Patents

Literature

47results about How to "High precision printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid ejecting apparatus

ActiveUS20110267393A1Reduce air turbulenceImprove accuracyOther printing apparatusComputer printingEngineering

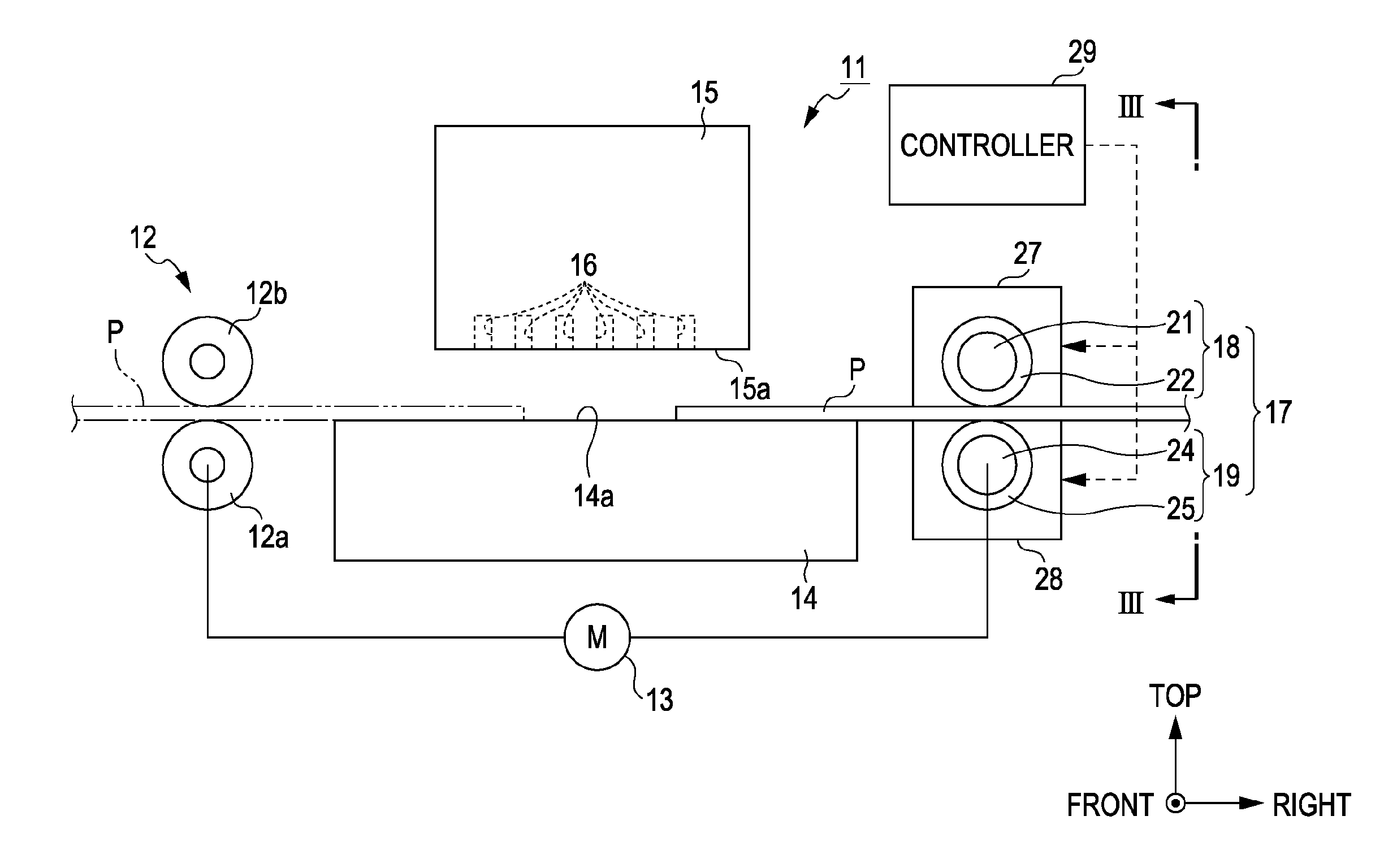

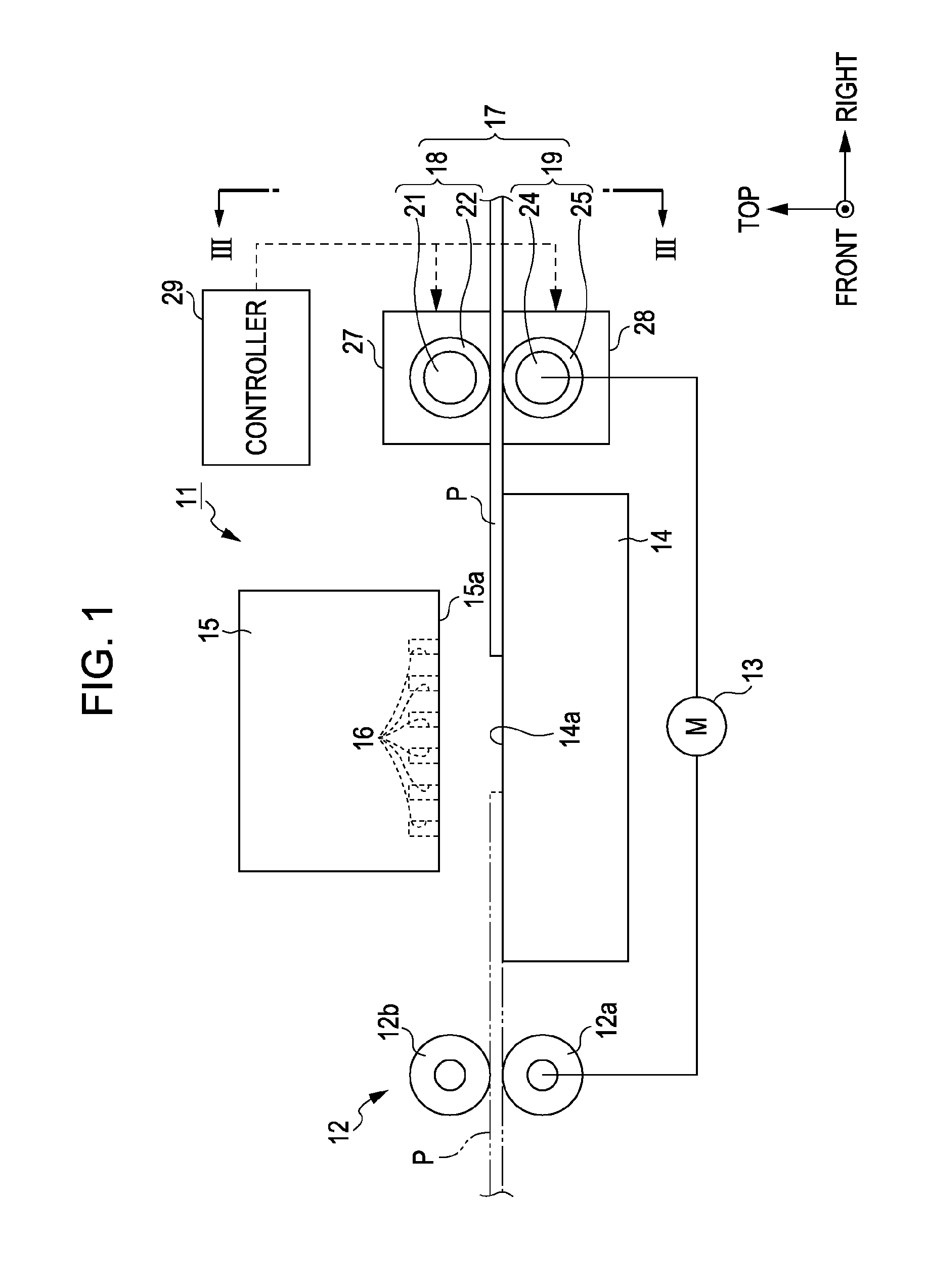

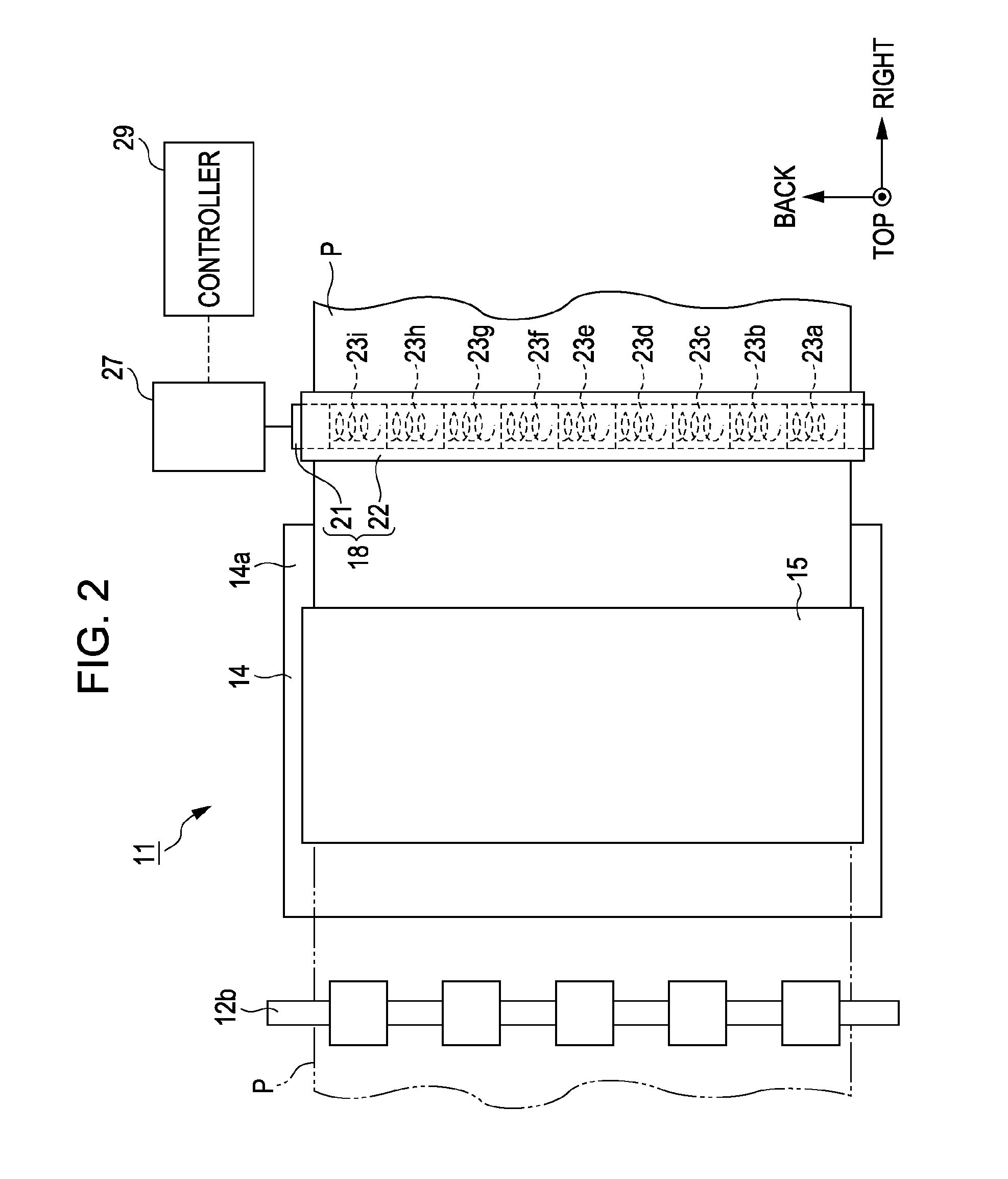

A printer includes a heating roller unit that heats recording paper at a position downstream of a recording head, which is provided at an upstream position, in the direction of the transportation of the recording paper. The recording head ejects ink to the recording paper that is transported from an upstream side to a downstream side. The heating roller unit is disposed along the direction of the width of the recording paper, which intersects with the transportation direction thereof. The heating roller unit is divided into a plurality of areas in the width direction. Heat applied by first areas of the plurality of areas to the recording paper is different from heat applied by second areas, which are adjacent to the first areas in the width direction, to the recording paper.

Owner:SEIKO EPSON CORP

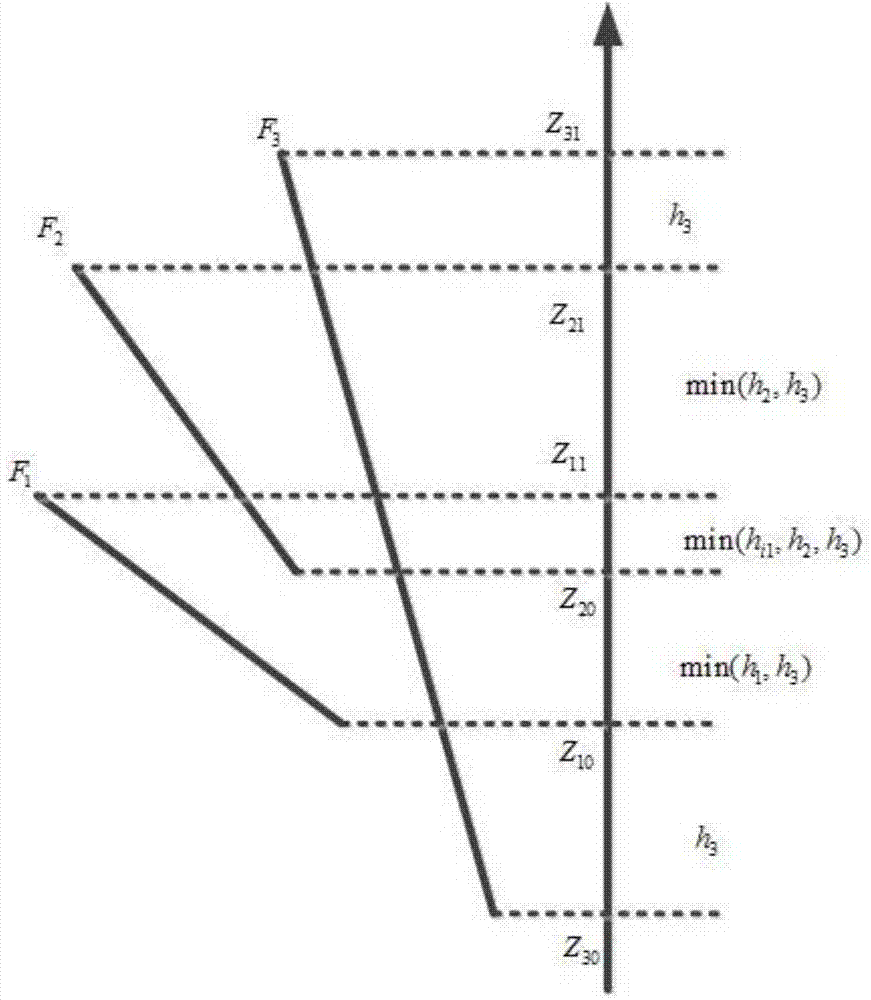

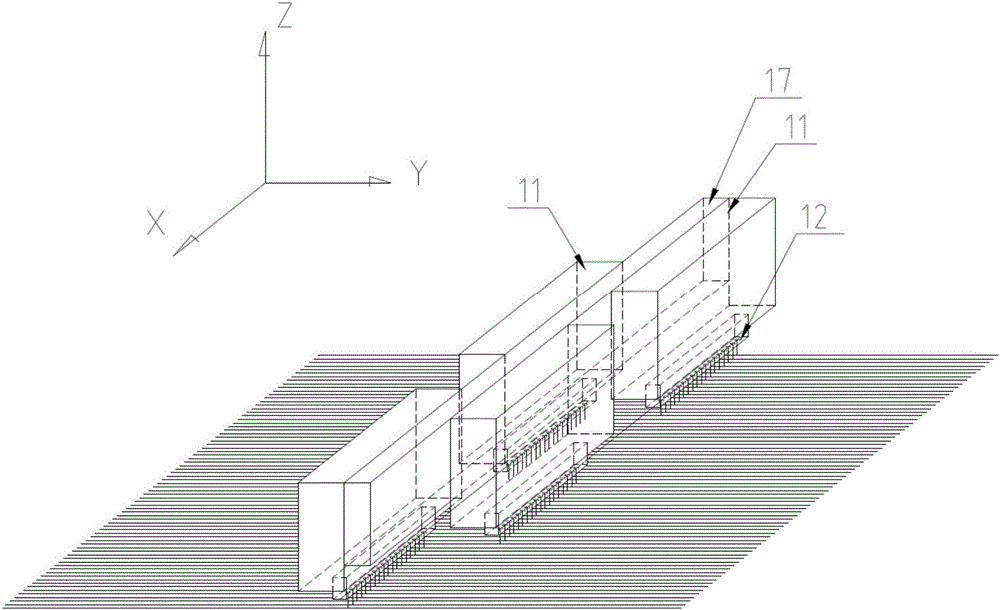

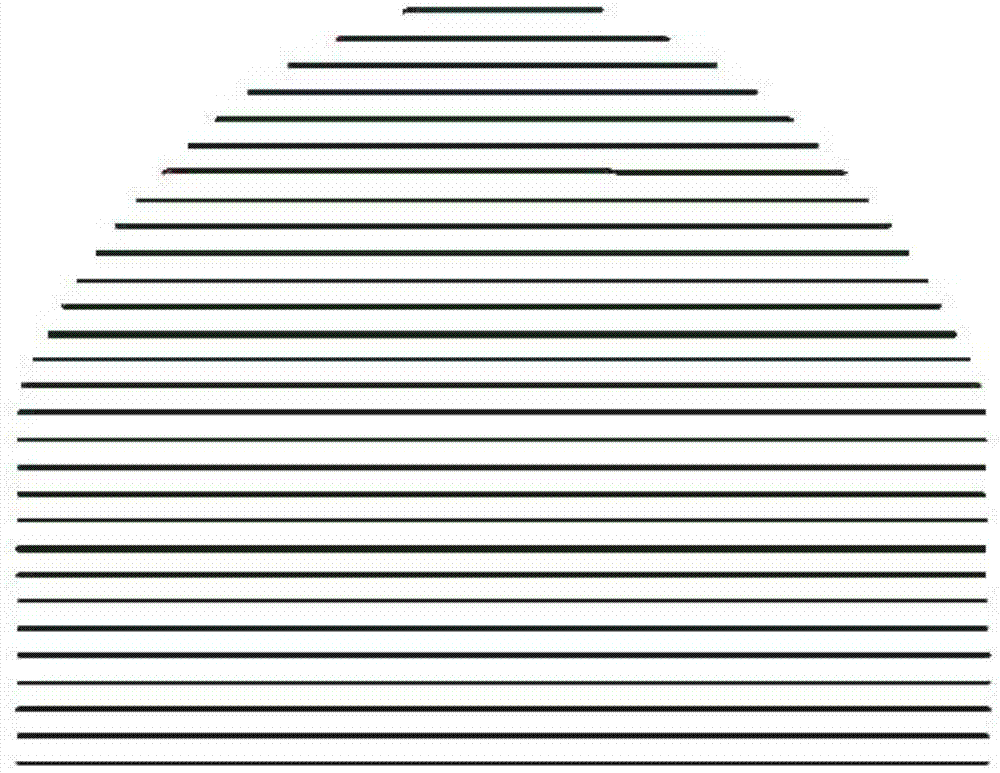

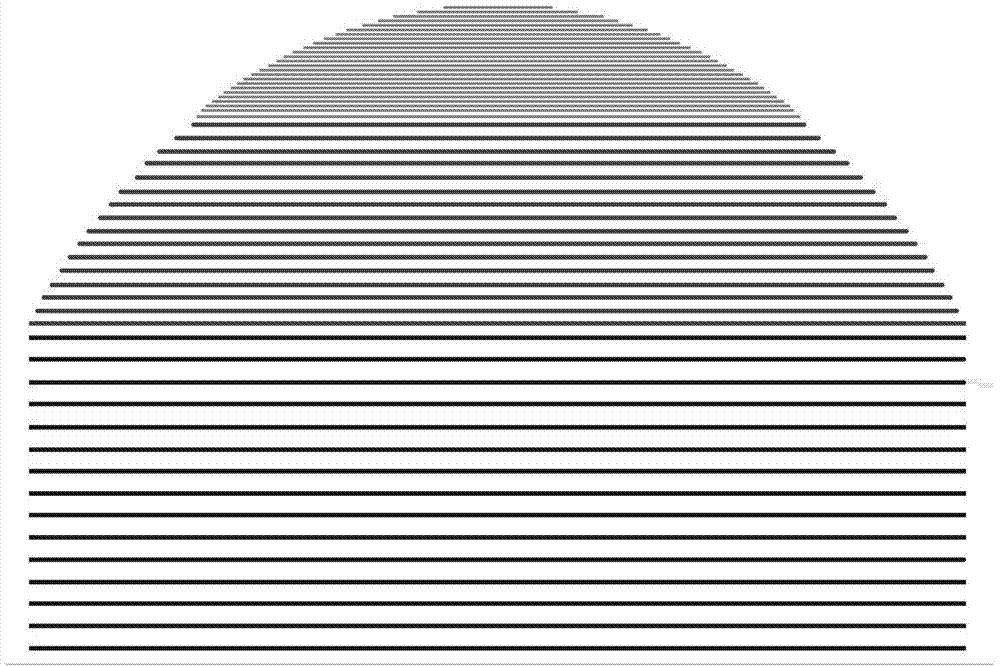

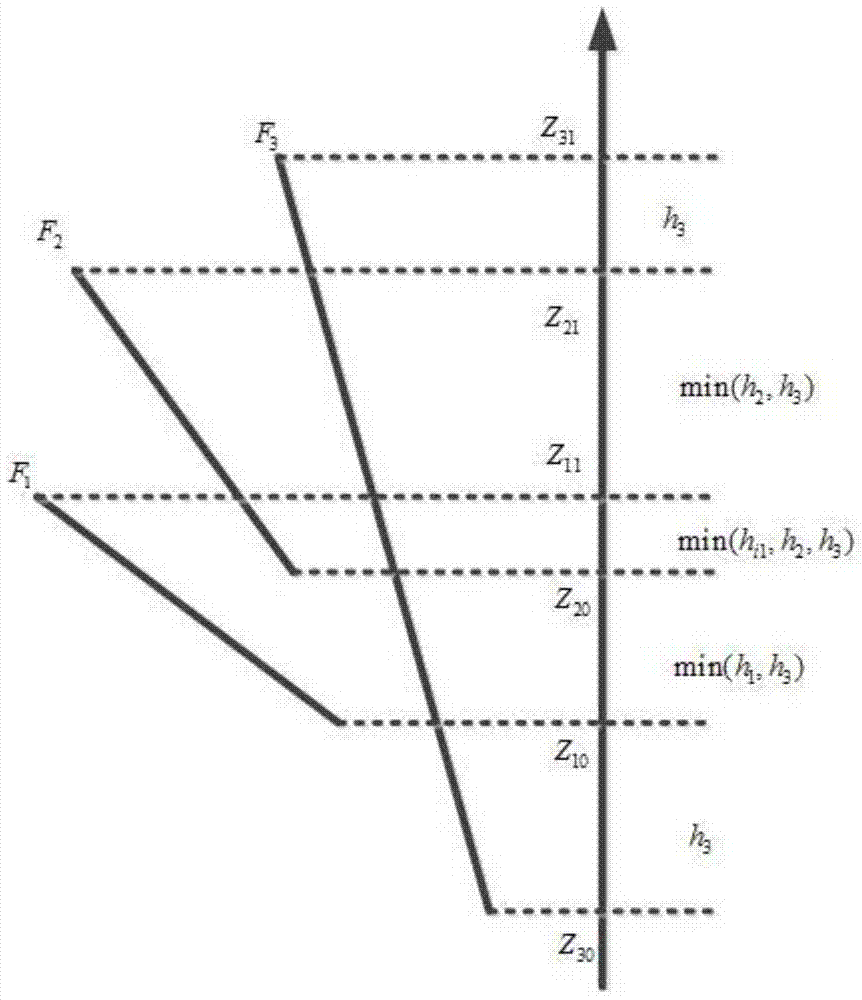

Self-adaption layering method of 3D printing

ActiveCN104503711AHigh precisionImprove Layering Efficiency3D object support structuresImage data processing3d printerSelf adaptive

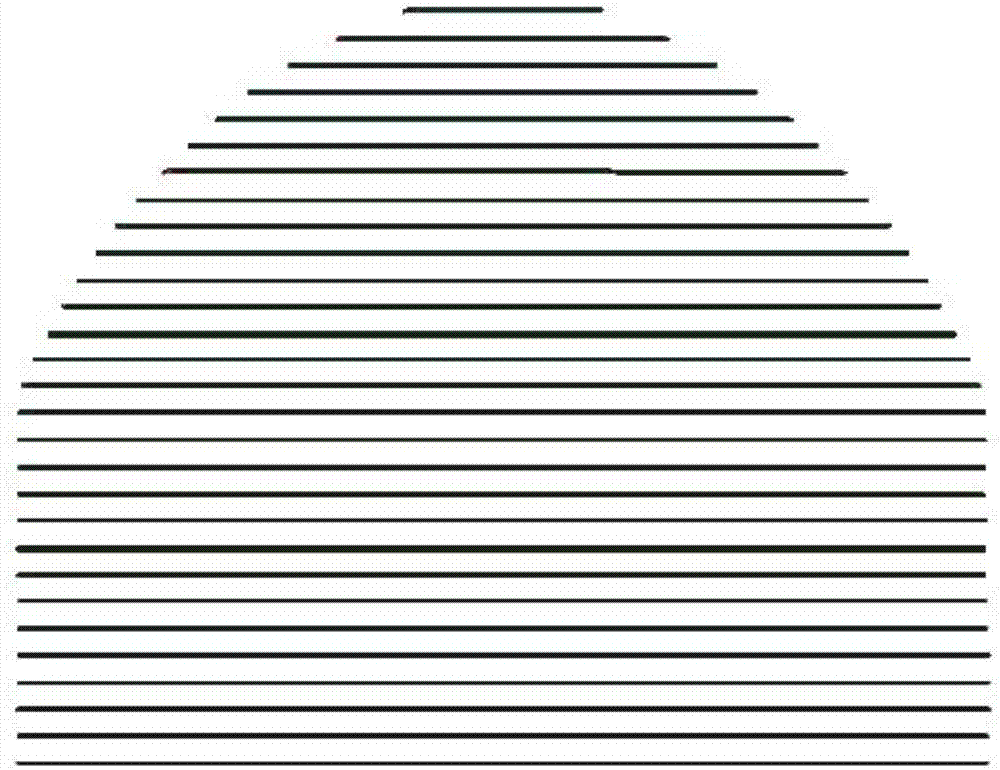

The invention discloses a self-adaption layering method of 3D printing. The self-adaption layering method comprises the following steps: in a process that STL (Standard Template Library) model data is read, calculating layering height corresponding to a triangular patch according to a normal vector of each triangular patch; subsequently, according to the layering height of each triangular patch, calculating optimal layering height within any height range in a vertical direction, and establishing a layering height table (HT); and inquiring the HT to obtain the layering height required for a subsequent layering operation. The self-adaption layering method has the characteristics that layering efficiency is improved, high-precision layering outline data can be obtained, and reliable data support is provided for the high-efficiency and high-precision printing of a 3D printer.

