A vacuum filtering apparatus and an operating method thereof

A technology of a filtering device and an operating method, applied in the field of pre-coating vacuum filtering devices, can solve the problems of time limit of analysis, difficult data selection, productivity, uneconomical cost, etc., to avoid large-scale, realize cost and Effect of waste and reduction in the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

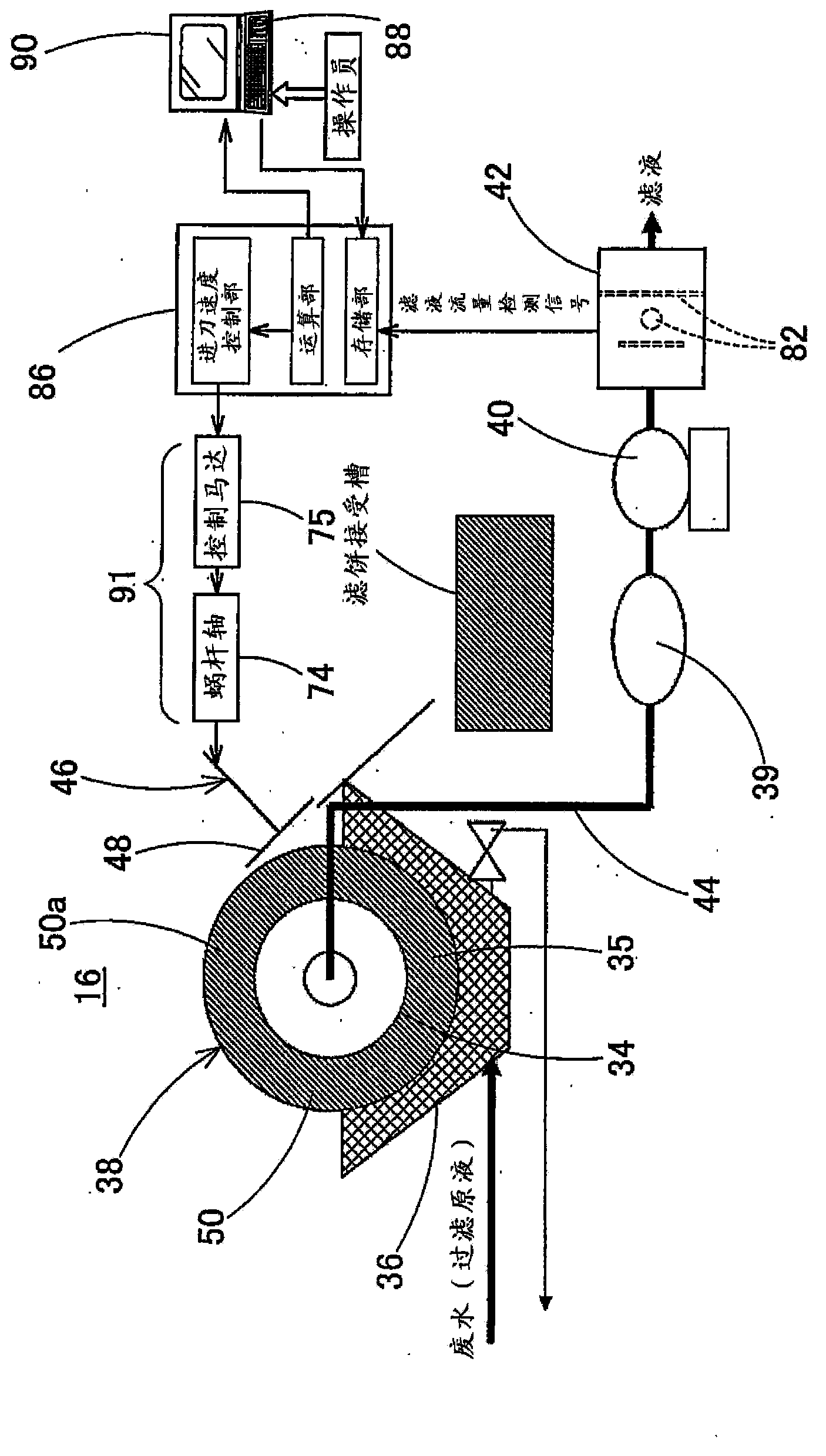

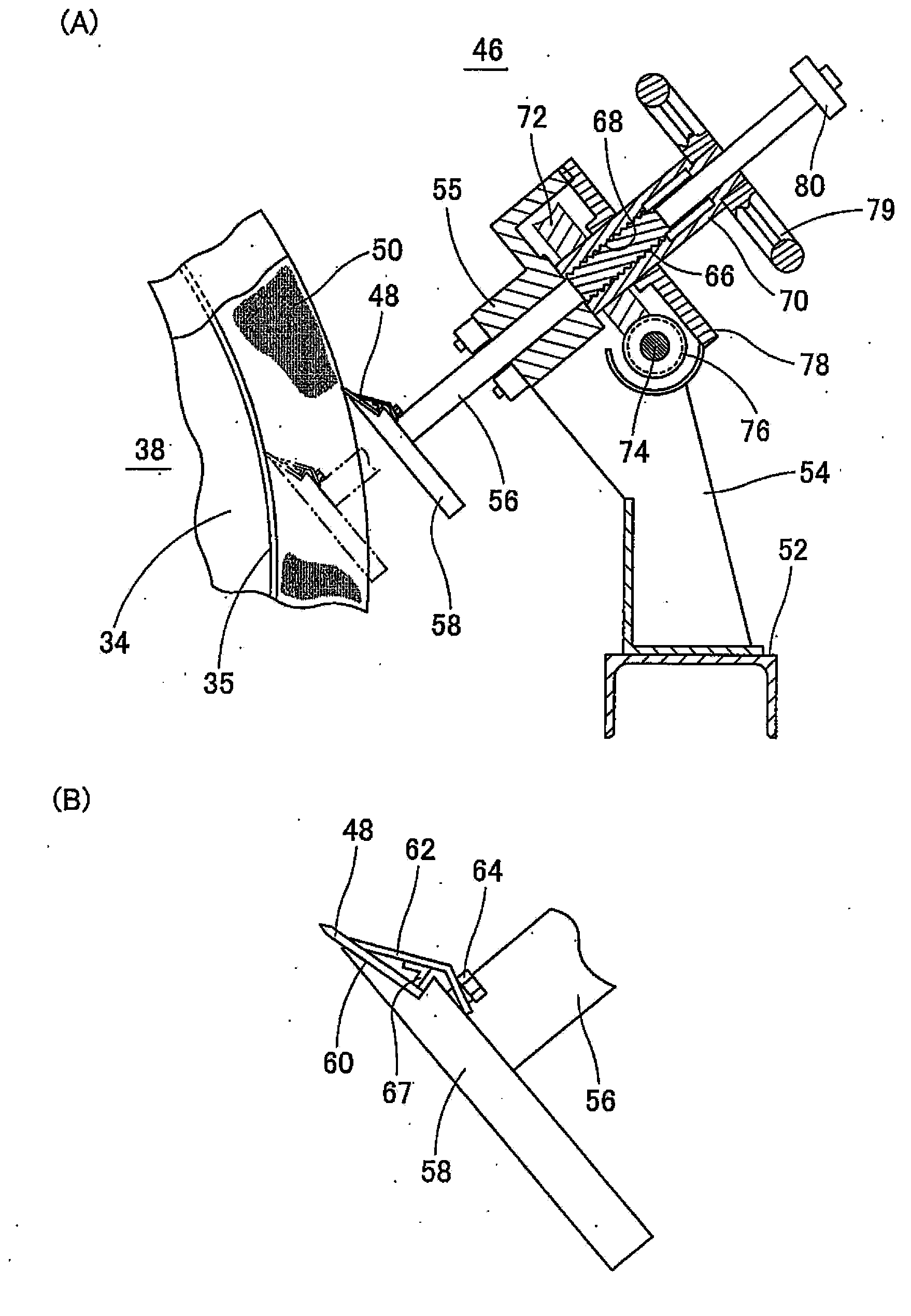

[0042] below, in figure 1 , figure 2 In the wastewater treatment system shown, in order to apply the present invention to have image 3 The case of a pre-coated vacuum filter with a scraper device shown is explained as an example.

