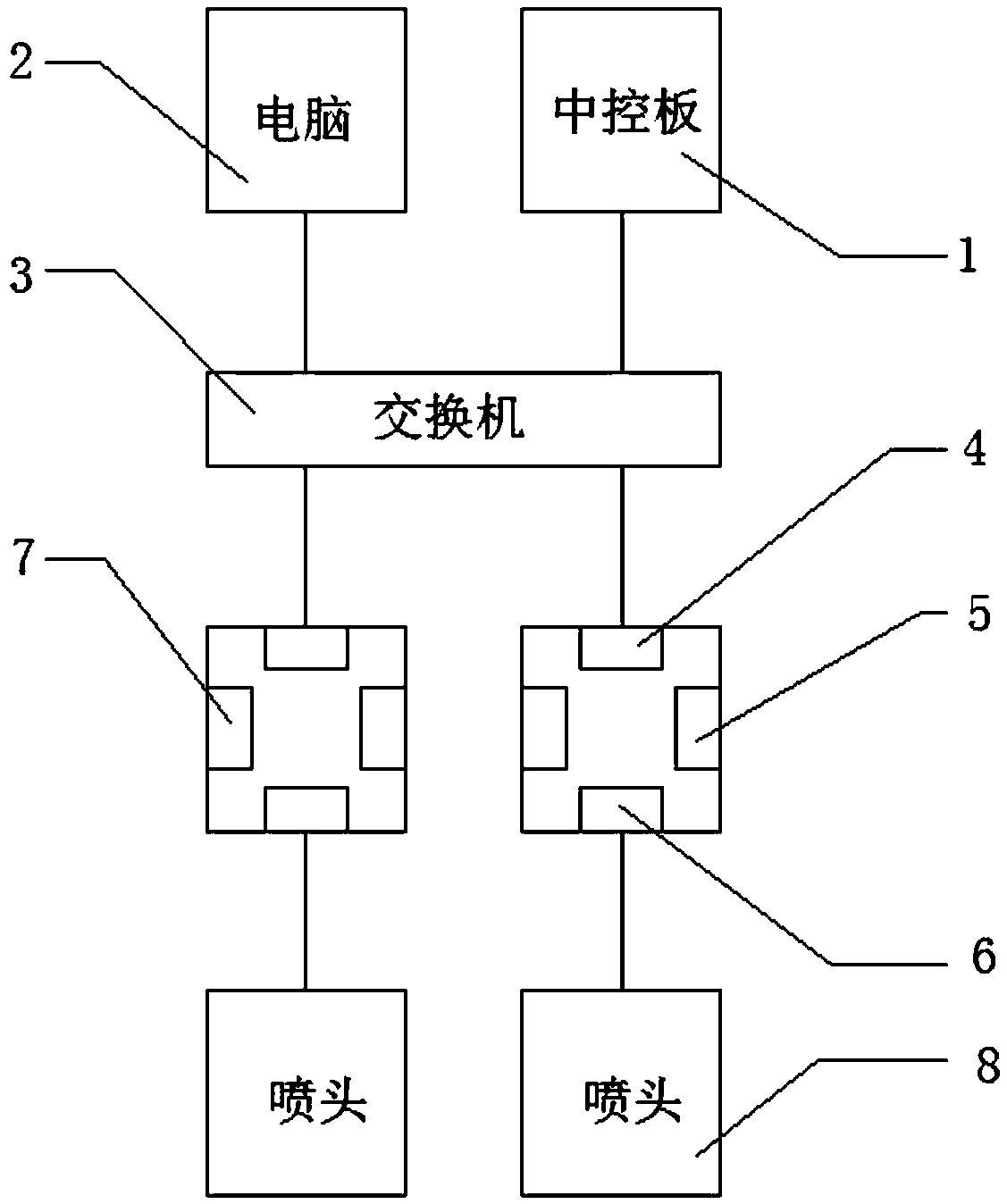

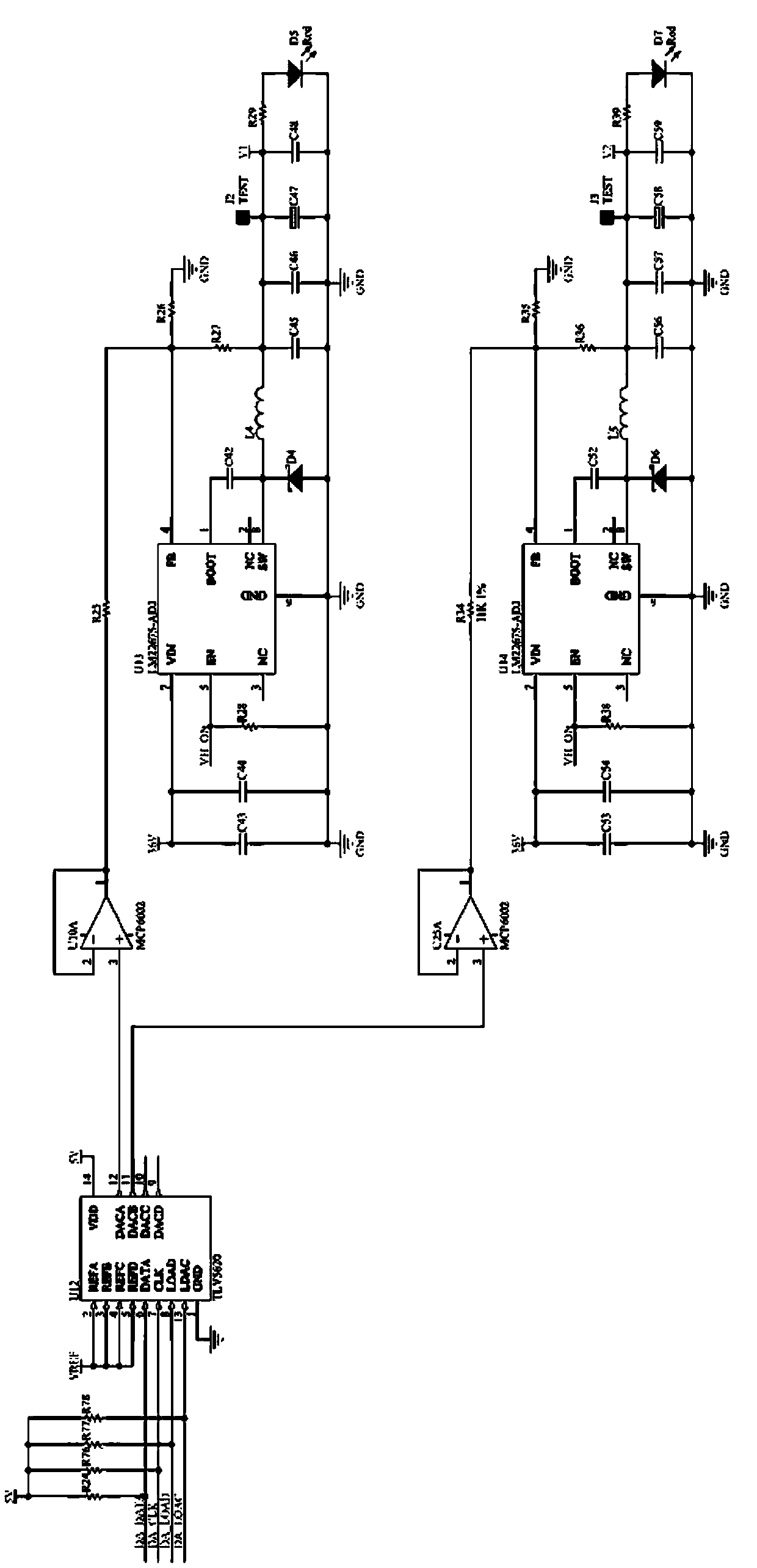

Flat offline industrial printing printer

ActiveCN104723680BImprove data transfer efficiencyFlexible printingTypewritersOther printing apparatusElectricityEngineering

The invention relates to a flat off-line industrial printing machine which solves the problems in the prior art. According to the technical scheme, the flat off-line industrial printing machine comprises a computer, a center control panel, a switch and at least one printing unit, the computer and the center control panel are electrically connected with the switch, the switch is electrically connected with the input end of each printing unit, and each printing unit comprises a sprayer plate and a sprayer. Each sprayer plate comprises a sprayer drive circuit, a network interface, a sprayer data interface, a serial port, a power interface and a data storage circuit, wherein a power source supplies power to the sprayer plate through the power interface, the output end of the network interface and the output end of the serial port are connected with the data storage circuit, the input end of the network interface is connected with switch, the serial port is a parameter setting input port, the sprayer data interface is electrically connected with the corresponding sprayer, and the input end of the sprayer data interface is electrically connected with the data storage circuit through the sprayer drive circuit.

Owner:WUHAN JINGFENG TECH

Luminescent anti-counterfeiting element, detection method and detection system thereof

ActiveCN108956549BUnique Luminous PropertiesEasy to detectInksAnalysis by material excitationParticle physicsQuantum electrodynamics

The invention provides a luminescent anti-counterfeiting element, a detection method and a detection system thereof. The light-emitting anti-counterfeiting element has the following light-emitting characteristics: the light-emitting anti-counterfeiting element is irradiated by the first excitation light, and after the first excitation light is removed, when it is further irradiated by the second excitation light, it produces second emission light visible to the naked eye; the light-emitting anti-counterfeiting element When not irradiated by the first excitation light in advance, when directly irradiated by the second excitation light, a third emission light invisible to the naked eye is produced; wherein, the wavelength of the second excitation light is greater than the wavelength of the first excitation light, and the wavelength of the second excitation light greater than the wavelength of the second emitted light. Since the luminous anti-counterfeit element provided by the present invention has the above-mentioned unique luminous effect, it has the characteristics of convenient detection and high concealment. The invention also provides a detection method and a detection system for the above-mentioned luminescent anti-counterfeiting element.

Owner:CHINA BANKNOTE PRINTING & MINTING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com