Solder ball printing apparatus

A technology of solder balls and supply parts, applied in the direction of tin feeding devices, auxiliary devices, welding equipment, etc., can solve problems such as difficult to supply in any amount, blockage of granular materials, reduction of measurement accuracy, etc., and achieve the effect of avoiding large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

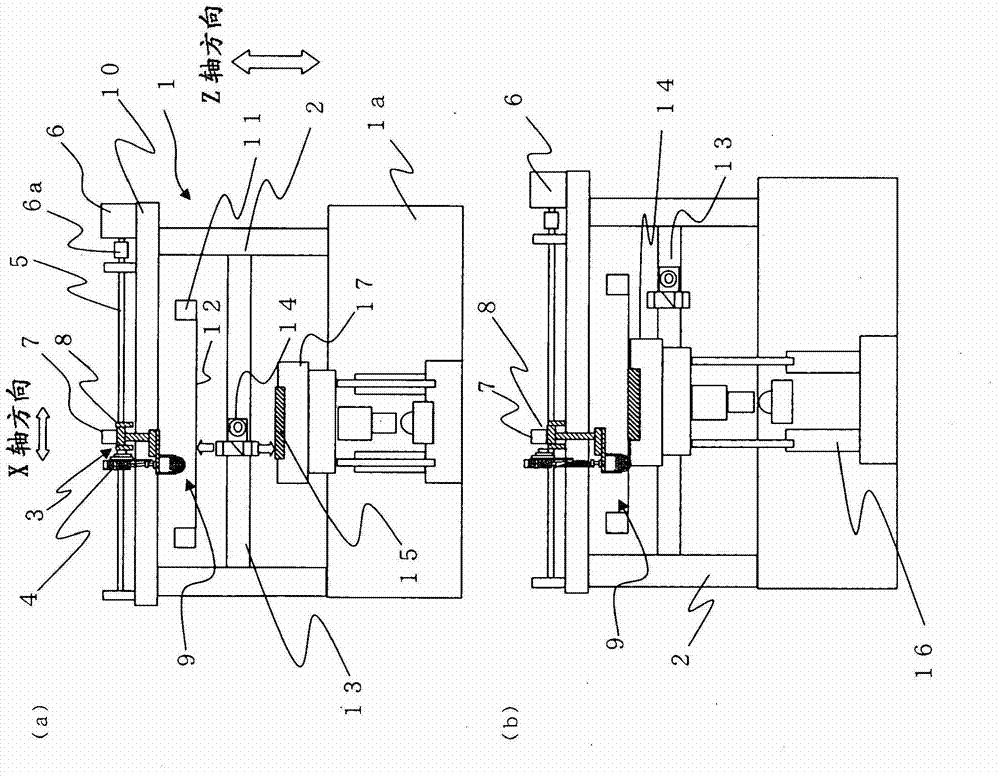

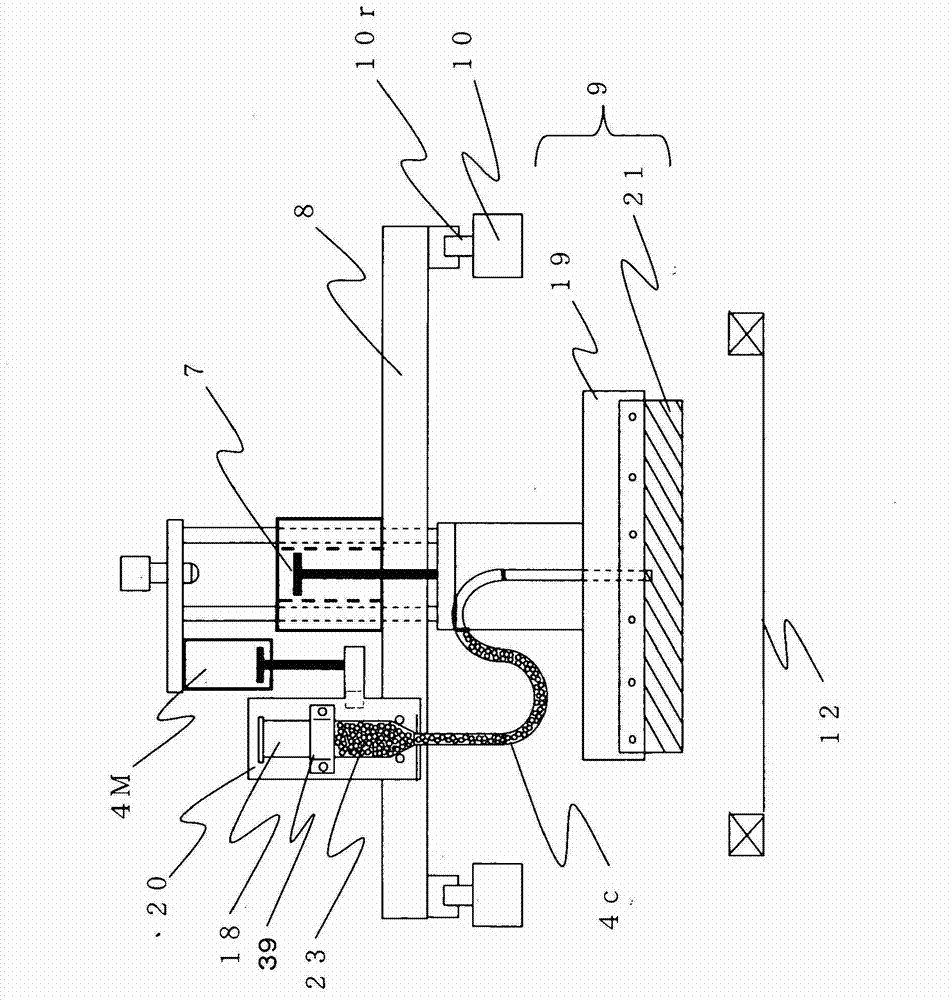

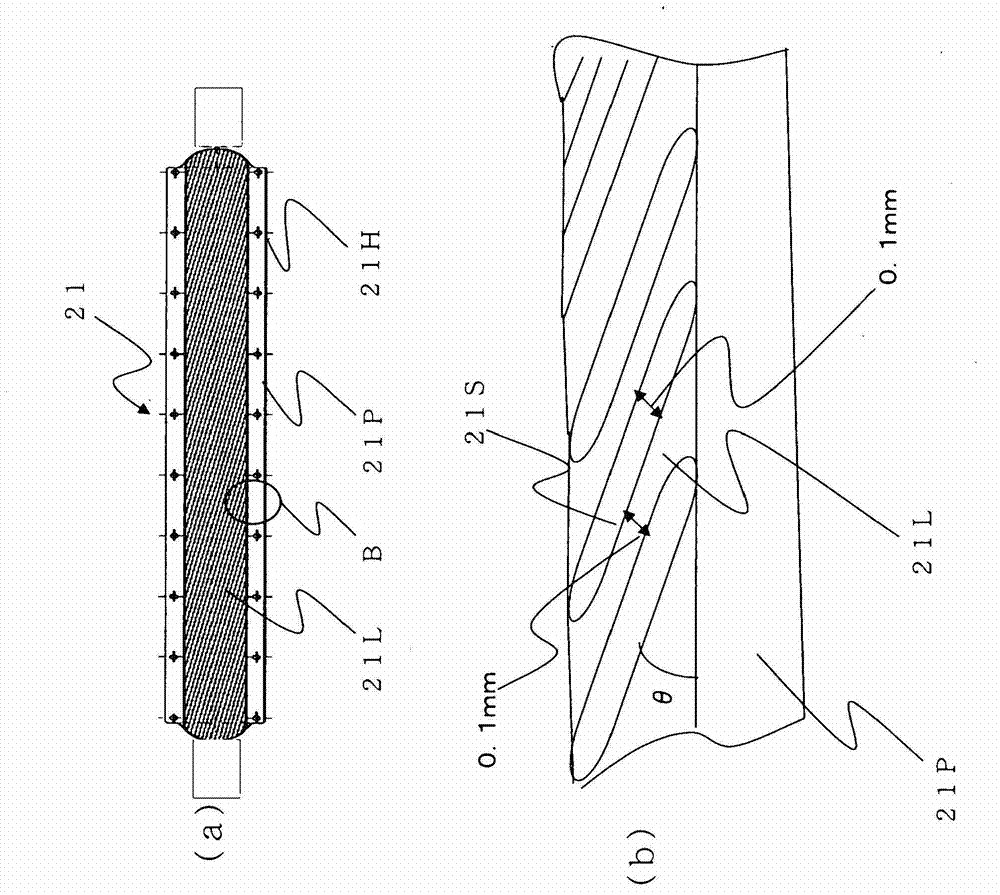

[0026] Hereinafter, the present invention will be described using the drawings. figure 1 The overall structure of the solder ball printer of the present invention is shown. figure 1 (a) represents the state before filling the solder balls, figure 1 (b) shows the state where solder balls are being filled. figure 2 It shows the state separated from the mask surface in the configuration diagram of the head portion for solder ball printing. image 3 It is a figure which shows the state which the solder ball supply part contacted with the mask surface. Figure 4 It is a figure which shows the state which supplies a solder ball from a solder ball supply part to a mask surface.

[0027] Such as figure 1 As shown, the solder ball printing machine 1 is provided with a support 2 , and a moving beam 10 for the solder ball filling head 3 to move horizontally on the surface of the mask 12 is arranged on the upper part of the support 2 . The head table 8 provided with the solder ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com