Owner:SHINING 3D TECH CO LTD

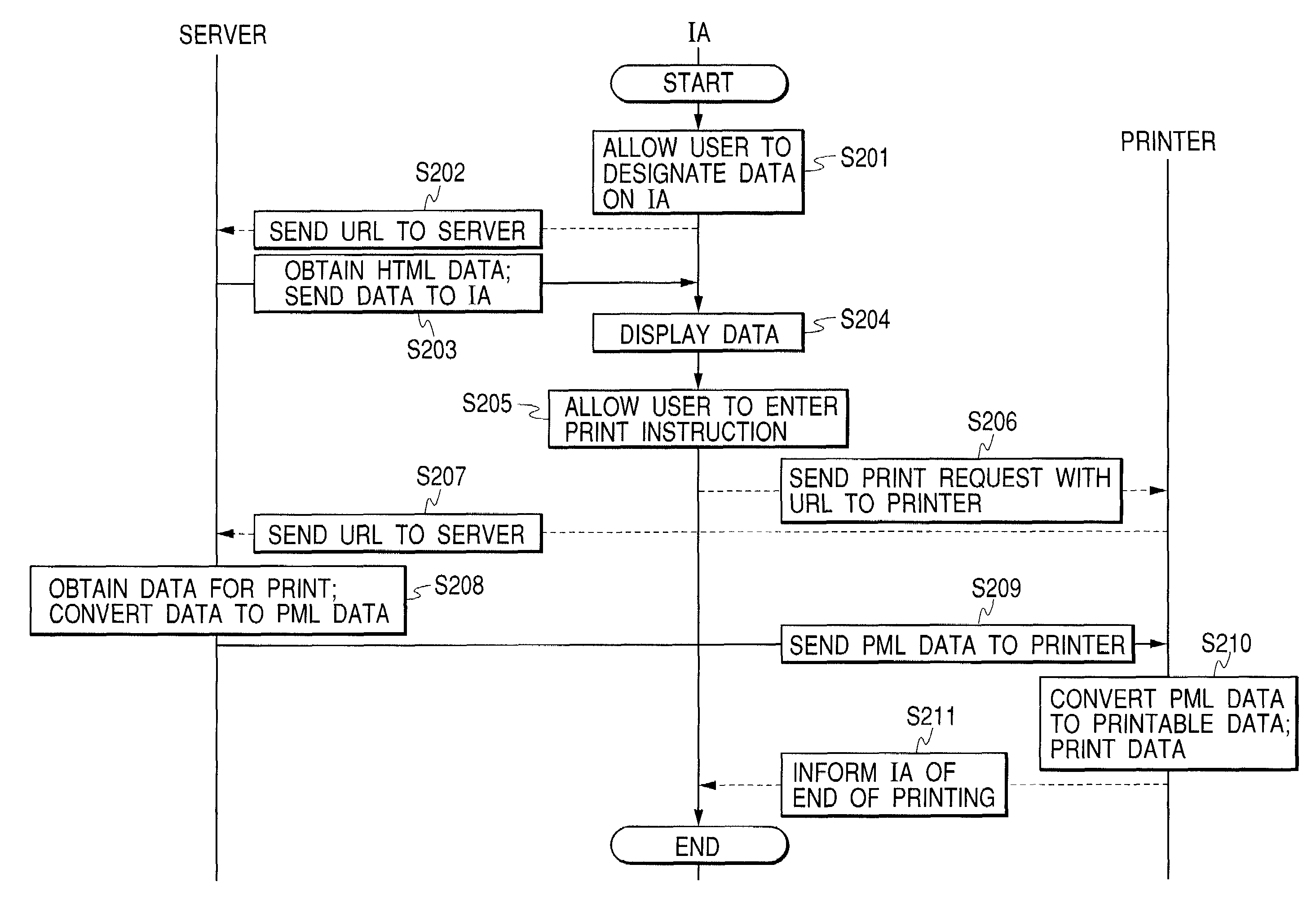

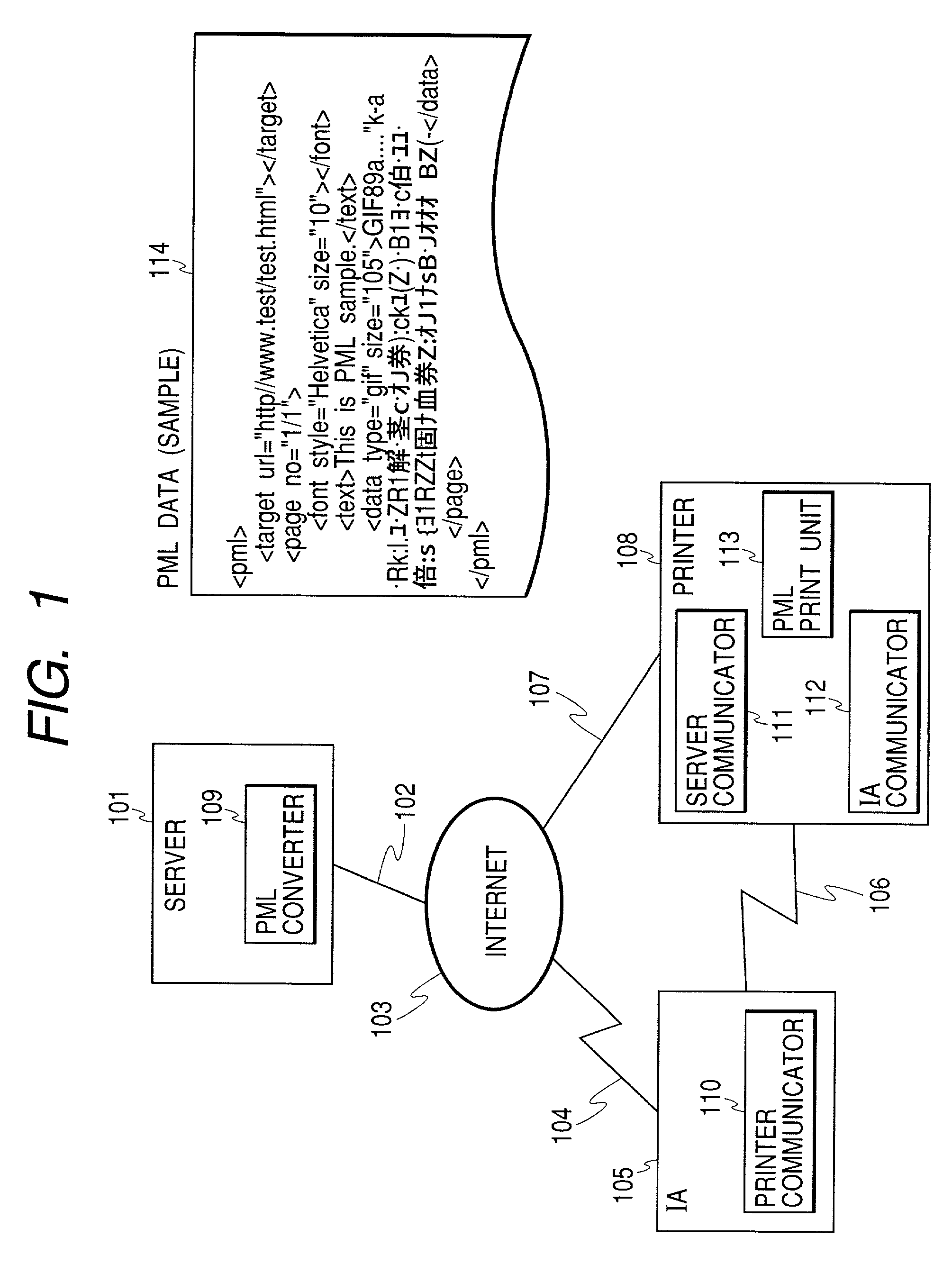

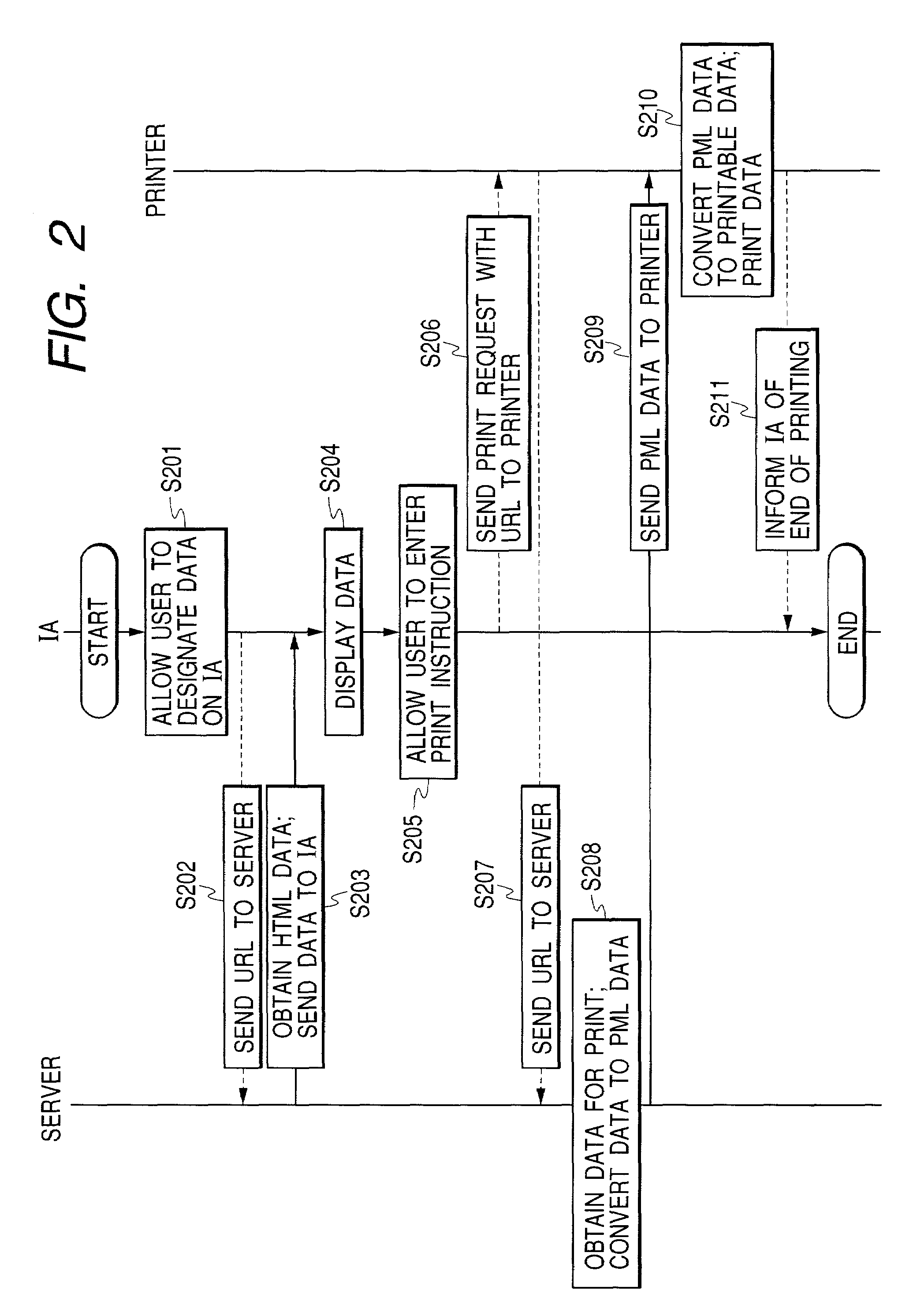

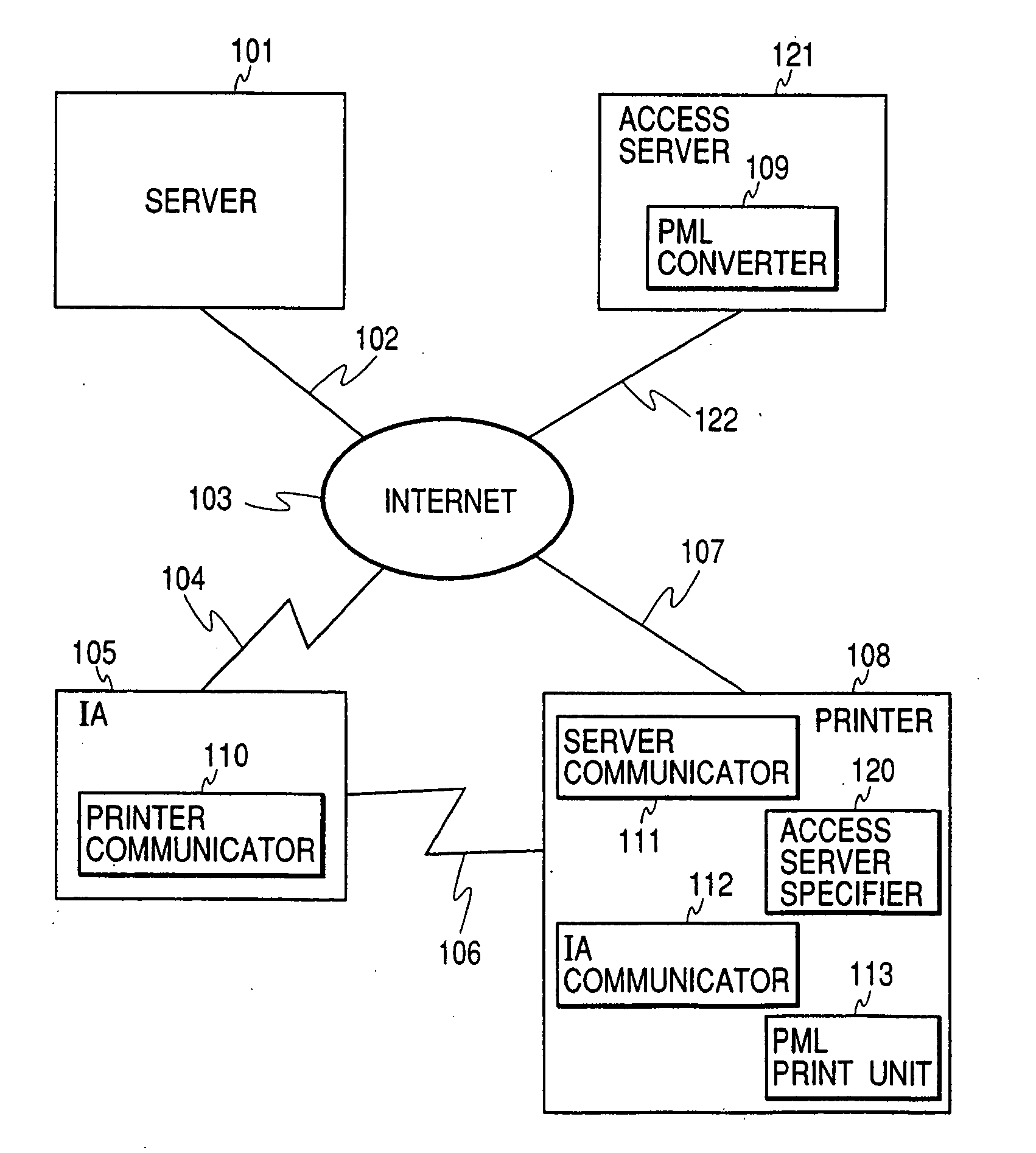

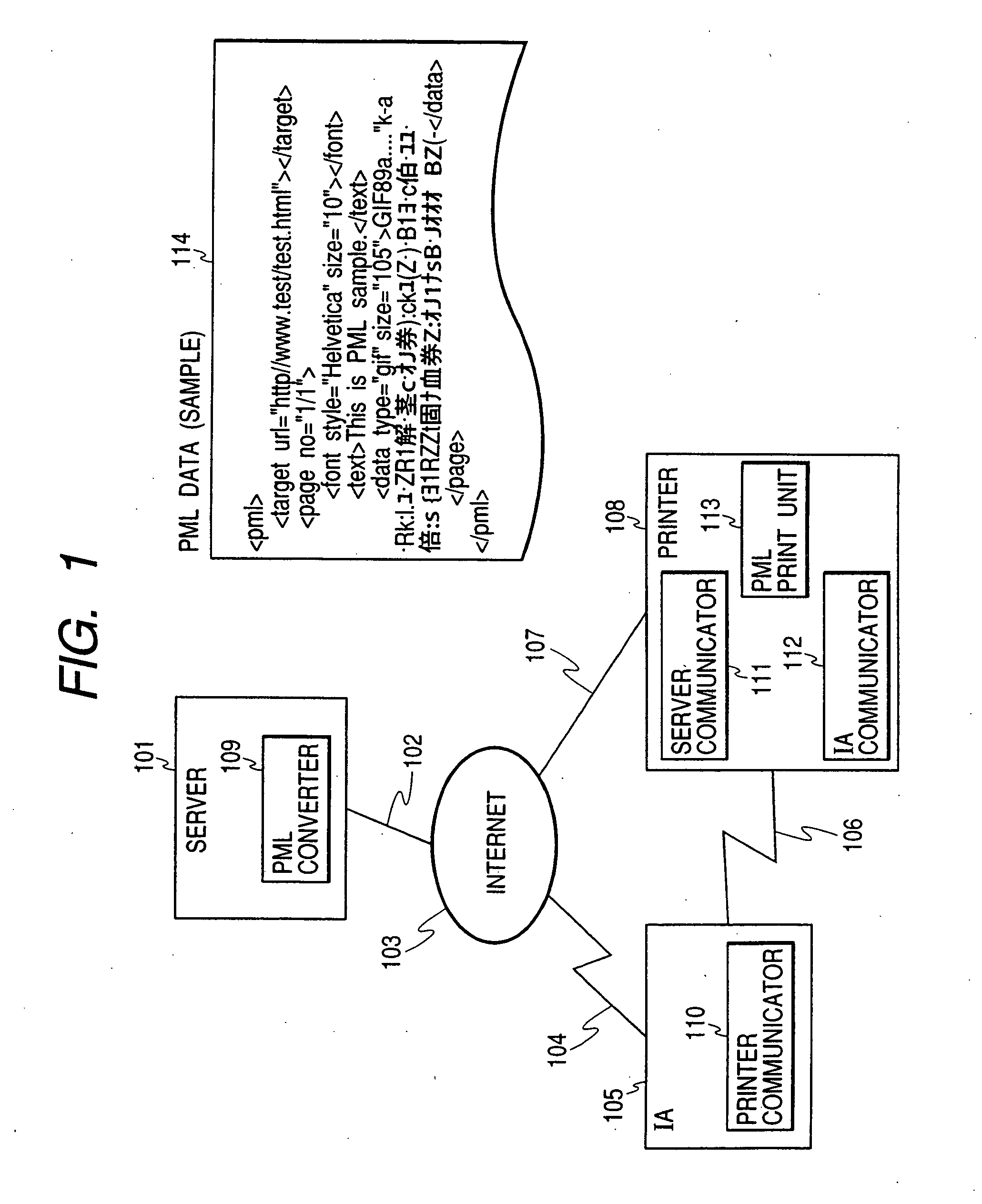

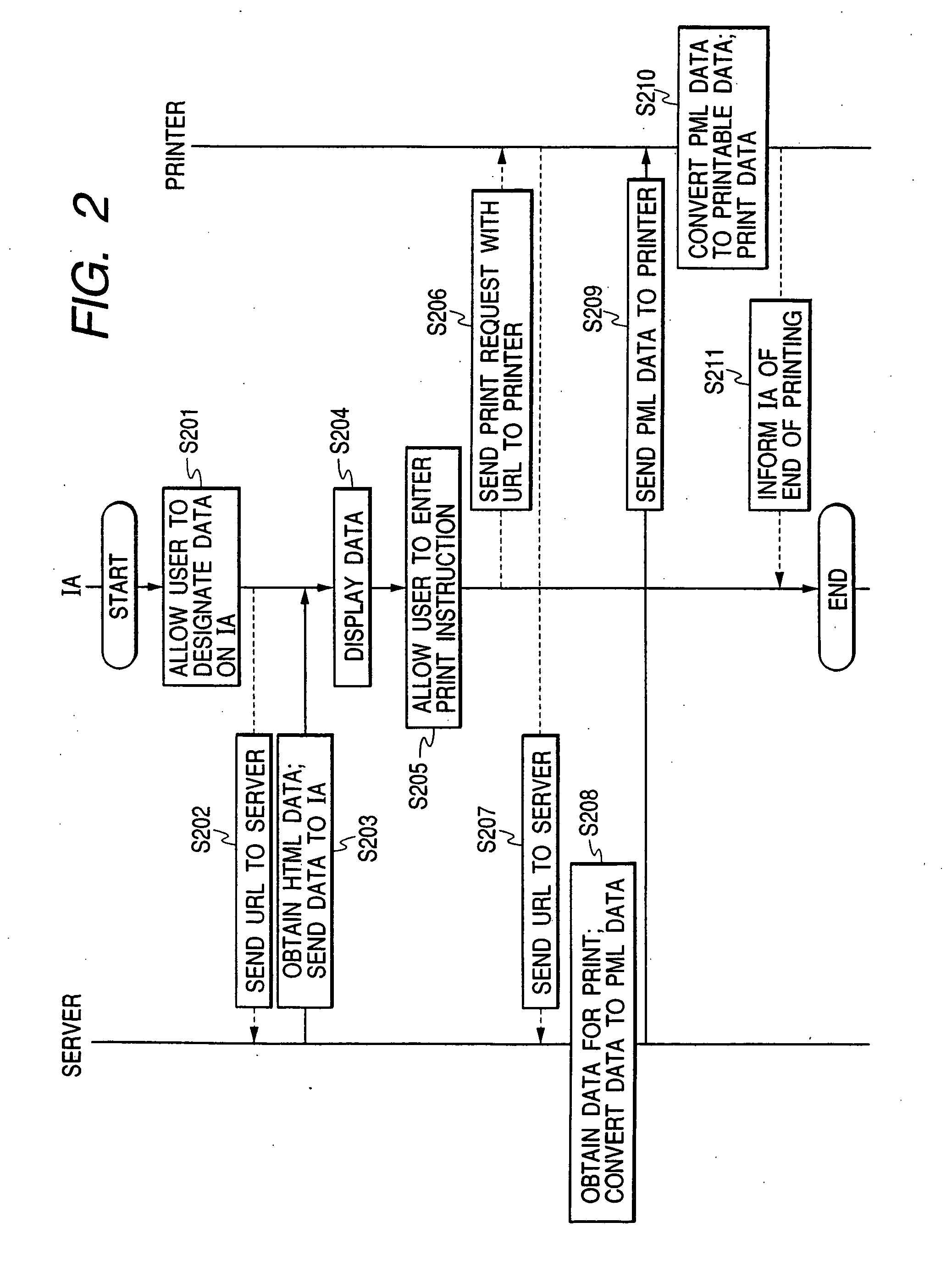

Print system, printing method, and server

InactiveUS6970263B2Reduce the burden onQuality improvementDigital computer detailsTransmissionDatabaseInformation appliance

There is provided a print system in which a print instruction is received from an information appliance (IA), a print request is issued to a server in response to the print instruction from the IA, and print data formed by the server is received in accordance with the print request, thereby enabling the print data to be printed from the IA.

Owner:CANON KK

Color 3D printing system based on 3DP and light curing technology

The invention discloses a color 3D printing system based on 3DP (three dimensional printing and gluing) and a light curing technology. The color 3D printing system based on 3DP and the light curing technology comprises a mechanical system, a control system, an ink supply system, layering software and a molding material. Many color light curing resin materials can be printed as needed through a standard ink jet method (the 3DP technology), so color 3D products can be printed in high precision. The problems of low fineness and low strength of the surface of the color products made through the current 3DP technology are solved.

Owner:QINGDAO UNIQUE PRODS DEV

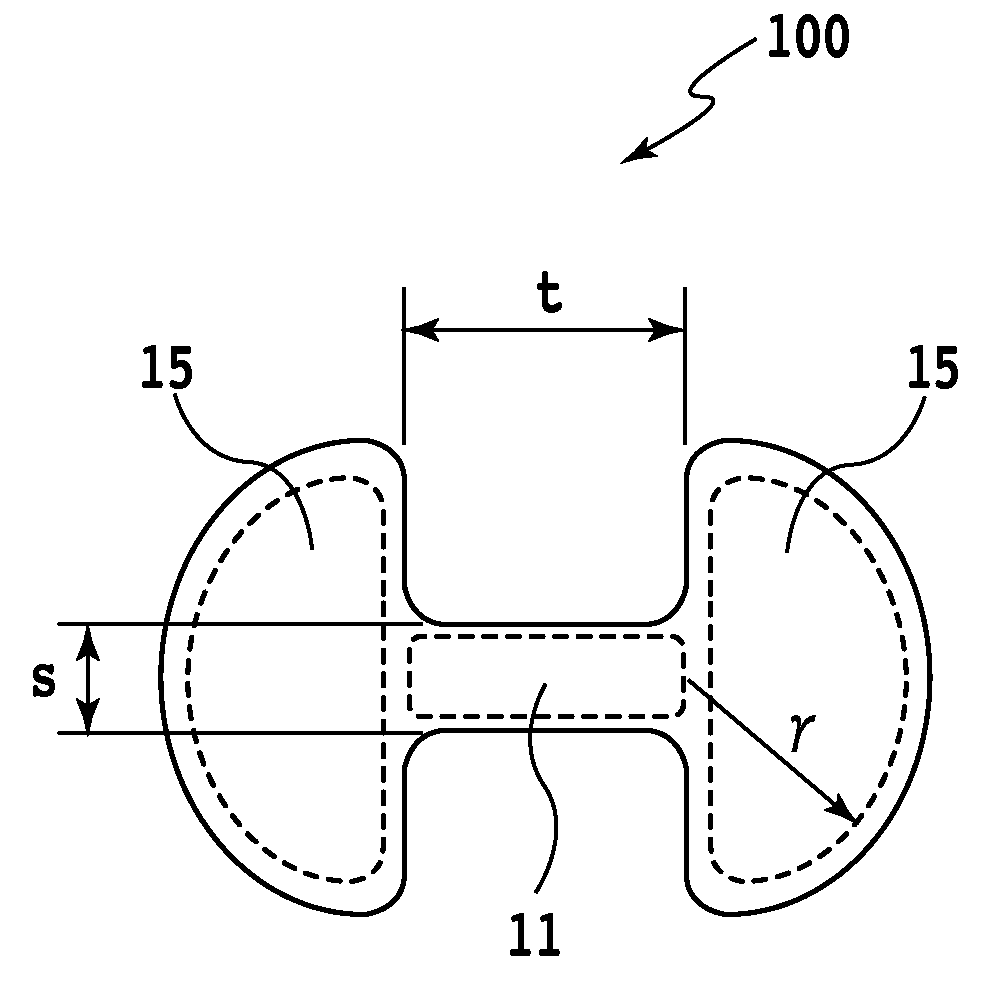

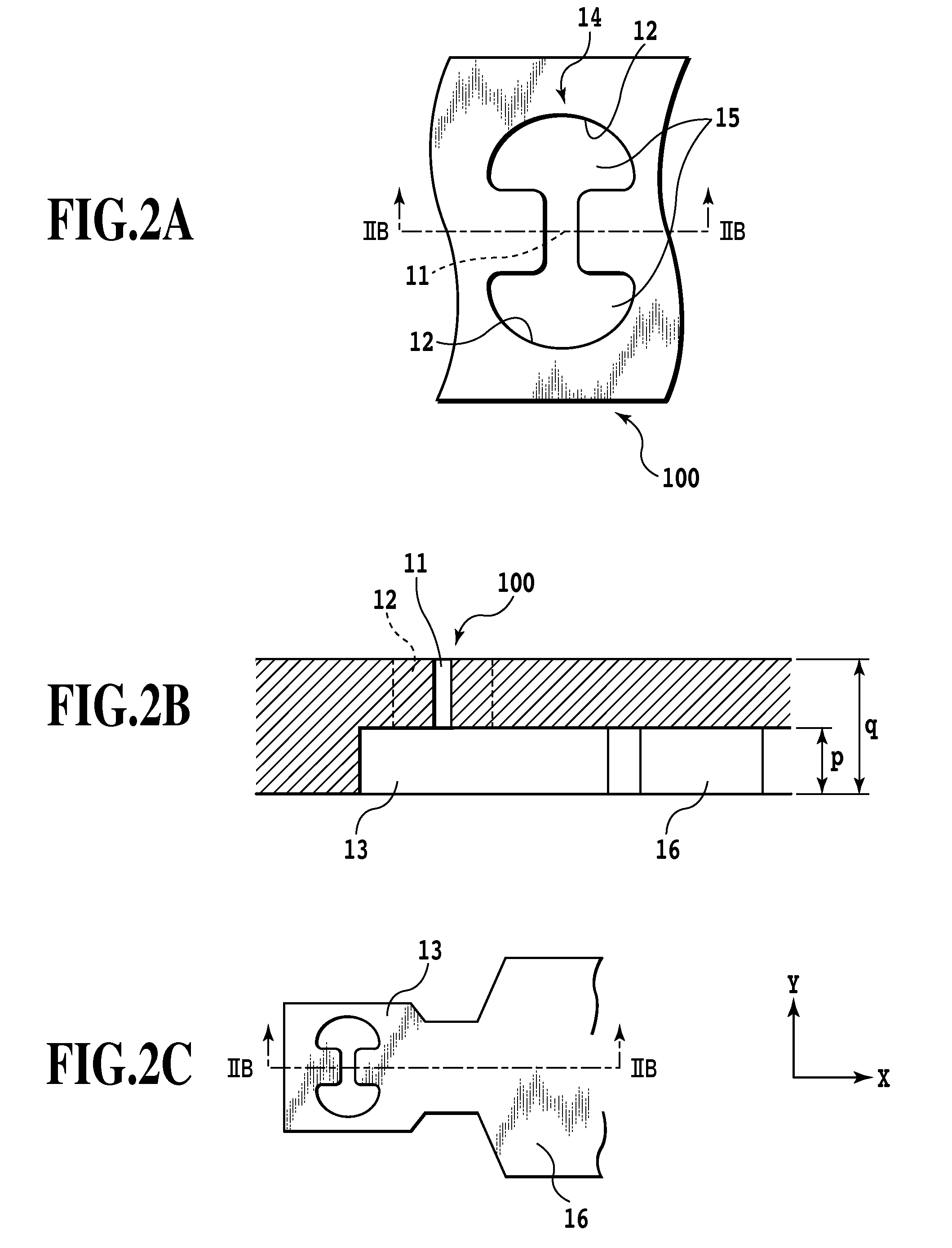

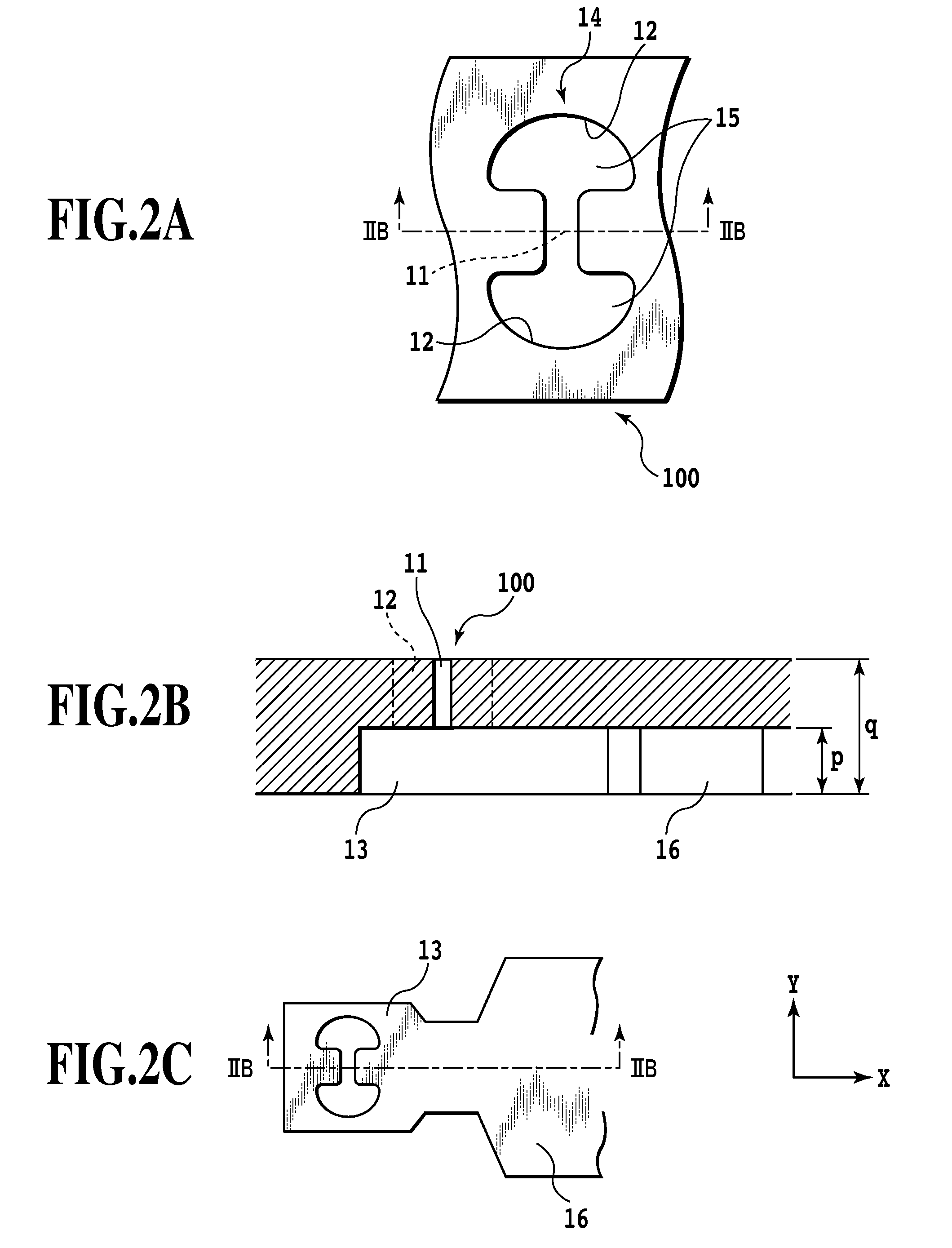

Liquid ejection head and liquid ejection method

ActiveUS20080291244A1Little dot landing position deviationLittle dot landing position deviationsInking apparatusLarge dropletElectrical and Electronics engineering

A liquid ejection method is provided which ejects small-volume droplets from ejection openings and causes them to reliably combine together on the fly into a large droplet that is less susceptible to influences of air flows, thus realizing a printing with reduced droplet landing position deviations. To that end, each of the ejection openings is constructed of two openings spaced apart and a slit-like constricted connection portion that connects the two openings together.

Owner:CANON KK

Print system, printing method, and server

InactiveUS20050213152A1Reduce burdenHigh qualityVisual presentation using printersTransmissionDatabaseInformation appliance

There is provided a print system in which a print instruction is received from an information appliance (IA), a print request is issued to a server in response to the print instruction from the IA, and print data formed by the server is received in accordance with the print request, thereby enabling the print data to be printed from the IA.

