Liquid processing apparatus and method thereof

A technology for liquid treatment and liquid treatment, applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

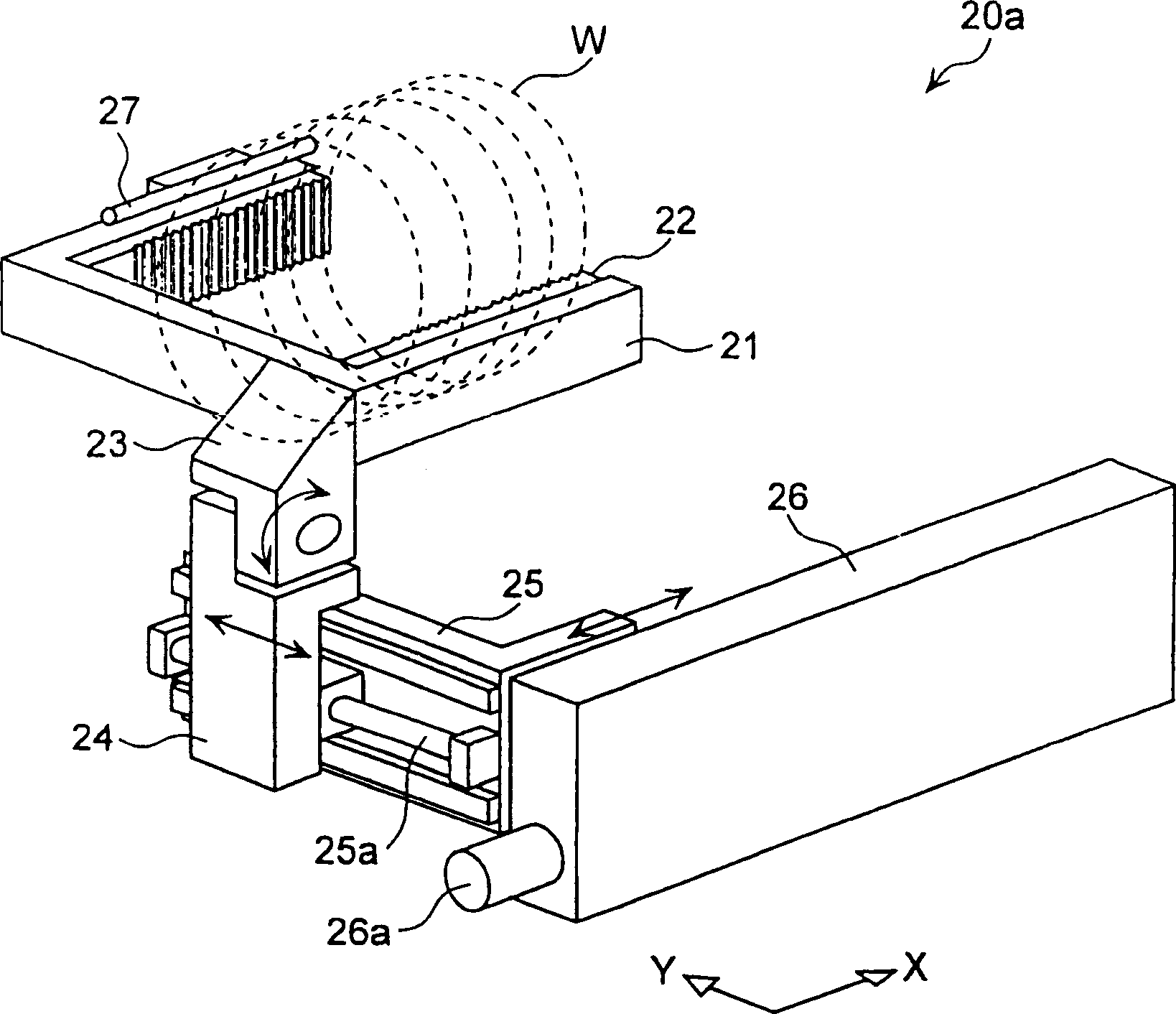

[0048] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Here, it is assumed that a description is given of applying the present invention to a cleaning processing apparatus configured to transport semiconductor wafers (wafers) in batches in series? cleaning? dry.

