Slm direct writer

A spatial light modulator, sub-exposure technology, applied in optics, instruments, optomechanical equipment, etc., can solve the problems of complex and high chip complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

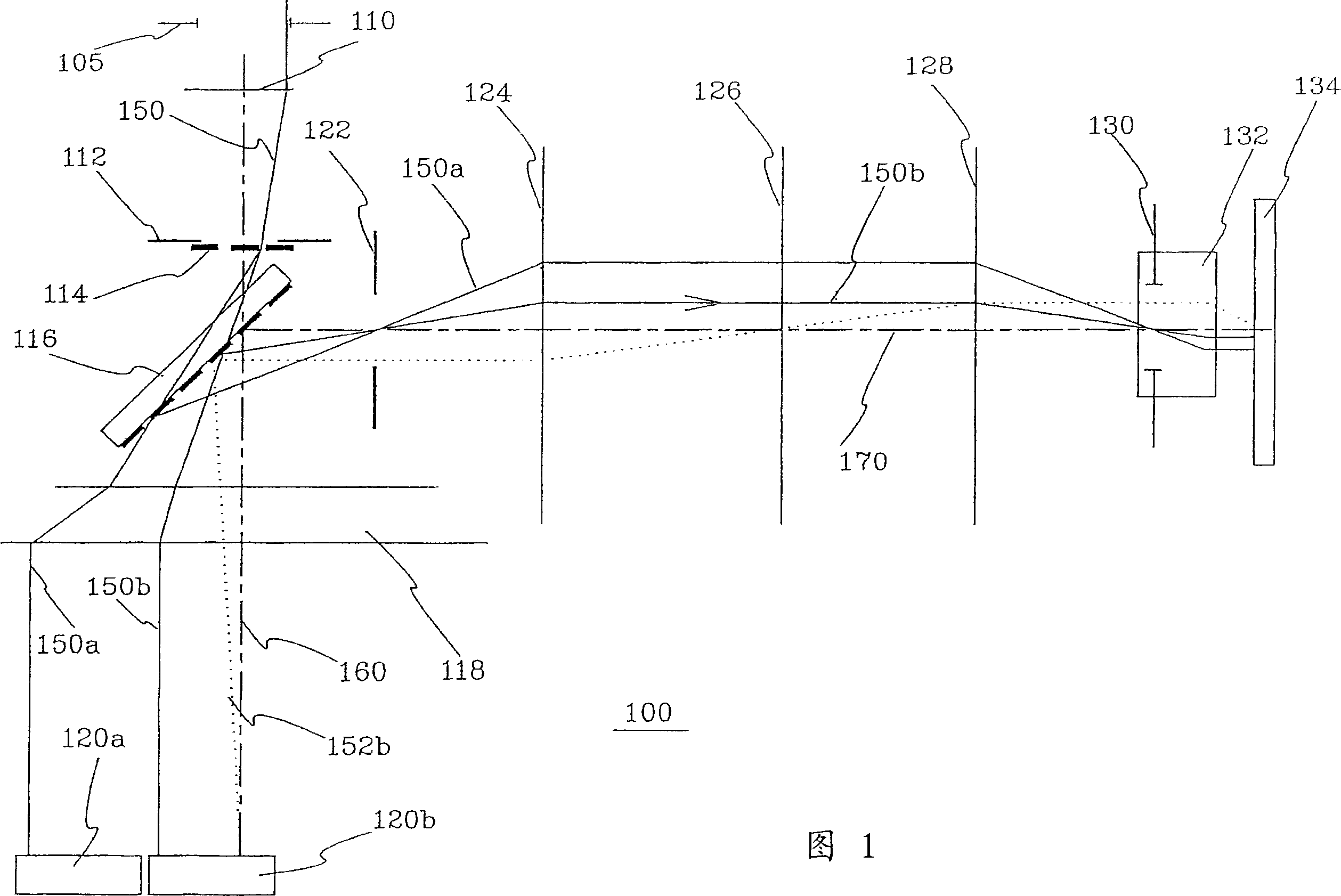

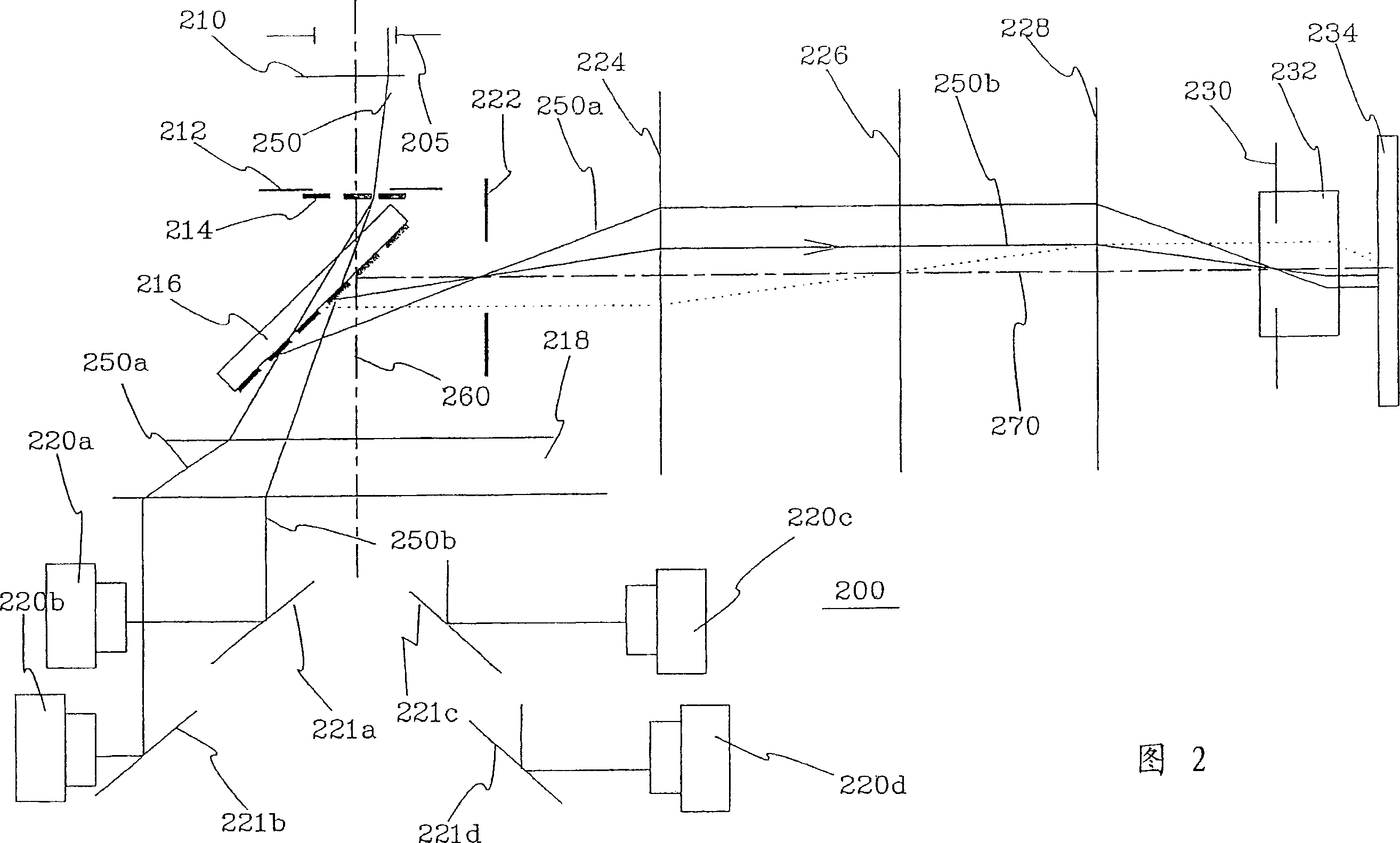

[0021] The following detailed description is made with reference to the accompanying drawings. The preferred embodiments are described in order to illustrate the invention, not to limit its scope as defined by the claims. Those skilled in the art will recognize numerous equivalent variations to the description below.

[0022] Furthermore, the preferred embodiments are described with reference to an analog spatial light modulator. It will be obvious to those skilled in the art that there may be situations where other spatial light modulators than analog spatial light modulators are equally applicable; for example digital spatial light modulators like the Digital Micromirror Device (DMD) manufactured by Texas Instruments. Modulator. Additionally, SLMs can be composed of reflective or transmissive pixels. Furthermore, preferred embodiments are described with reference to excimer laser sources. Obviously for those skilled in the art, the present invention method can use the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com