Owner:CANON KK

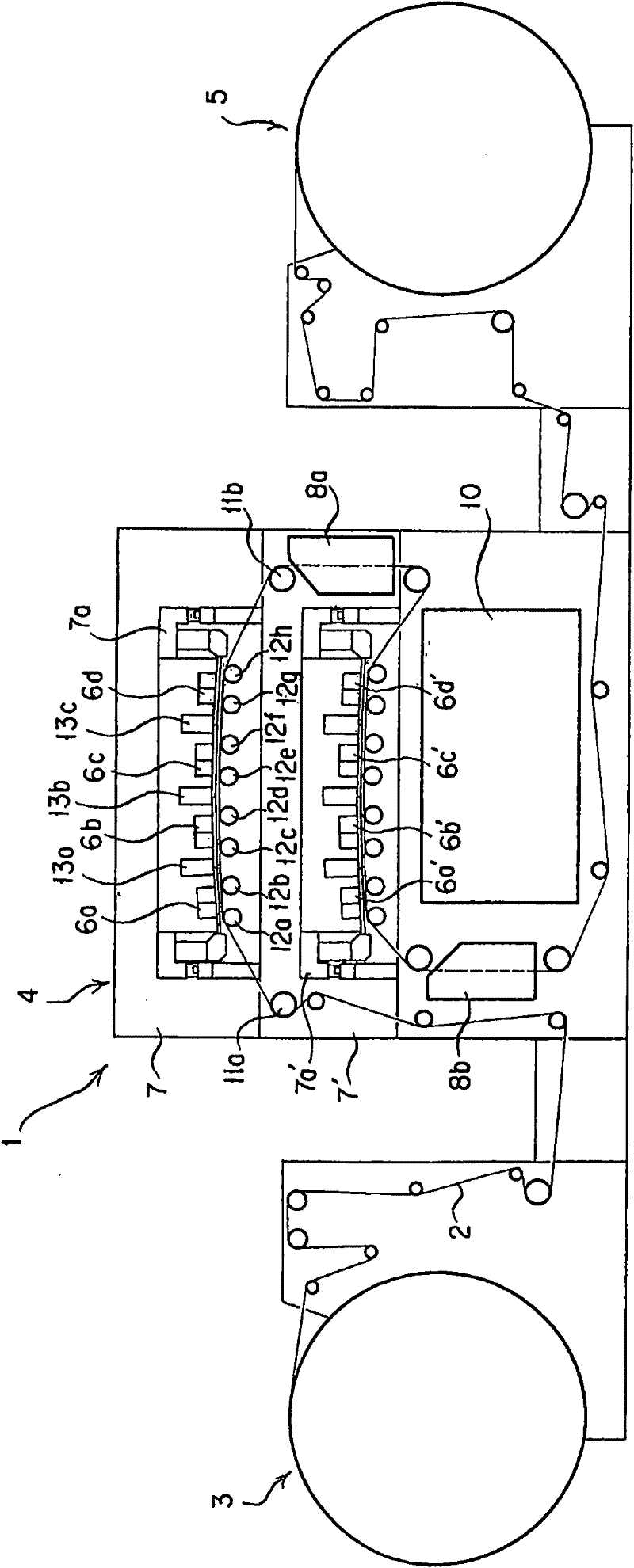

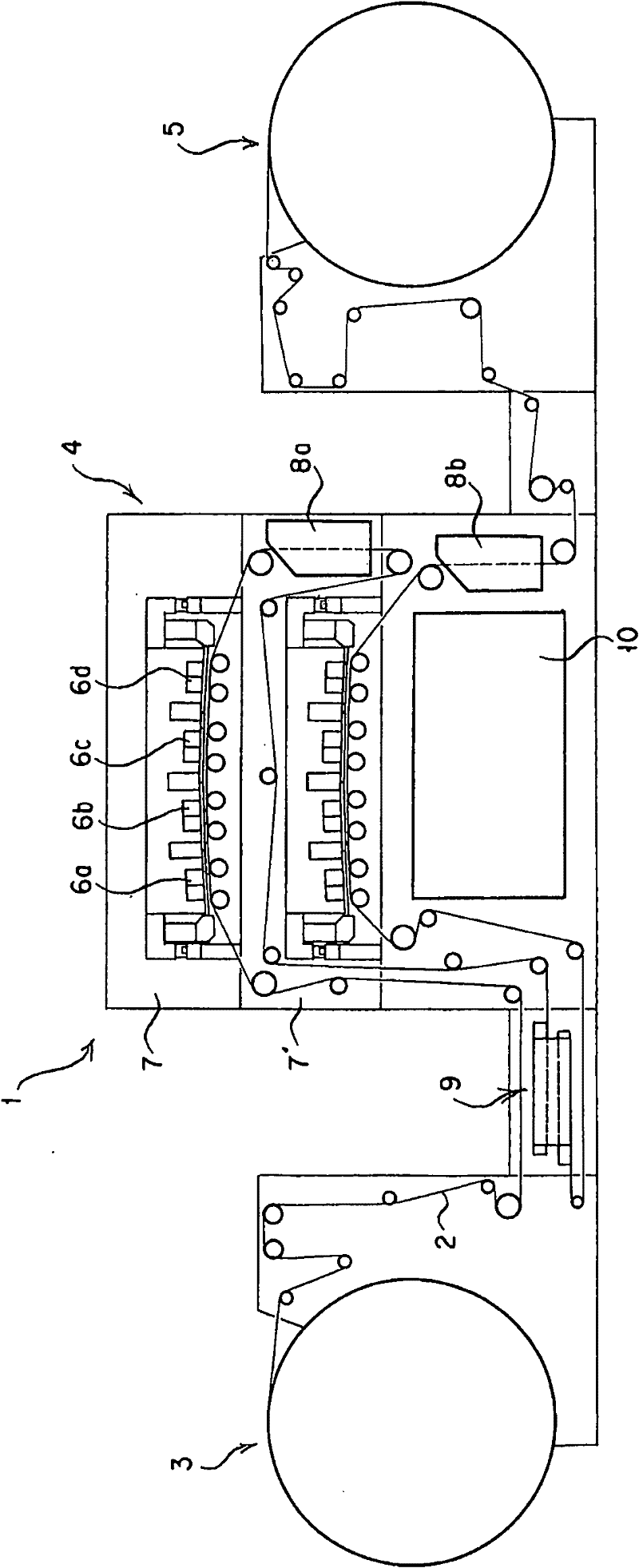

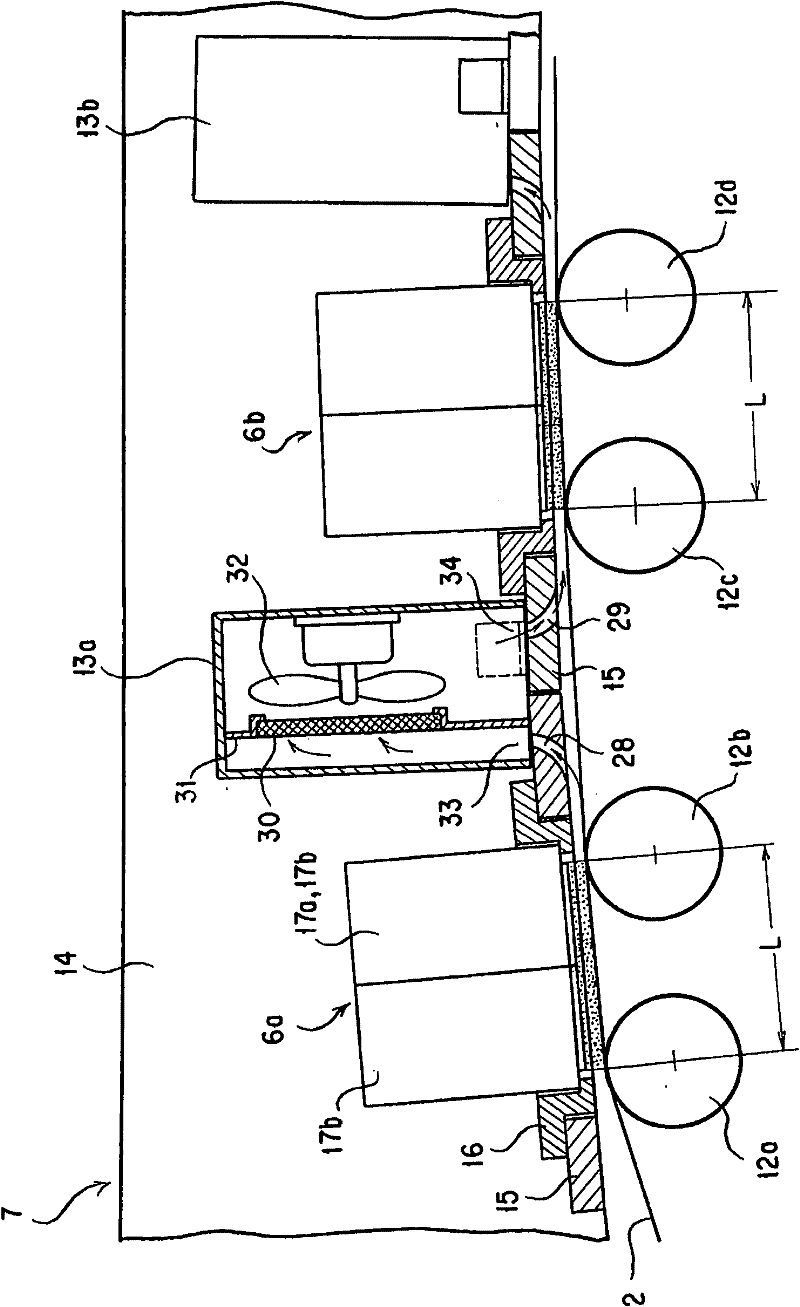

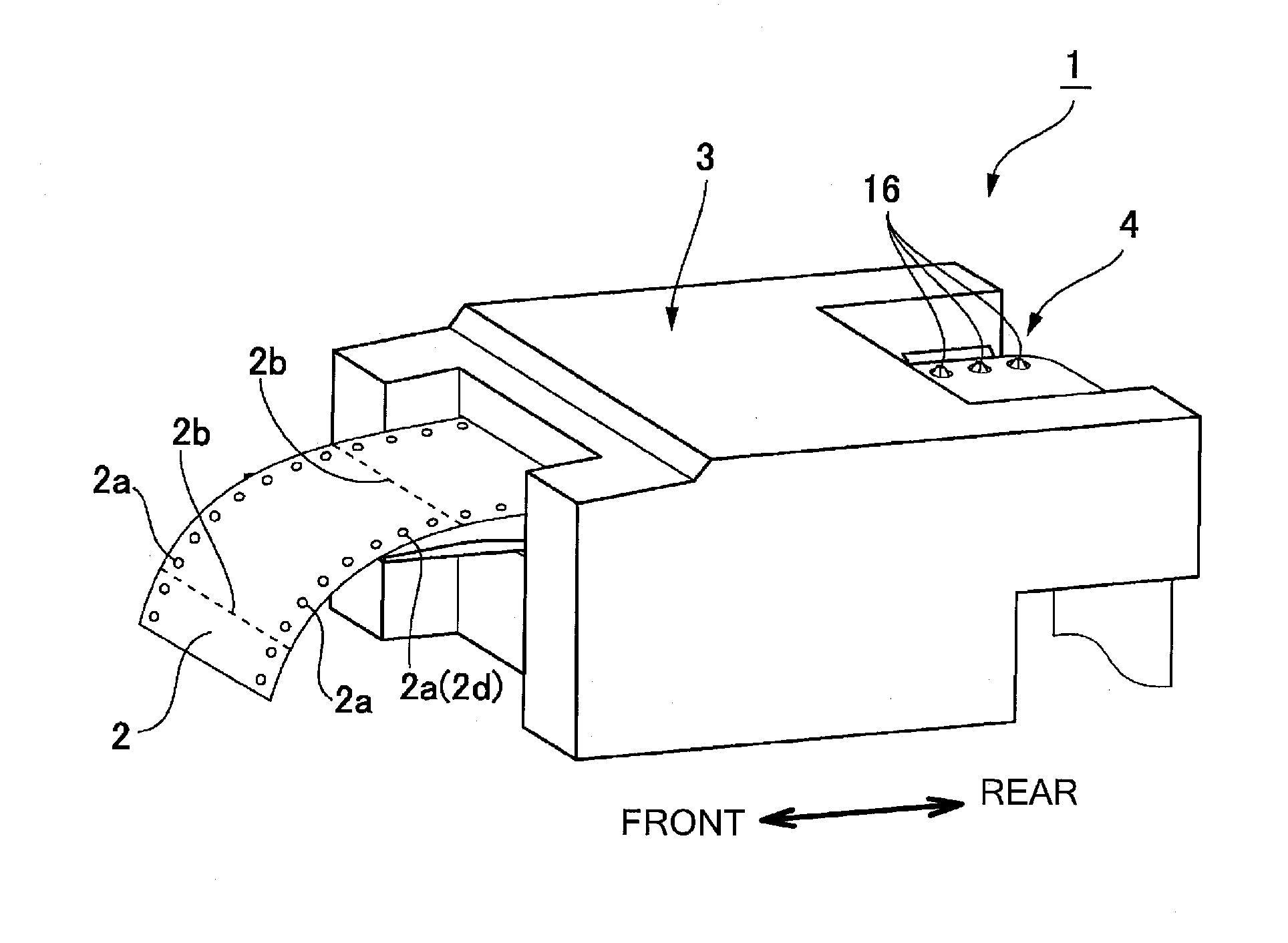

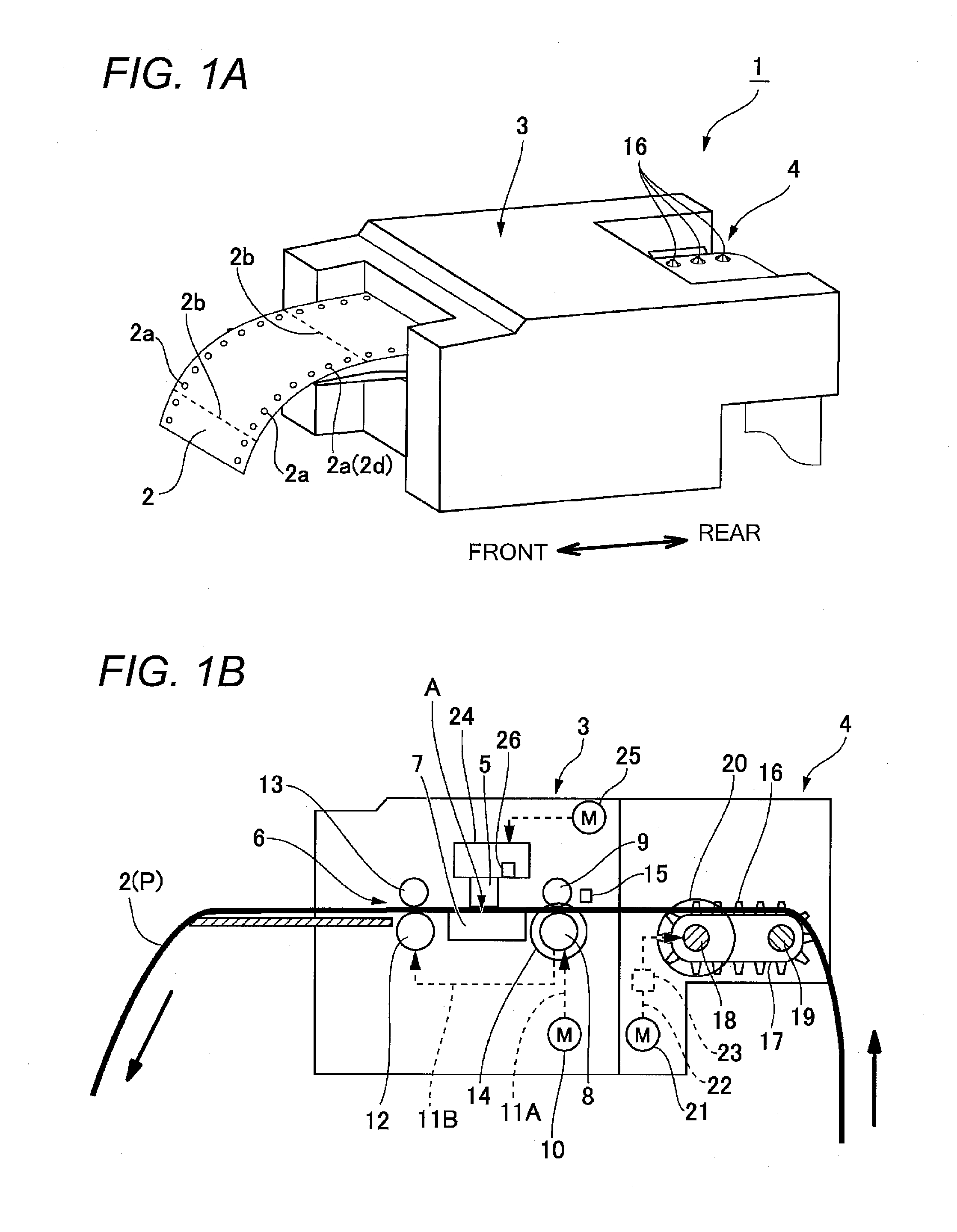

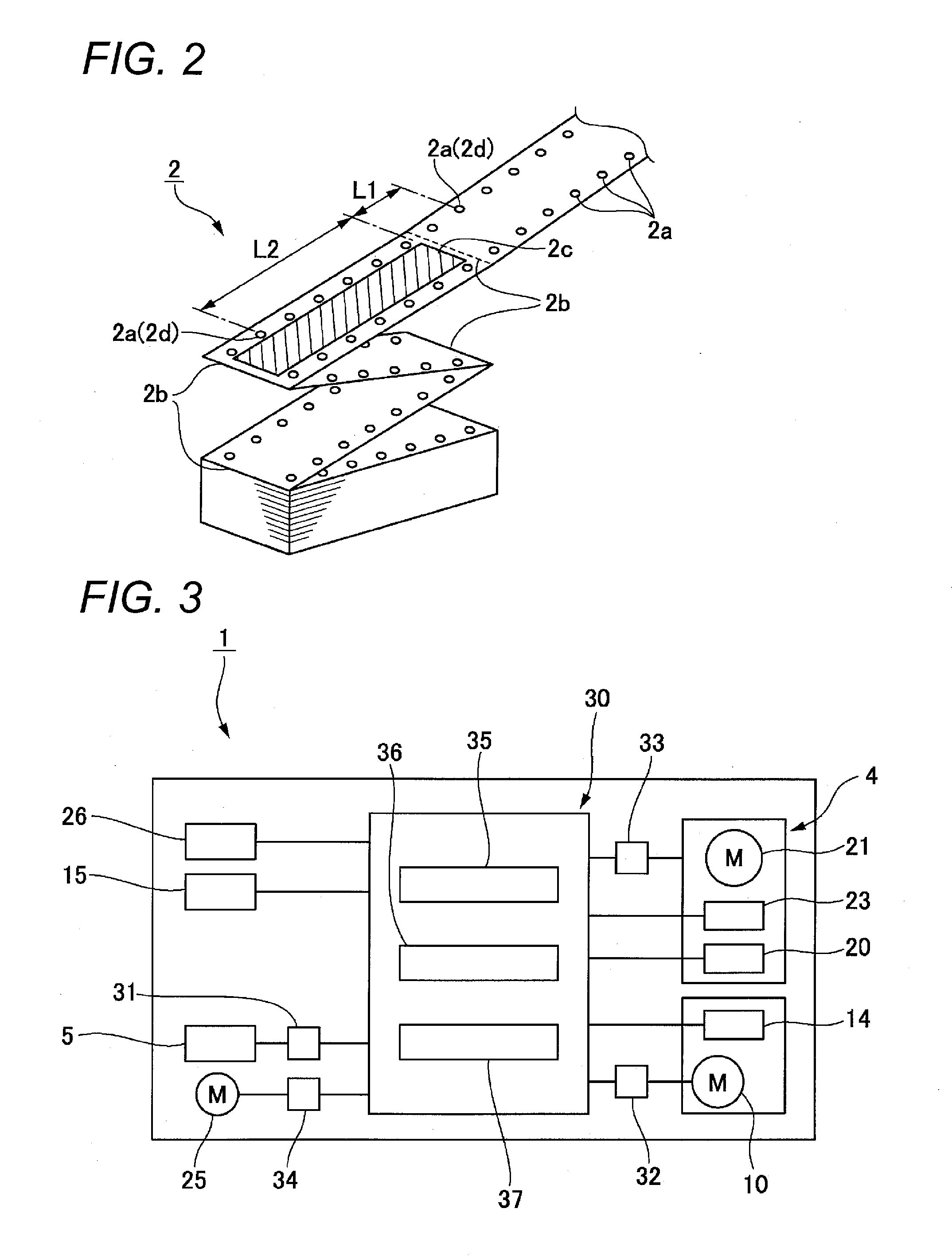

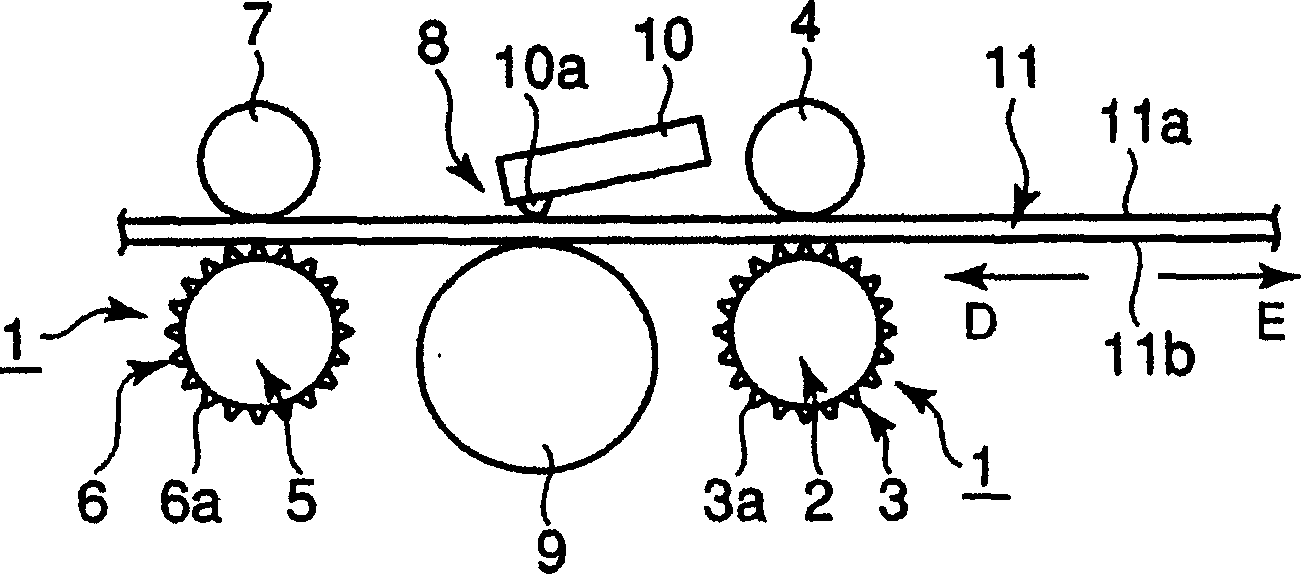

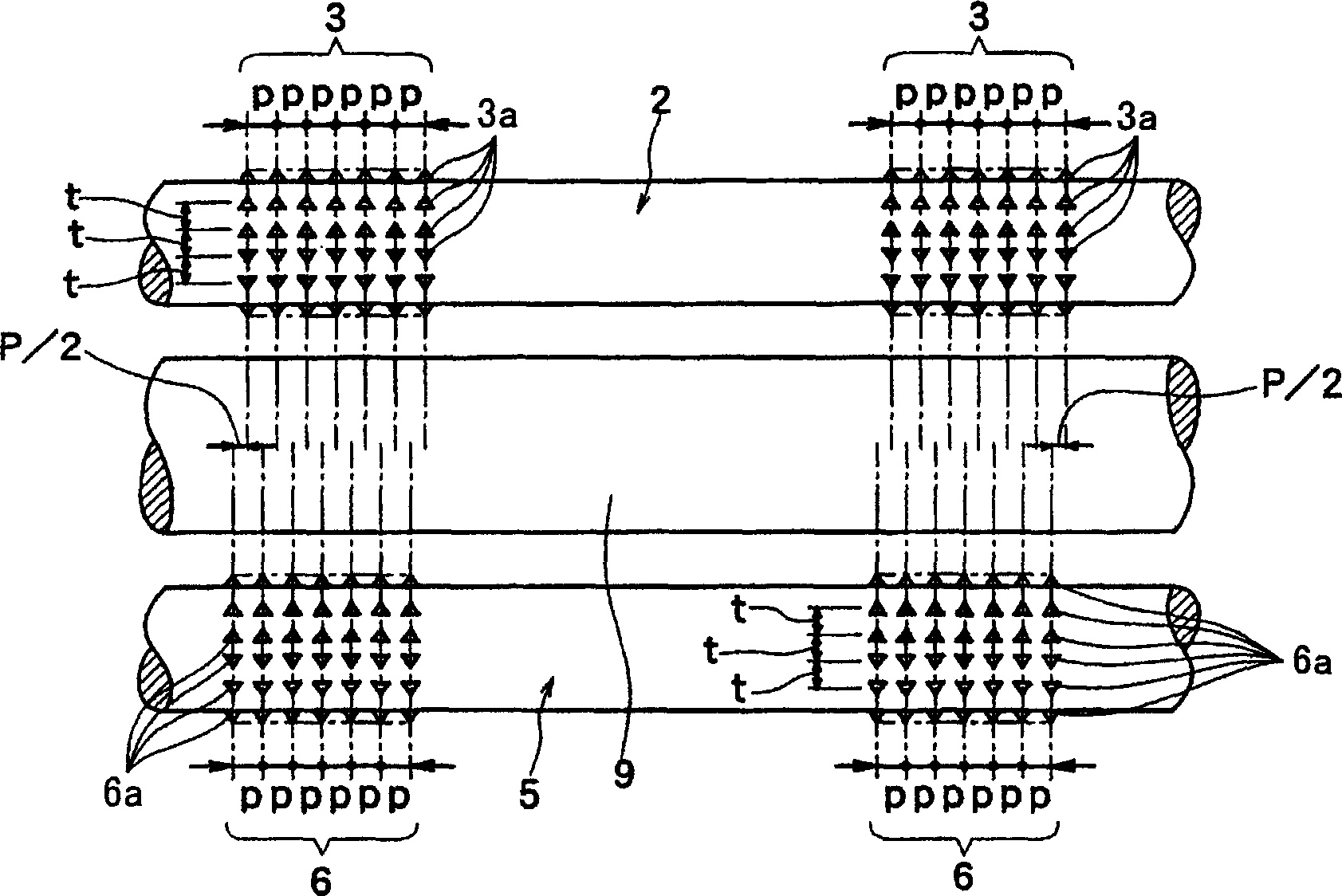

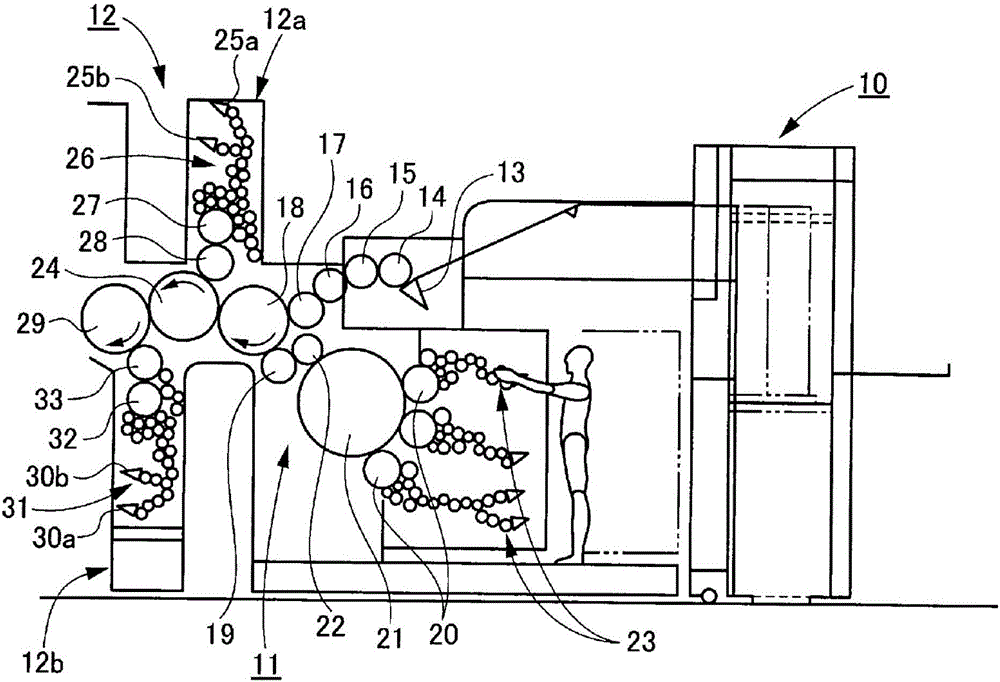

Inkjet recorder

ActiveCN102196918ASuppress tremorImprove printing qualityInking apparatusTypewritersPaper sheetHead parts

Disclosed is an inkjet recorder which ensures good print quality by minimizing flapping of a sheet which travels in parallel with the nozzle width region of an ink jet head while facing the nozzle width region. An inkjet recorder is equipped with an inkjet print section (4) having print units (7, 7') for printing on a sheet (2) traveling on an arcuate sheet passage formed of a plurality of guide rollers (12a-12h) by means of a plurality of inkjet heads (6a-6d, 6a'-6d'), wherein an on-demand inkjet head equipped with a plurality of nozzle arrays in the traveling direction of sheet as a nozzle width region is used as the inkjet head of the print unit, the sheet passage opposite to the nozzle surface of each inkjet head is constituted of two guide rollers (12a, 12b) disposed on the upstream side and downstream side in the traveling direction of sheet, and the end portions of a sheet in the nozzle width region (L) of each inkjet head on the upstream side and downstream side in the traveling direction of sheet are located as closely as possible to each contact point between the guide rollers on the upstream side and downstream side on the inside of each contact point where the sheet touches the guide rollers, respectively, and being wound therearound.

Owner:MIYAKOSHI PRINTING MACHINERY

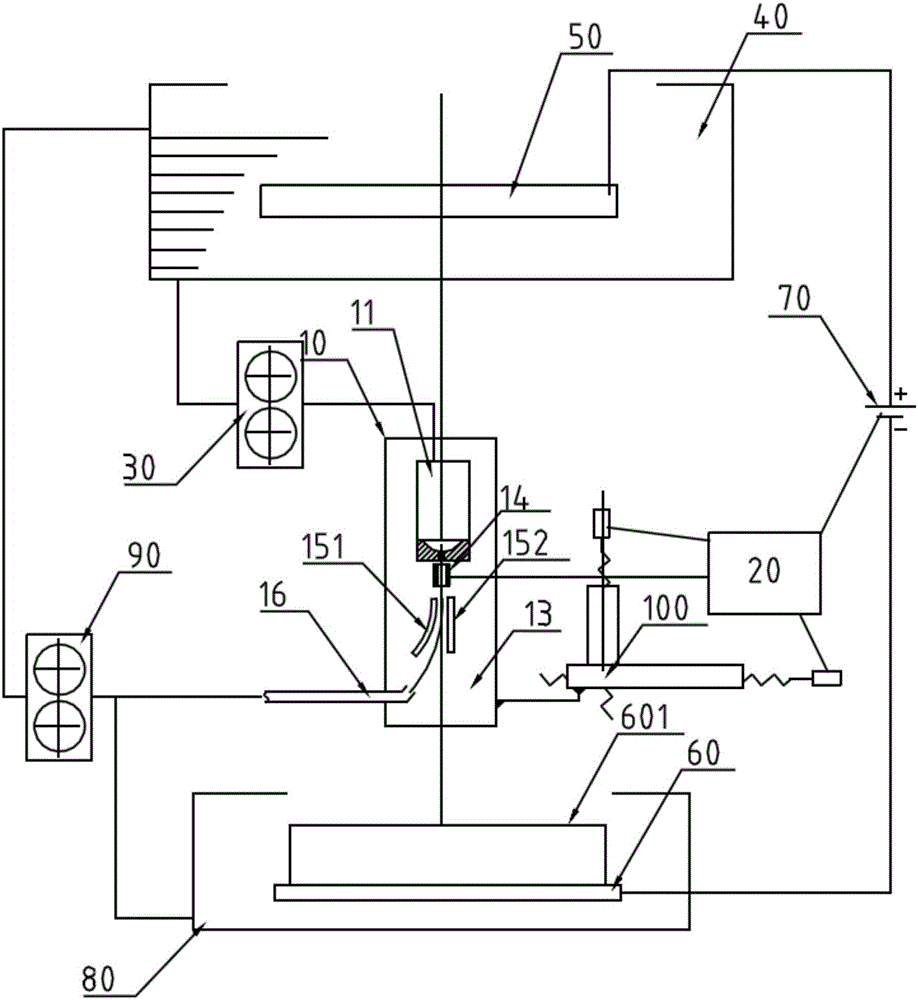

Printing head, printing device and printing method for rapid forming of metal piece

InactiveCN105112965ATo overcome the shortcomings of low printing efficiencyFast printAdditive manufacturing apparatusEtchingEngineering

The invention discloses a printing head, a printing device and a printing method for rapid forming of a metal piece. The printing head comprises a body, a plurality of nozzles, a first electrode and a second common electrode. When the printing head is in the working state, electroplate liquid is sprayed out through the multiple nozzles and sequentially passes through the first electrode and the second common electrode. The printing device is provided with the printing head. According to the printing method, when electrochemical deposition or electrolytic etching is conducted on the electroplate liquid, the electroplate liquid is electrified and is directly sprayed onto a position needing to be printed; in the position which does not need to be printed, the electroplate liquid deflects when flowing through a deflection electric field by changing the electrical characteristic of the electroplate liquid, and the electroplate liquid is prevented from being sprayed onto the position which does not need to be printed. By the adoption of the printing head, the printing device and the printing method for rapid forming of the metal piece, the defects that a three-dimensional (3D) printer for the metal piece in the prior art is low in printing efficiency and low in precision are overcome, and rapid, high-quality and high-precision printing of 3D metal pieces is achieved.

