Patents

Literature

99results about How to "Reduce placement requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

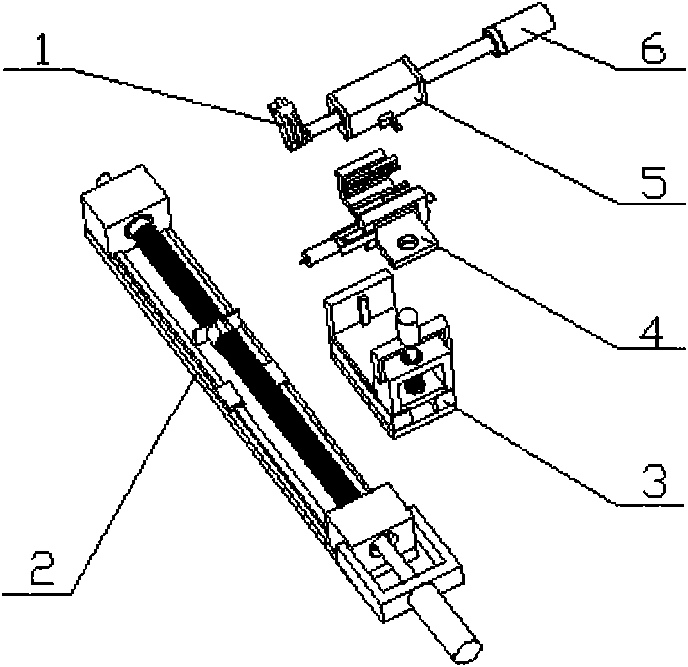

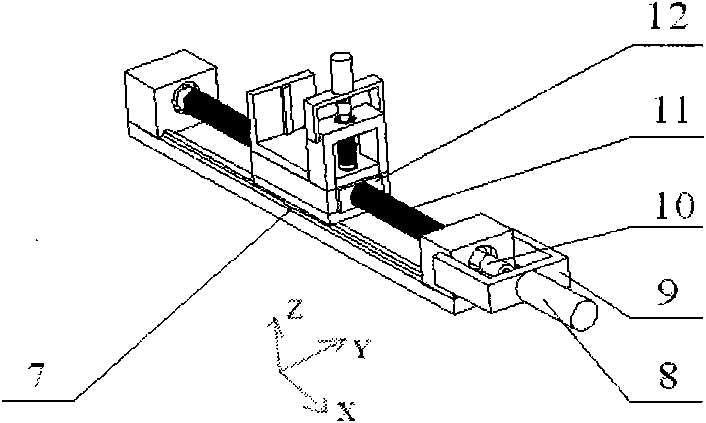

