Printing head, printing device and printing method for rapid forming of metal piece

A printing device and printing head technology, applied in the direction of additive processing, etc., can solve the problems of low printing efficiency, achieve the effects of improving printing efficiency, improving utilization rate, and overcoming low printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

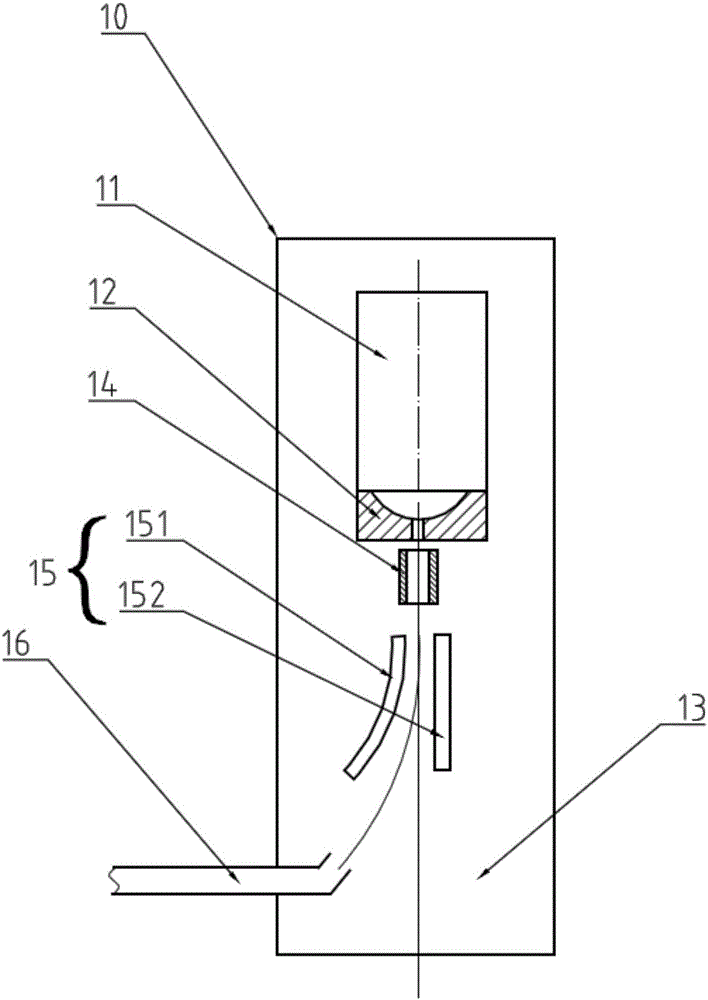

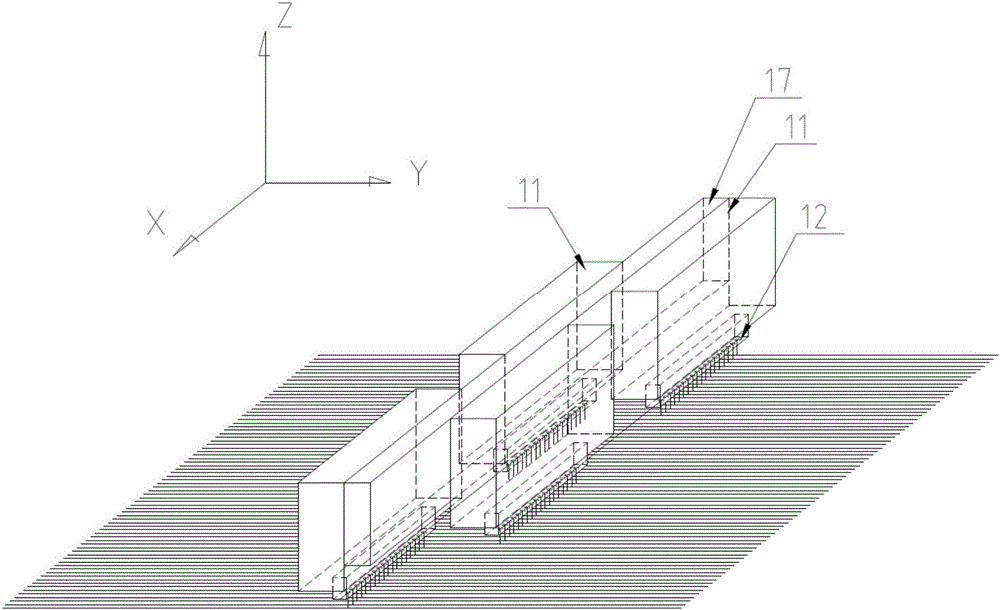

[0073] This embodiment discloses a printing head 10 for rapid prototyping of metal parts, which includes a body 11 and multi-nozzles 12 , and the multi-nozzles 12 are arranged on the body 11 .

[0074] Such as figure 1 As shown, the print head 10 of the present embodiment also includes: a mounting base plate 13, a first electrode 14 for controlling the electrical properties of the electroplating solution ejected through the multi-nozzle 12, and a non-neutral electroplating solution for making the electrical properties The deflected second common electrode 15 and the recovery tank 16 for receiving the deflected electroplating solution for recovery.

