Color 3D printing system based on 3DP and light curing technology

A 3D printing and light-curing technology, applied in the field of 3D printing, can solve the problems of not enough delicate surface and weak strength of color products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment

[0020] Specific implementation 1

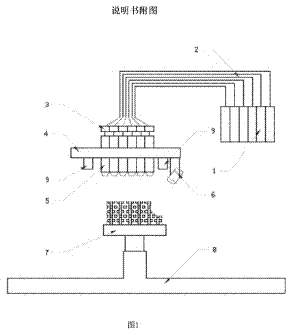

[0021] The color 3D printer involved in this embodiment is as figure 1 As shown, 6 piezoelectric standard inkjet print nozzles (5) are installed on the print head bracket (4), and the 6 nozzles correspond to the five colors of C, M, Y, K, W, UV resin ink and UV resin respectively. The ink is supported, and the printing method is the scanning method. Two LED ultraviolet light sources (9) are installed on the print head support (4), a heating element is installed at the installation place of each print head, and a temperature measuring element is installed at the ink inlet of the print head. A grating ruler is installed in the X-axis direction, which is used as a measuring element for full-closed-loop servo control. The main ink tank (1) supplies ink of the corresponding color and function at a suitable pressure for each nozzle, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com