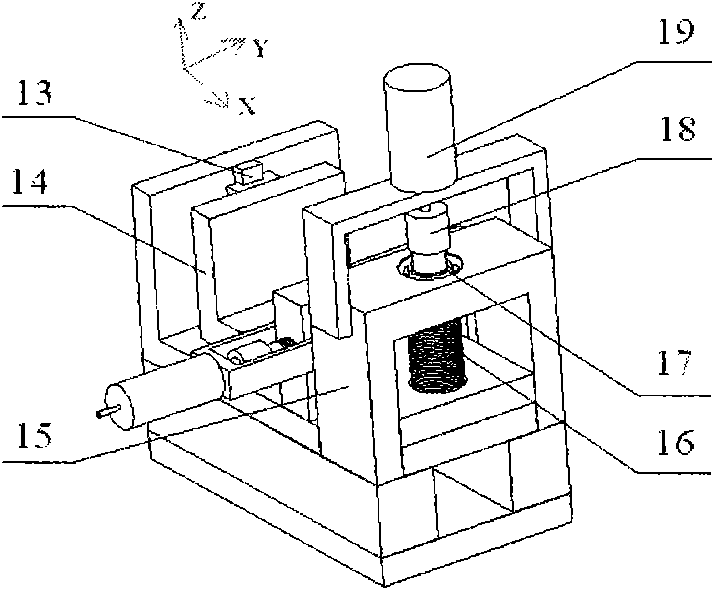

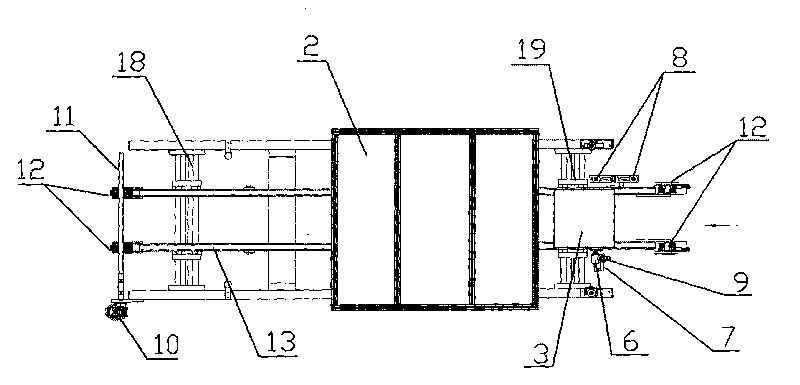