[0075] The main body 11, the multi-nozzle 12, the first electrode 14, the second common electrode 15 and the recovery tank 16 of this embodiment are as figure 1 As shown, they are sequentially arranged on the same side of the installation base plate 13 from top to bottom, the recovery tank 16 is arranged on the lower side of the s...

Embodiment 2

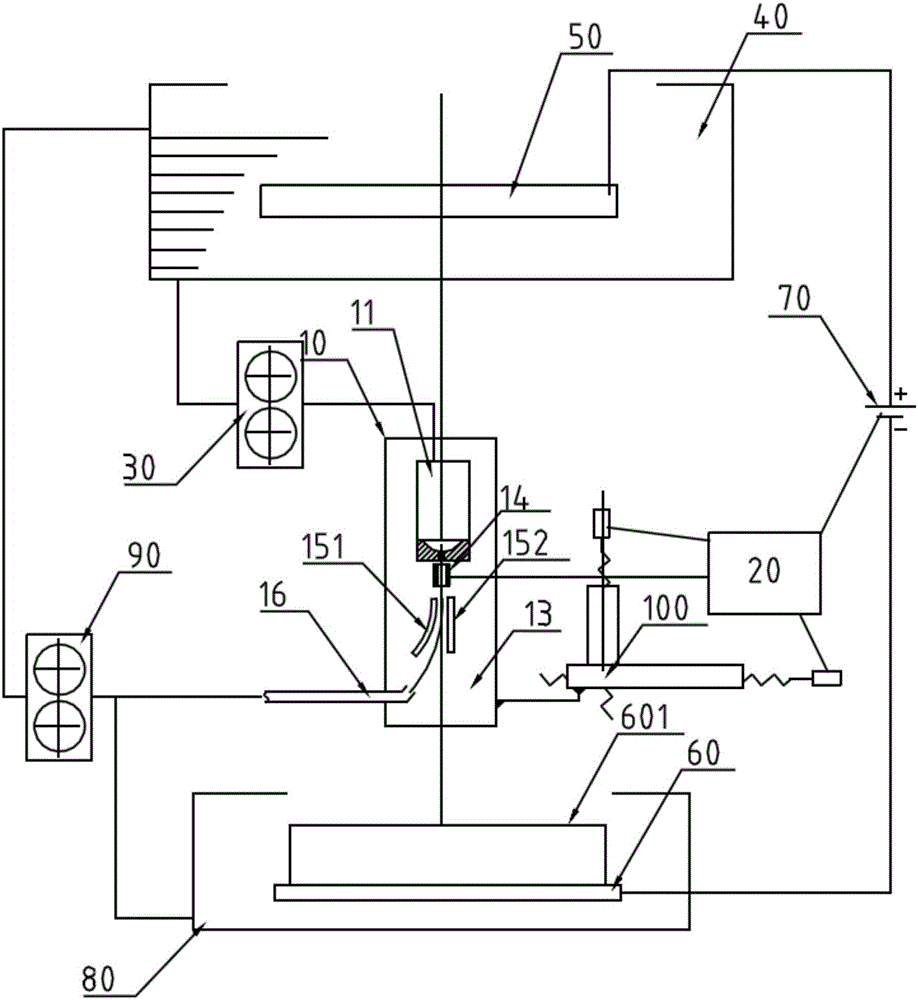

[0086] Such as figure 2 As shown, this embodiment proposes a printing device for rapid prototyping of metal parts, including a control system 20, a booster pump 30, a print head 10, an electroplating solution tank 40, a first electroplating plate 50, and a second electroplating plate 60 And electroplating power supply 70, one end of electroplating power supply 70 is connected with the first electroplating pole plate 50, and the other end of electroplating power supply 70 is connected with the second electroplating pole plate 60, and the first electroplating pole plate 50 is placed in the electroplating solution box 40, the second One side of the electroplating pole plate 60 faces the print head 10, and the electroplating solution in the electroplating solution tank 40 is pumped to the print head 10 by the booster pump 30, and the electroplating solution is ejected to the second electroplating pole plate 60 by the print head 10. Electrochemical deposition or electrolytic etchi...

Embodiment 3

[0112] This embodiment proposes a rapid prototyping printing method for metal parts, which uses electroplating solution to form electrochemical deposition or electrolytic etching layer by layer to print metal parts. During the electrochemical deposition or electrolytic etching process of the electroplating solution, Controlling the electrical properties of the plating solution.

[0113] At the position where the electroplating solution needs to be printed, the electroplating solution is directly sprayed onto the position to complete the printing of the position.

[0114] At positions that do not need to be printed, the electrical characteristics of the ejected electroplating solution are changed so that the electroplating solution is deflected so that the electroplating solution does not appear at the position that does not need to be printed.

[0115] Specifically, in this embodiment, the printing device described in Embodiment 2 prints metal parts (the specific structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com