[0043]

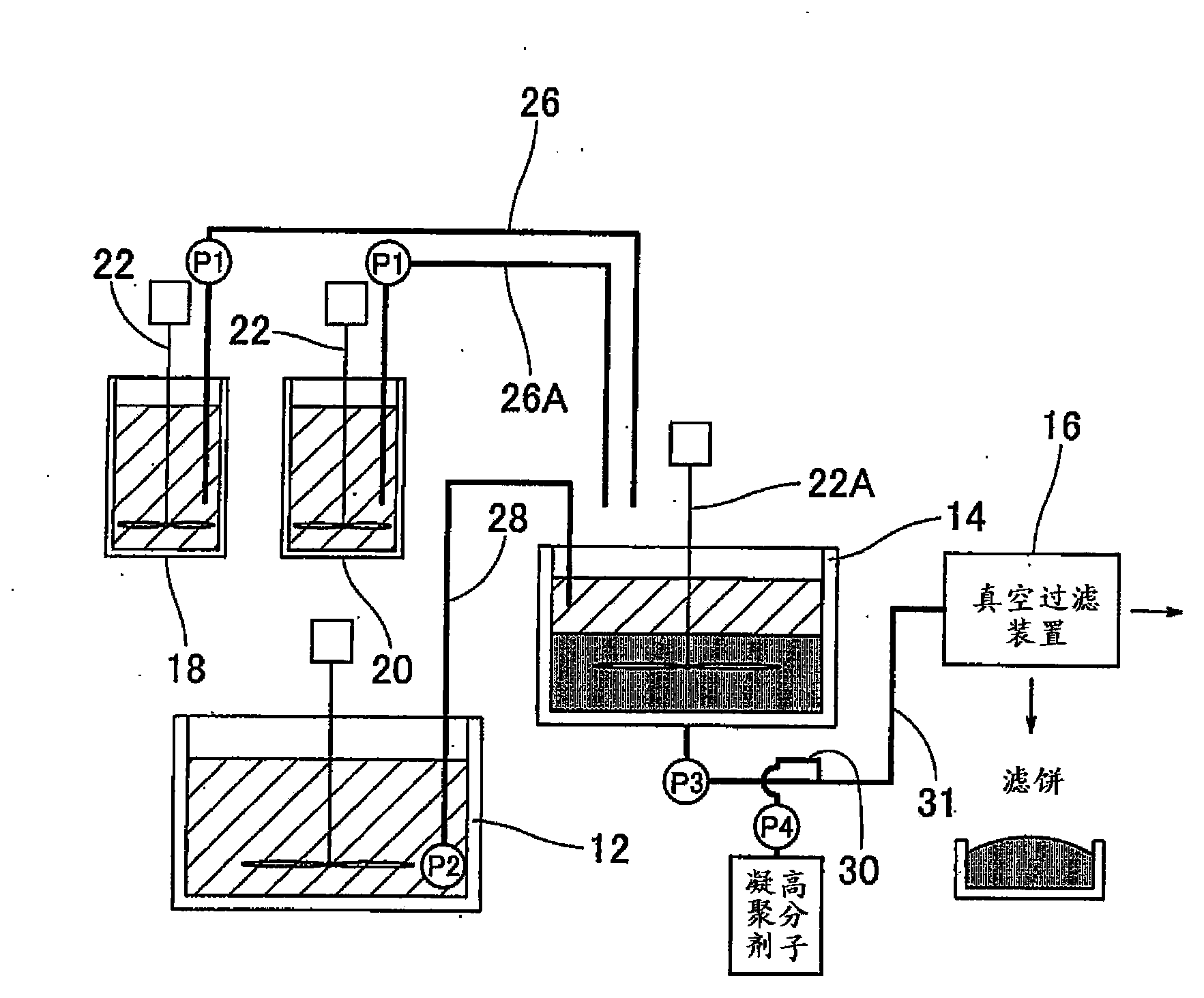

[0044] exist figure 1An example of a flow diagram of a wastewater treatment system is shown in . This flowchart assumes treatment of waste water such as grinding waste water, acid waste water, and flexographic printing ink waste water.

[0045] A waste water tank 12, a reaction tank 14, and a vacuum filter 16 are provided as a basic structure. In addition, an alkali solution tank 18 and an inorganic coagulant tank 20 are attached to the reaction tank 14 .

[0046] In this embodiment, slaked lime (Ca(OH) 2 ) water dispersion, aluminum sulfate (Al 2 (SO 4 ) 3 ·nH 2 O), PAC (Al 2 (OH) n C 16-n ) and other aqueous dispersions. In addition, these respective tanks 18 and 20 are provided with agitators 22 and 22 , and supply pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com