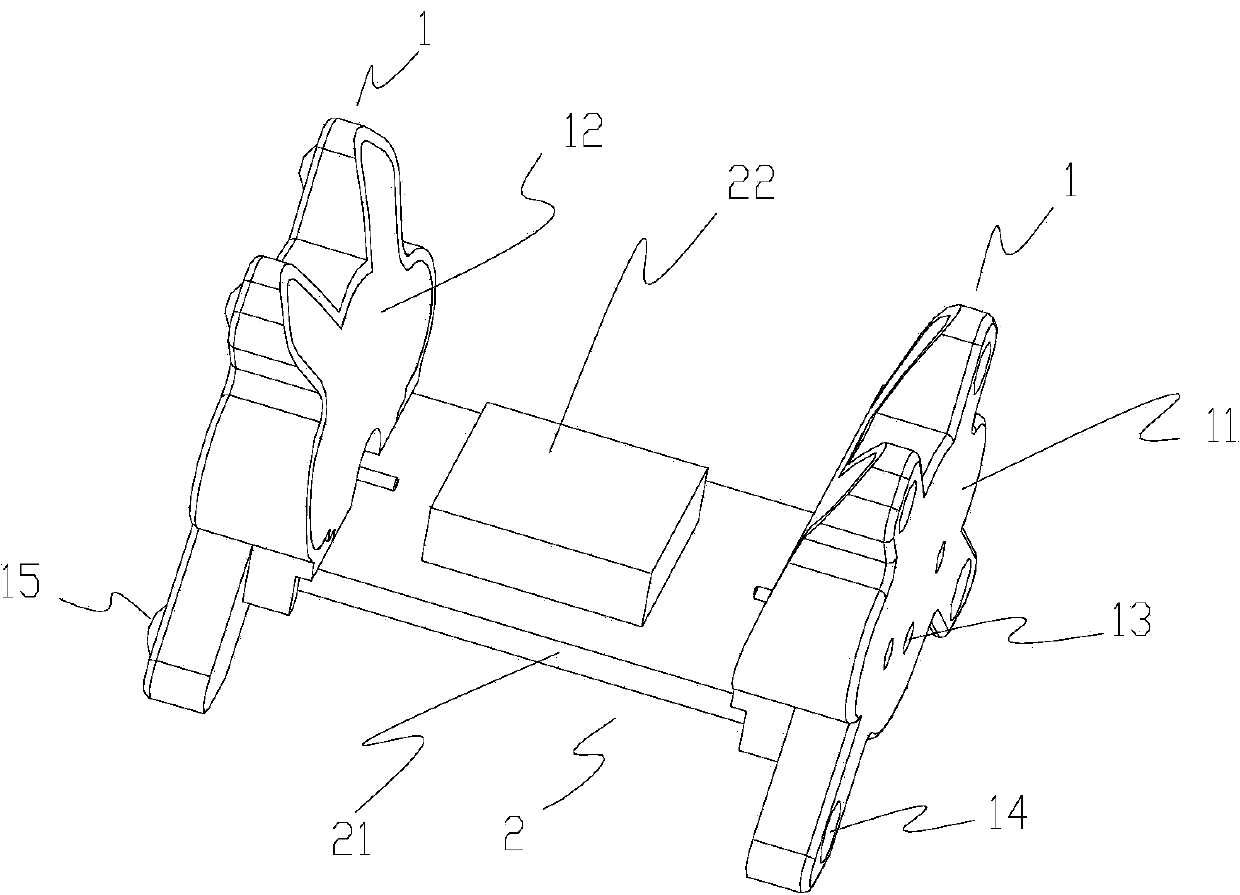

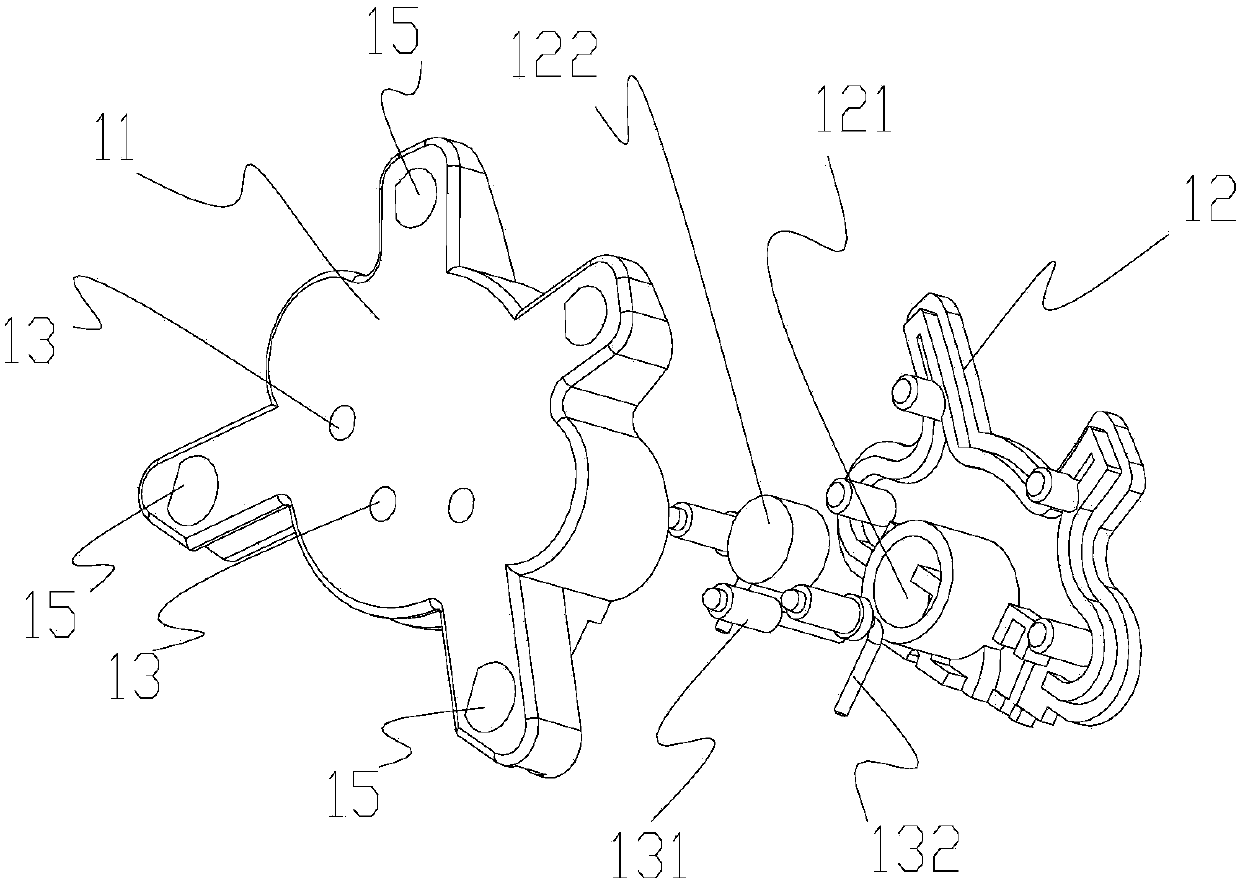