Owner:SHANGHAI SHENGKUANG ELECTROMECHANICAL TECH

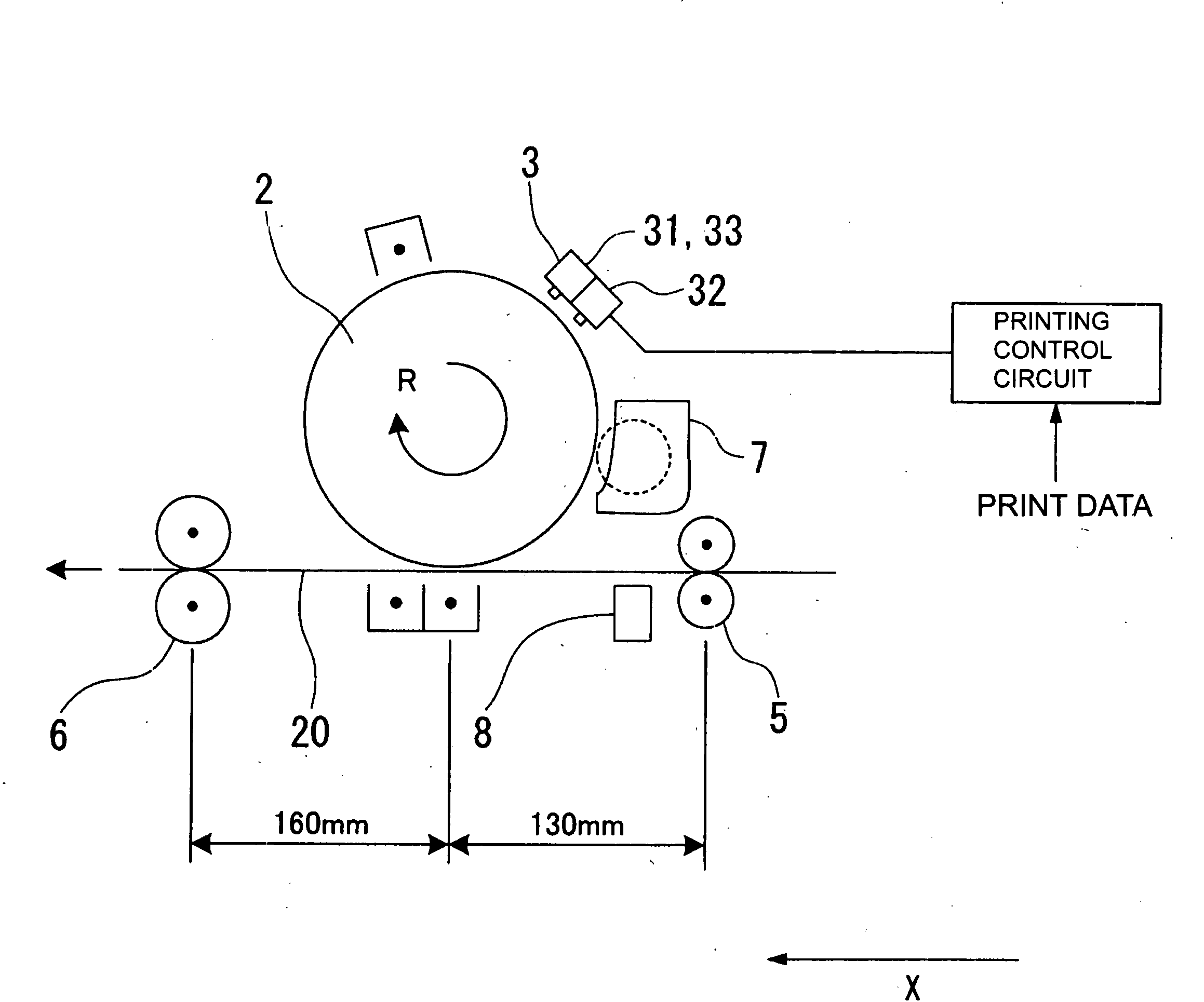

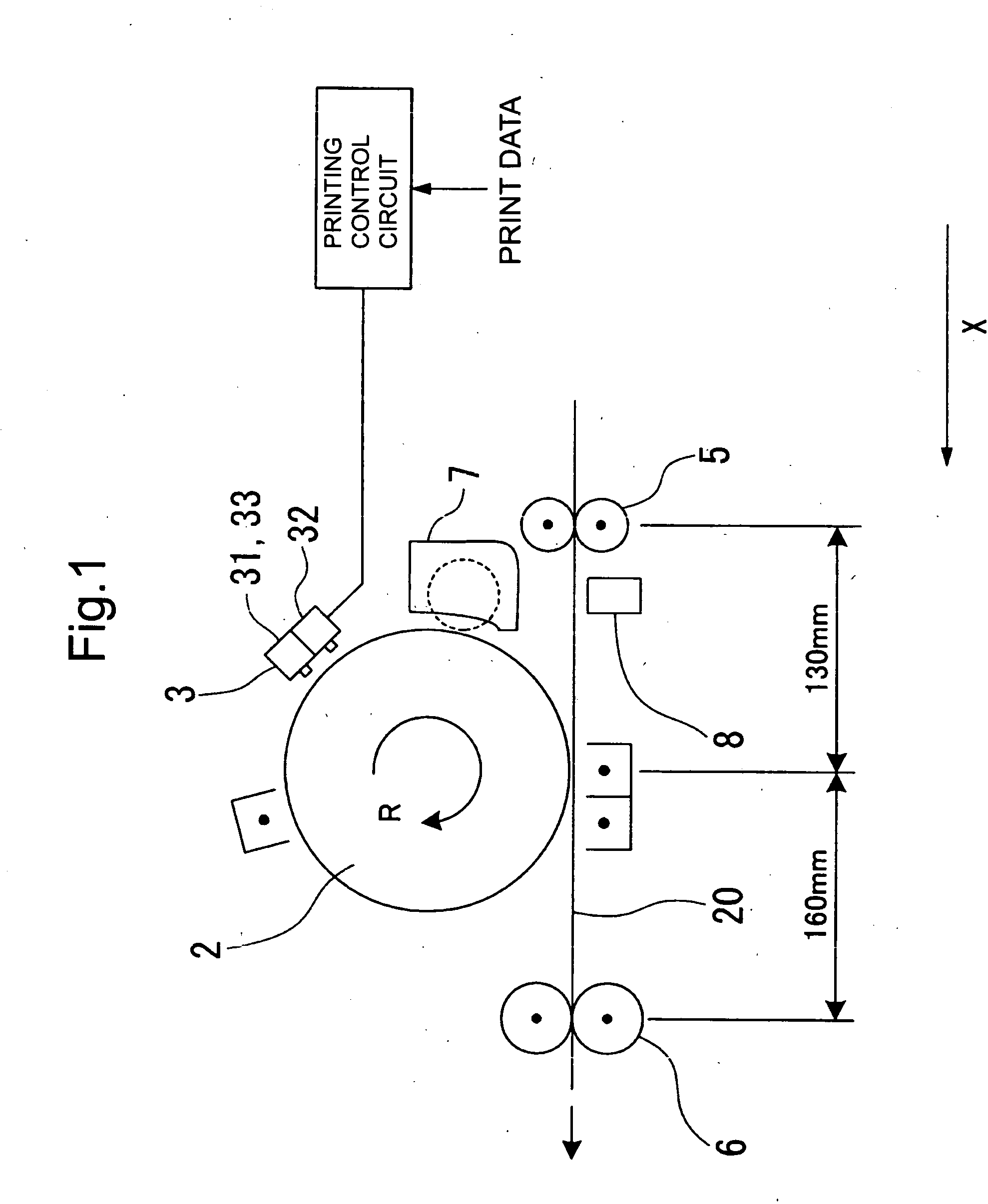

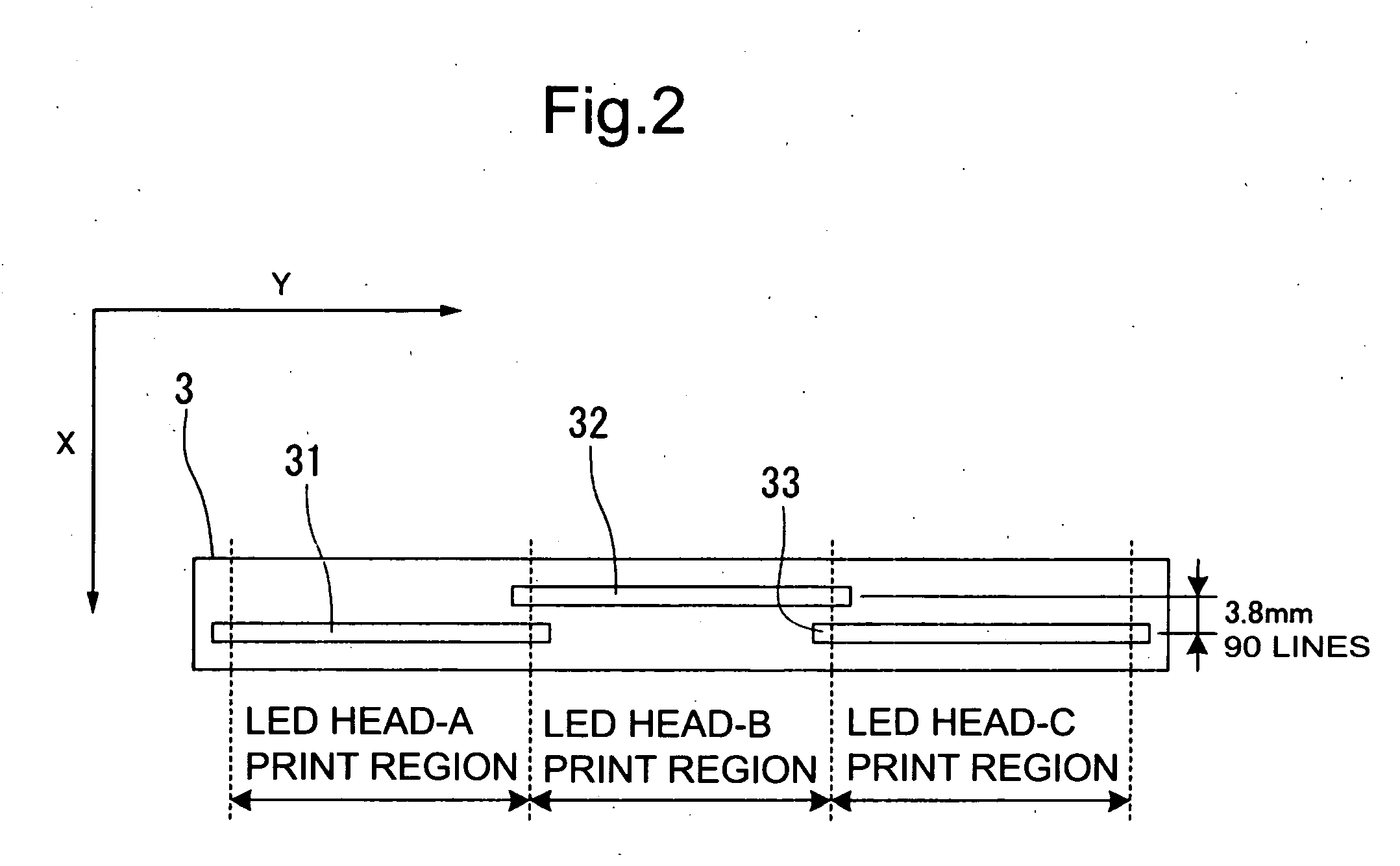

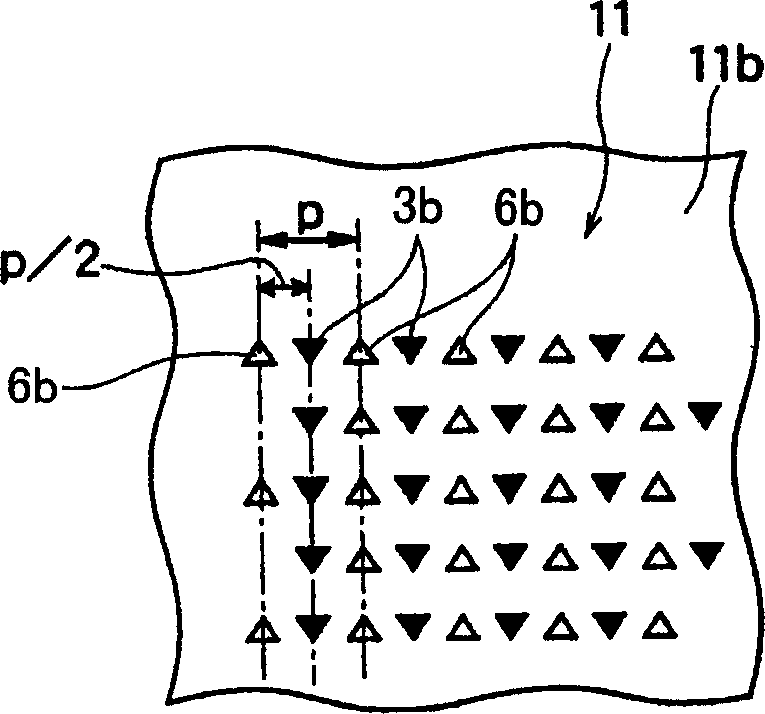

LED printer and print control method

InactiveUS20080252713A1High-precision printingElectrographic process apparatusPrintingConstant speedControl circuit

The LED printer includes: a photosensitive drum; a resist roller for feeding a printing medium to the photosensitive drum at a first constant speed; a fixing device for discharging the printing medium from the photosensitive drum at a second constant speed; a separation type LED head arranged zigzag; and a printing control circuit for detecting a position of the printing medium fed by the resist roller or the fixing device and adjusting printing timings of the first portion LED head and the second portion LED head based on the detected position and the LED head interval. The LED printer can normally correct a print length in each of a front end region and a rear end region of a sheet.

Owner:OKI DATA CORP

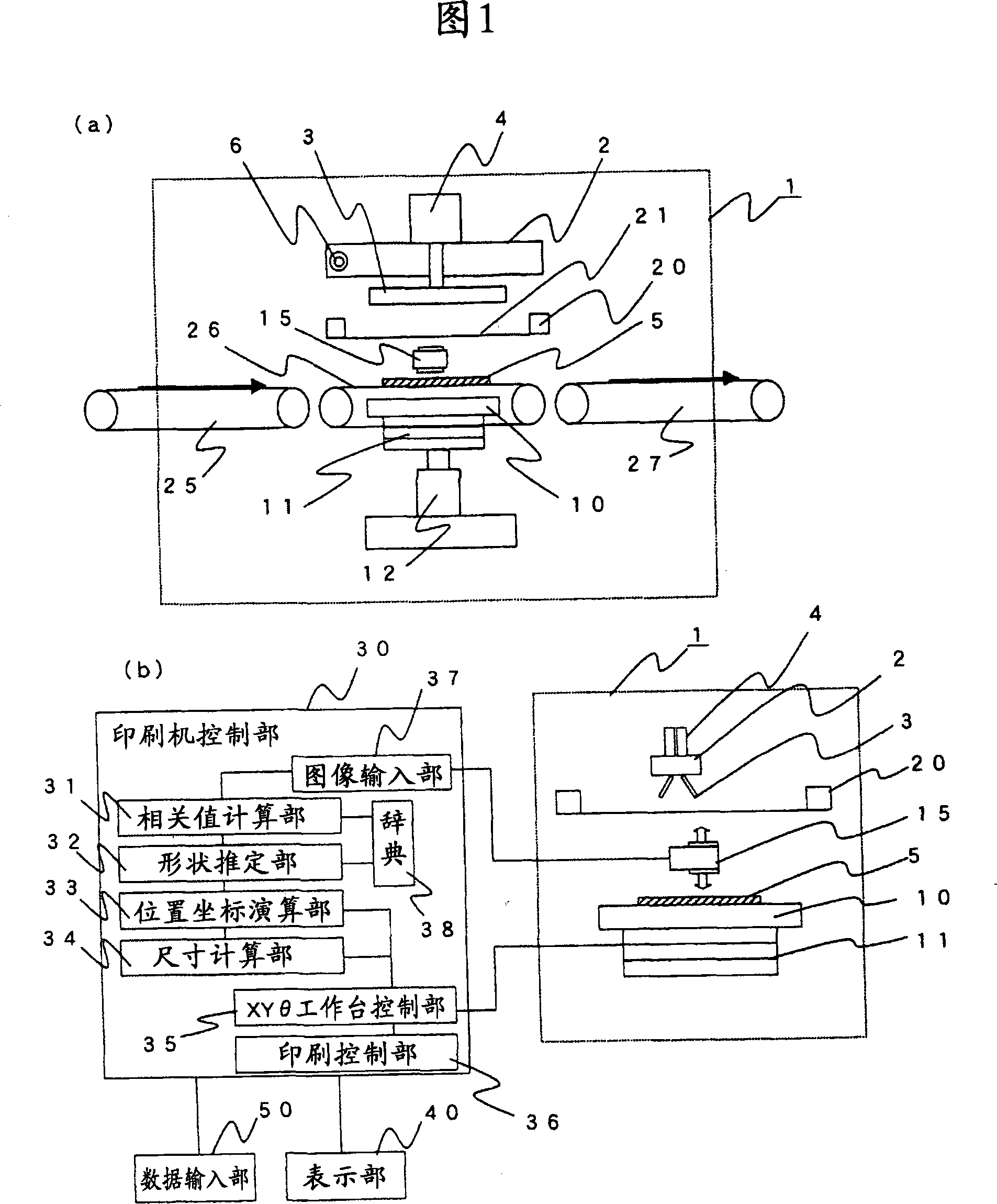

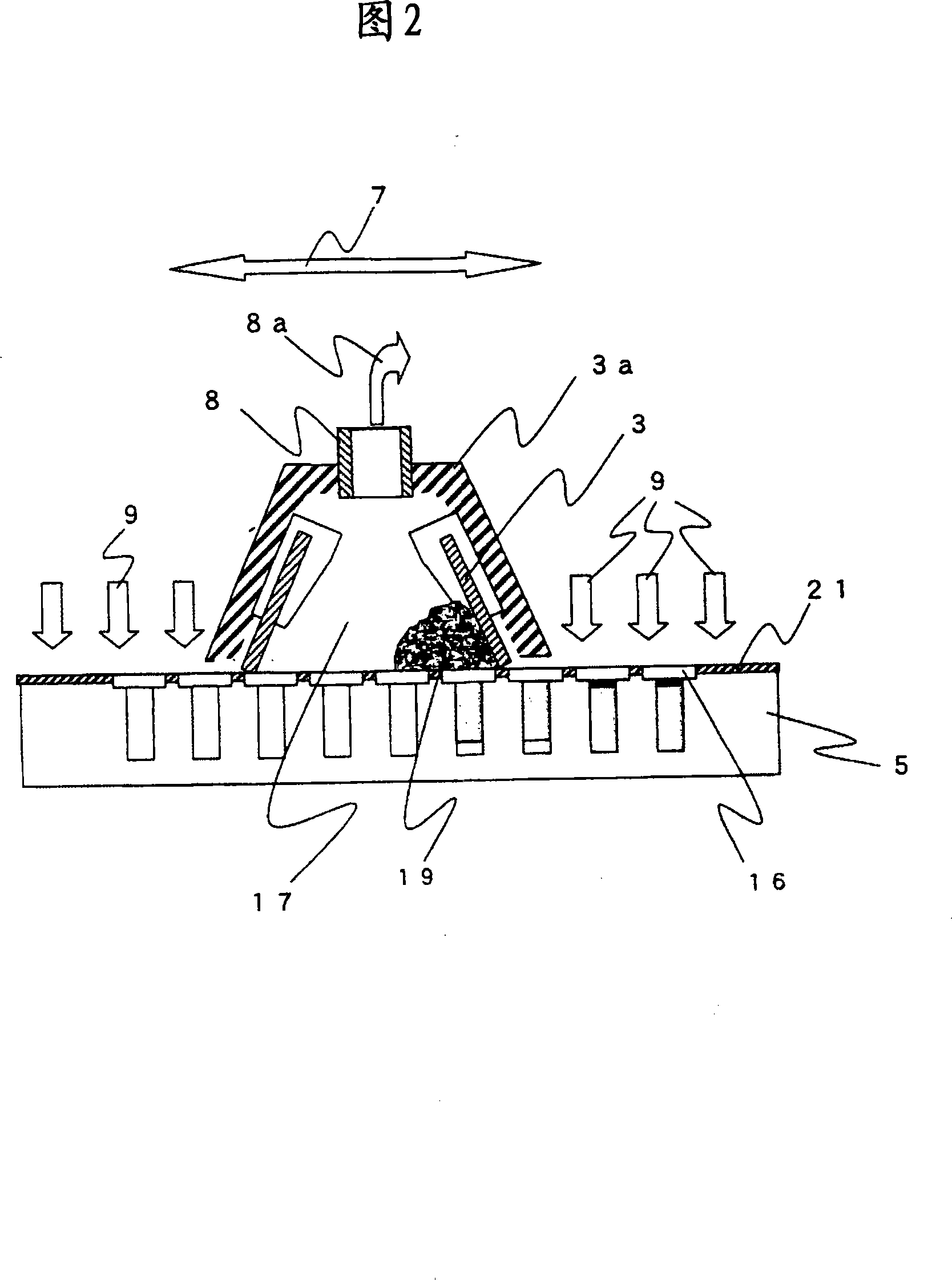

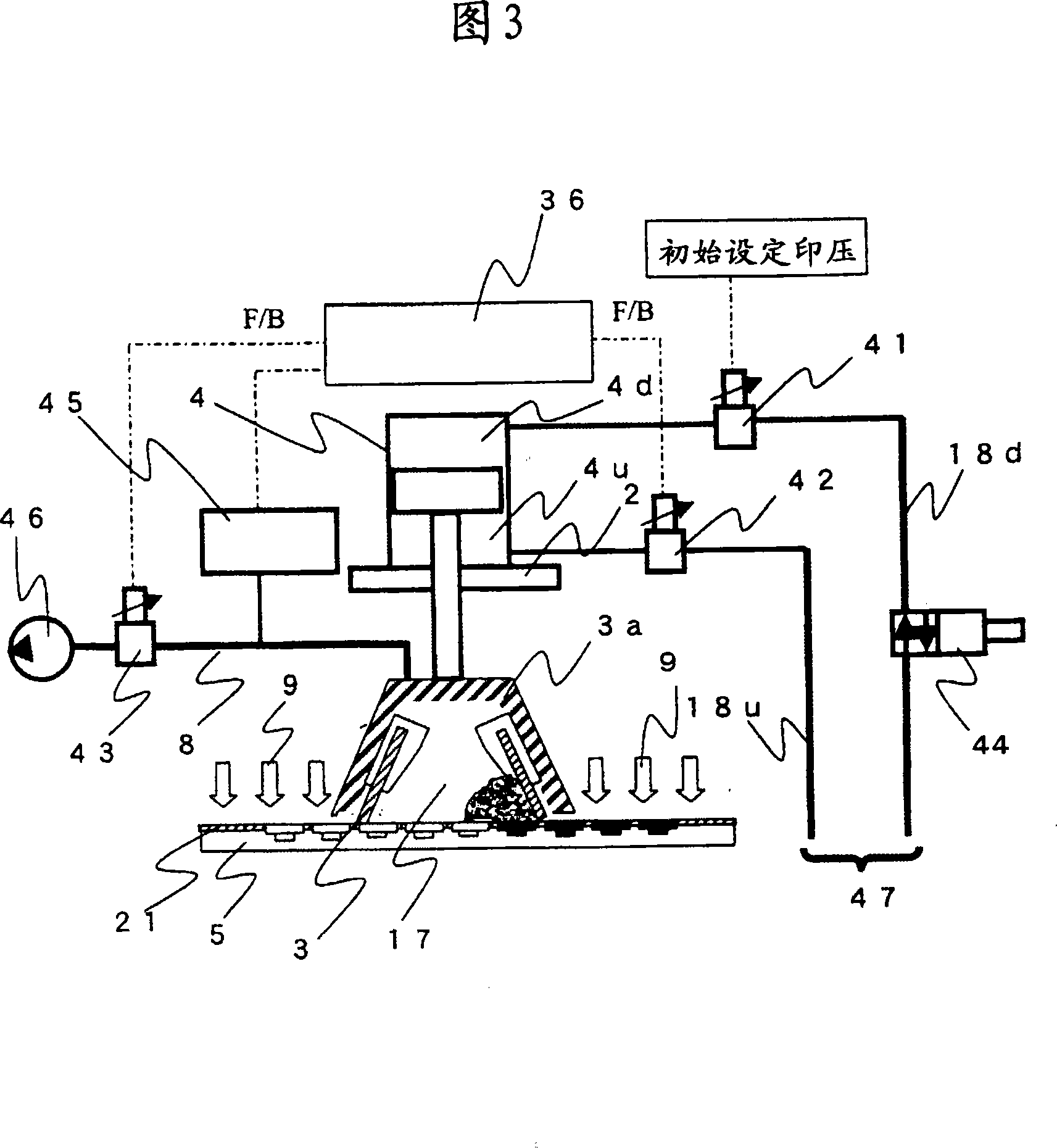

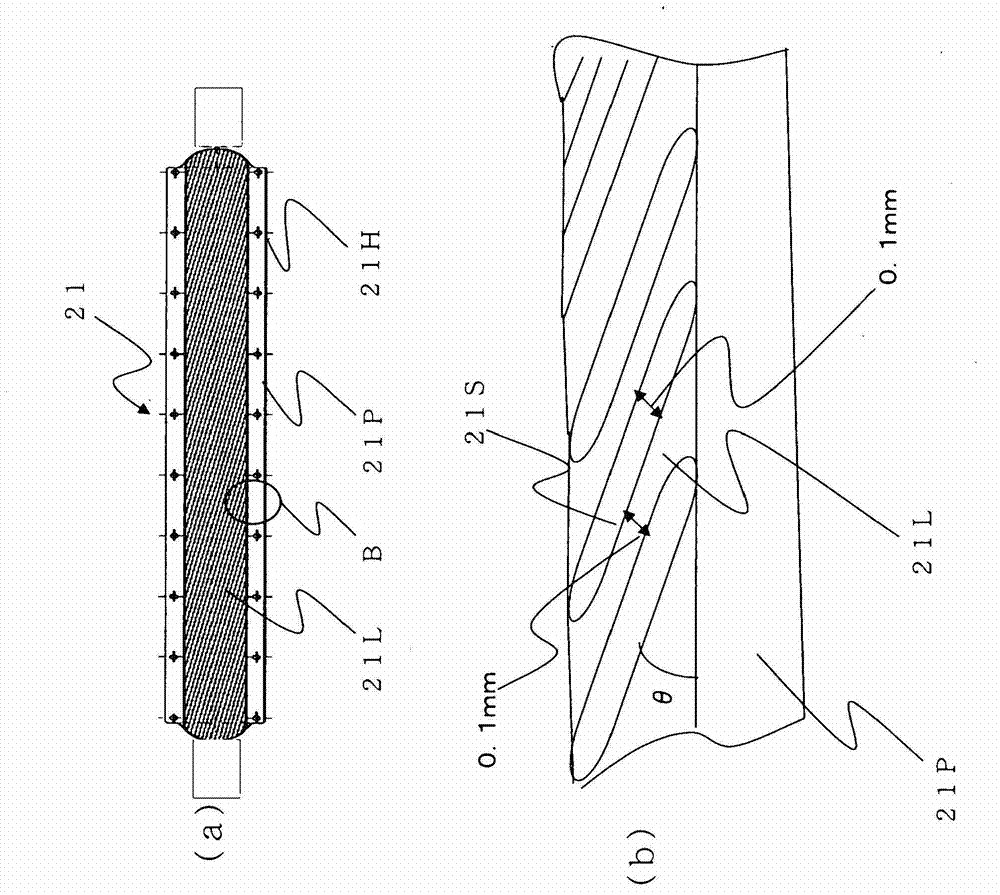

Silk screen printing device and printing method thereof

InactiveCN101134389AHigh precision printingPrinted circuit assemblingScreen printersScreen printingElectrical and Electronics engineering

The invention solves the technology problems that a printing device using a screen mask can not print with good precision when the printing objects need to be fine. In the invention, a squeegee blade head of a screen opening portion which is supplied with paste is a closed squeegee blade head, when printing, the interior of the squeegee blade head is in a negative pressure state, arranging a control mechanism makes the stamping pressure related to the squeegee blade head at a proper value through the negative pressure and printing, thereby preventing macro-scale of the device for printing with high precision.