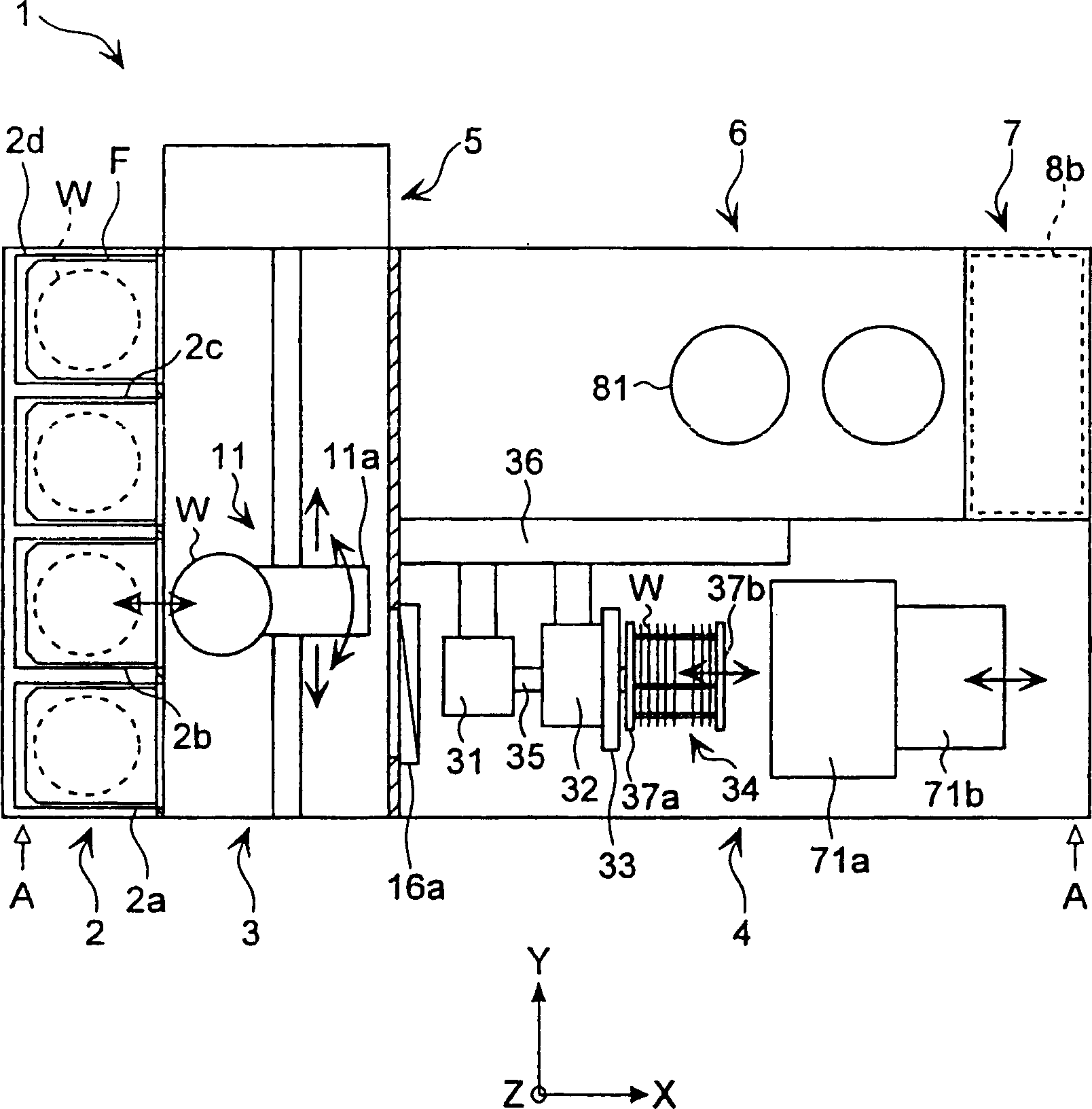

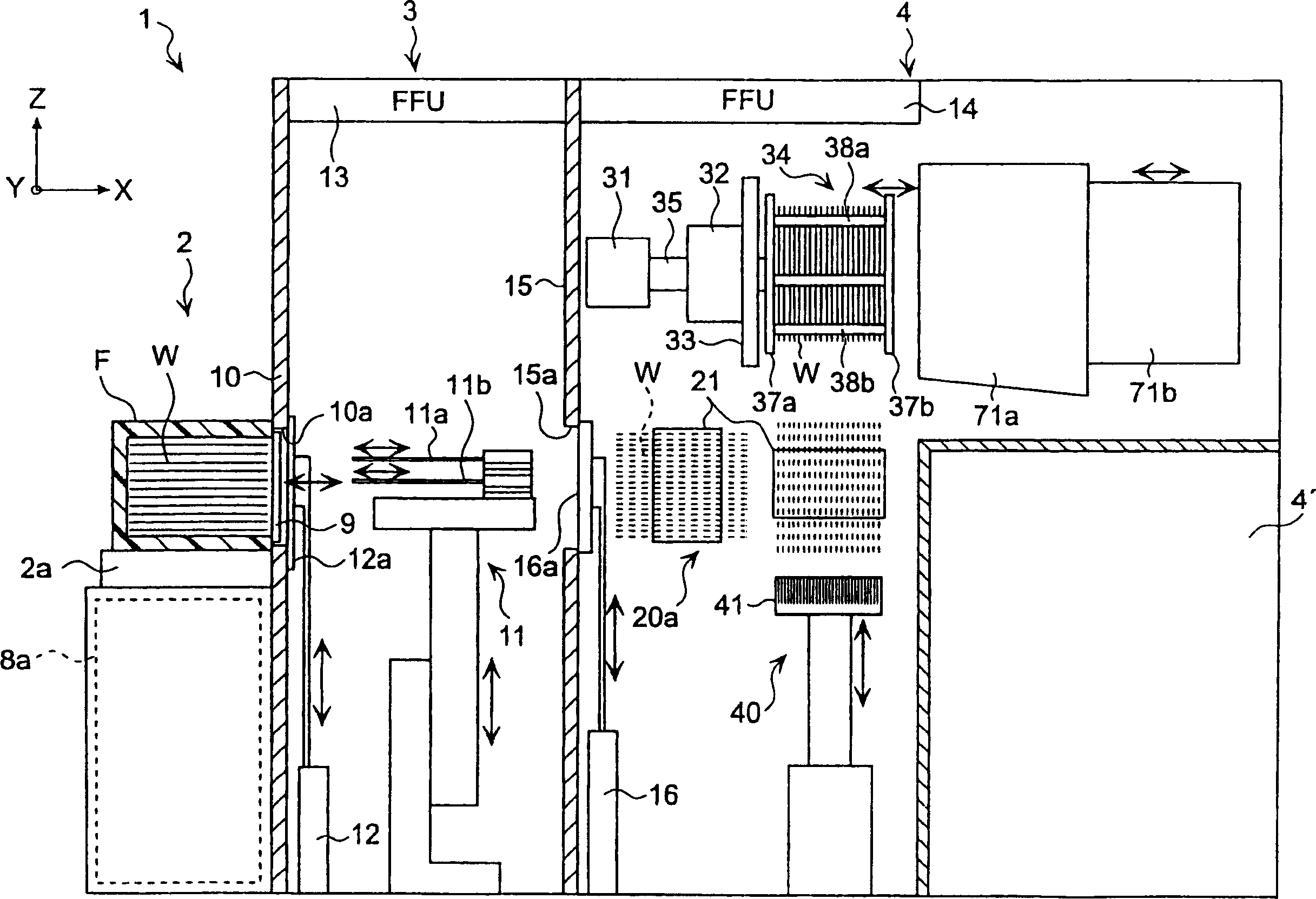

[0049] figure 1 It is a side view showing the outline of the cleaning treatment device 1, figure 2 From figure 1 A schematic side view seen in the direction of arrow AA shown in . The cleaning processing apparatus 1 includes: a hoop loading / unloading unit 2 on which a hoop (carrier) F for accommodating a wafer W is mounted; a cleaning processing unit 4 for performing cleaning processing on the wafer W; Wafer transfer unit 3 for transferring wafer W to and from cleaning unit 4, power unit 5 for various electric drive mechanisms or electronic control devices installed in cleaning unit 1, storage and supply of chemical solutions for cleaning treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com