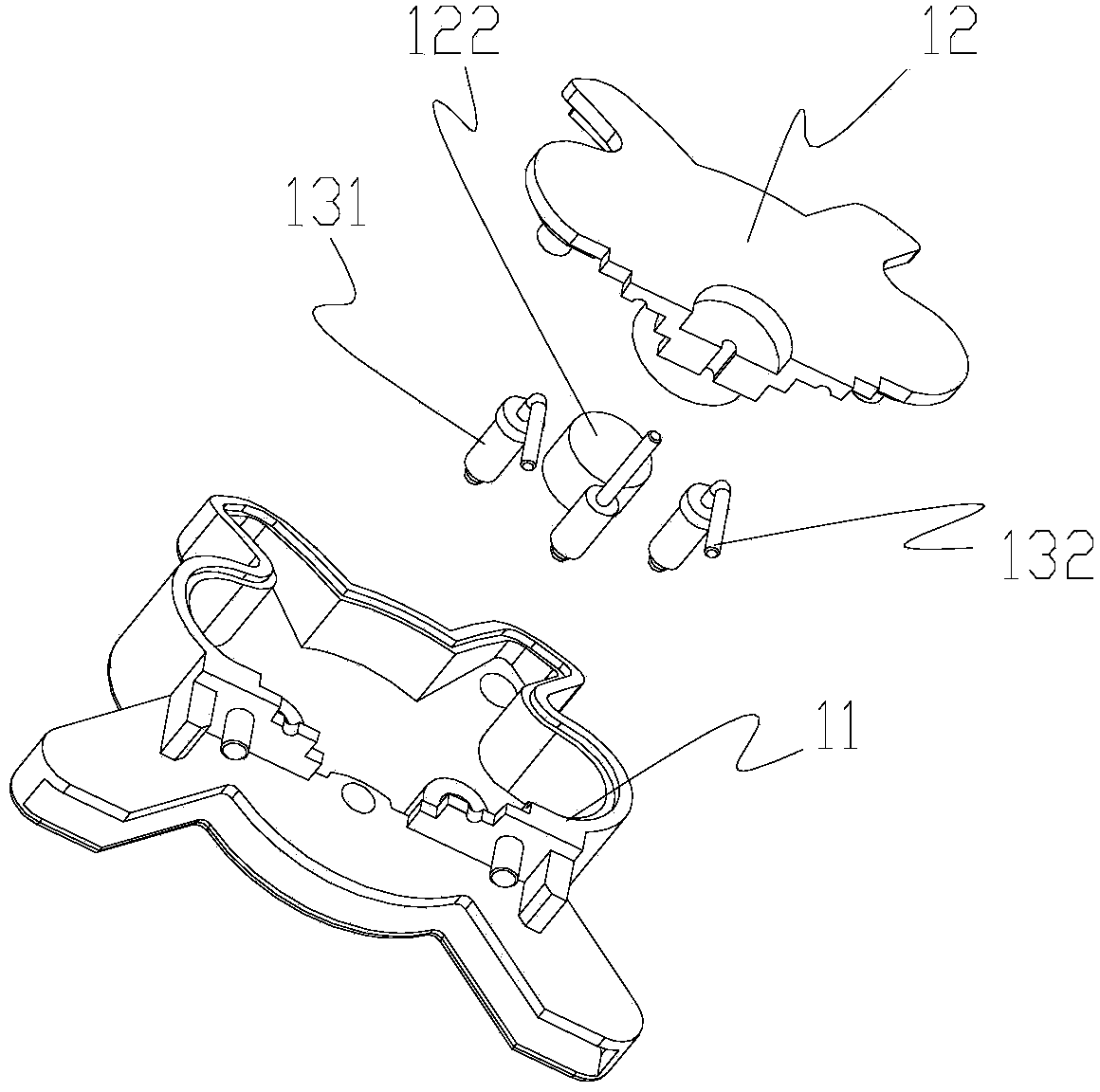

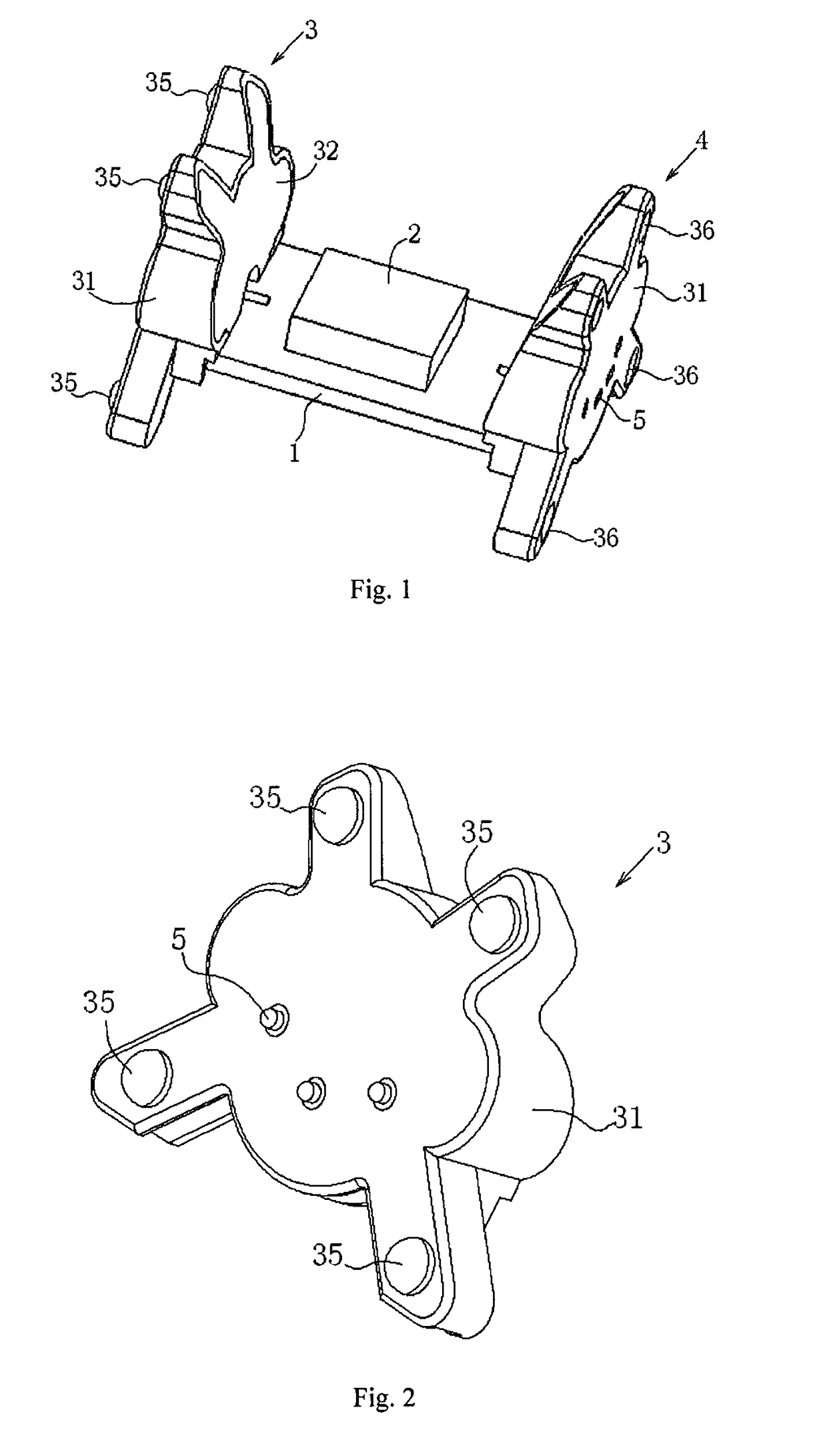