Owner:HITACHI LTD

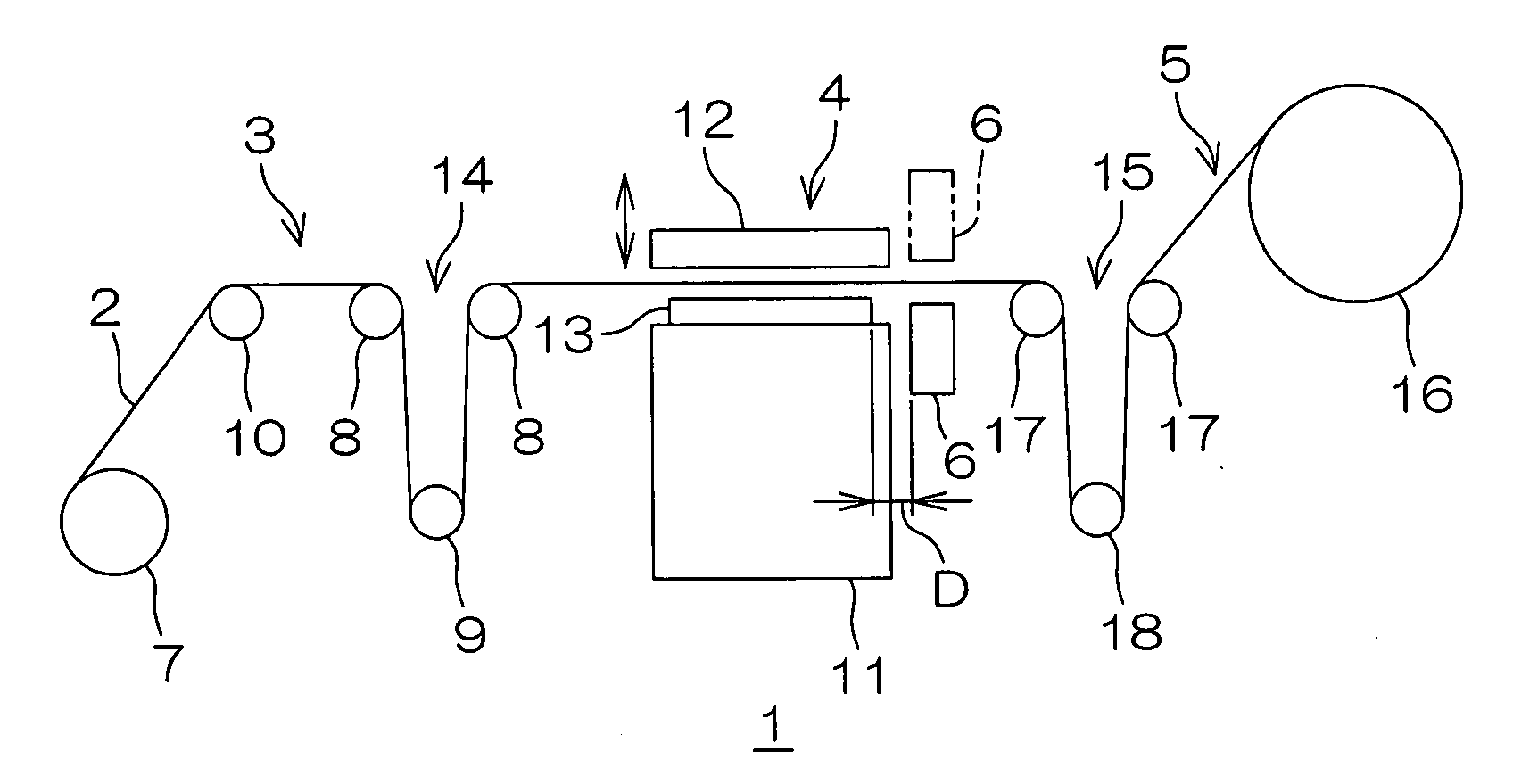

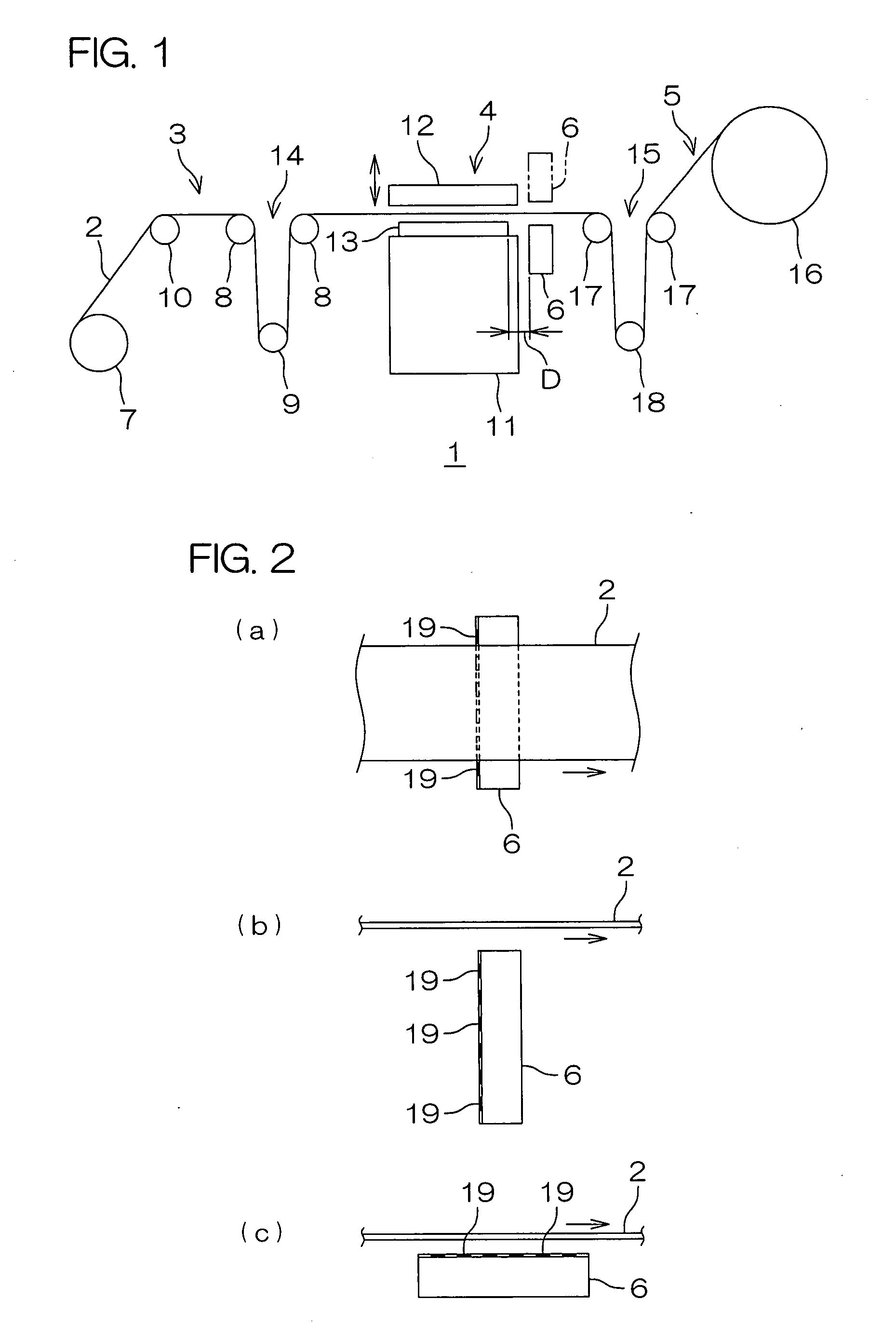

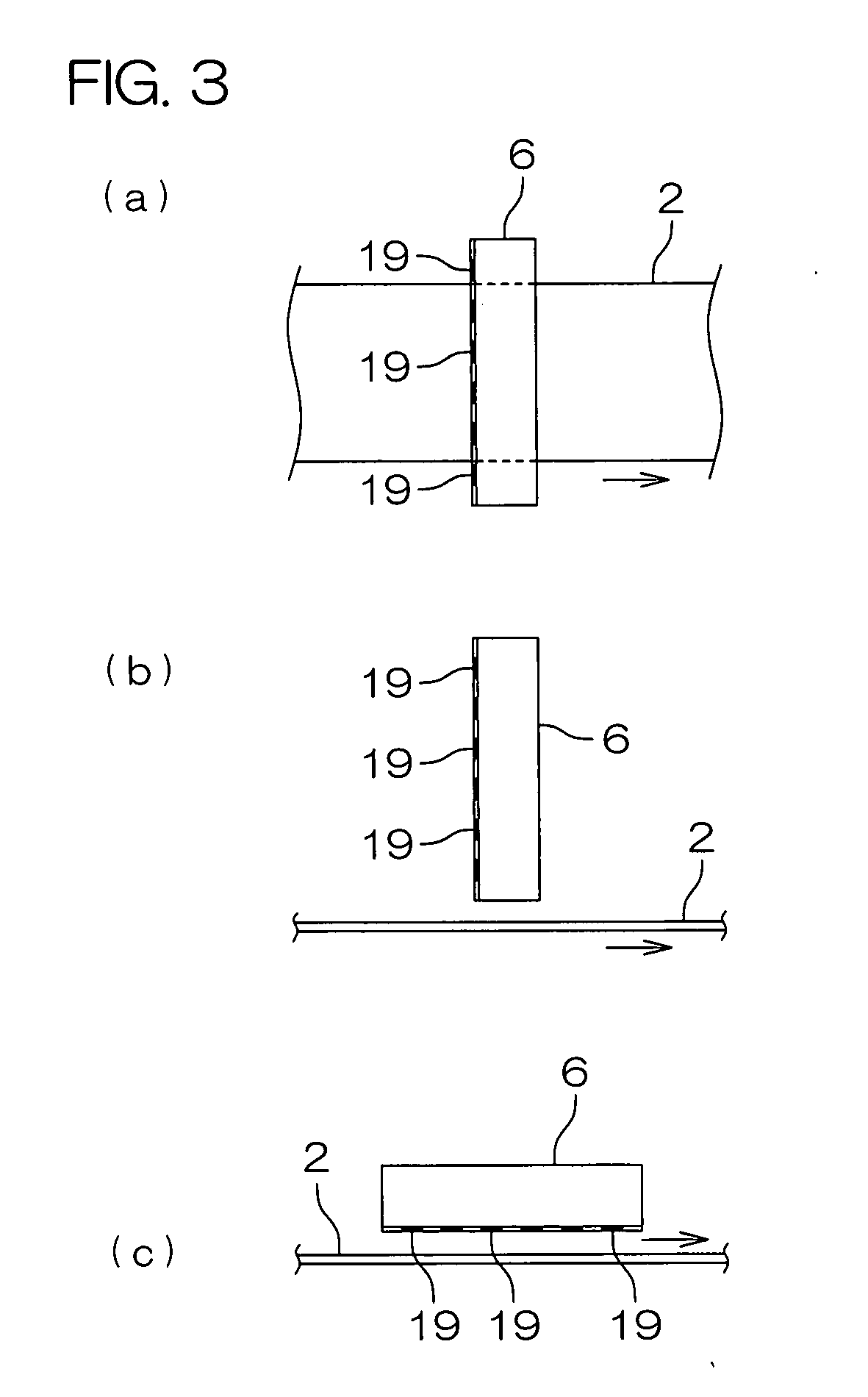

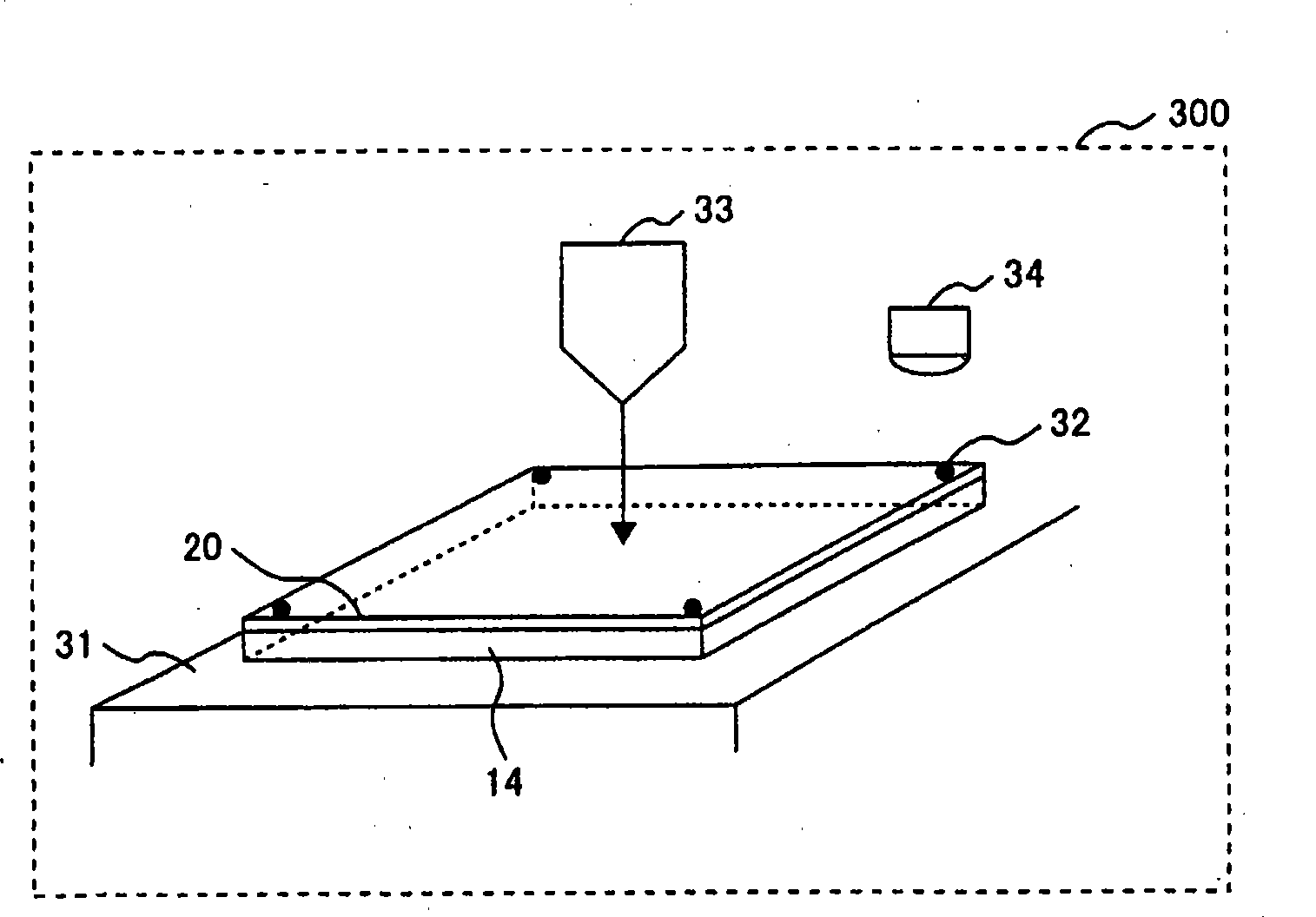

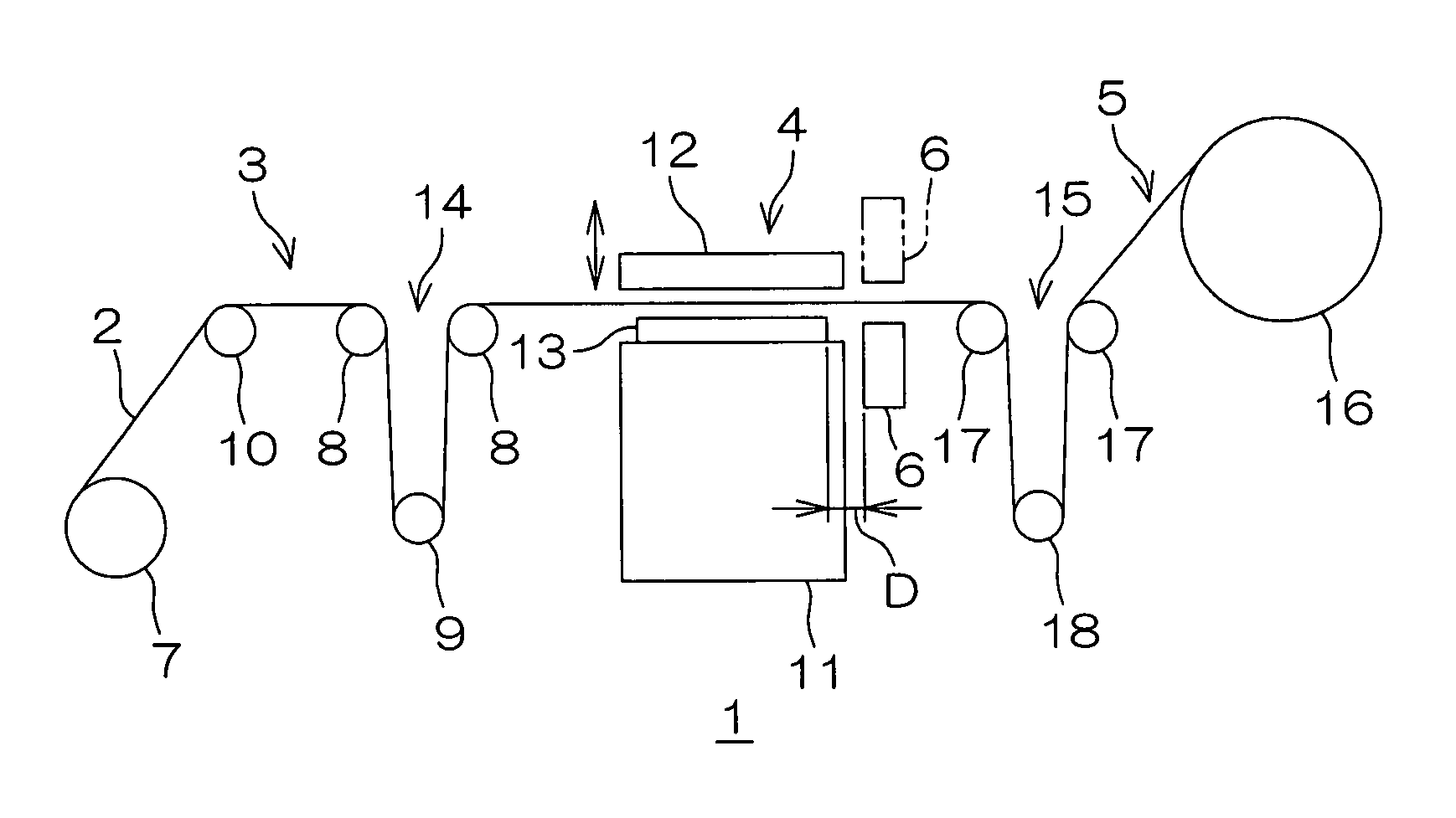

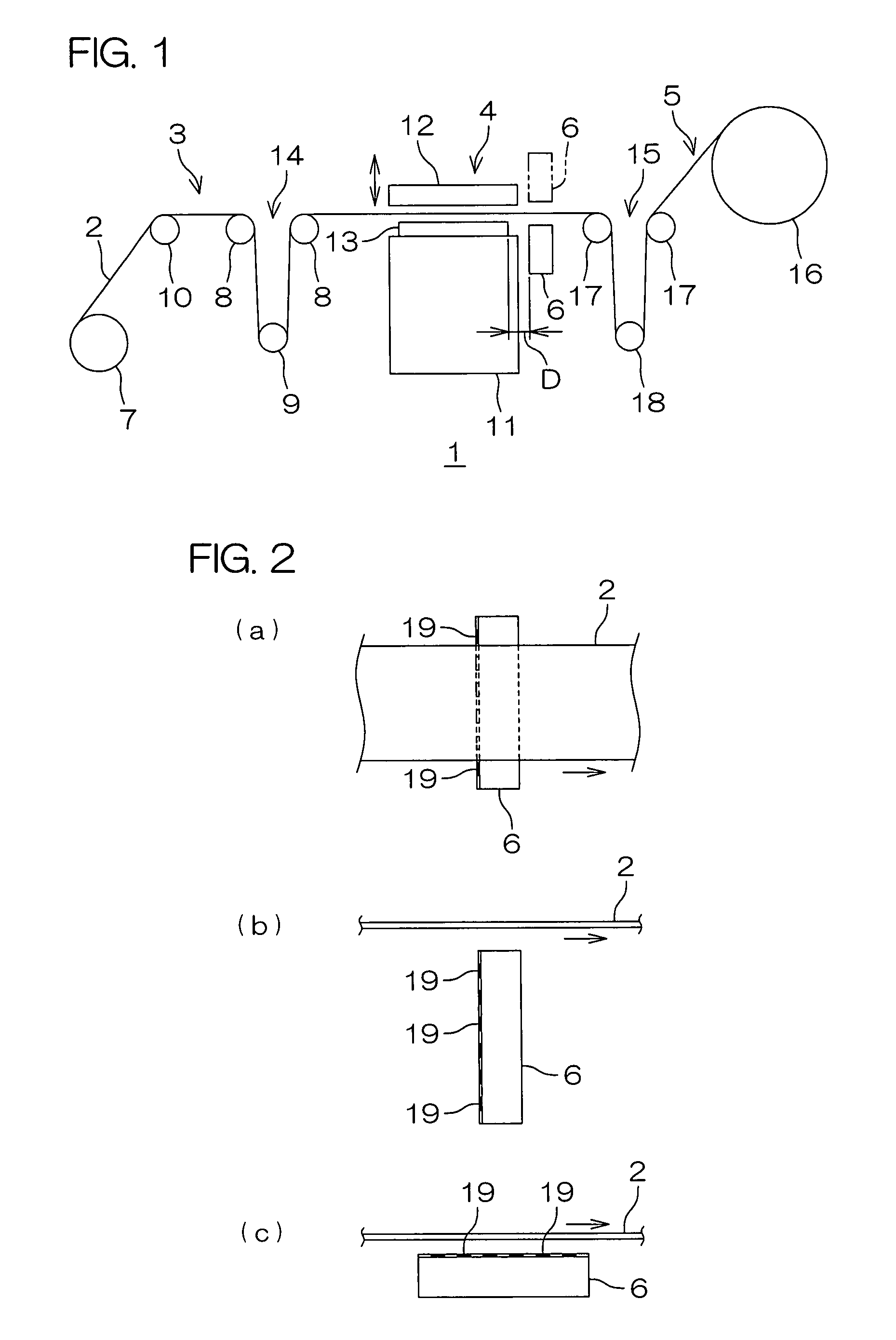

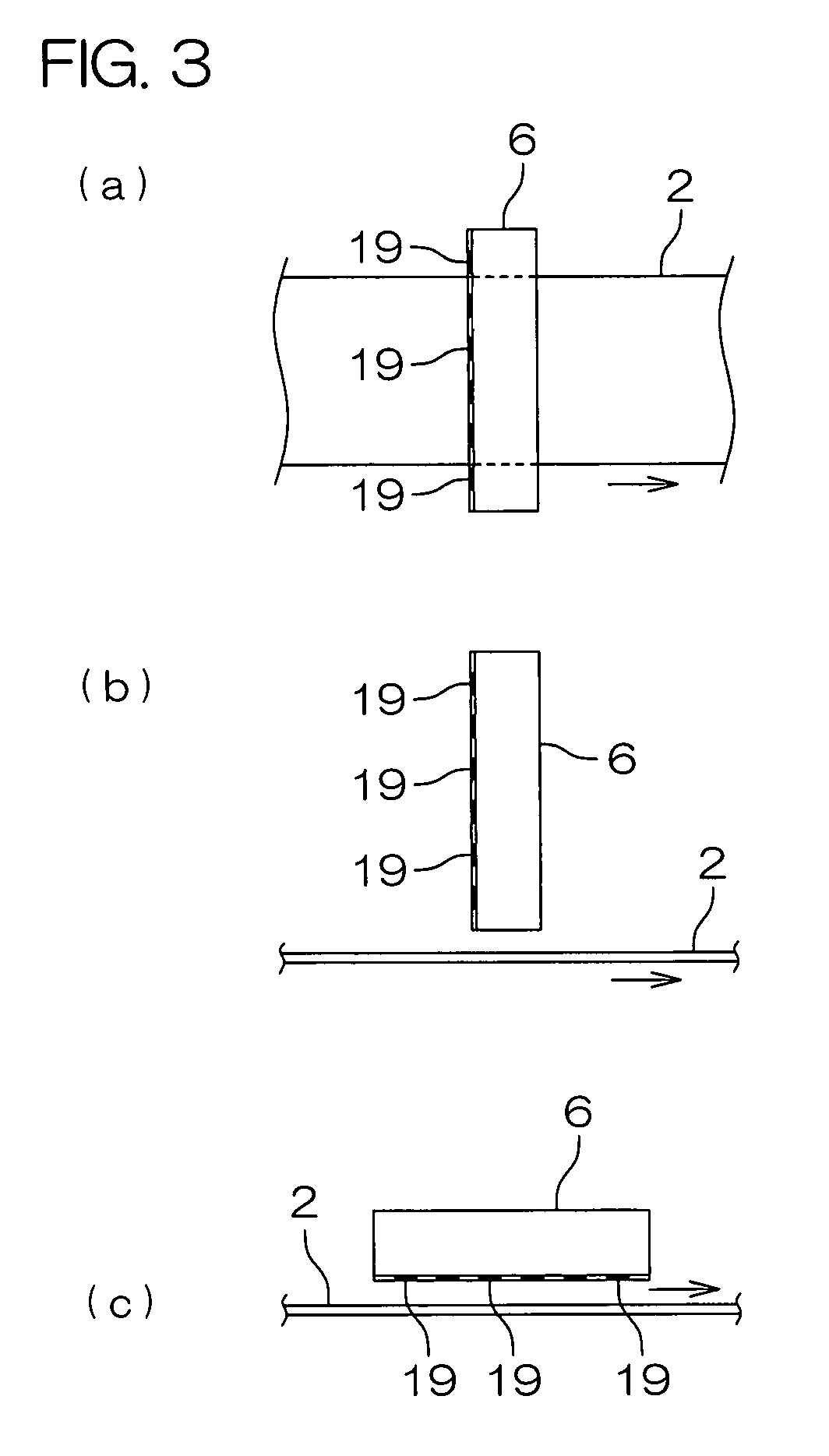

Printing apparatus and printing method

InactiveUS20070227372A1Improve accuracyAvoid flowInking apparatusLiquid surface applicatorsResistEngineering

A printing apparatus includes a feed-out unit for feeding out an elongated base material which is wound up in a roll, a printing unit for printing a liquid resist onto the elongated base material that is fed out of the feed-out unit, a wind-up unit for winding up the elongated base material on which the liquid resist is printed by the printing unit into a roll, and a suction unit positioned between the printing unit and the wind-up unit in a transport direction of the elongated base material for sucking up a solvent in the liquid resist.

Owner:NITTO DENKO CORP

Liquid ejection head and liquid ejection method

ActiveUS7967413B2Little dot landing position deviationsHigh precision printingInking apparatusEngineeringLarge droplet

A liquid ejection method is provided which ejects small-volume droplets from ejection openings and causes them to reliably combine together on the fly into a large droplet that is less susceptible to influences of air flows, thus realizing a printing with reduced droplet landing position deviations. To that end, each of the ejection openings is constructed of two openings spaced apart and a slit-like constricted connection portion that connects the two openings together.

Owner:CANON KK

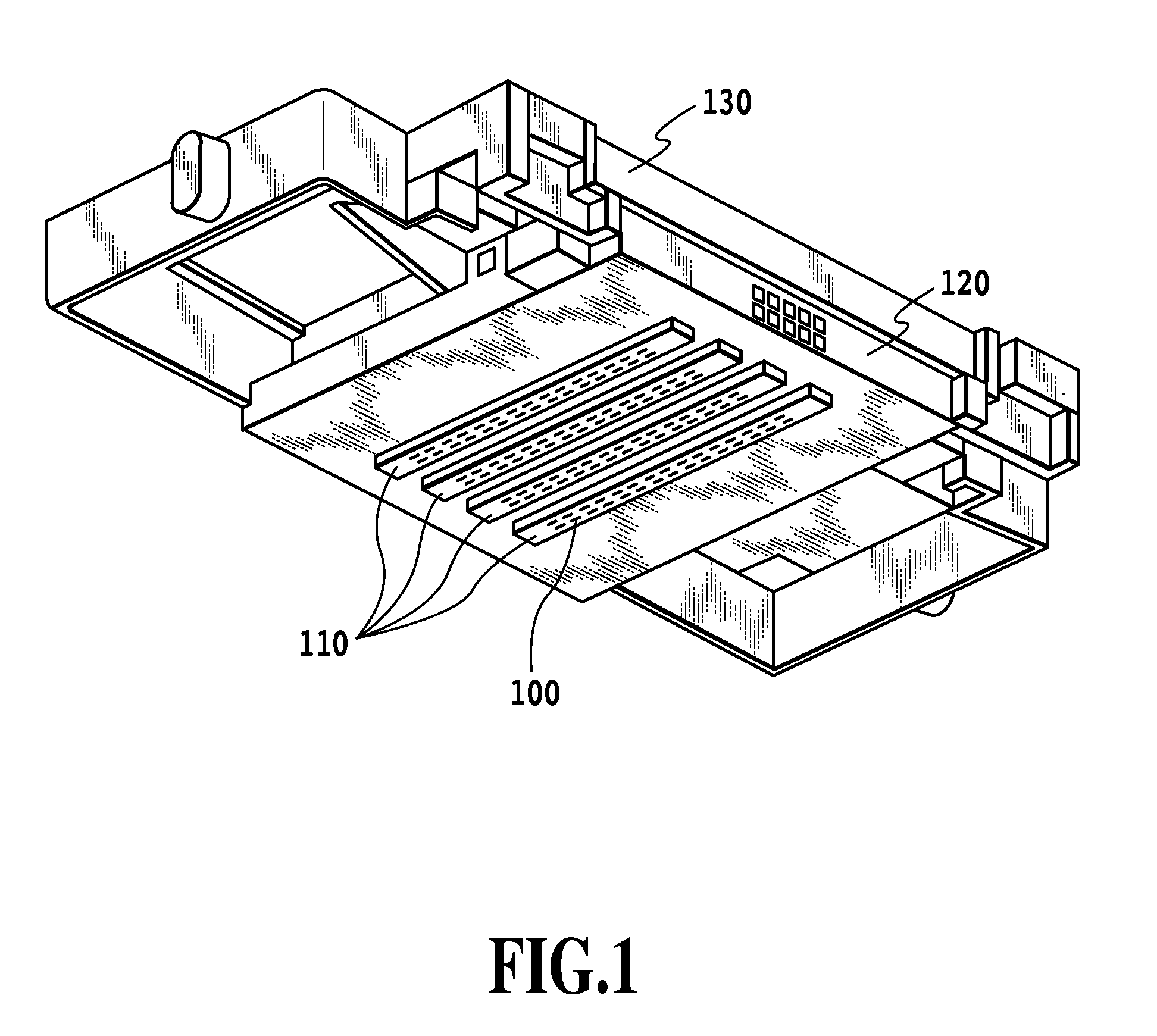

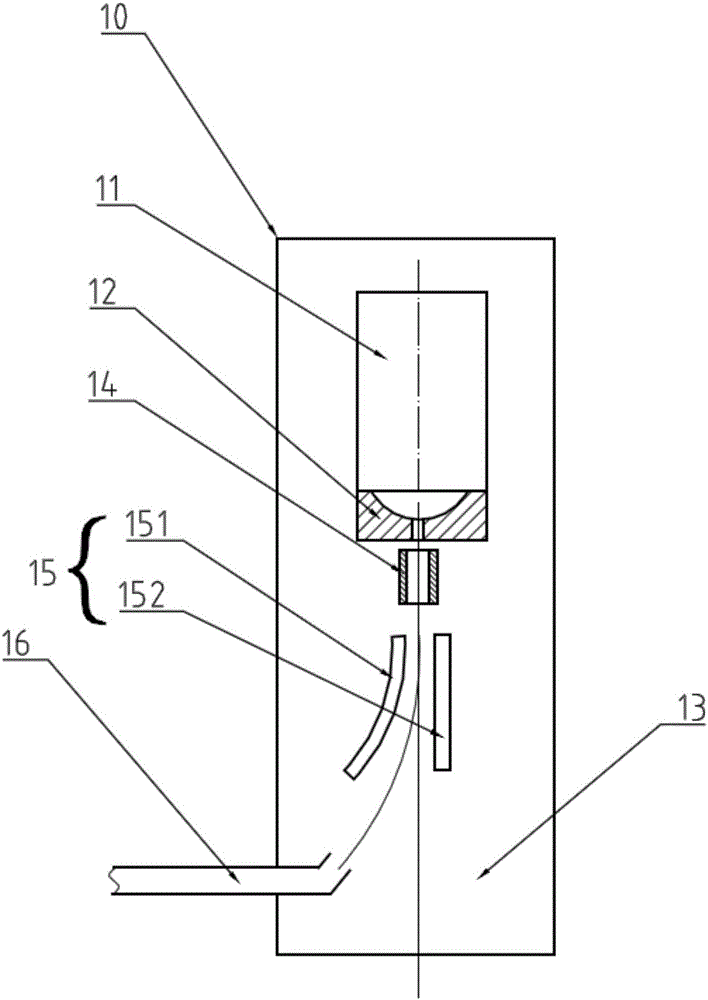

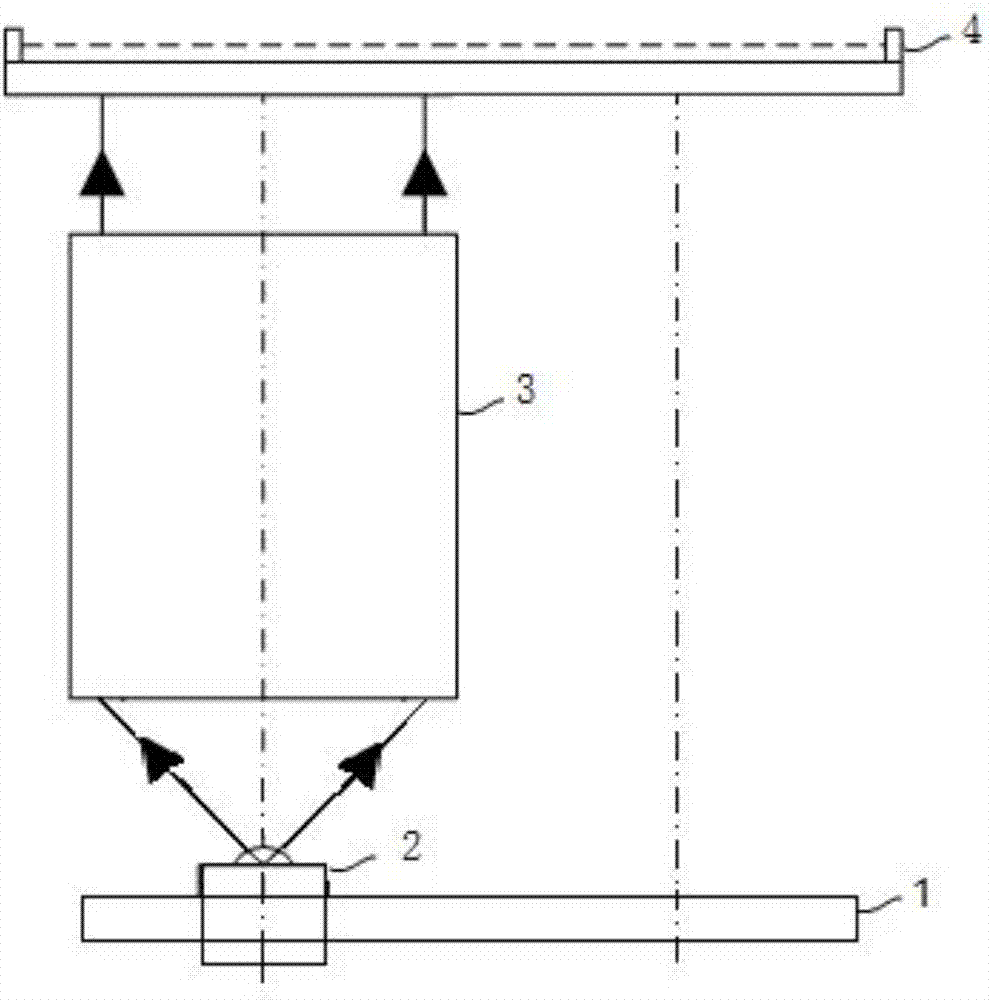

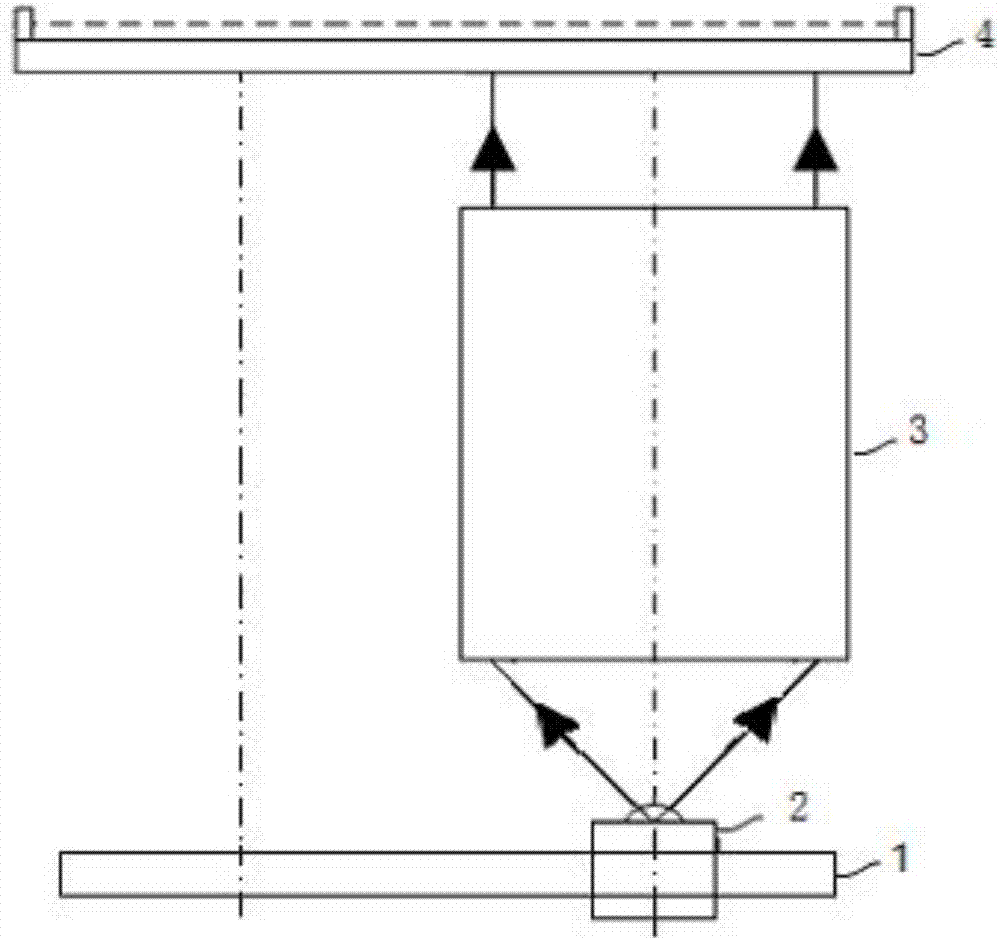

Micro-projection photo-curing printing device and method with doubled single-time printing area

InactiveCN107364129APrint size increaseHigh precision printingAdditive manufacturing apparatus3D object support structuresEngineeringProjection system

The invention discloses a micro-projection photo-curing printing device and method with a doubled single-time printing area. The micro-projection photo-curing printing device comprises a linear guide rail, a light source system, an optical projection system and a transparent resin groove for containing photosensitive resin, wherein the transparent resin groove is formed above the linear guide rail and is parallel to the linear guide rail; the light source system and the optical projection system are arranged between the transparent resin groove and the linear guide rail from bottom to top; the linear guide rail is provided with a driving mechanism; and the light source system and the optical projection system are driven through the driving mechanism to move to a pre-set position along a track of the linear guide rail. According to the device disclosed by the invention, the light source system and the optical projection system are driven through the driving mechanism to move on the linear guide rail to reach a first printing position and a second printing position of each layer of pattern; and two pieces of sub-pictures are spliced. By adopting a simple and feasible technical means, an actual printing size can be doubled and high-precision printing can be realized; and a plurality of camera lenses or high-pixel chips do not need to be utilized, so that the cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Transfer control method of continuous paper and printer

InactiveUS20140043387A1High precision printingInhibit transferOther printing apparatusWebs handlingPaper basedPulp and paper industry

A transfer control method of continuous paper includes controlling a transfer amount of the continuous paper based on a rotational amount detected by a roller feeding amount detecting unit which detects the rotational amount of a paper feed roller, when each page of the continuous paper is printed, and when the printing on each page is completed, performing a cueing process of transferring the continuous paper until a printing start position of a next page reaches the printing position. The cueing process includes transferring the continuous paper until the continuous paper reaches a reference transfer position based on the feeding amount of the tractor detected by a tractor feeding amount detecting unit for detecting a feeding amount of the tractor and after the continuous paper reaches the reference transfer position, setting the transfer amount of the continuous paper as a target feeding amount.

