Dual-servo motor control device for flat plate type digital ink-jetting printing machine

A dual-servo motor, digital inkjet technology, used in typewriters, power transmission devices, printing and other directions, can solve problems such as affecting the printing effect, and achieve the effect of high cost performance, easy installation and high-precision printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

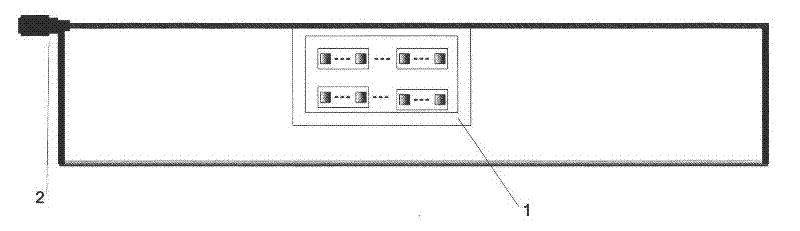

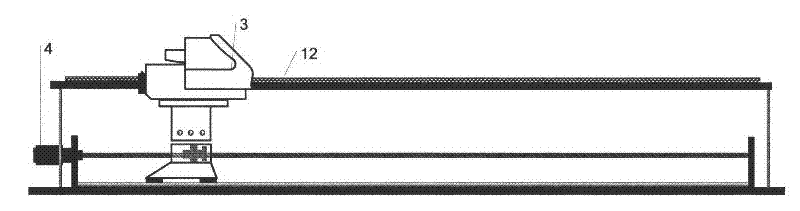

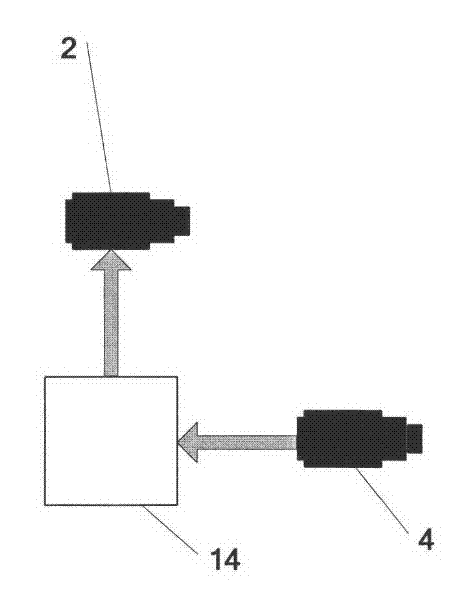

[0009] For the mobile head digital inkjet printing machine, the printed fabric is placed on the printing plate (12) supported by the plate tray (13), and the feet of the printing plate are supported by four support rods (6). The machine head assembly (3) is connected on the ball screw (5) by the lead screw moving nut (10) on the one hand, and on the other hand is connected to the machine base chassis ( 7) on the linear guide rail (8). When printing, first, the servo motor 1 (2) controls the nozzle group (1) in the head assembly to run a width distance in the fabric width direction to complete a lead, and then the servo motor 2 (4) controls the head assembly ( 3) Move forward along the high-precision ball screw (5) for one printing width in the length direction of the fabric, and this process is repeated until the printing of the entire fabric is completed.

[0010] Depend on figure 1 As shown, the servo motor 1 (2) is used to control the movement of the nozzle group (1) in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com