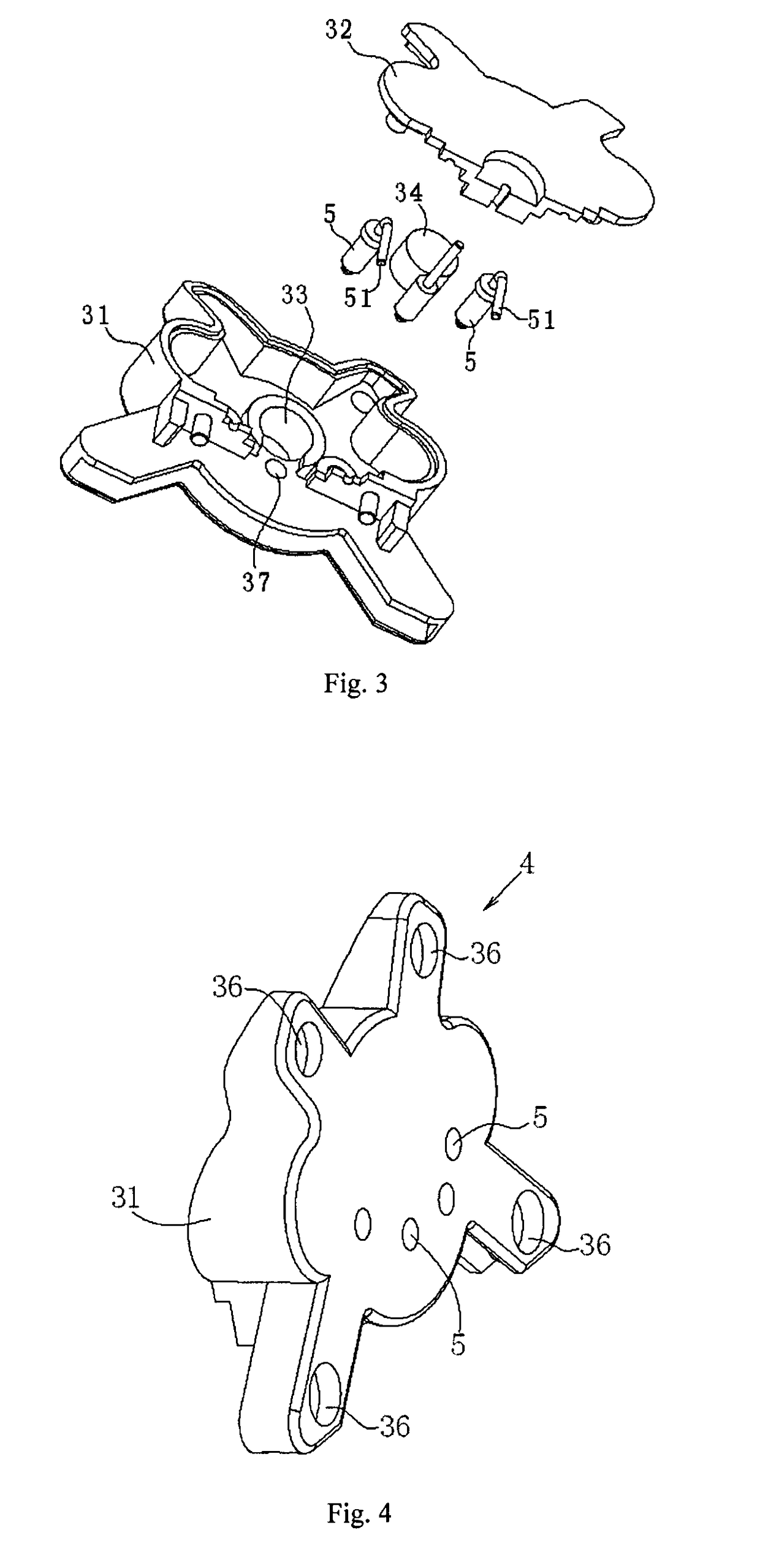

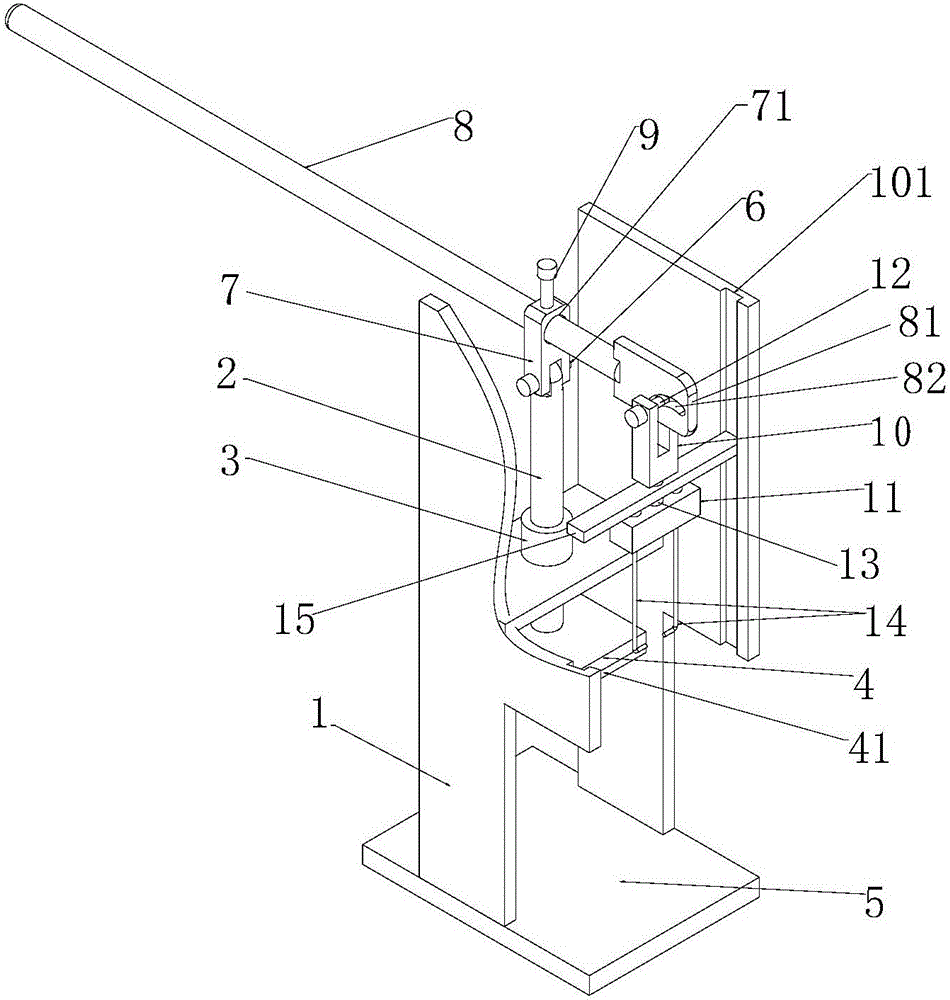

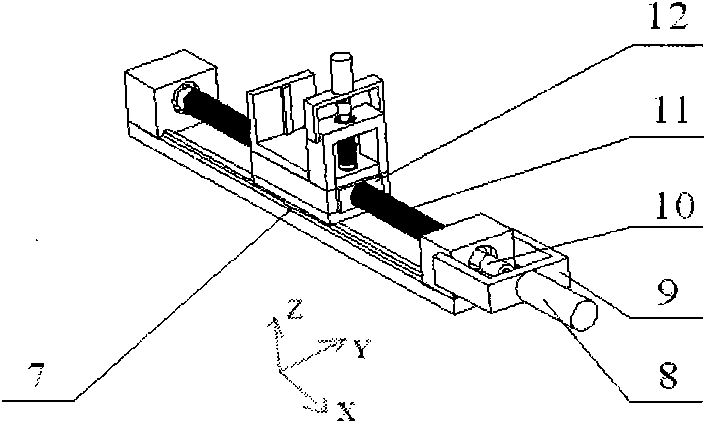

