A temperature control structure of fdm nozzle

A temperature control and nozzle technology, applied in the field of 3D printing, can solve the problems of reducing heating efficiency, increasing equipment size, material melting, etc., to achieve the effect of improving printing accuracy, reducing equipment size, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

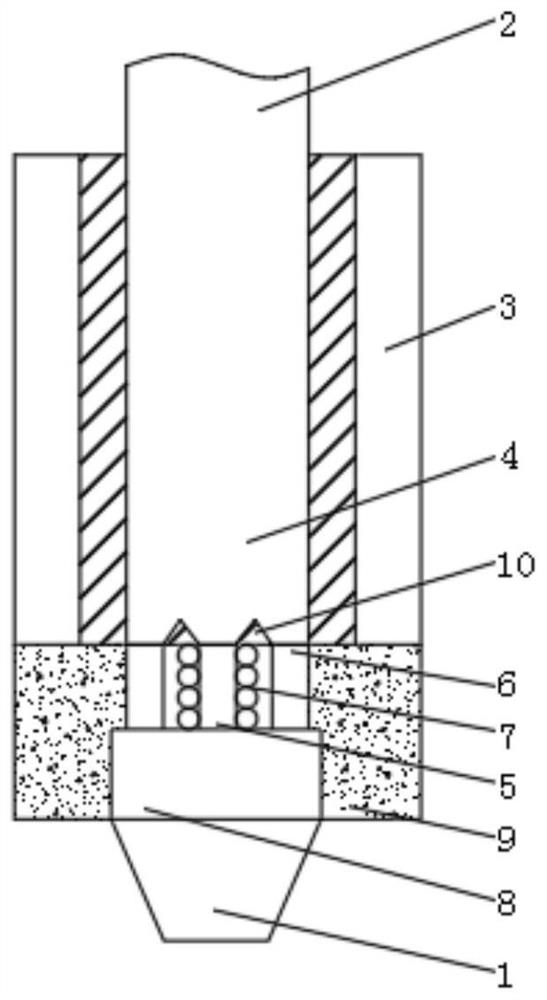

[0024] see Figure 2-3 , a FDM nozzle temperature control structure, including an extrusion nozzle 1 and a feed assembly 2, the lower end of the feed assembly 2 is fixedly connected with a preheating chamber 4, and the outer wall of the preheating chamber 4 is fixedly installed with a heating block 3, heating The block 3 preliminarily heats the printing material in the preheating chamber 4 to make it basically melt. The lower end of the preheating chamber 4 is connected with the central branch pipe 5 and the peripheral split body 6, and the central branch pipe 5 and the peripheral split body 6 are fixedly installed with Heating wire 7, the heating wire 7 surrounds the outer wall of the central branch pipe 5, the completely melted external printing material in the preheating chamber 4 enters the heating wire 7, and the incompletely melted printing material in the preheating chamber 4 enters the central branching pipe 5 Among them, the heating wire 7 further heats the printing m...

Embodiment 2

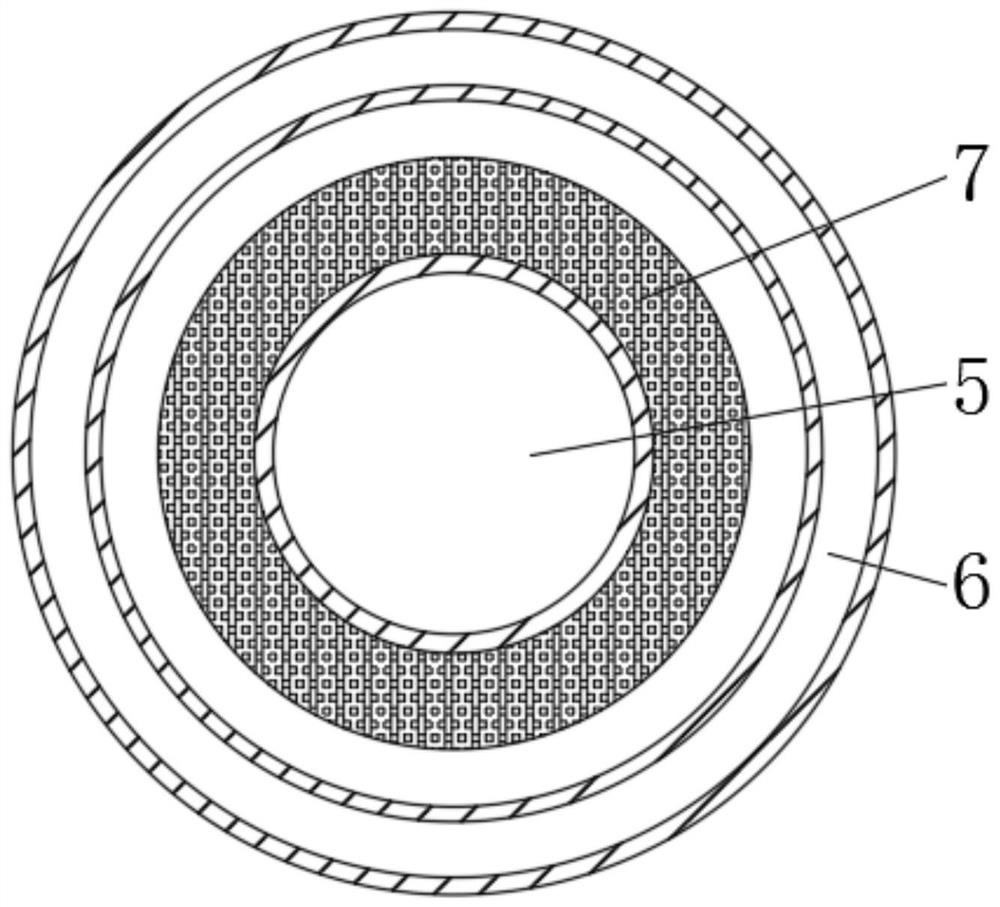

[0030] see Figure 4 The second embodiment is basically the same as the first embodiment, except that the outer peripheral split body 6 is a circular tube surrounding the outside of the central branch pipe 5. Compared with the first embodiment, although the use of heat is reduced, it is convenient to replace the heating wire 7, Relatively convenient to use.

[0031] Working principle of the present invention:

[0032] After the printing material is transported into the preheating chamber 4 through the feeding assembly 2, it starts to melt under the action of the heating block 3. Since the temperature of the preheating chamber 4 is relatively low and the length is relatively short, the outer peripheral part of the printing material is completely melted , but the axis has not completely melted. Under the action of the material distribution slope 10, the completely melted material on the outer periphery enters the outer peripheral split body 6, and the printing material on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com