Micro-projection photo-curing printing device and method with doubled single-time printing area

A printing device and photo-curing technology, which is applied in the direction of additive manufacturing, additive processing, metal processing equipment, etc., can solve the problems of cost increase, and achieve the effects of reducing process cost, simplifying structure, and simple assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

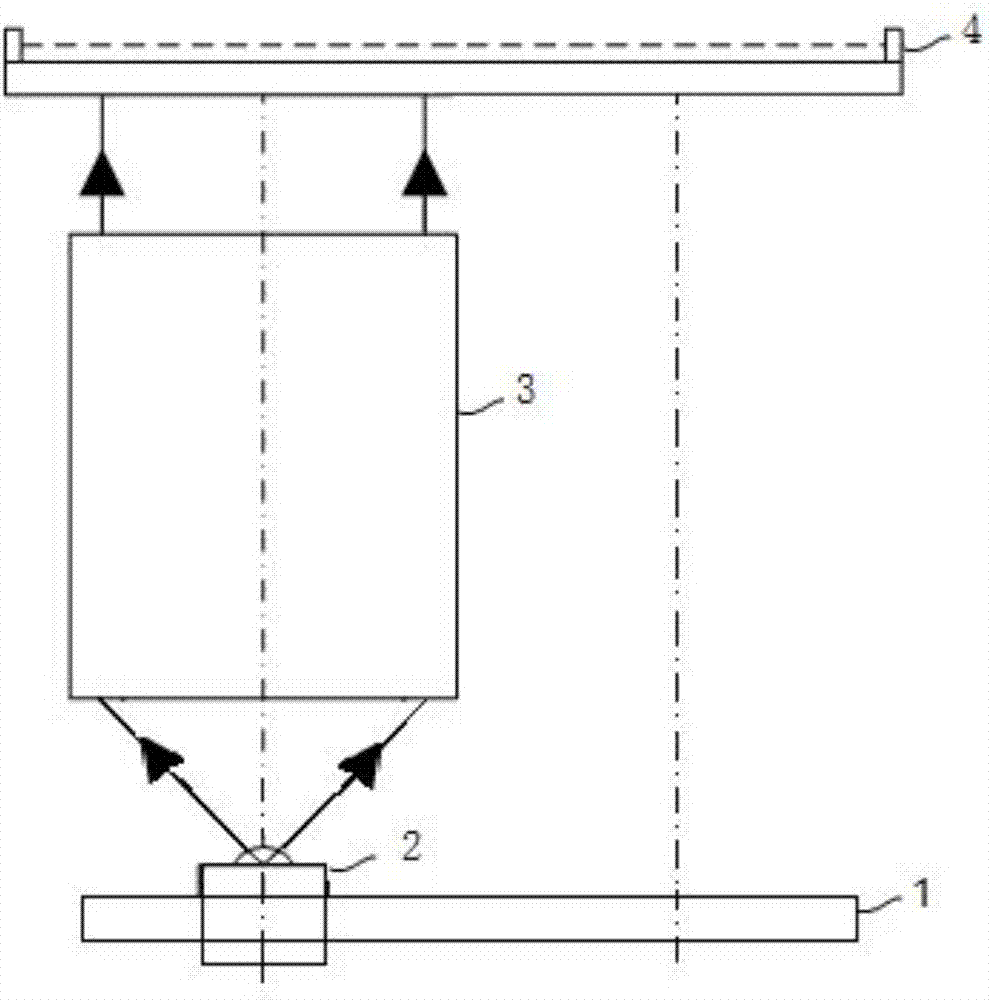

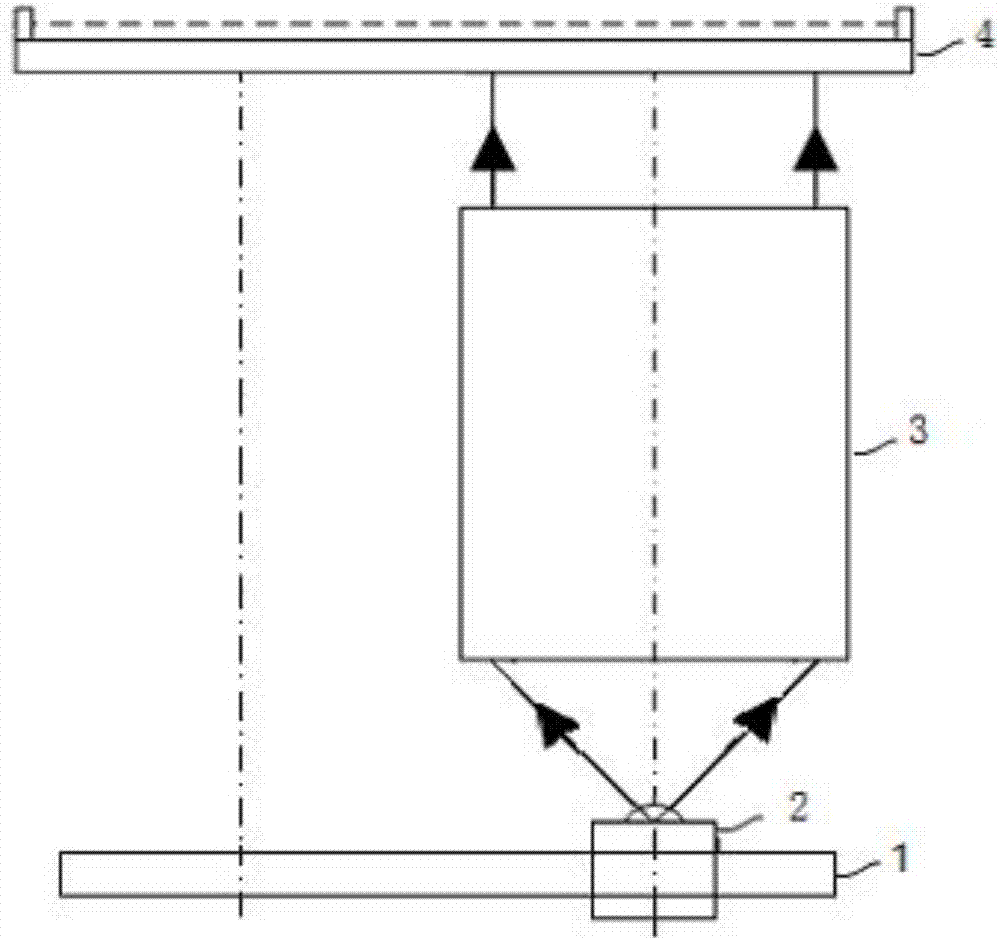

[0036] Such as figure 1 , 2 shown. The invention discloses a micro-projection light-curing printing device with doubled single printing area, comprising a linear guide rail 1, a light source system 2, an optical projection system 3 and a transparent resin tank 4 for containing photosensitive resin;

[0037] The transparent resin tank 4 is arranged above the linear guide rail 1 and parallel to the linear guide rail 1;

[0038] The light source system 2 and the optical projection system 3 are arranged between the transparent resin tank 4 and the linear guide rail 1 from bottom to top;

[0039] A drive mechanism is provided on the linear guide rail 1; through the drive mechanism, the light source system 2 and the optical projection system 3 are moved to a predetermined position along the track of the linear guide rail 1;

[0040] The light source system 2 is used to emit multiple beams of parallel light to illuminate the optical projection system 3;

[0041] The optical proje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com