Full-automatic 3D printing system based on gantry type variable dimensions

A 3D printing and variable size technology, applied in the field of 3D printing, can solve problems such as inability to adapt to printing conditions, limited printing range, and single form of material printing, and achieve the effect of expanding the scope of practical application, expanding the scope, and increasing the printing size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

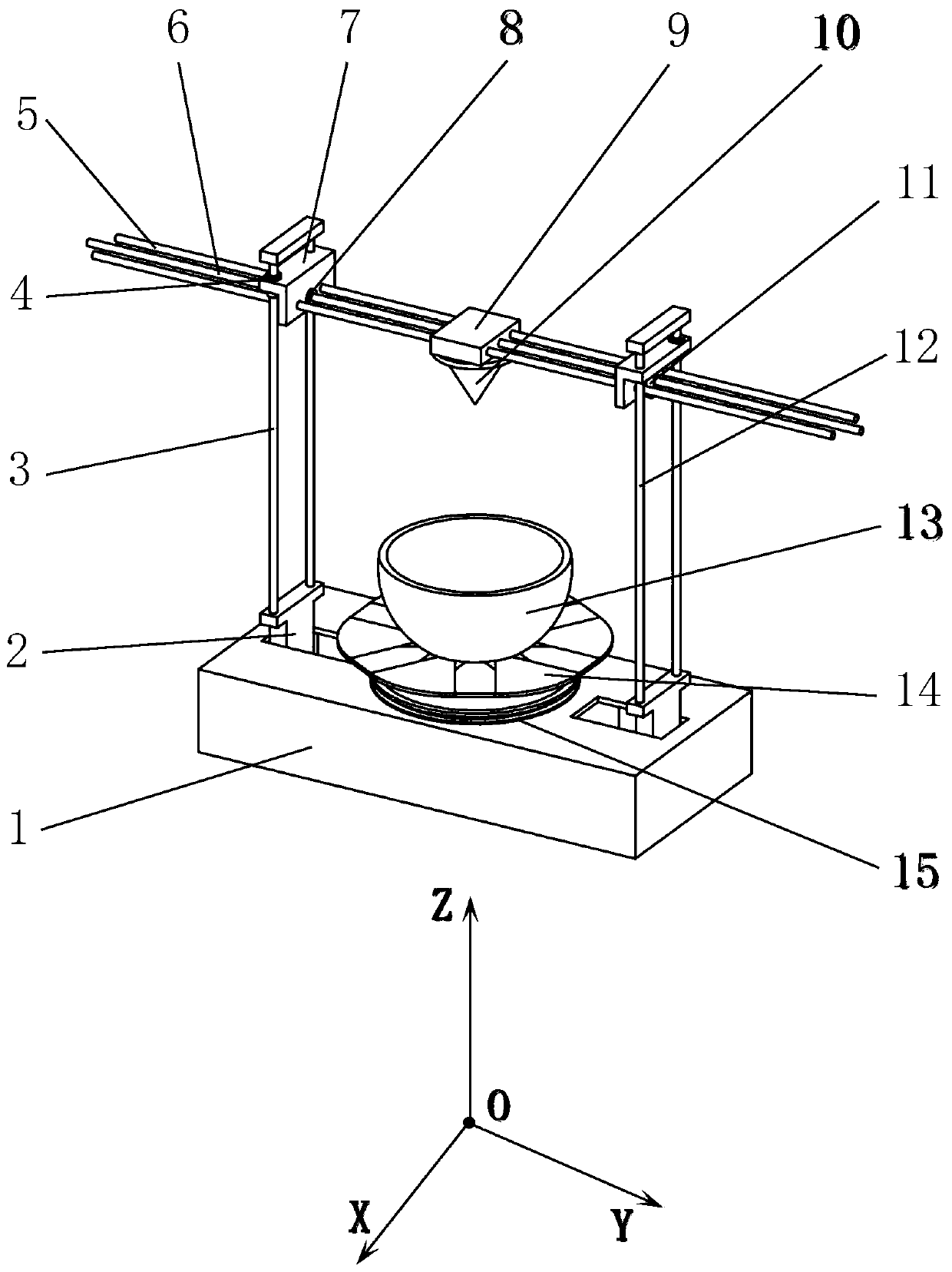

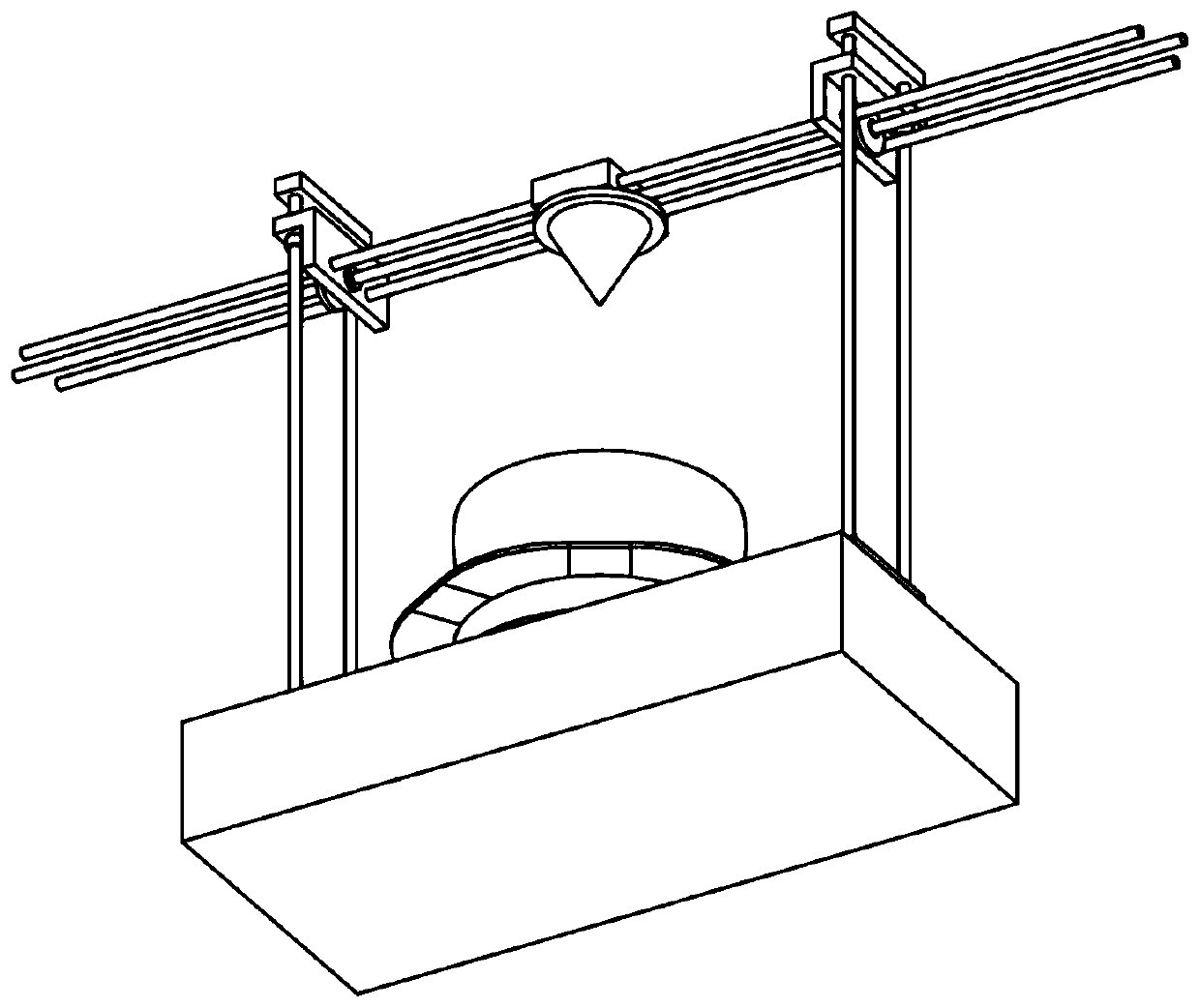

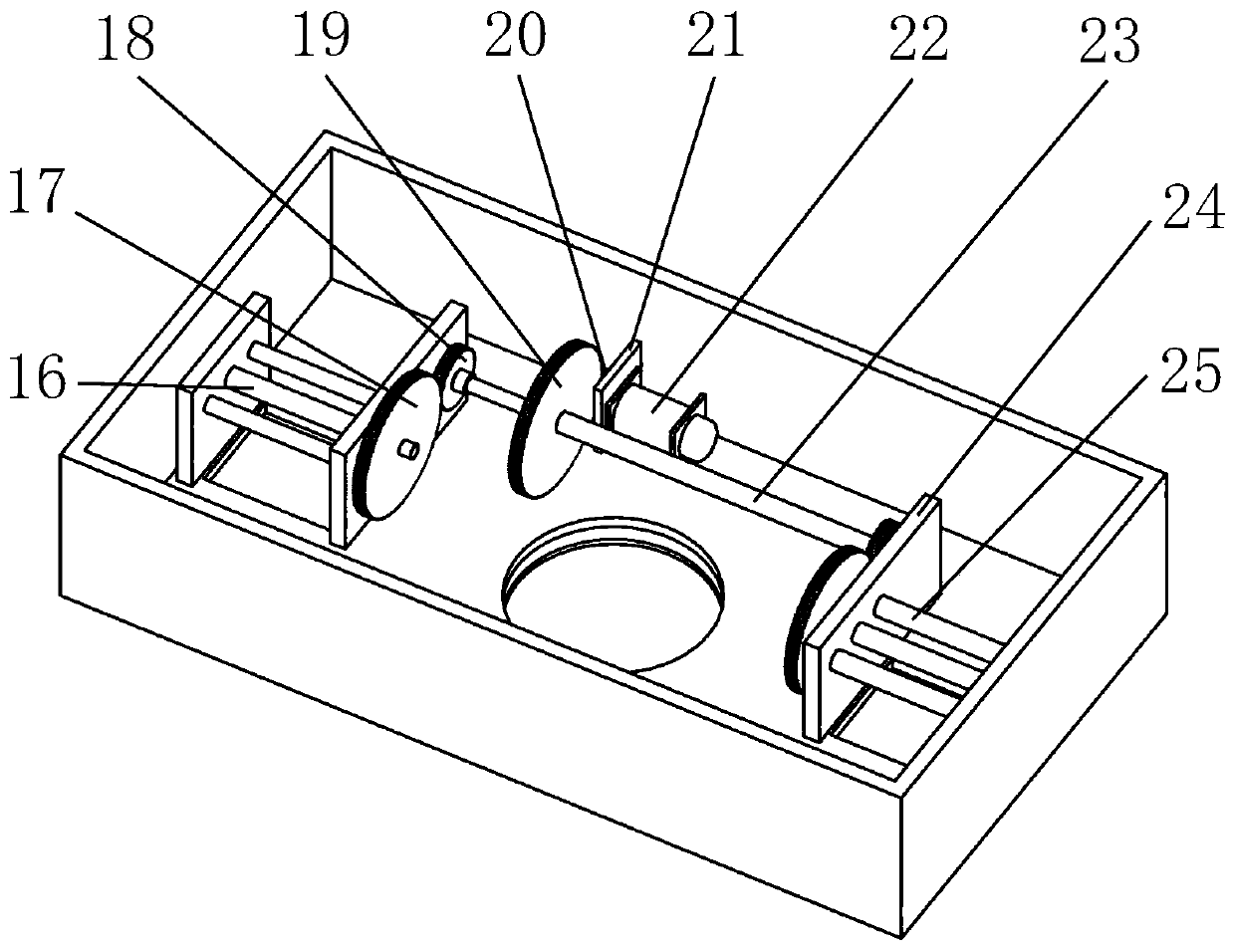

[0030] see Figure 1-7 , based on a gantry-type variable-size automatic 3D printing system, including a base 1, characterized in that a pair of symmetrical through grooves are respectively provided on both sides of the top surface of the base 1, and a vertical rod seat 2 is arranged in the groove; the vertical rod A ball screw a3 and a cylindrical guide rail b12 are respectively provided on the left and right sides of the top of the seat 2; the ball screw a3 passes through the connecting seat 7 and is connected with the ball screw seat a4; the lower part of the connecting seat 7 is provided with three horizontal through holes, two A cylindrical guide rail a5 is provided in the through holes on both sides of the connecting seat 7; a ball screw b6 is provided in the through hole in the middle of the two connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com