Optical projection system for realizing large-size photocuring 3D printing

A 3D printing and optical projection technology, applied in optics, optical components, instruments, etc., can solve the problems of reducing printing accuracy, high price, and limiting the application of DLP and LCD projection technology, and achieve the effect of increased printing size and high-precision cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

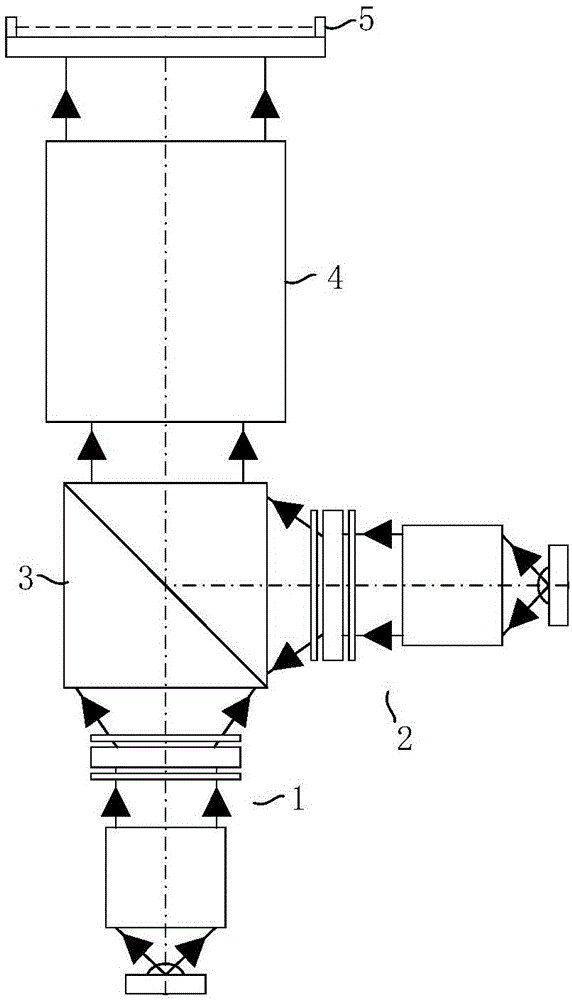

[0024] Such as figure 1 As shown, the embodiment of the present invention is composed of a first LCD lighting module 1 , a second LCD lighting module 2 , a polarizing beam splitter 3 , a projection lens 4 and a resin tank 5 . The optical structures of the first LCD lighting module 1 and the second LCD lighting module 2 are completely the same.

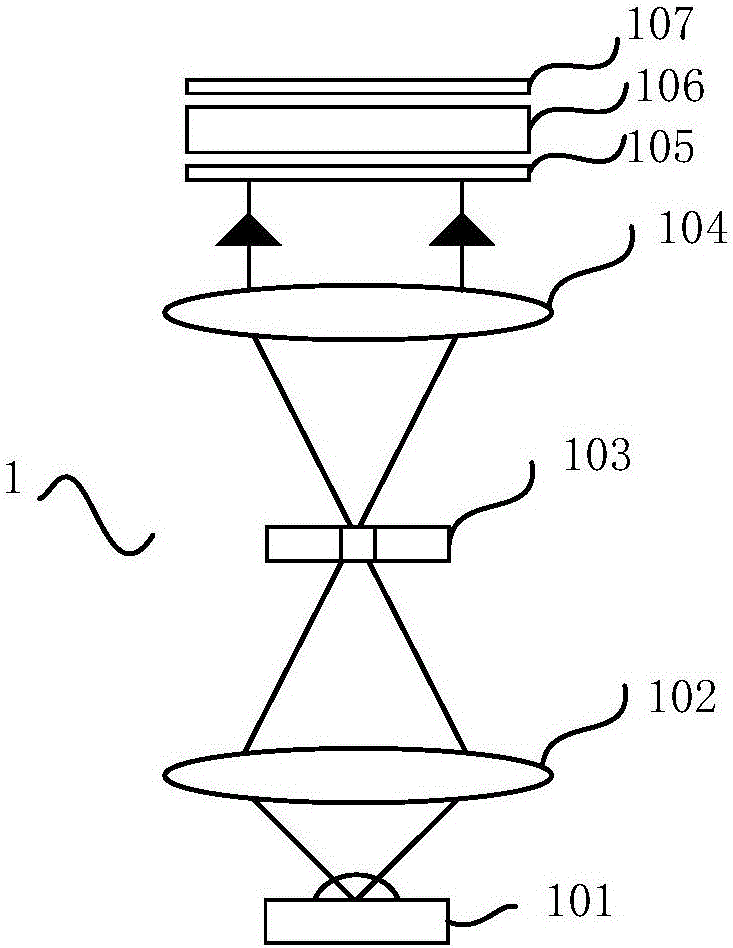

[0025] The specific lighting implementation of the system, taking the first LCD lighting module 1 as an example, includes an LED light source 101, a condenser lens 102, a diaphragm 103, a collimating lens 104, a first polarizer 105, an LCD liquid crystal plate 106, and a second polarizer 107 ,Such as figure 2 shown.

[0026] Firstly, after the LED light source 101 passes through the lighting module composed of the condenser lens 102, the aperture 103, and the collimating lens 104, the incident light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com