Owner:SEIKO EPSON CORP

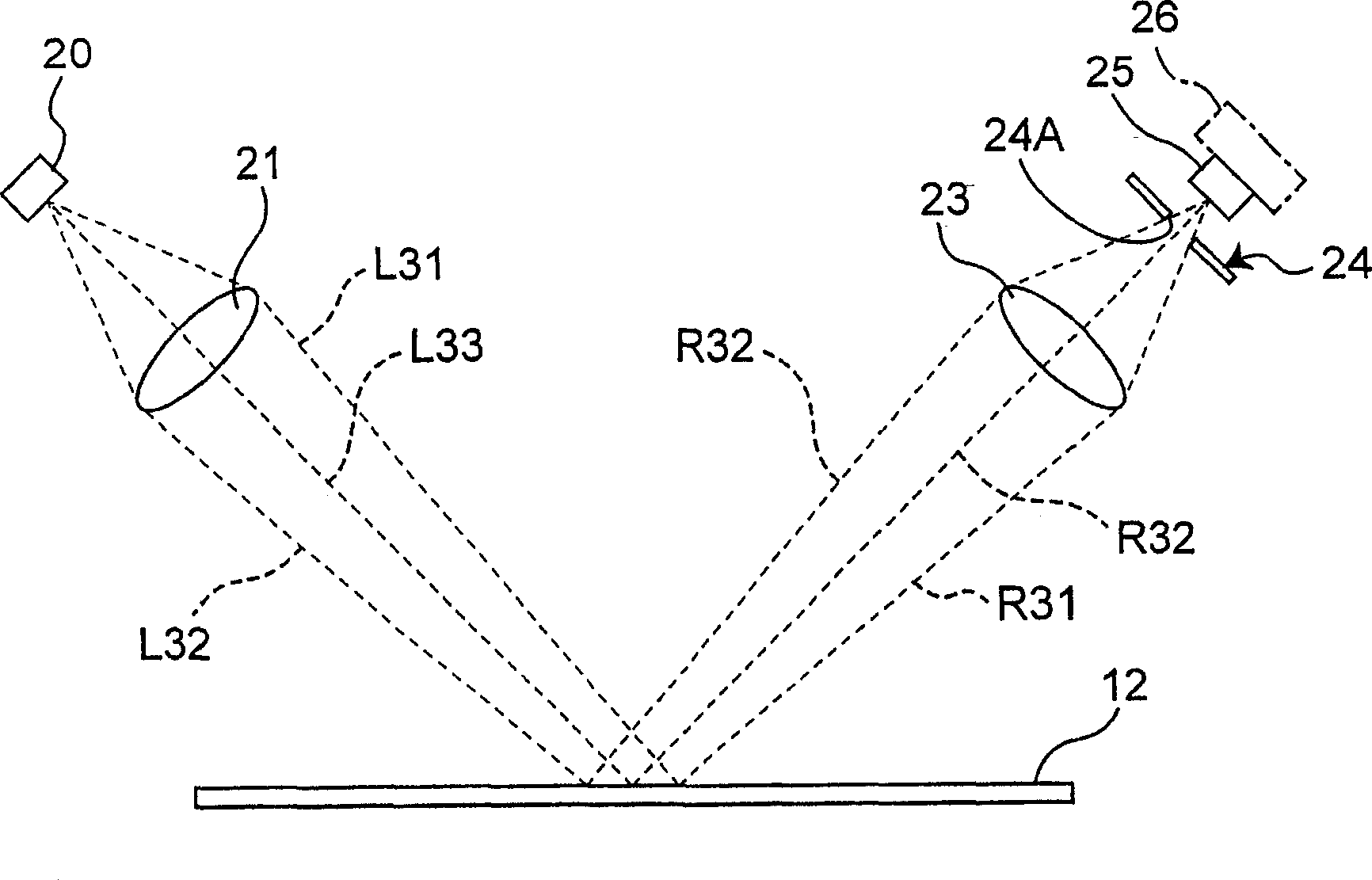

Color information measuring device, print object information measuring device, printing device and electrronic equipment

InactiveCN1896701AAccurate measurementHigh precisionColor measuring devicesOther printing apparatusLight fluxLight beam

In the color information measuring device, the print object information measuring device, the printing device and the electronic equipment, three light fluxes of mutually different wavelengths applied to a measurement object from a red LED, a green LED and a blue LED of a light-emitting part have a common illumination area on the measurement object. The common illumination area on the measurement object contains such an observation area on the measurement object that a reflected ray is made to be incident on a photodiode via a condenser lens and a slit member. Therefore, the common illumination area in which three light fluxes of different wavelengths overlap with one another can reliably be made to be an observation area, so that intensities of a plurality of reflected rays of different wavelengths derived from the observation area can be observed equivalently, hence an improved measurement accuracy.

Owner:SHARP KK

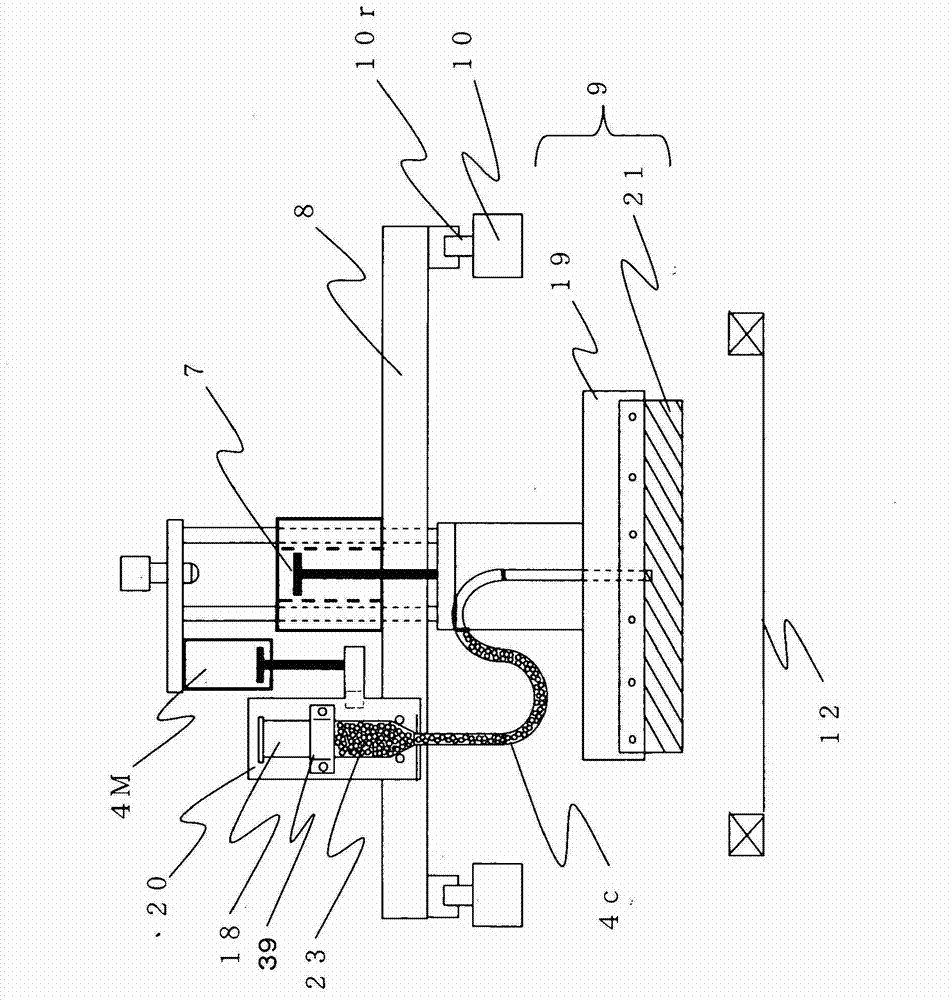

Transfer device for offset printing

InactiveCN102438834AFree rotationGood effectCylinder pressesRotary pressesLinear motionContact pressure

A gate-shaped frame (21) is provided to cross over a guide rail (13) provided on a mount (12). Right and left bearing housings (28a, 28b) which rotatably hold a rotational shaft (30) of a blanket roll (19) at a roll support frame (27) are attached to columns (23a, 23b, 23c, 23d) of the frame (21) through linear motion guides moving in the vertical direction, and further, nuts (36) of ball screw mechanisms (33) are attached to respective bearing housings (28a, 28b), so as to form a transfer device (18) for offset printing. At the time of performing transferring or retransferring by pressing the blanket roll (19) from above a plate (14) on a plate table (15) or a print target (16) on a print target table (17) moving on the guide rail (13), with a predetermined contact pressure, deformation of mechanical structure portions other than the blanket roll (19) caused by the reaction force of the contact pressure can be prevented.

Owner:IHI CORP

Control method of printing machine with heat dissipation assembly

InactiveCN111845045AEasy to controlAchieve energy saving and emission reductionCylinder pressesGas treatmentEngineeringPrinting press

The invention discloses a control method of a printing machine with a heat dissipation assembly. A temperature sensor detects the temperature of the printing machine, a control element receives the temperature of the printing machine, when a received temperature value detected by the temperature sensor is less than a first threshold value, the control element controls a ventilation valve to be opened, when a cooling fan does not work, an adjusting plate completely seals cooling holes, a first control valve and a second control valve are closed, an air feeder is closed, the ventilation valve achieves air connection of the whole device, cooling is achieved through an outer shell and a channel material, after printing is finished, a controller controls the cooling fan to continue working forpreset time, the ventilation valve is closed, the cooling holes are completely closed, the first control valve is closed, the second control valve is opened, and when a pressure signal of the pressuresensor does not reduced any more, the cooling fan is closed and the second control valve is closed.

Owner:王社

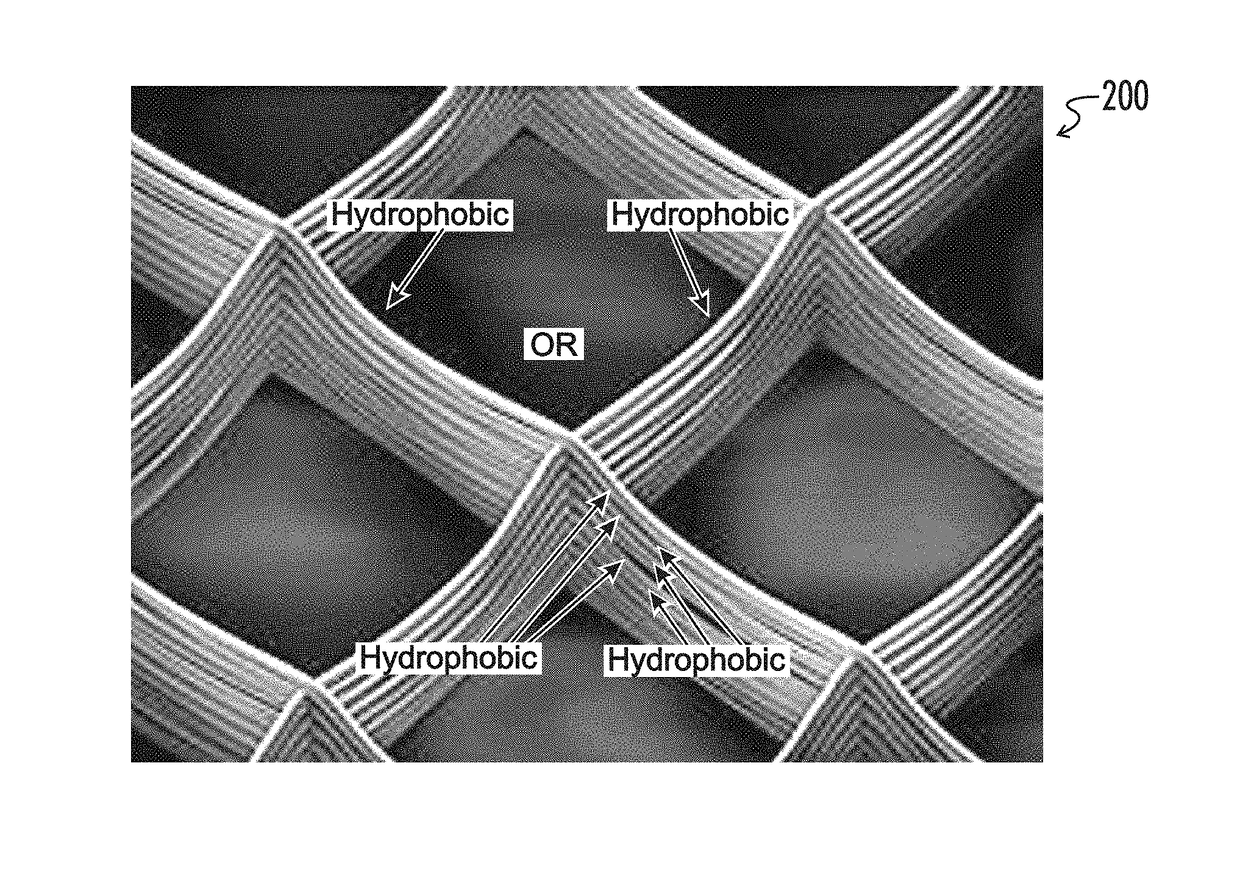

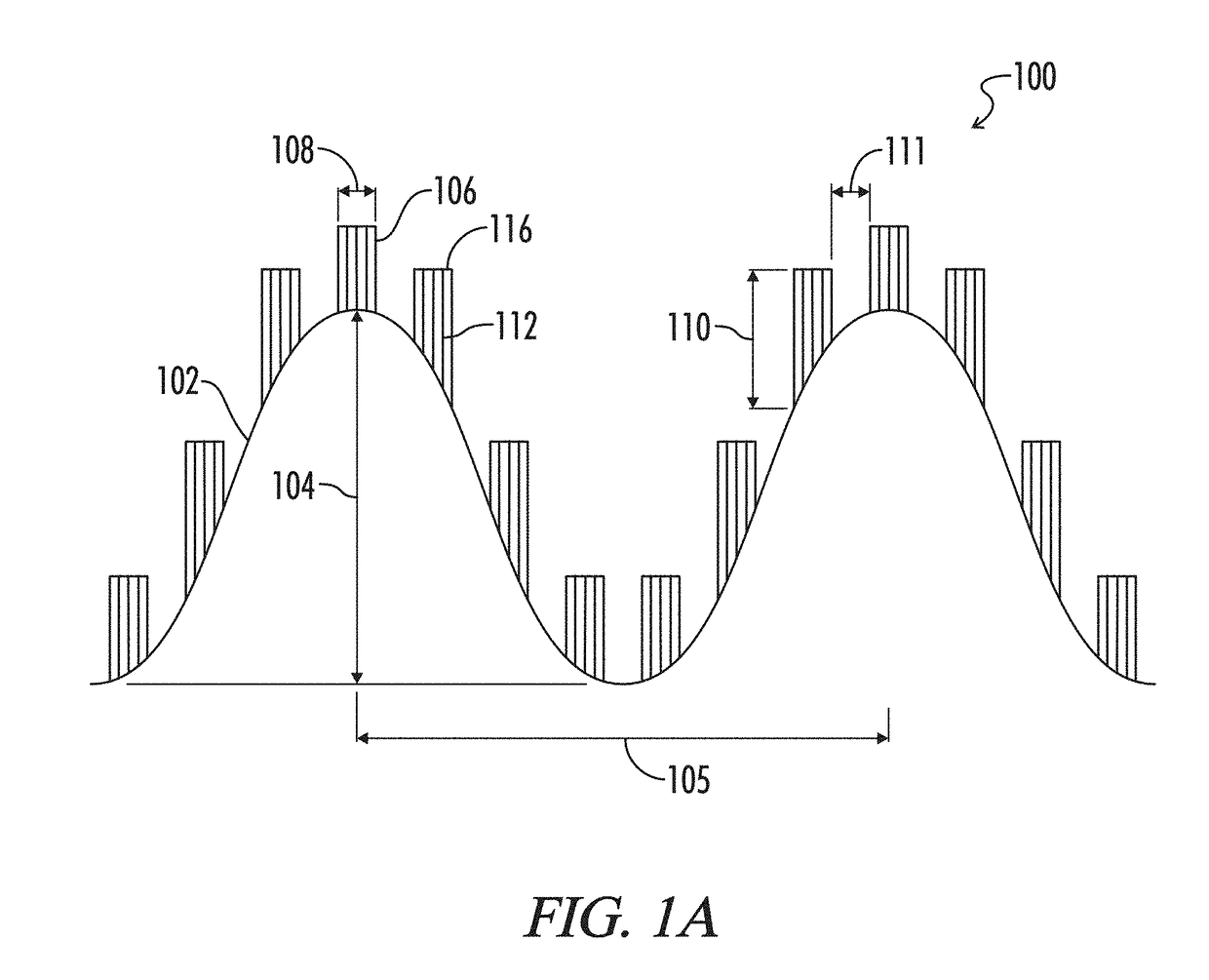

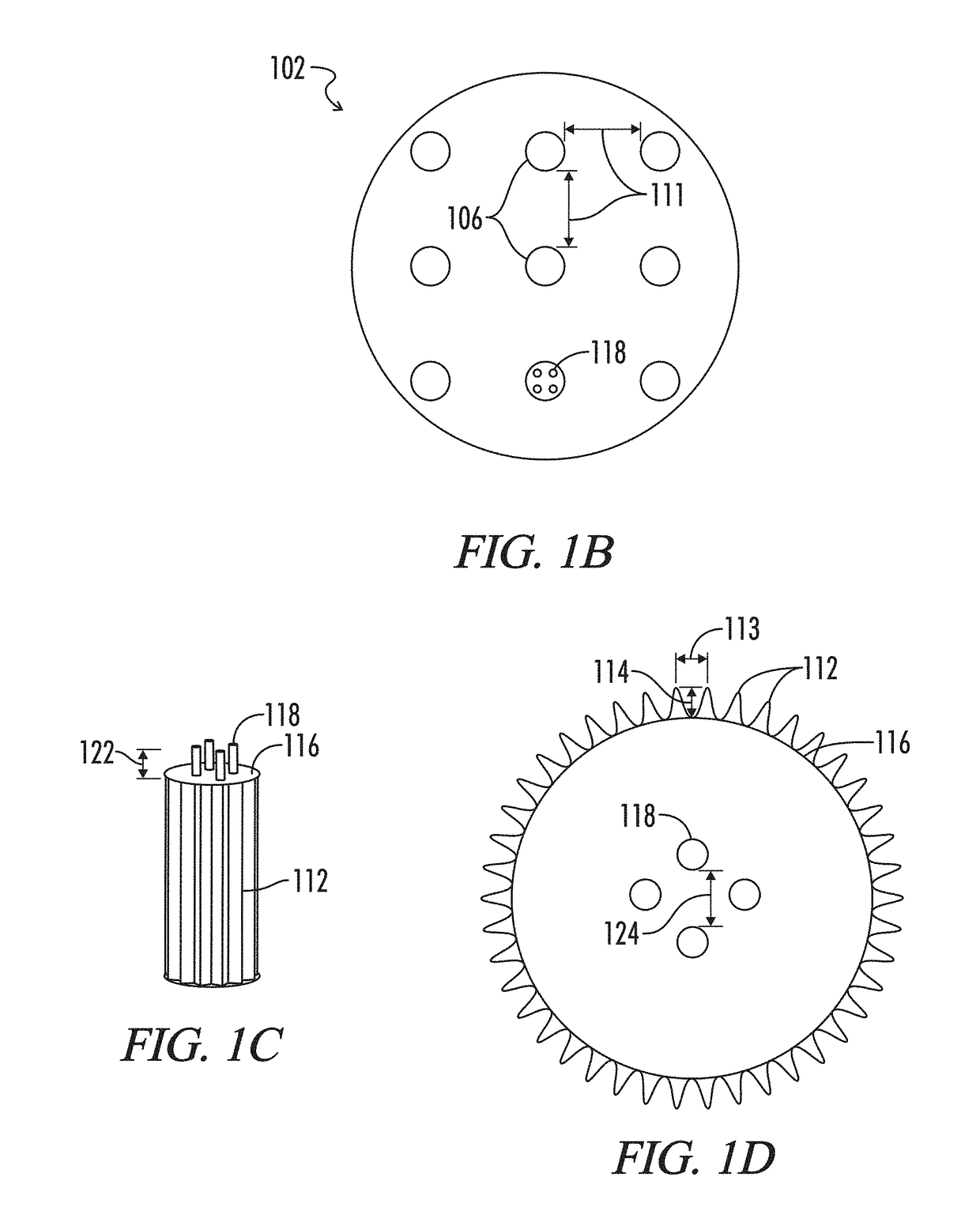

Microstructured haptotaxic implant

ActiveUS20180147321A1High precision printingImprove accuracyPharmaceutical delivery mechanismProsthesisAbsorbable polymersSurface chemical

The invention relates to the field of tissue engineering and regenerative medicine, and particularly to a three-dimensional biomimetic tissue scaffold that exploits the use of three-dimensional print technology. Surface energy is controlled by precisely placing polymers with differing surface chemistry, and using surface texture and bulk composition to pattern absorbable and non-absorbable polymers for the purpose of promoting functional healing in a mammalian body.

Owner:BVW HLDG

Printing machine with heat dissipation assembly

InactiveCN111806076AGuaranteed normal operationRapid heat dissipation and coolingCylinder pressesGas treatmentElectric machineryEngineering

The invention discloses a printing machine with a heat dissipation assembly. The printing machine with the heat dissipation assembly comprises a heat dissipation device outer shell; a plurality of ventilation channels are evenly formed in the rear end face of the heat dissipation device outer shell, heat dissipation fans are fixedly installed on the inner sides of the ventilation channels, a movable bottom plate is movably installed on the bottom face of the heat dissipation device outer shell, two dustproof plates are uniformly installed above the movable bottom plate, two moisture absorptionplates are installed on the middle of the two dustproof plates, anti-falling inserting pins are movably installed inside the two ends of the movable bottom plate, and movable sliding blocks are fixedly installed at the other ends of the anti-falling inserting pins. By installing the heat dissipation holes, an adjusting plate, a supporting column, an adjusting sliding block, a transmission screw and a motor, the ventilation hole diameter of the heat dissipation holes of a heat dissipation mechanism of the printing machine can be adjusted, adjustment can be conveniently conducted according to the internal temperature of the printing machine, the ventilation hole diameter of the heat dissipation holes is increased or decreased, heat dissipation is better conducted, and normal operation of the printing machine is guaranteed.

Owner:王社

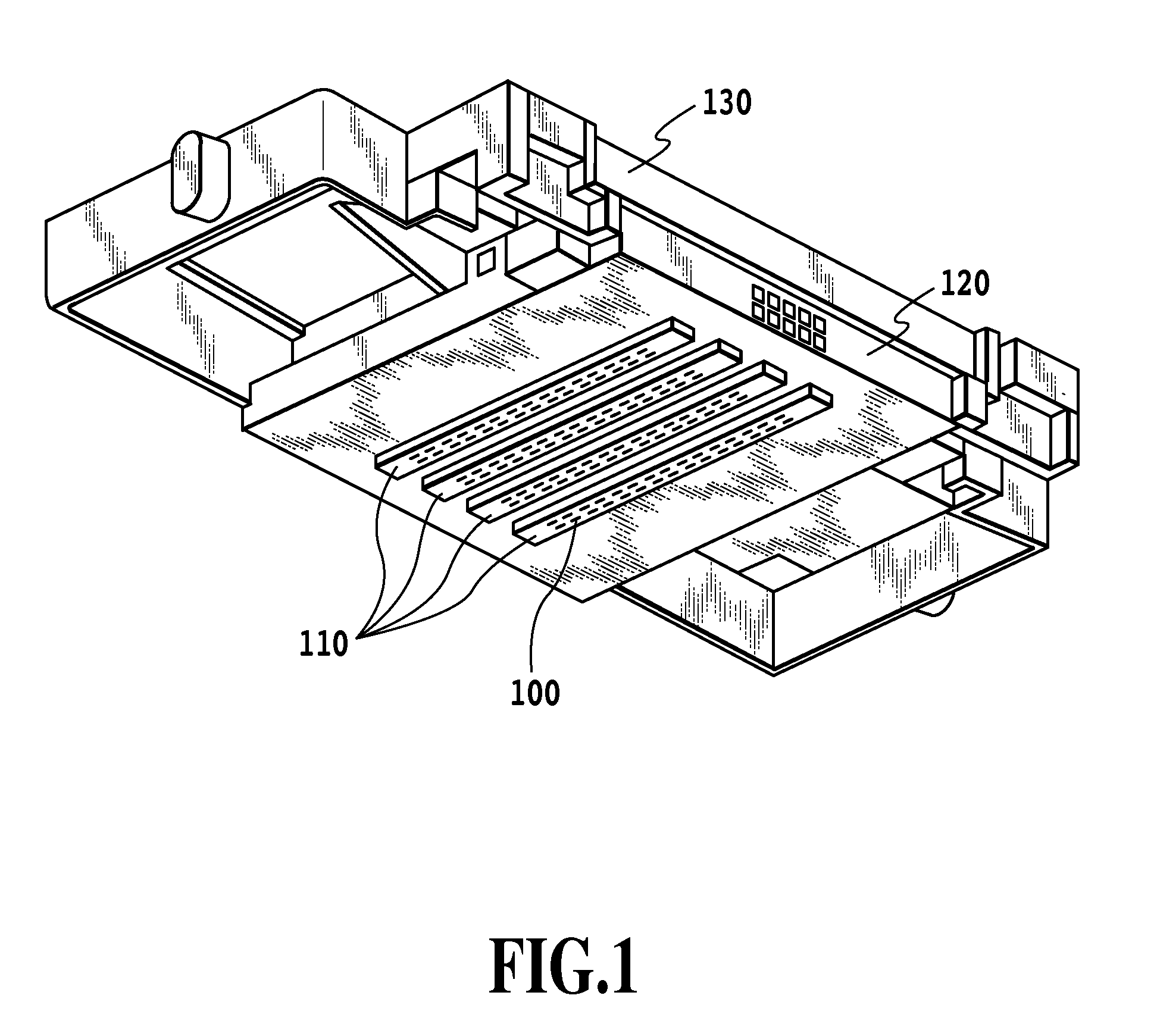

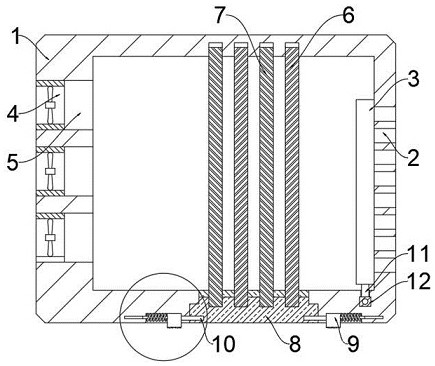

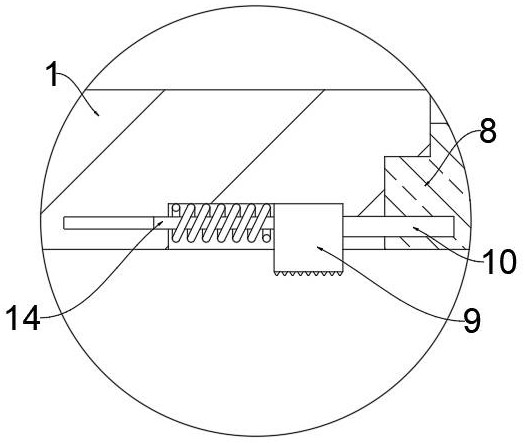

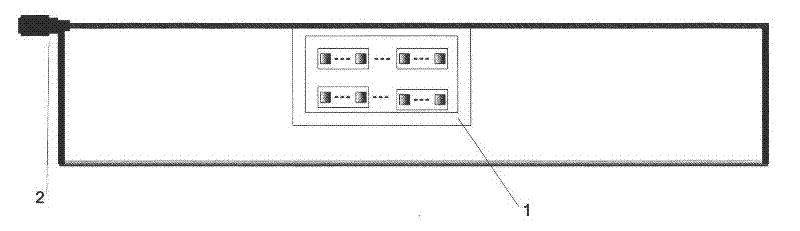

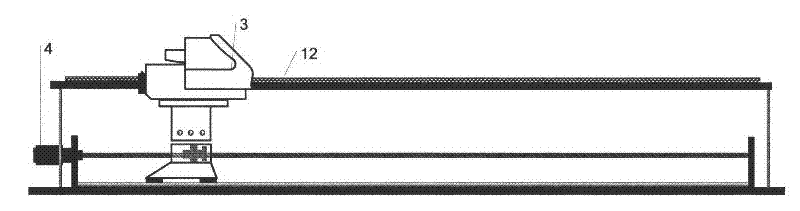

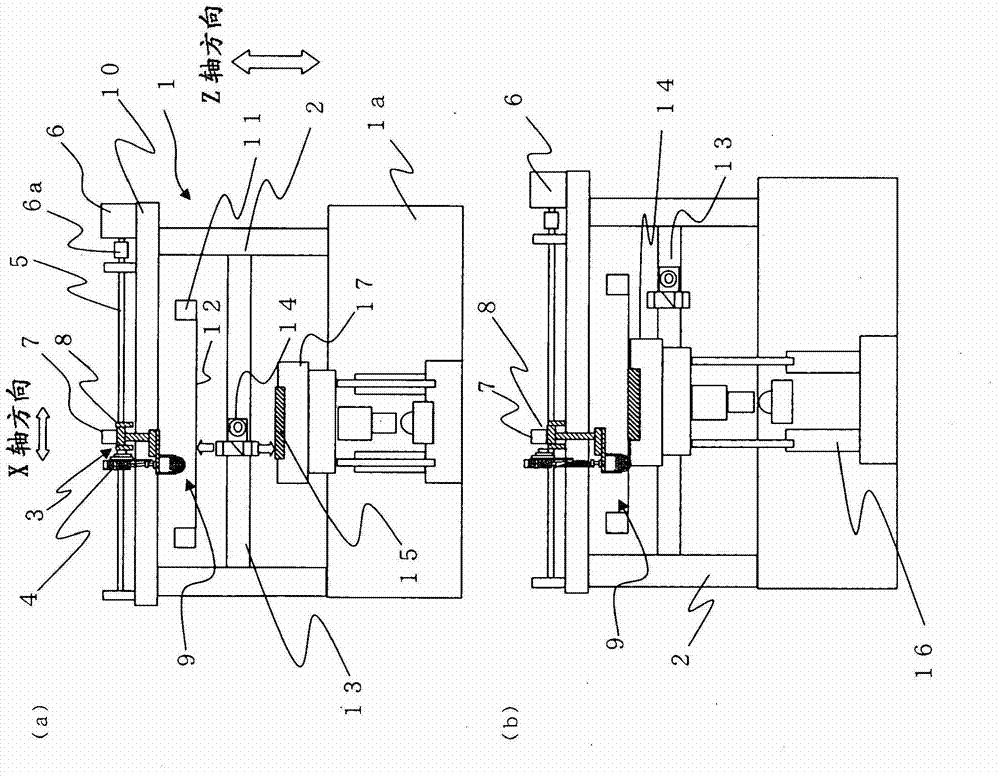

Dual-servo motor control device for flat plate type digital ink-jetting printing machine

InactiveCN102501631AHigh precision printingEasy to installTypewritersPower drive mechanismsDigital inkCost performance

The invention provides a dual-servo motor control device for a flat plate type digital ink-jetting printing machine. Two high-precision servo motors 1 and 2 are adopted, wherein the servo motor 1 is used for controlling motions of a nozzle group in a width direction of a printed textile, and the servo motor 2 is used for controlling motions of a machine head subassembly in a length direction of the printed textile. Furthermore, the servo motor 2 is connected with the servo motor 1 by a signal converting device, so that the synchronous intermittent movement which is complementary in time of the servo motor 1 and the servo motor 2 is accurately traced. Therefore, the heights of the motions of the machine head subassembly are coordinated and consistent, and the high-precision requirement in printing can be effectively ensured. The device can be directly applied to the ordinary flat plate type digital ink-jetting printing machine and has the advantages of convenience for entire installation and high cost performance.

