A paper defect detection method based on local brightness invariance priori

A local brightness and defect detection technology, which is applied in the direction of optical defect/defect, image data processing, instrument, etc., can solve the problem of insurmountable motor speed limit and stability, the failure rate of mechanical parts and detection parts is difficult to reduce, maintenance and Problems such as high debugging cost, achieve the effect of low performance requirements, high accuracy, and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] A paper defect detection method based on the local brightness invariance prior includes the following steps:

[0076] Step 1. Make the color area array camera face the surface of the paper to be detected. The surface of the paper to be detected is located in the field of view of the color area array camera. Take a picture with the color area array camera to capture a frame of color image of the paper surface to be detected. The pixel format of the color image Use RGB components to represent;

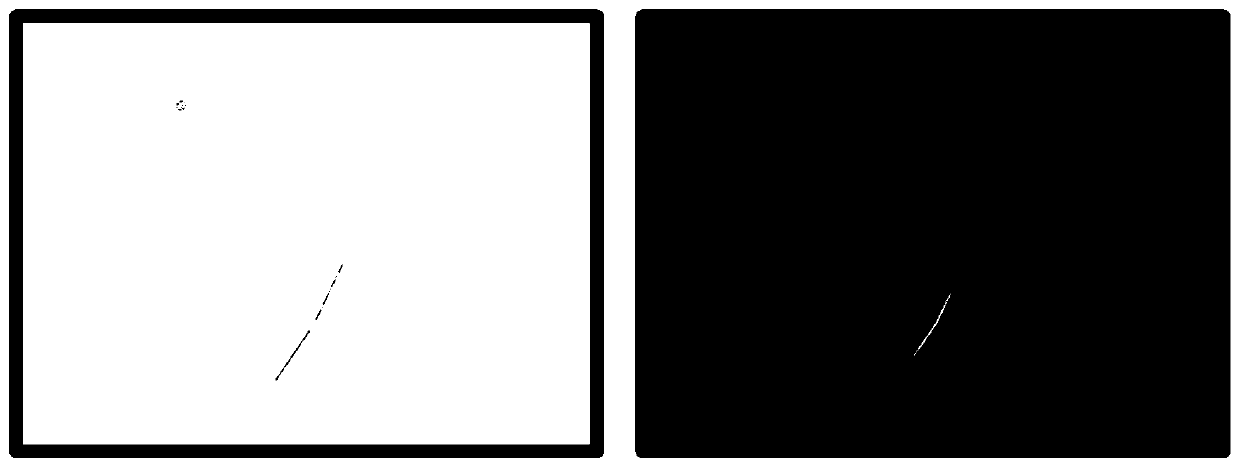

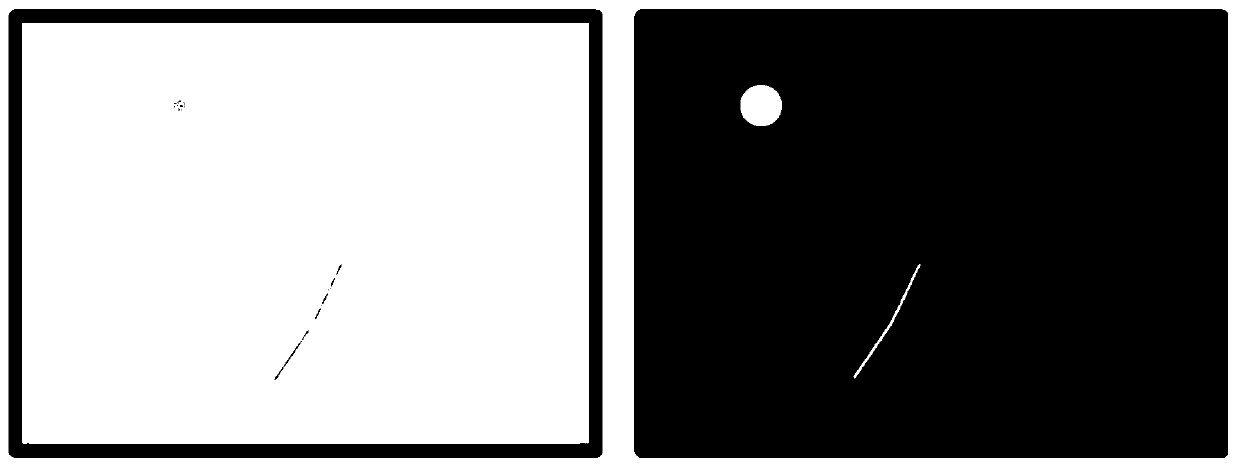

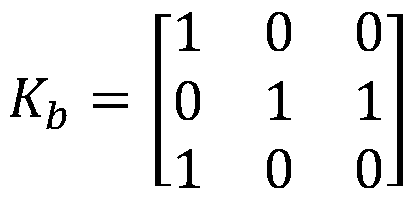

[0077] Step 2: Use a convolution template with local brightness invariance prior to perform non-linear grayscale operation on all pixels of the color image in the mask of the convolution template, and finally obtain the pixels corresponding to the convolution window; according to 1× The 1 convolution operation and the 3×3 convolution operation respectively obtain two grayscale images;

[0078] Step 3, dividing the corresponding position pixels of the two grayscale images to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com