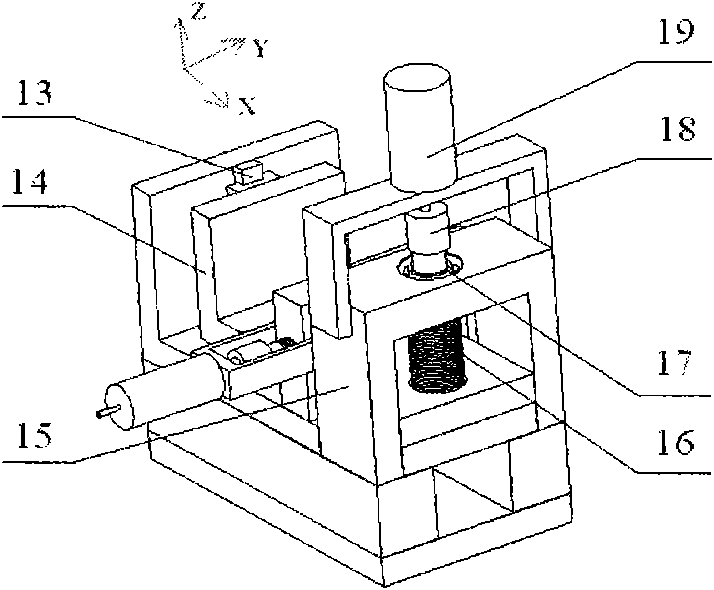

Bolt assembly and disassembly manipulator