An Adaptive Layering Method for 3D Printing

A 3D printing and self-adaptive technology, applied in the field of 3D printing, can solve the problems of low accuracy of layered contour data and low layering efficiency, and achieve the effect of improving layering efficiency and reliable data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

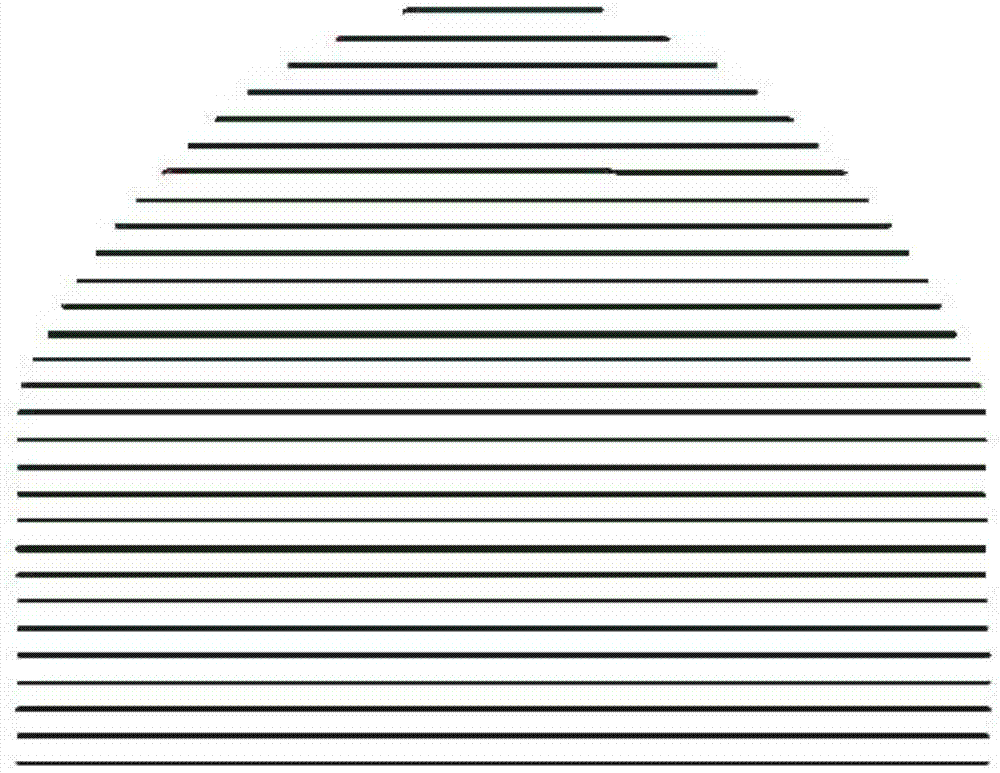

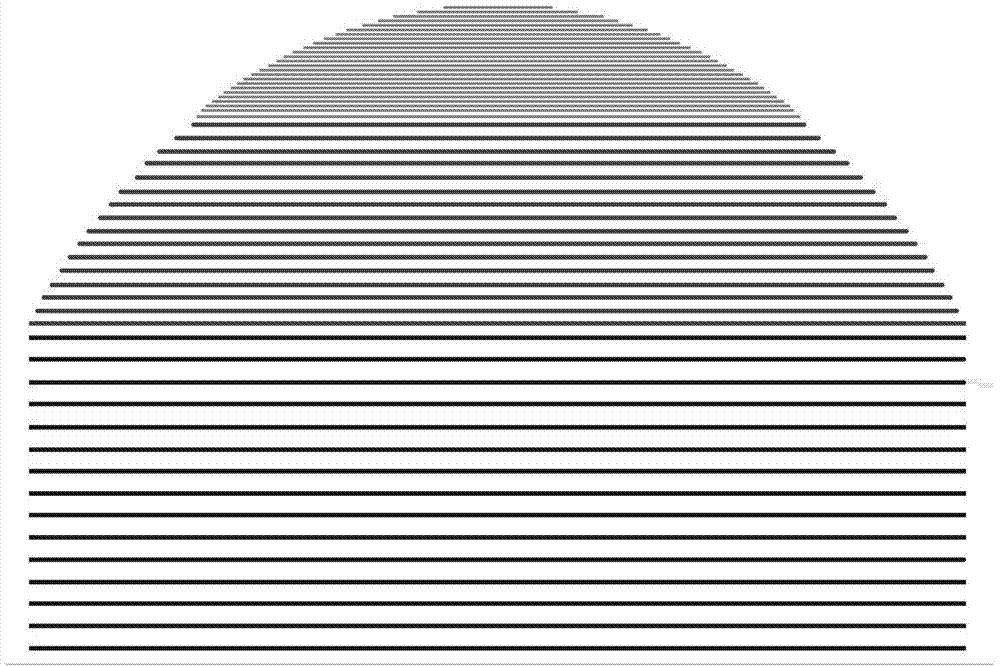

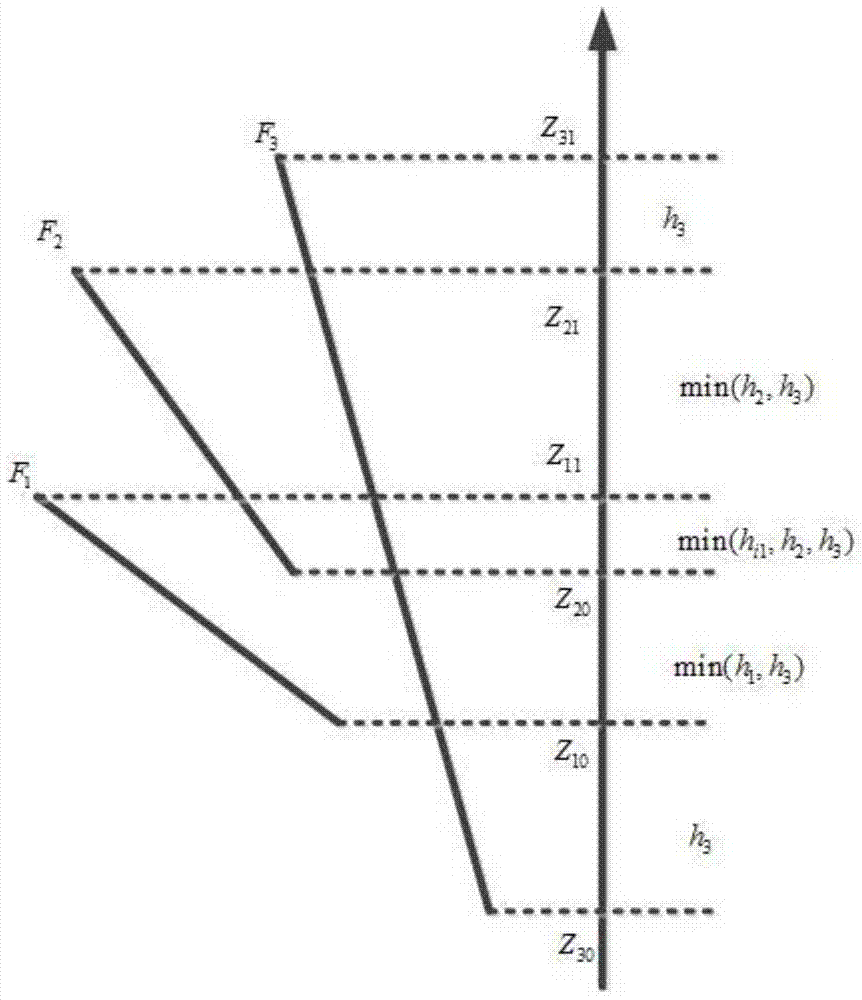

[0039] Such as Figure 4 The illustrated embodiment is an adaptive layering method for 3D printing, comprising the following steps:

[0040] Step 100, storing the STL model data of the sphere W to be printed in the computer, the STL model data includes 1000 triangular faces F i (i∈1000), the normal vector n corresponding to each triangle i , and the height range interval corresponding to each triangle patch [Z i0 ,Z i1 ];

[0041] Step 200, the computer reads the STL model data, and calculates the maximum values Z of 1000 height range intervals i1 , each minimum value Z i0 The total minimum value Z in min and total maximum Z max ;

[0042] Step 300, the computer reads the normal vector n of each triangle surface i , set the layering direction as the positive direction of the Z axis, the unit direction vector of the Z axis is Z(0,0,1), and the computer uses the formula Calculate n triangular faces F respectively i The angle α between the normal vector of and the po...

Embodiment 2

[0057] In embodiment 2, use h i =a 1 alpha i +b 1 instead of in Example 1 Among them, a 1 is 0.7, b 1 Be 0.1 millimeter; Other steps in the embodiment 2 are partly the same as in the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com