Silk screen printing device and printing method thereof

A technology of screen printing device and mask, which is applied in the direction of screen printing machine, printing device, printing, etc., can solve the problems of large-scale devices, time-consuming, and large chambers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

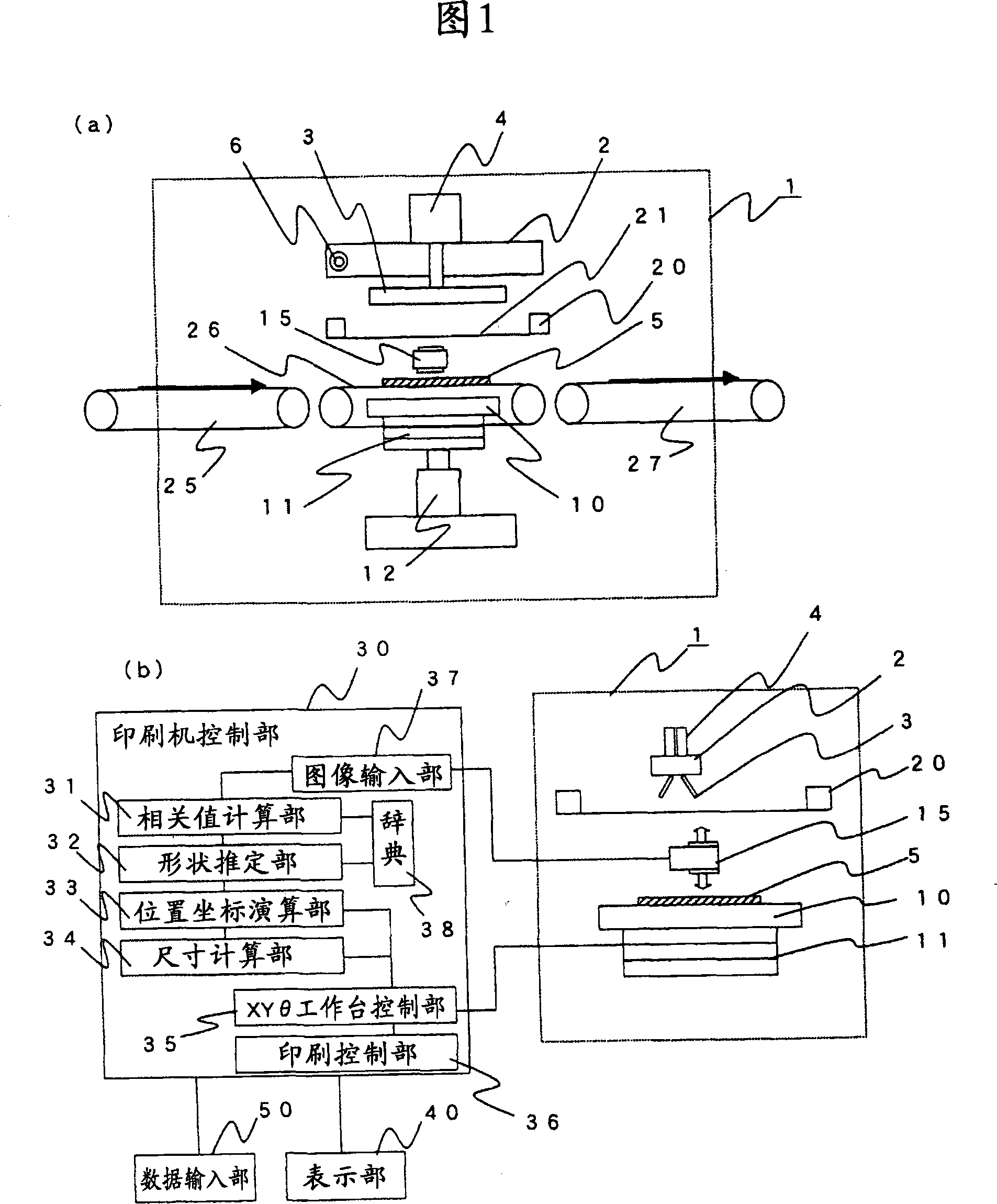

[0018] FIG. 1 shows the outline of the overall configuration of the screen printing device.

