Automatic pad printing machine

A pad printing machine and automatic technology, applied in the field of printing pad printing machines, can solve the problems of low quality and efficiency, high labor intensity, long cleaning time, etc., and achieve the effect of effective contact adsorption force, maintenance operation, and flexible printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below:

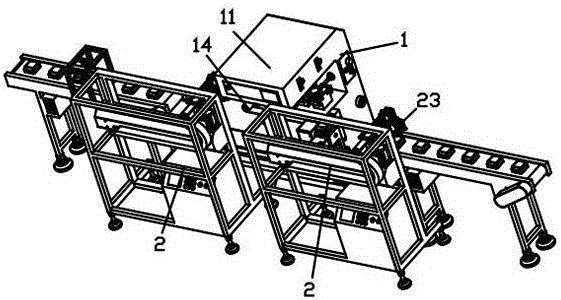

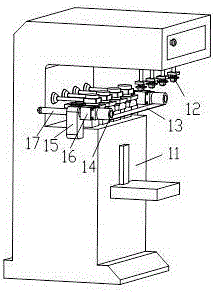

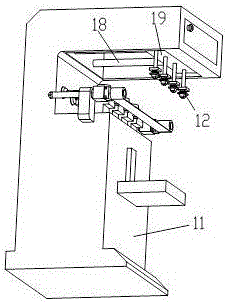

[0018] refer to Figure 1-5 , an automatic pad printing machine, including a transfer platform 2 and a printing mechanism 1, the printing mechanism includes a pad printing body 11, a pad printing rubber head 12 and a cleaning rubber cloth 13, and the pad printing rubber head 12 and cleaning rubber cloth 13 is set opposite to each other, and the two ends of the cleaning adhesive cloth 13 are respectively equipped with a retractable roller 14, an adjustment seat 15, a rotating motor 16 and a horizontal adjustment rod 17. The center of the adjustment seat 15 is hollowed out, and the horizontal adjustment rod 17 passes through the The adjustment seat 15 moves back and forth relative to the adjustment seat; the rotating motors 16 are respectively fixed with the ends of the horizontal adjustment rods 17, and the retractable rollers 14 are connected with the rotating motor 16, and are driven by the rotating motor 16 to retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com