Owner:JIANGNAN UNIV

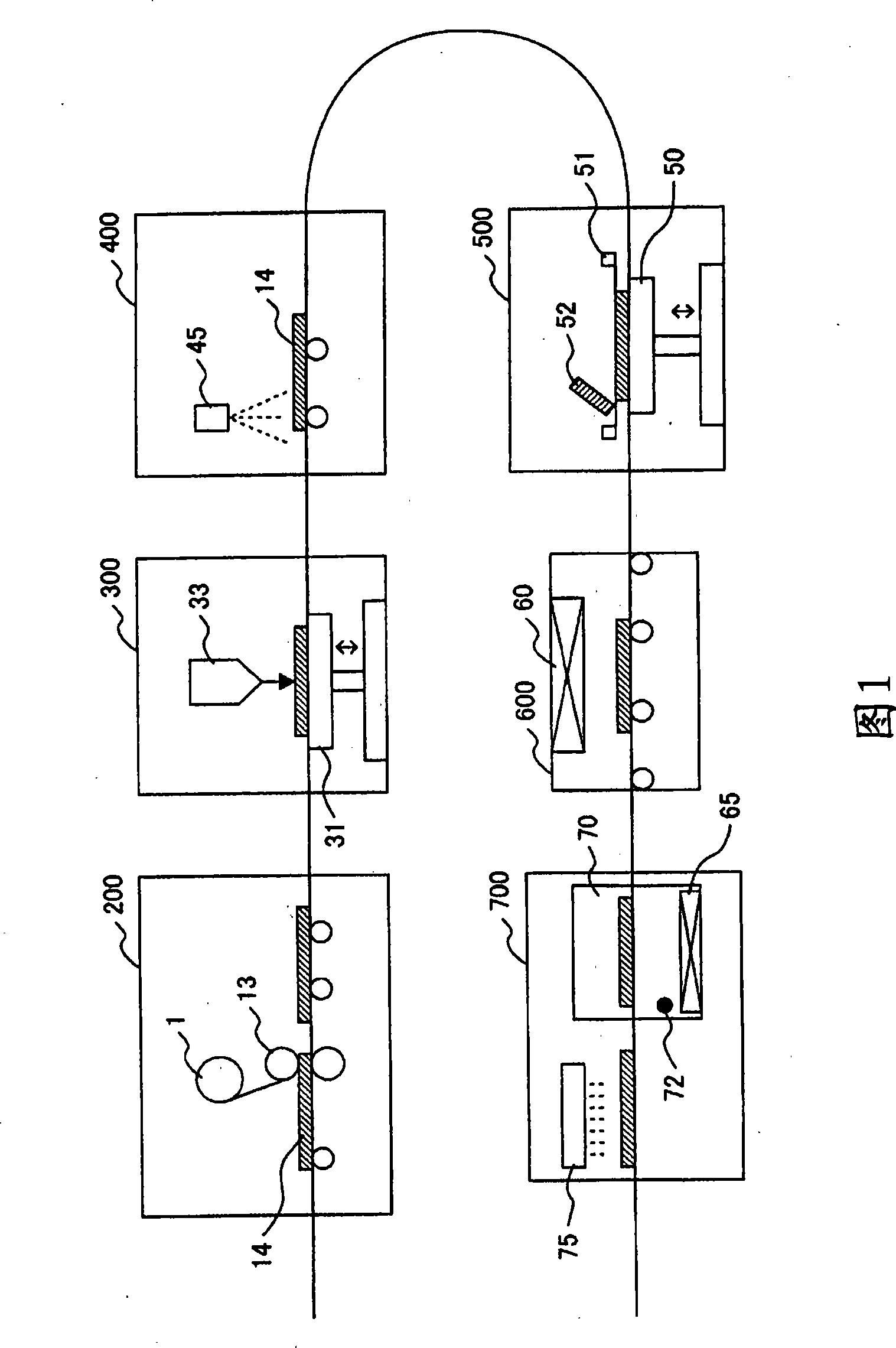

Sheet peeling device and sheet printing system using same device

InactiveCN101384135AHigh precision printingImprove insulation performancePrinted circuit assemblingConductive material mechanical removalEngineeringSolder paste

The invention claims a sheet printing system, in which undesirable printing caused by dislocation of a sheet component will not be brought when arranging an opening on the sheet component and printing by supplying soldering paste to the opening, comprising a paste portion, a pattern making portion, a printing portion, a backflow furnace and a stripping portion, characterized in that the paste portion pastes the sheet component onto a base plate for coating soldering paste; the pattern making portion forms an opening pattern for coating soldering paste on the sheet component; the printing portion prints soldering paste on the base plate mounting with the sheet component that forms the opening pattern; the backflow furnace heats the base plate printing with soldering paste to fix the soldering paste onto surface of the base plate; and the stripping portion removes the sheet component from the surface of the base plate fixing with soldering paste.

Owner:HITACHI LTD

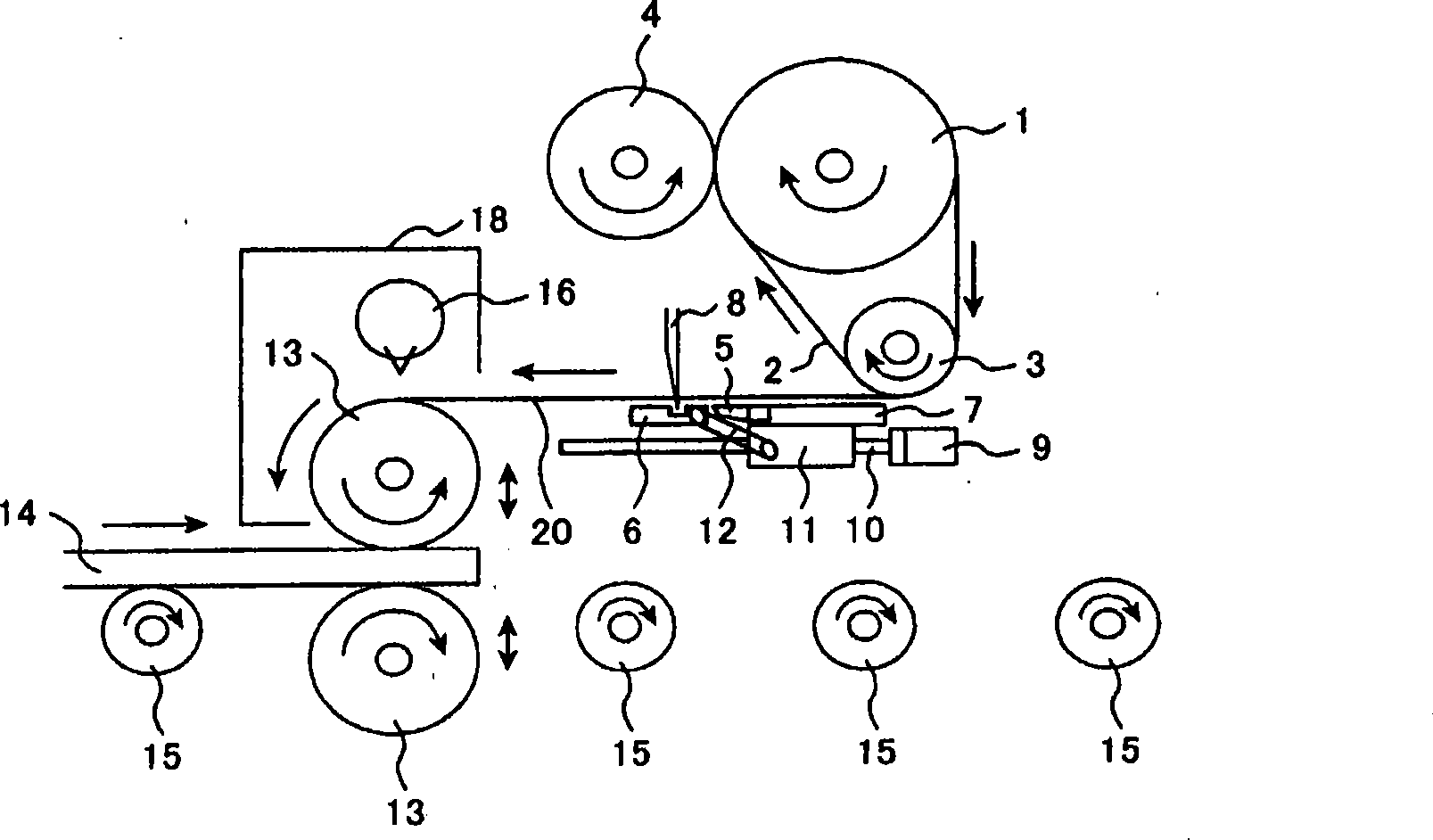

Solder ball printing apparatus

InactiveCN103077896ACorrect consumptionAvoid oversizingSemiconductor/solid-state device manufacturingPrinted circuit manufactureSolder ballEngineering

The present invention discloses a solder ball printing apparatus for supplying solder balls to a mask surface in an appropriate amount and preventing solder ball wastage as possible. In the invention, the solder ball printing apparatus is provided with a mask and a solder ball filling head. The mask prints solder balls on electrodes which are formed on a substrate that is carried on the printing worktable. The solder ball filling head is provided with a vertical driving mechanism that vertically moves on the mask surface. The solder ball printing apparatus is characterized in that: the solder ball filling head is composed of a solder ball filling part and a solder ball supplying part; the solder ball filling head is provided with the vertical driving mechanism which cause the solder ball filling part and the solder ball supplying part to vertically move simultaneously and a supplying part driving mechanism that causes the solder ball supplying part to move vertically; a static-resistant pipe is used for connecting a syringe for storing the solder balls with the solder ball filling part in the solder ball supplying part; and through action of the supplying part driving mechanism, the static-resistant pipe is extended or bent, thereby supplying the solder balls or stopping.

Owner:HITACHI LTD

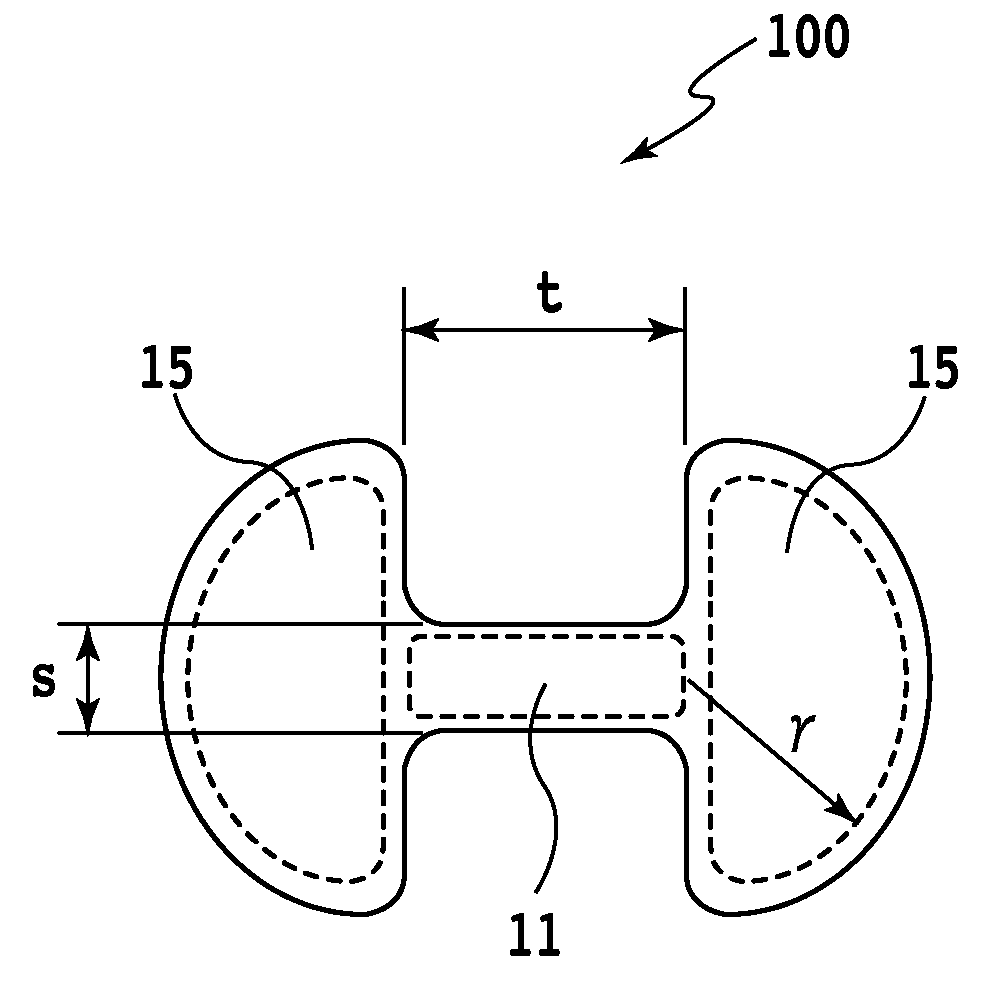

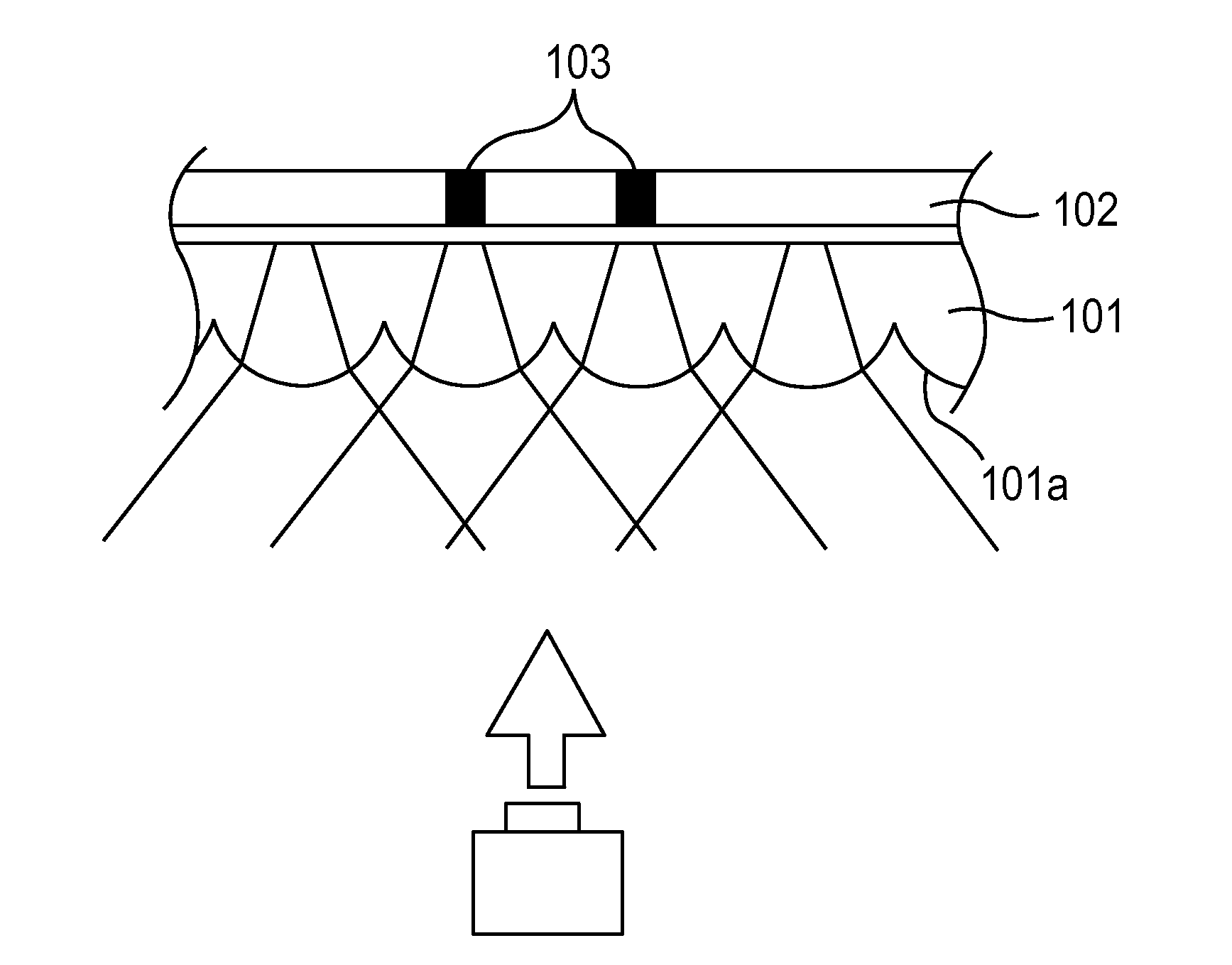

Method for manufacturing image print sheet, image print sheet and printing apparatus

InactiveUS20110188124A1Increase costIncrease in sizePattern printingMounting boardsProduction rateLenticular lens

Present invention provides an image print sheet printable in high accuracy without reducing productivity. After a lenticular sheet 101 and a reception layer sheet 102 on which a detection pattern 103 is printed are inserted in an attachment apparatus 110 from insertion openings, the optical density is measured repeatedly by a density sensor 111 while rotating and parallel-moving the lenticular sheet 101. When the maximum density is measured, the reception layer sheet 102 is attached to the lenticular sheet 101. In this way, an image print sheet 100 having the detection pattern 103 parallel to the longitudinal direction of convex parts 101a and coinciding with the vertexes of the convex parts 101a is produced. When printing on the image print sheet 100, the detection pattern is detected by a photo-sensor, an azimuth adjustment and a print start position determination will be performed. Consequently, printing with high accuracy is available.

Owner:FUJIFILM CORP

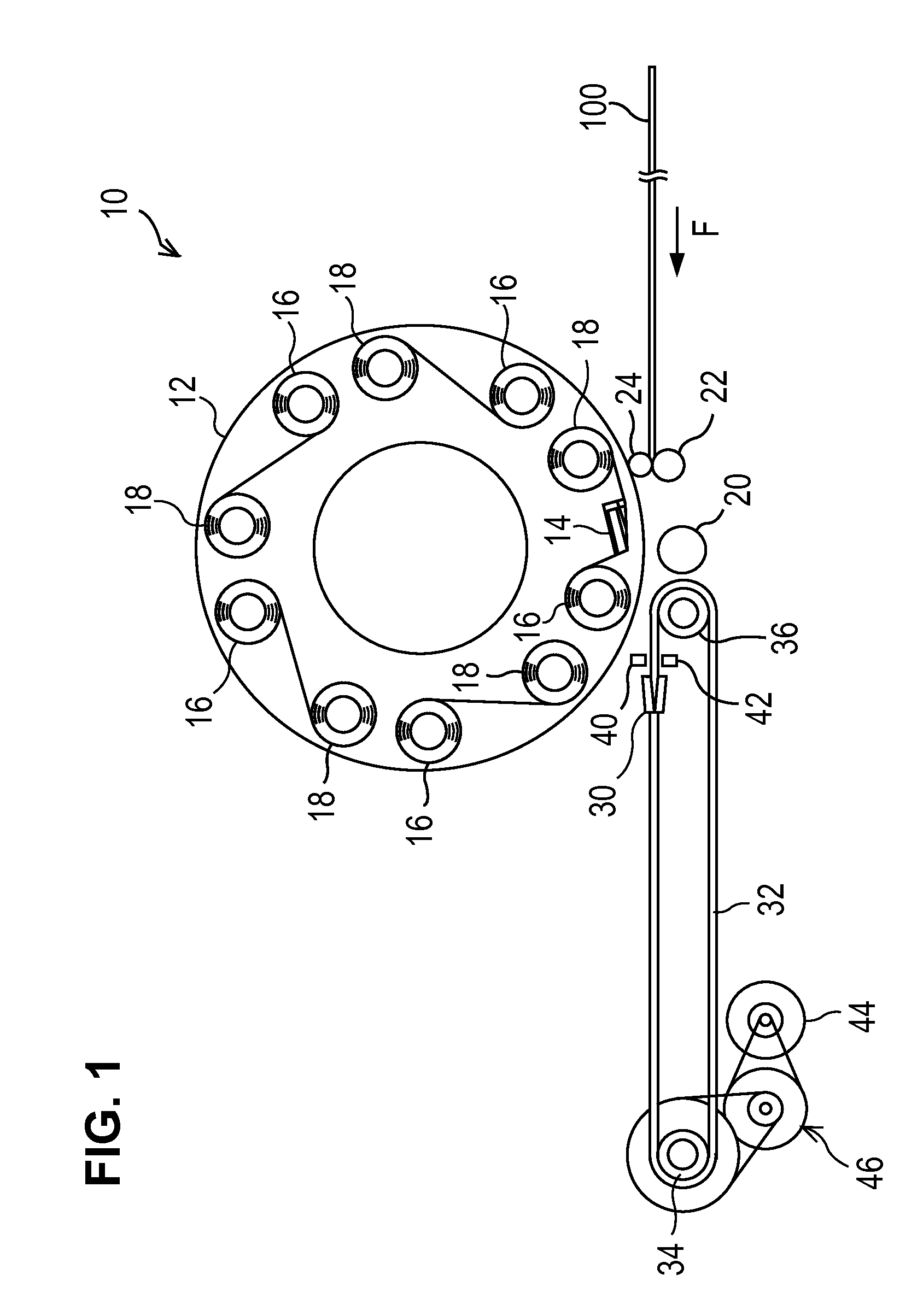

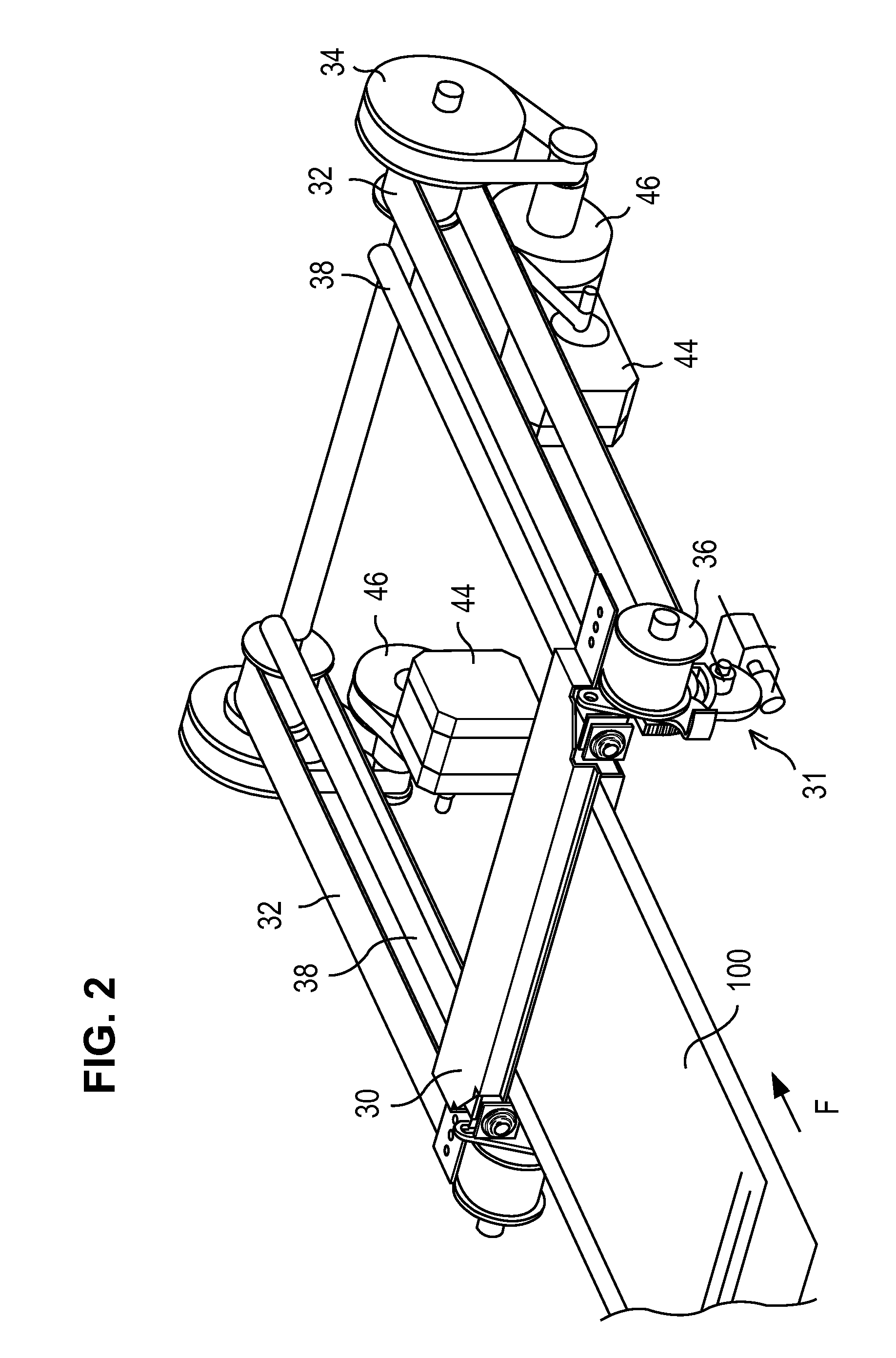

Paper feed mechanism

InactiveCN1899836AHigh precision printingHigh-precision conveyance of recording paper during printingOther printing apparatusArticle feedersPaper sheetEngineering

Owner:ALPS ALPINE CO LTD

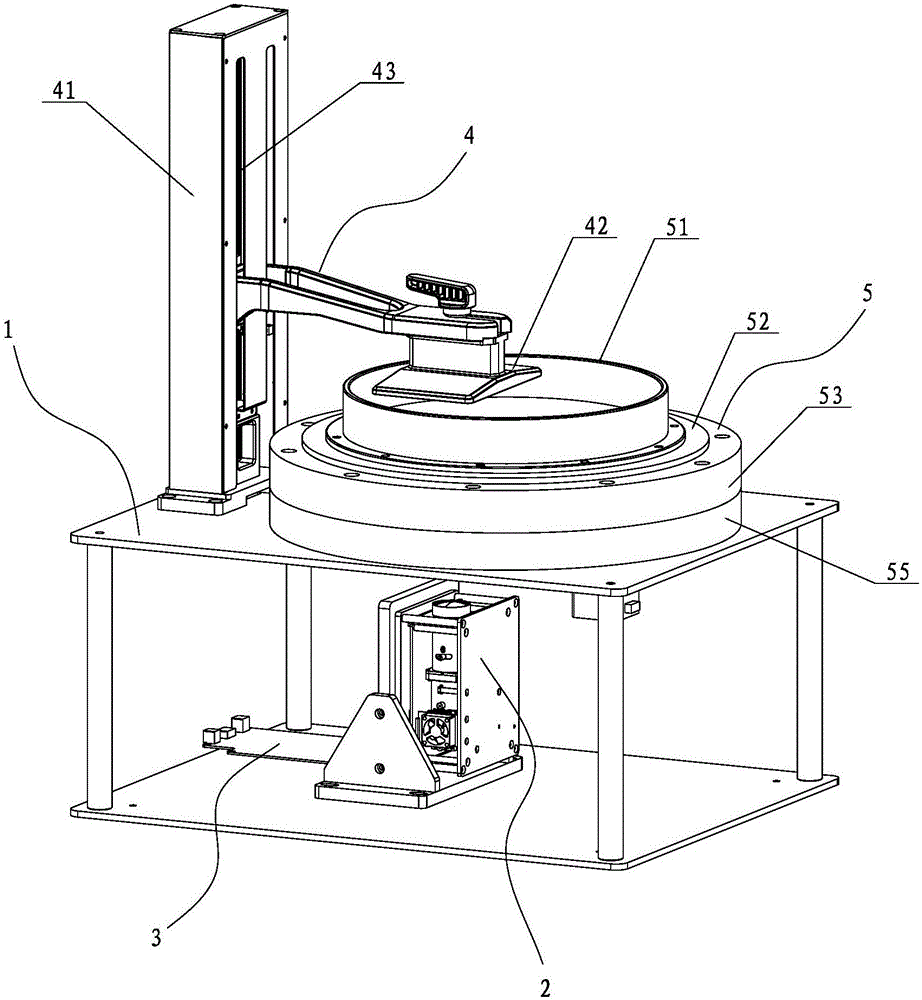

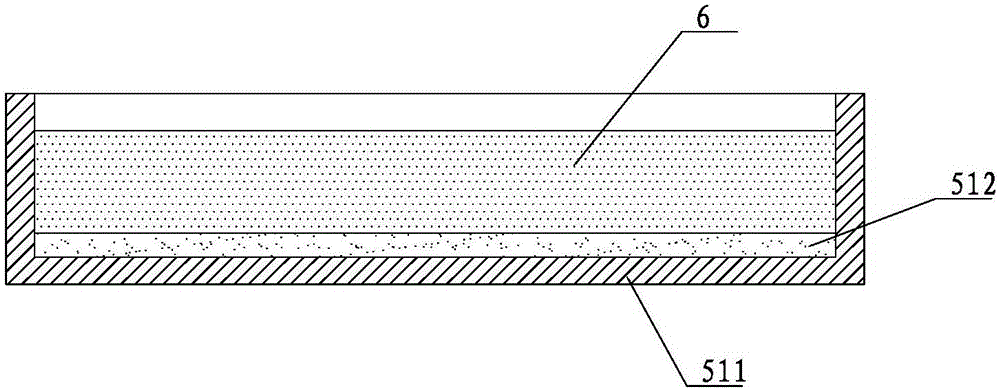

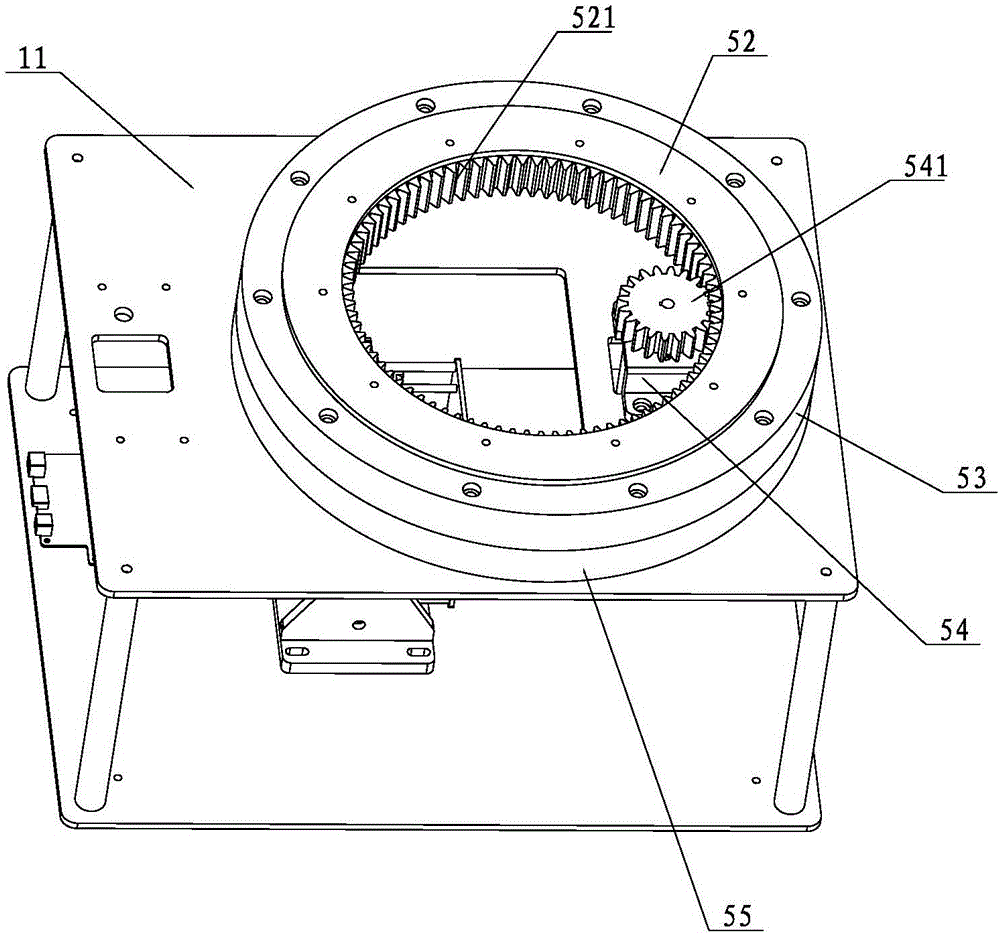

Quick 3D printing device and quick printing method

InactiveCN106626375AIncrease printing speedHigh precision printingManufacturing platforms/substratesManufacturing enclosuresEngineeringElectrical and Electronics engineering

The invention discloses a quick 3D printing device and a quick printing method. The device comprises a base, an exposure mechanism, a control mechanism, a printing mechanism and a liquid containing mechanism, wherein the exposure mechanism and the control mechanism are arranged in the base; the printing mechanism and the liquid containing mechanism are arranged on the base; the printing mechanism comprises a module and a printing platform slidably mounted on the module; the liquid containing mechanism comprises a material tank used for containing a printing solution and a driving assembly used for driving the material tank to rotate; the bottom of the material tank is provided with a completely transparent bottom plate or a partially transparent bottom plate; the bottom plate is covered with a layer of transparent liquid film with the uniform thickness; an exposure port of the exposure mechanism corresponds to the printing platform and used for allowing exposure curing light to pass through the transparent material tank bottom and be directly irradiated onto the printing platform. The quick 3D printing device and the quick printing method provided by the invention has the characteristics that the printing speed is high, the precision is high, the service life is long, the size is small, and operation is easy.

