Paper feed mechanism

A paper feeding mechanism and paper feeding technology, applied in printing, printing device, object supply, etc., can solve the problems of waste of recording paper 44, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

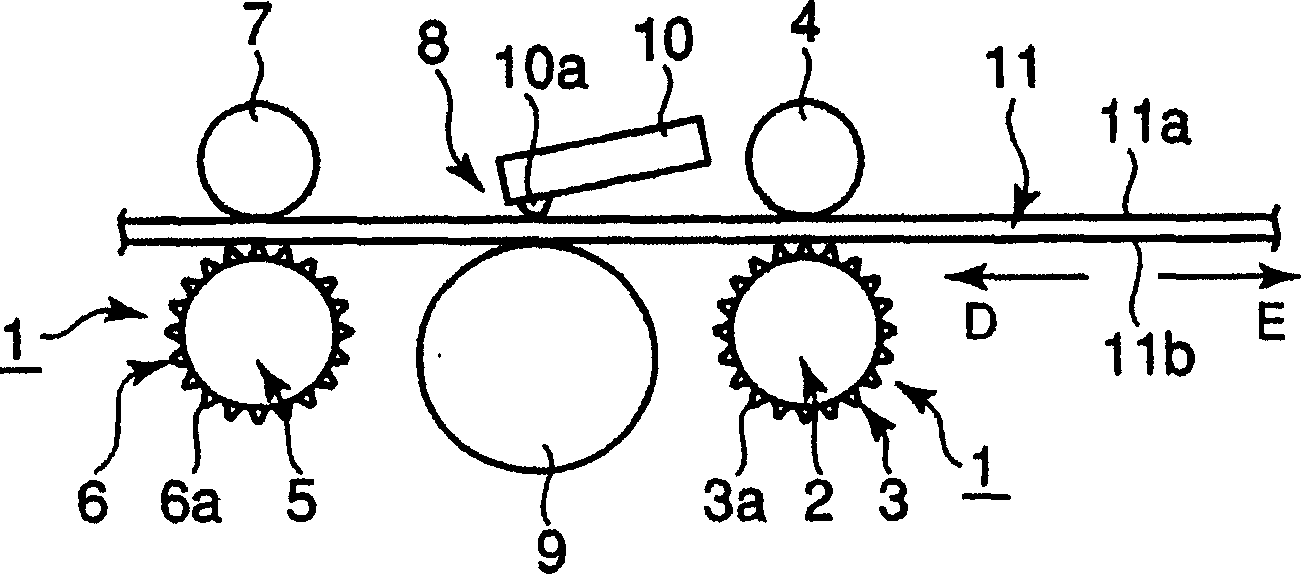

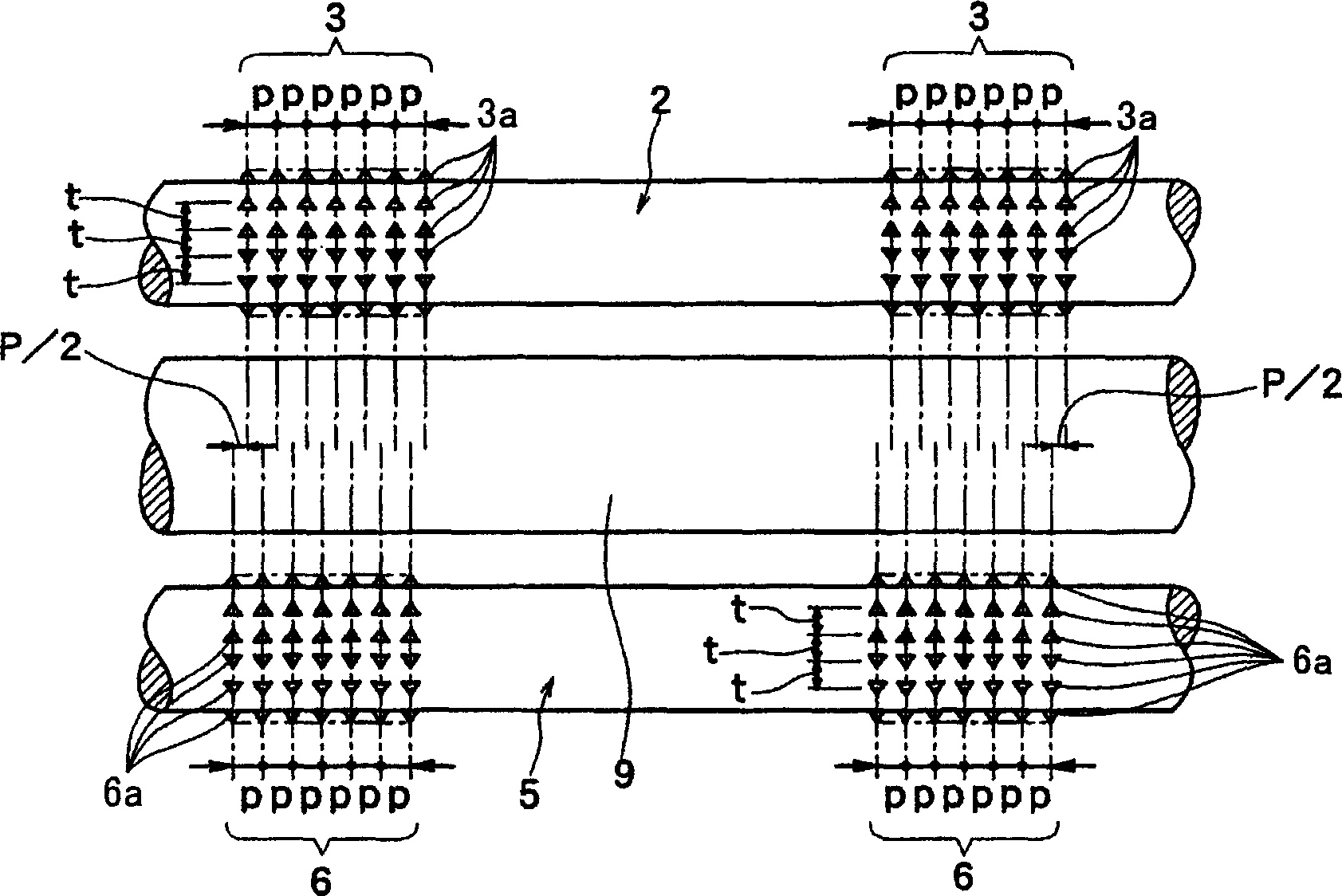

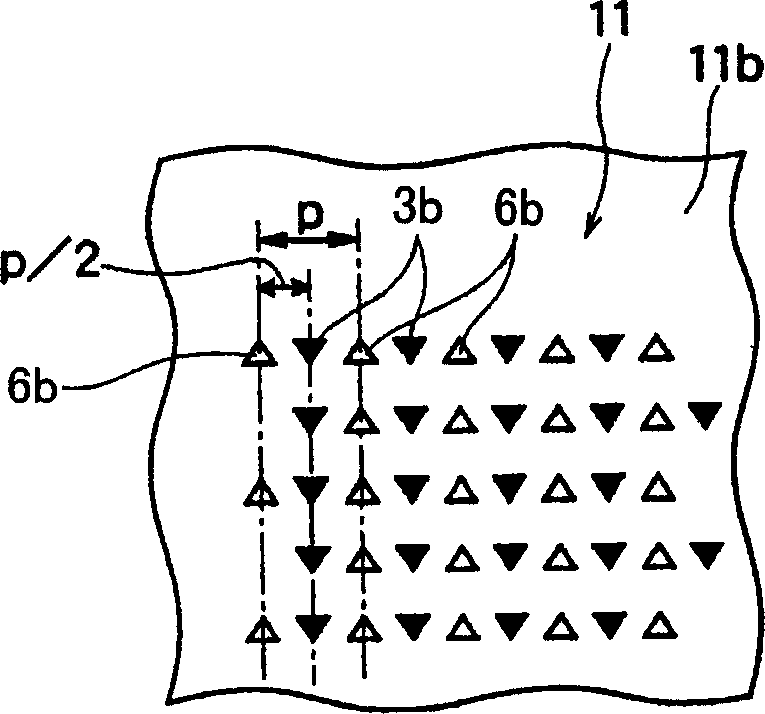

[0048] Hereinafter, the paper feeding mechanism of the present invention will be described based on the drawings. figure 1 is a schematic diagram of a printer using the paper feeding mechanism of the present invention, figure 2 It is a schematic diagram illustrating the positional relationship between the first and second paper feed rollers according to the first embodiment of the present invention, image 3 , Figure 4 It is a schematic diagram explaining the mark produced by the protrusion formed in the paper feed roller of the 1st Embodiment of this invention, Figure 5 is a schematic diagram illustrating another embodiment of the first embodiment, Image 6 is a schematic diagram illustrating the first and second paper feed rollers according to the second embodiment of the present invention, Figure 7 , Figure 8 It is a schematic diagram explaining the marks produced by the protrusions of the first and second paper feed rollers in the second embodiment, Figure 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com