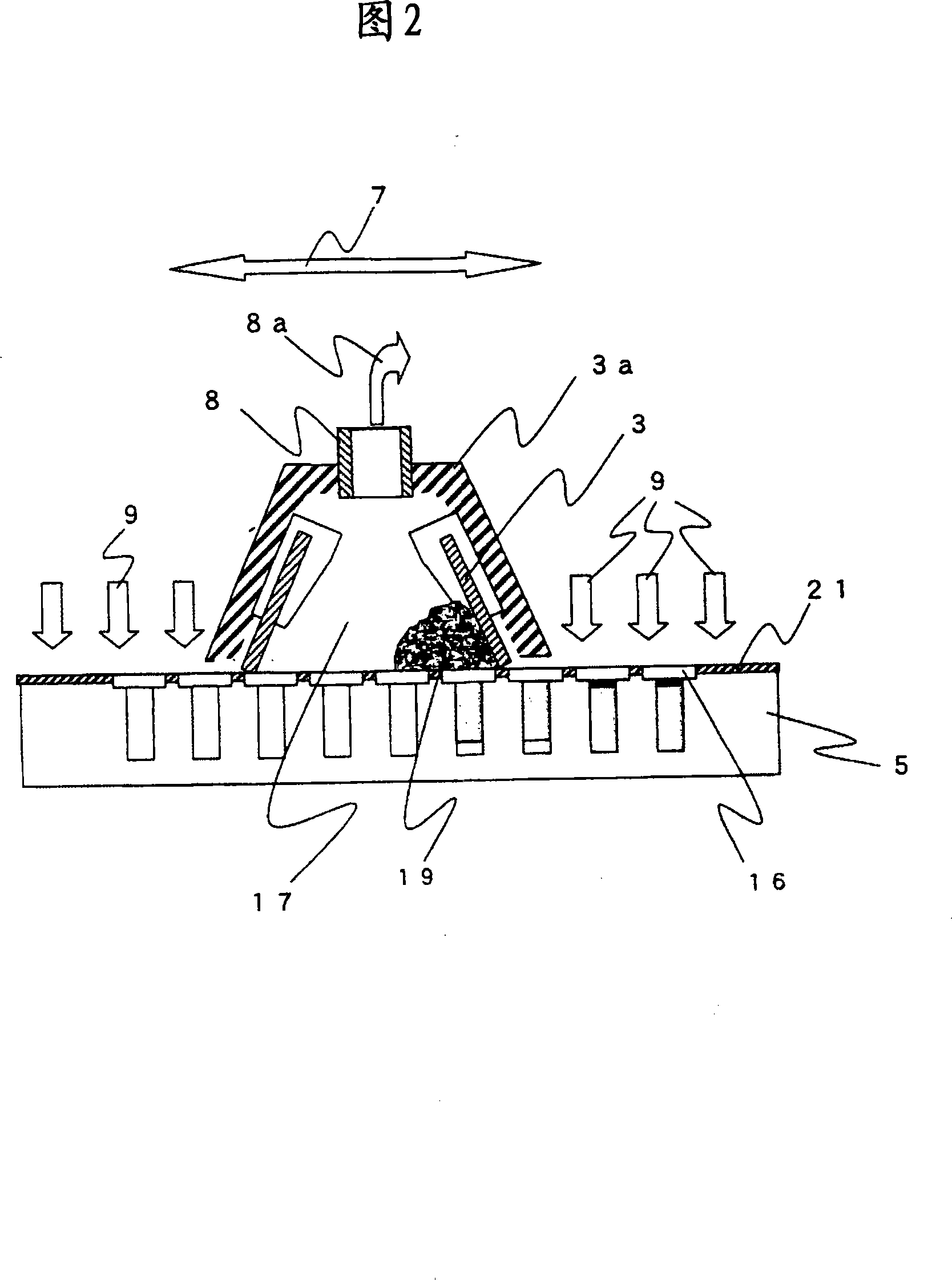

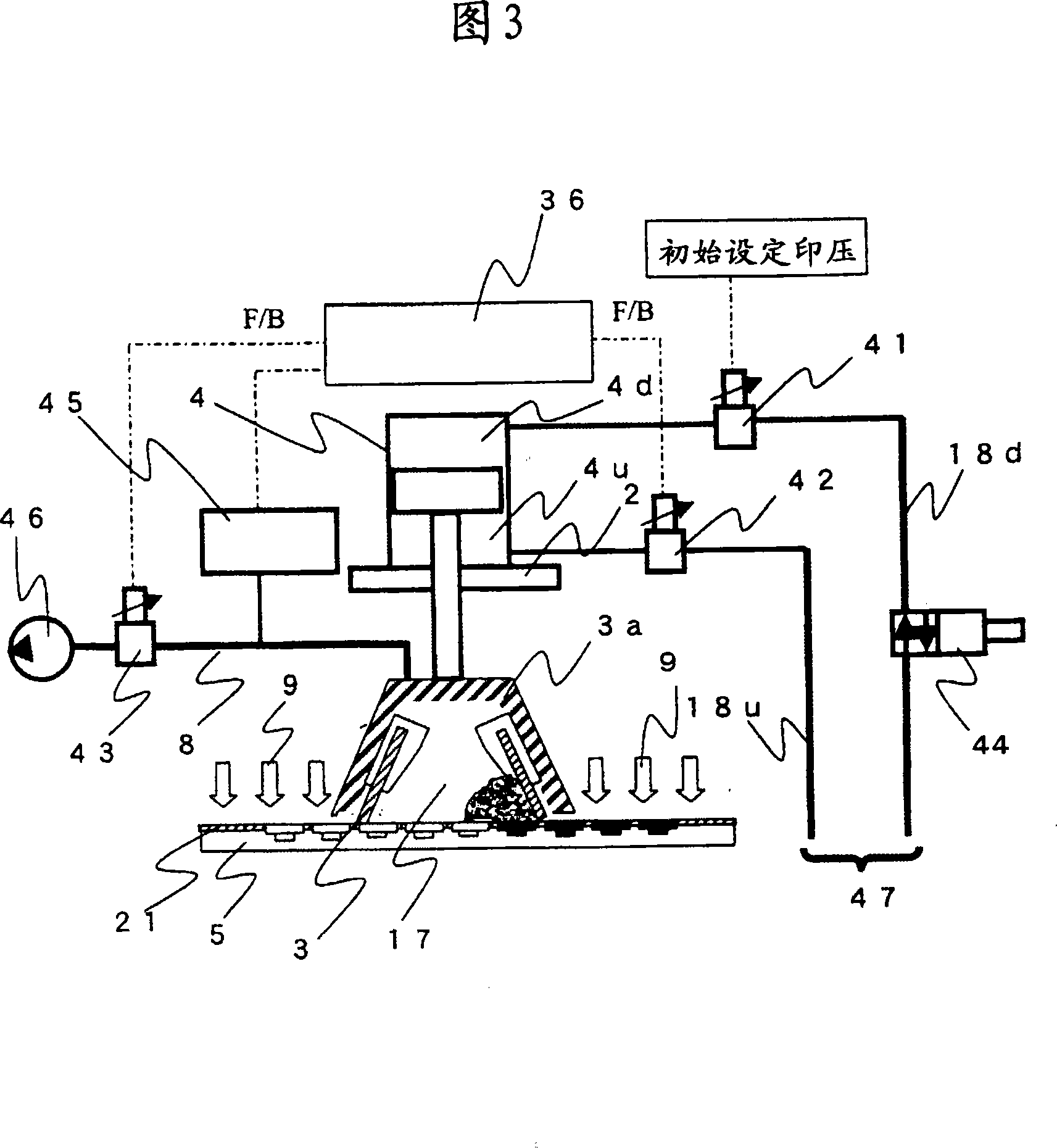

[0019] On the main body frame of the screen printing machine 1 of the present invention, a plate frame support member not shown in the figure is set, and a mask 20 with a screen 21 hanging on it is set on the plate frame support member (including the screen screen below, and also with the mask In the case of the mold being described together), the screen 21 has a printed pattern as an opening. A squeegee head 2 is arranged above the mask 20 , and a squeegee 3 is attached to the squeegee head 2 . The squeegee head 2 can move in the horizontal direction through the squeegee moving mechanism 6 , and the squeegee 3 can move in the up and down direction through the squeegee lifting mechanism 4 . In this embodiment, an example in which an air cylinder is used for the doctor blade lifting mechanism 4 is shown (hereinafter, the doctor blade lifting mechanism may simply be referred to as an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com