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD

Printing apparatus and printing method

InactiveUS7798062B2Improve accuracyAvoid flowInking apparatusLiquid surface applicatorsResistEngineering

A printing apparatus includes a feed-out unit for feeding out an elongated base material which is wound up in a roll, a printing unit for printing a liquid resist onto the elongated base material that is fed out of the feed-out unit, a wind-up unit for winding up the elongated base material on which the liquid resist is printed by the printing unit into a roll, and a suction unit positioned between the printing unit and the wind-up unit in a transport direction of the elongated base material for sucking up a solvent in the liquid resist.

Owner:NITTO DENKO CORP

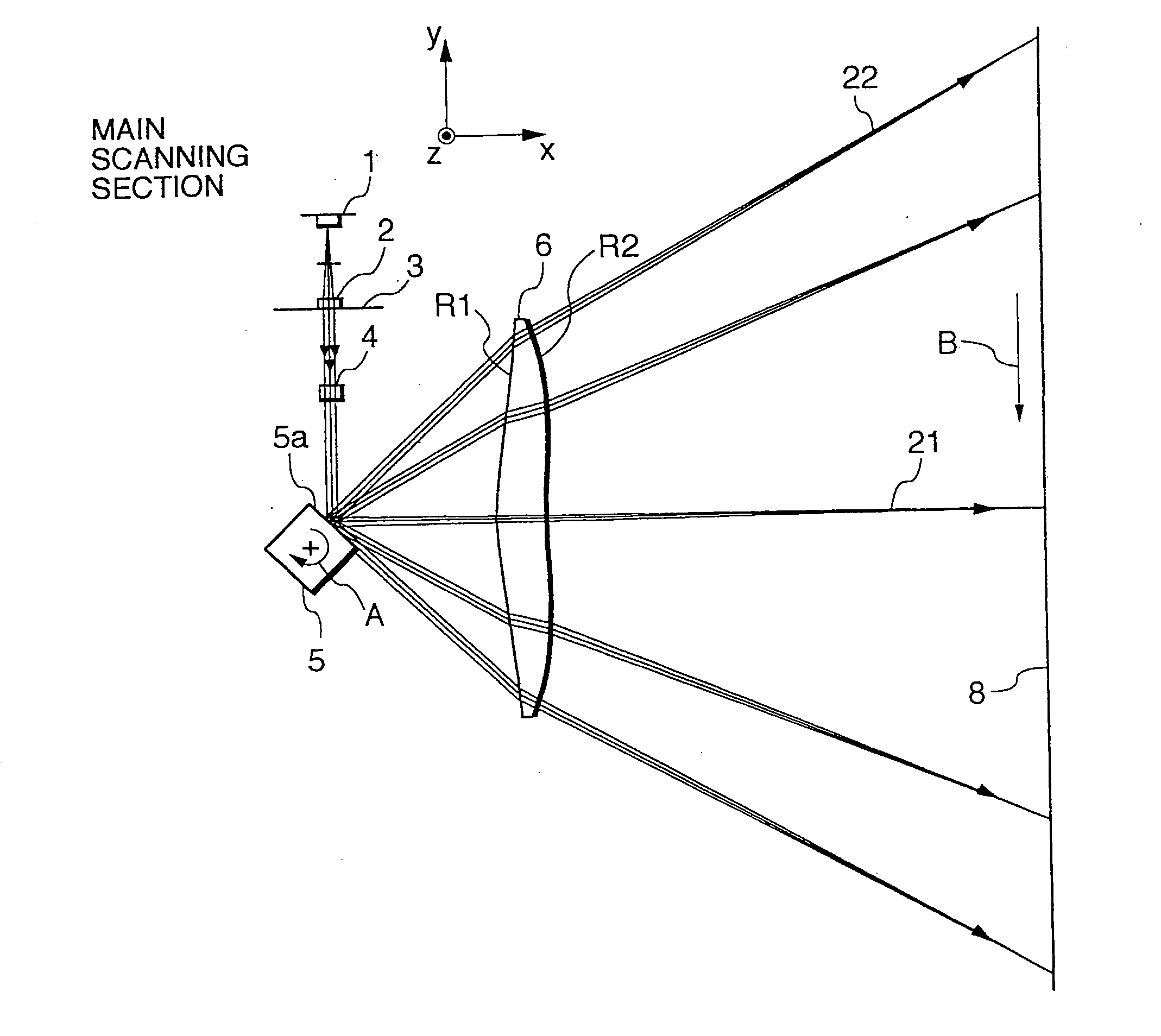

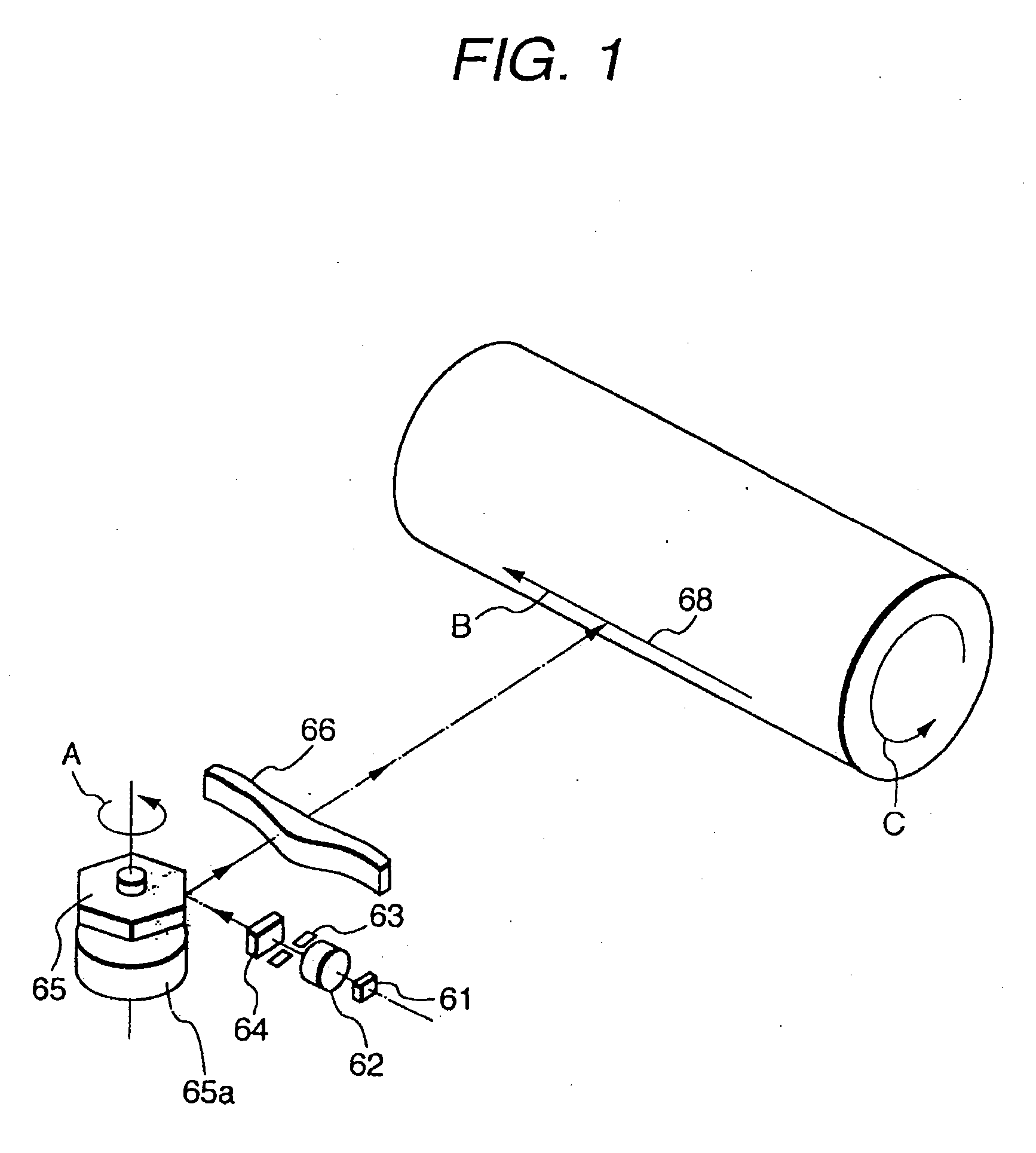

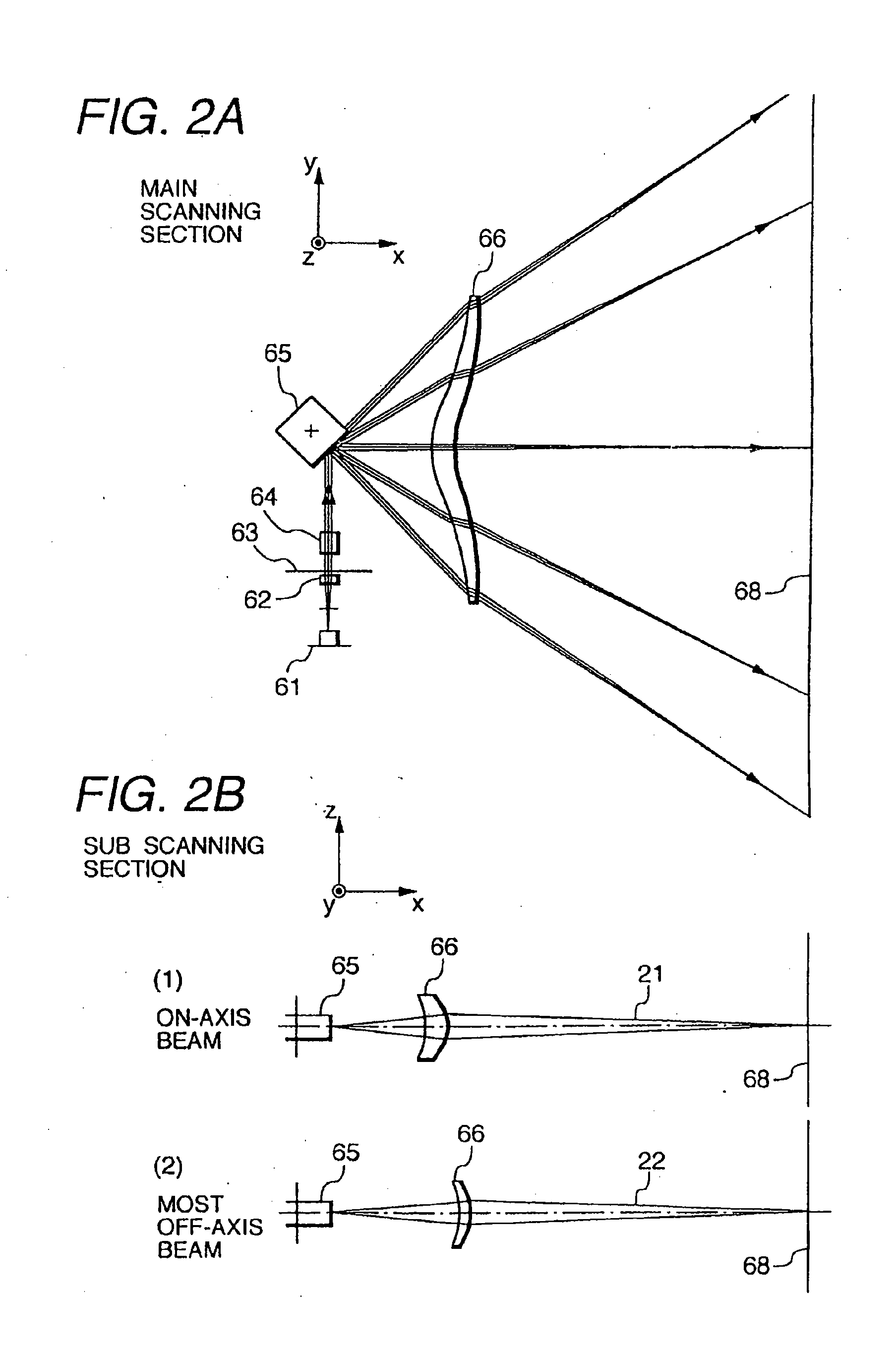

Scanning optical apparatus

InactiveUS20100141730A1High precision printingEliminate unevennessInking apparatusOther printing apparatusCamera lensLight beam

A scanning optical apparatus includes a light source, a deflecting element for deflecting a beam of light emitted from the light source, an optical device for causing the beam of light emitted from the light source to be imaged into a linear shape long in the main scanning direction on the deflecting surface of the deflecting element. The optical device is comprised of a first optical element and a second optical element, and a third optical element for causing the beam of light deflected by the deflecting element to be imaged into a spot-like shape on a surface to be scanned. The third optical element includes a single lens, the opposite lens surfaces of which both include a toric surface of an aspherical surface shape in the main scanning plane, the curvatures of the opposite lens surfaces in the sub scanning plane being continuously varied from the on-axis toward the off-axis in the effective portion of the lens.

Owner:CANON KK

An Adaptive Layering Method for 3D Printing

ActiveCN104503711BHigh precisionImprove Layering Efficiency3D object support structuresImage data processingSelf adaptive3d printer

The invention discloses a self-adaption layering method of 3D printing. The self-adaption layering method comprises the following steps: in a process that STL (Standard Template Library) model data is read, calculating layering height corresponding to a triangular patch according to a normal vector of each triangular patch; subsequently, according to the layering height of each triangular patch, calculating optimal layering height within any height range in a vertical direction, and establishing a layering height table (HT); and inquiring the HT to obtain the layering height required for a subsequent layering operation. The self-adaption layering method has the characteristics that layering efficiency is improved, high-precision layering outline data can be obtained, and reliable data support is provided for the high-efficiency and high-precision printing of a 3D printer.

Owner:SHINING 3D TECH CO LTD

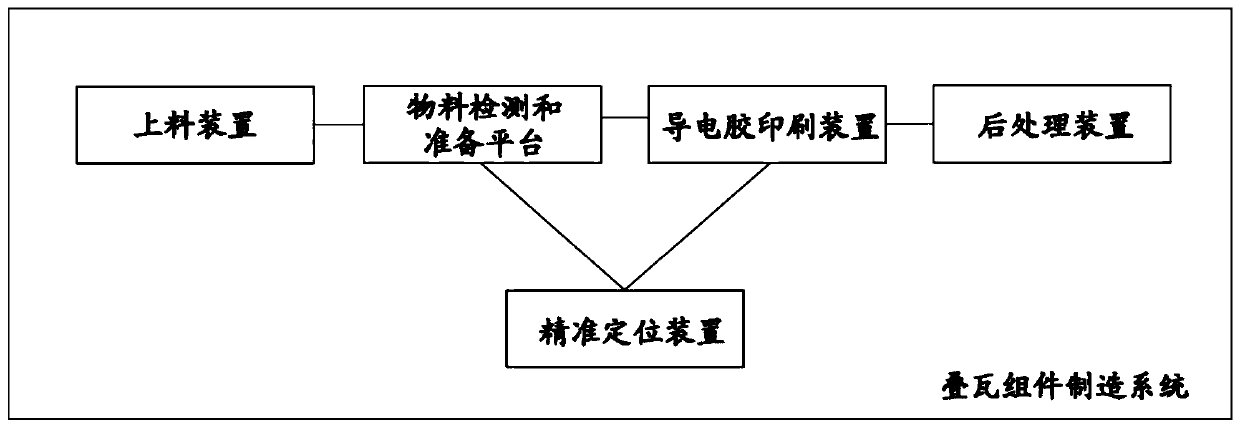

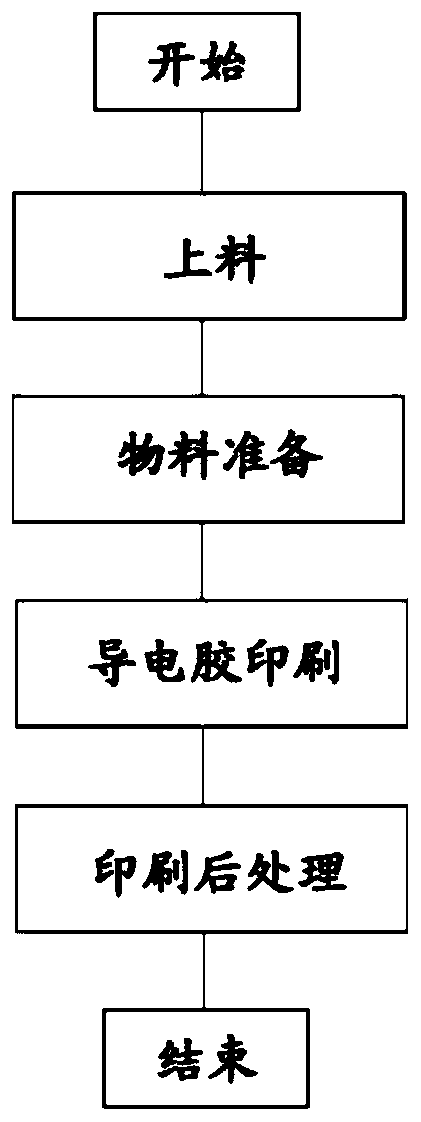

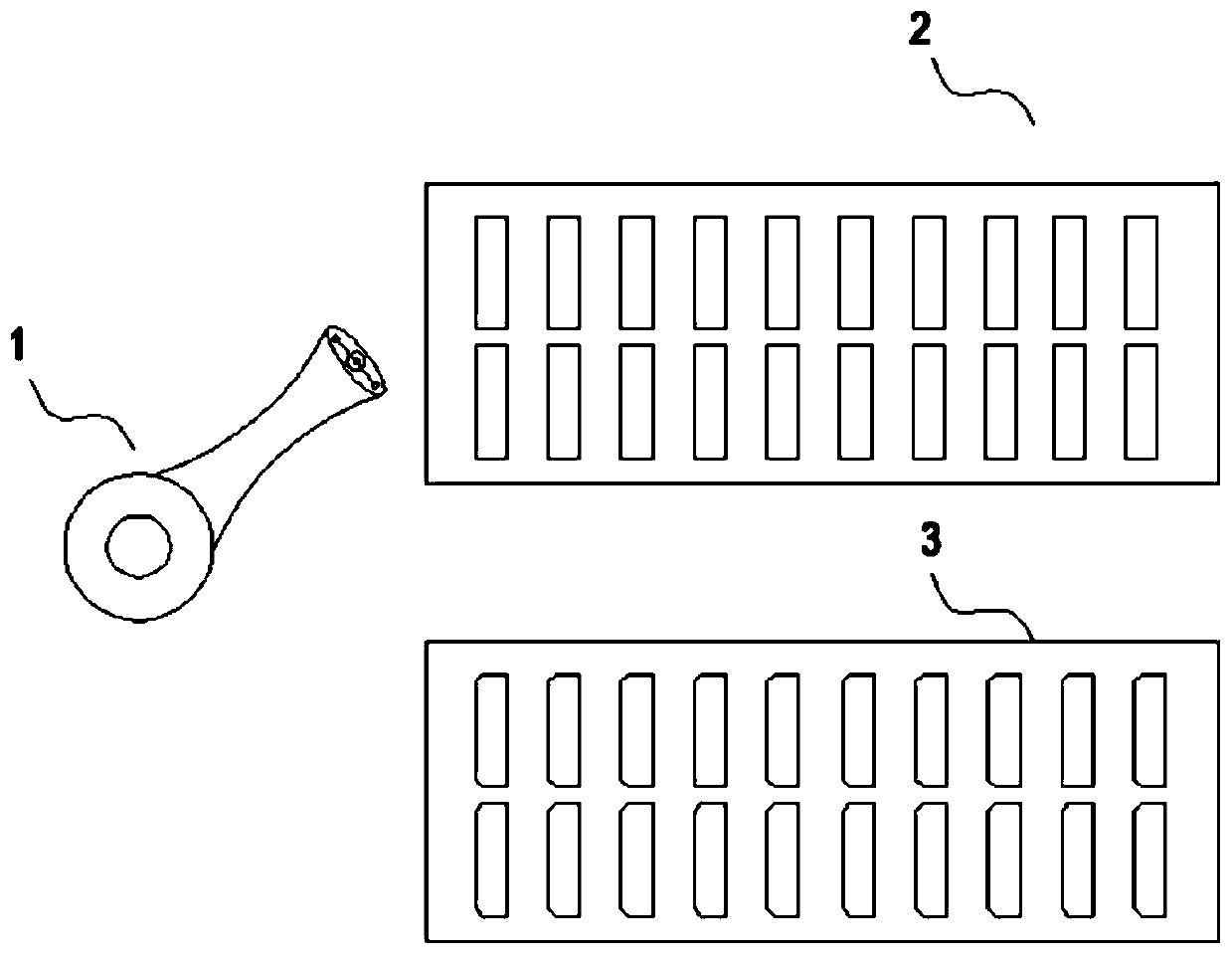

Tile assembly making system and method

PendingCN110289336AGuaranteed uniformityAvoid adding stringent process requirementsFinal product manufactureSemiconductor/solid-state device manufacturingMaterials preparationEngineering

The invention provides a tile assembly making system, which comprises a feeding device for supplying a cell slice, a material detecting and preparing device for performing visual detection and classification preparation on the cell slice, a conductive adhesive printing device with at least one carrying surface for printing the conductive adhesive on multiple cell slices at the same time, a post-processing device for performing subsequent processing on the cell slice after the conductive adhesive is printed on the cell slice, and an accurate positioning device for enabling the multiple cell slices to be aligned and positioned on the at least one carrying surface. The invention also provides a making method by adopting the making system, which comprises steps of feeding, material preparation, conductive adhesive printing and printing post-processing. Low-cost and high-efficiency scale mass production can be realized, accurate patching can be ensured, and the uniformity of online mixing of the conductive adhesive can also be ensured.

Owner:CHENGDU YEFAN SCI & TECH CO LTD

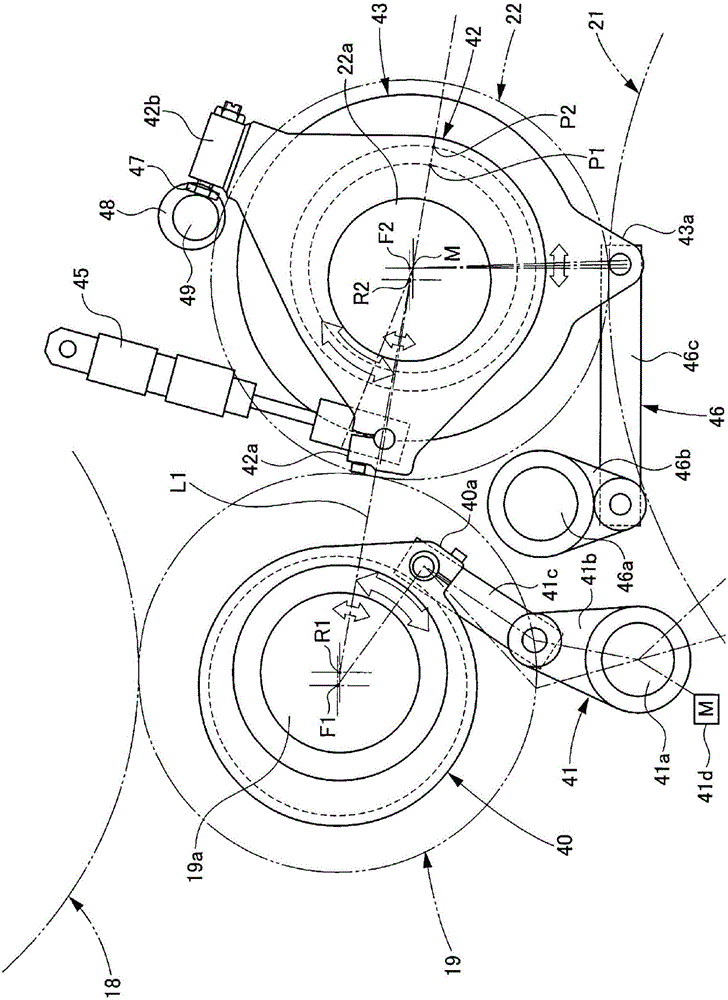

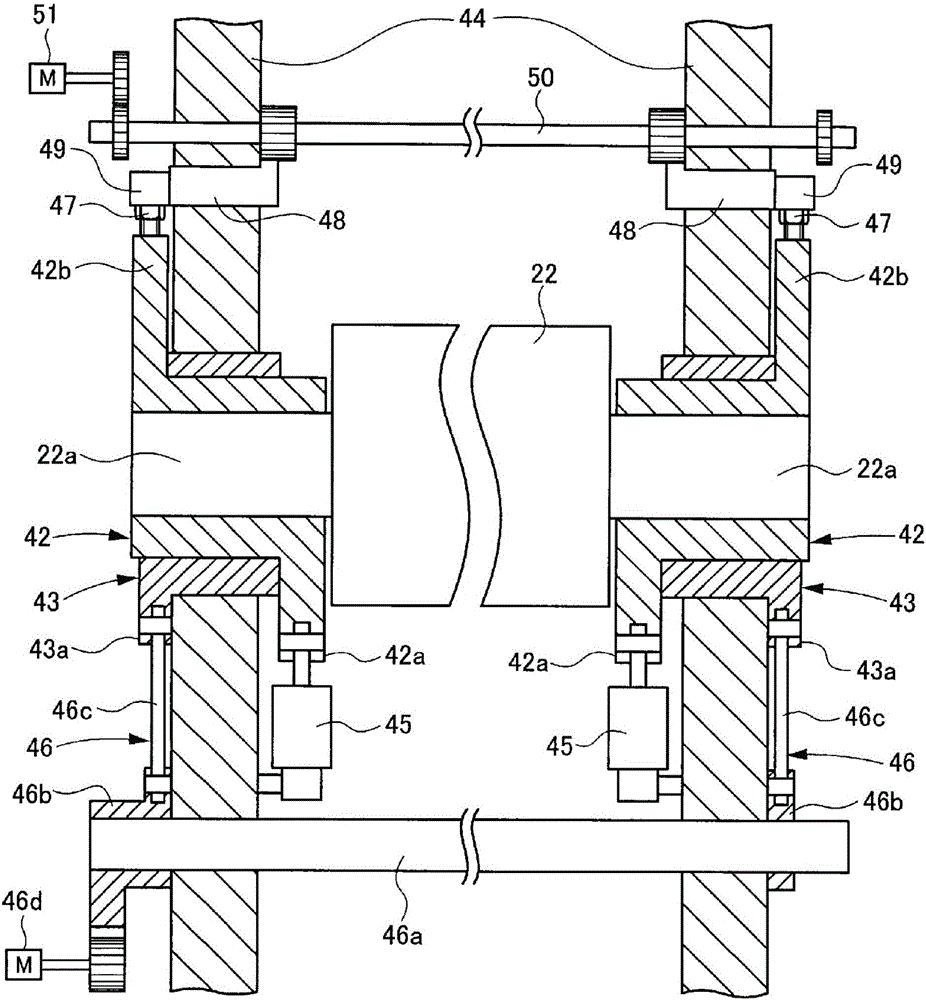

Cylinder device for printing press

InactiveCN106457817AAdjust printing pressureSimple structureRotary pressesHydraulic cylinderEngineering

Provided is a cylinder device for a printing press, which is simple in configuration, and with which the printing pressure in at least three cylinders can be adjusted in a highly accurate manner. The device is provided with: a collecting plate cylinder (22) supported so as to be capable of moving towards or away from a collecting blanket cylinder (21) and a blanket cylinder (19); an eccentric inner metal (42) that rotatably supports the collecting plate cylinder (22), and that by rotating moves the collecting plate cylinder (22) towards or away from the collecting blanket cylinder (21); a hydraulic cylinder (45) that rotates the eccentric inner metal (42); an eccentric outer metal (43) that axially supports the eccentric inner metal (42), and that by rotating moves the collecting plate cylinder (22) towards or away from the blanket cylinder (19); a drive device (46) for rotating the eccentric outer metal (43); a stopper (49) provided to a main machine frame (44); and an adjustment bolt (47) provided to the eccentric inner metal (42), for abutting the stopper (49) when the collecting plate cylinder (22) moves towards the collecting blanket cylinder (21).

Owner:KOMORI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com