Tile assembly making system and method

A technology for manufacturing systems and components, applied in semiconductor/solid-state device manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limited weight of conductive adhesives, ineffective mixing of conductive adhesives, uneven glue, etc. The effect of adding slurry too frequently, large-scale mass production with low cost and high efficiency, and increasing the number of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings in the manner of specific embodiments, but the present invention is not limited to these embodiments.

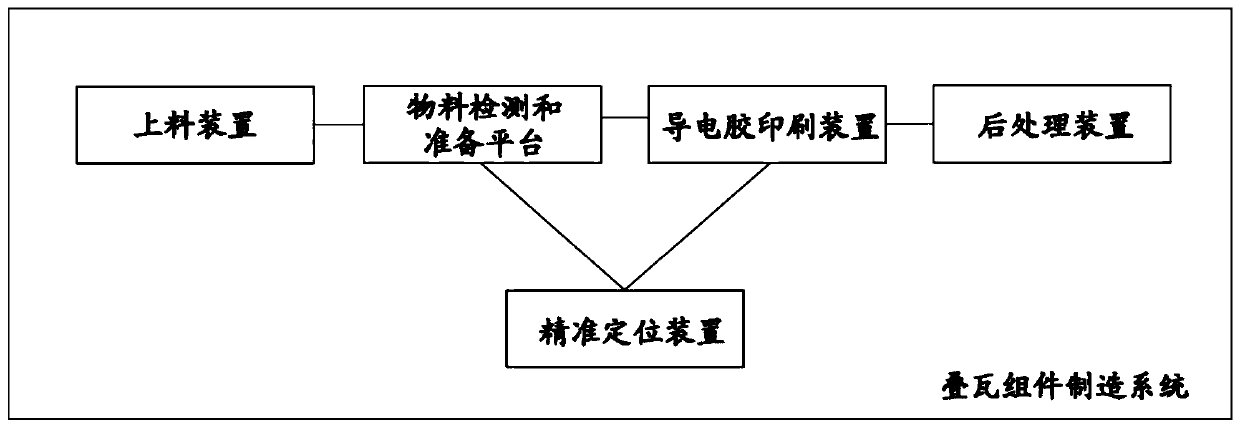

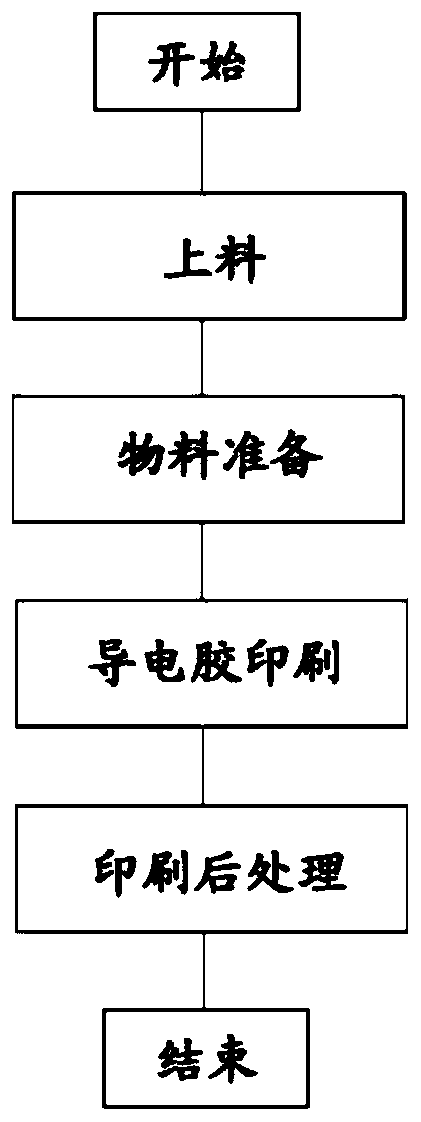

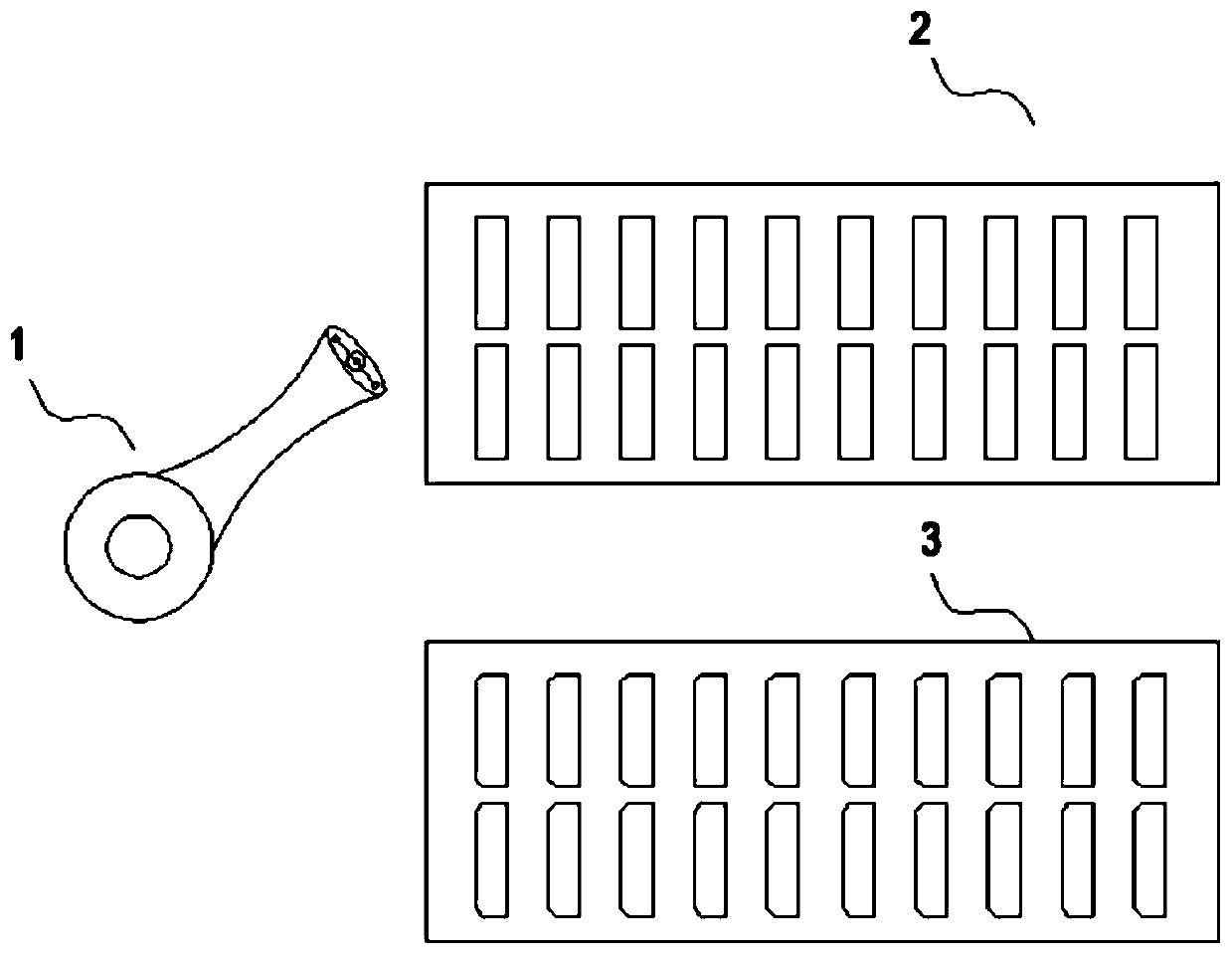

[0059] The system and method for manufacturing shingled components of the present invention provide a solution to upgrade the conventional screen printing process of shingling to printing multiple small or large cells at one time, that is, to make batteries in the core process of shingling The stringing link provides a solution for printing n shingled batteries at a time, that is, in the core process, the shingled large or small battery sheets are printed synchronously with 1 to n smallest printing units to complete the bonding of shingled batteries and make them into strings. Finally, high-efficiency, large-scale and precise shingled battery printing and patching will be realized. Among them, shingled cells 1~n and shingled single-polycrystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com