capable of moving with three degrees of freedom

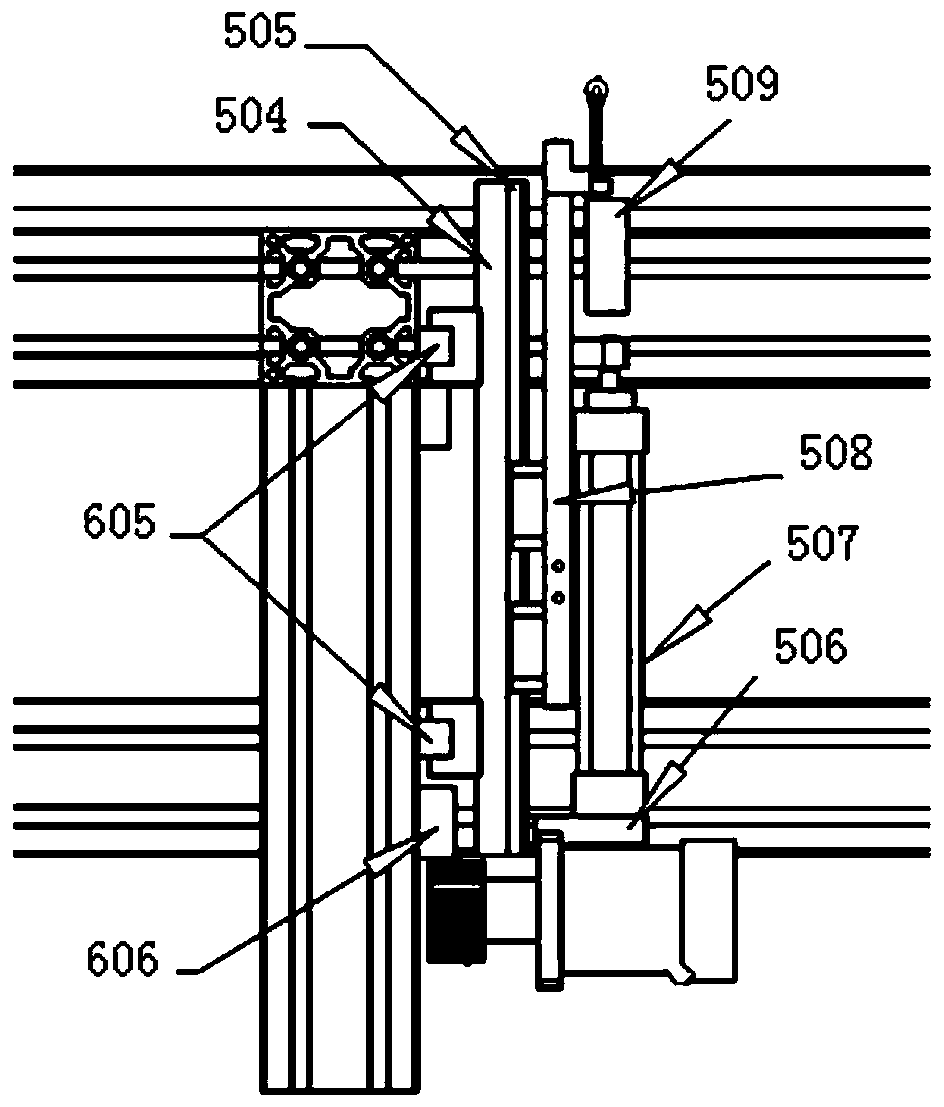

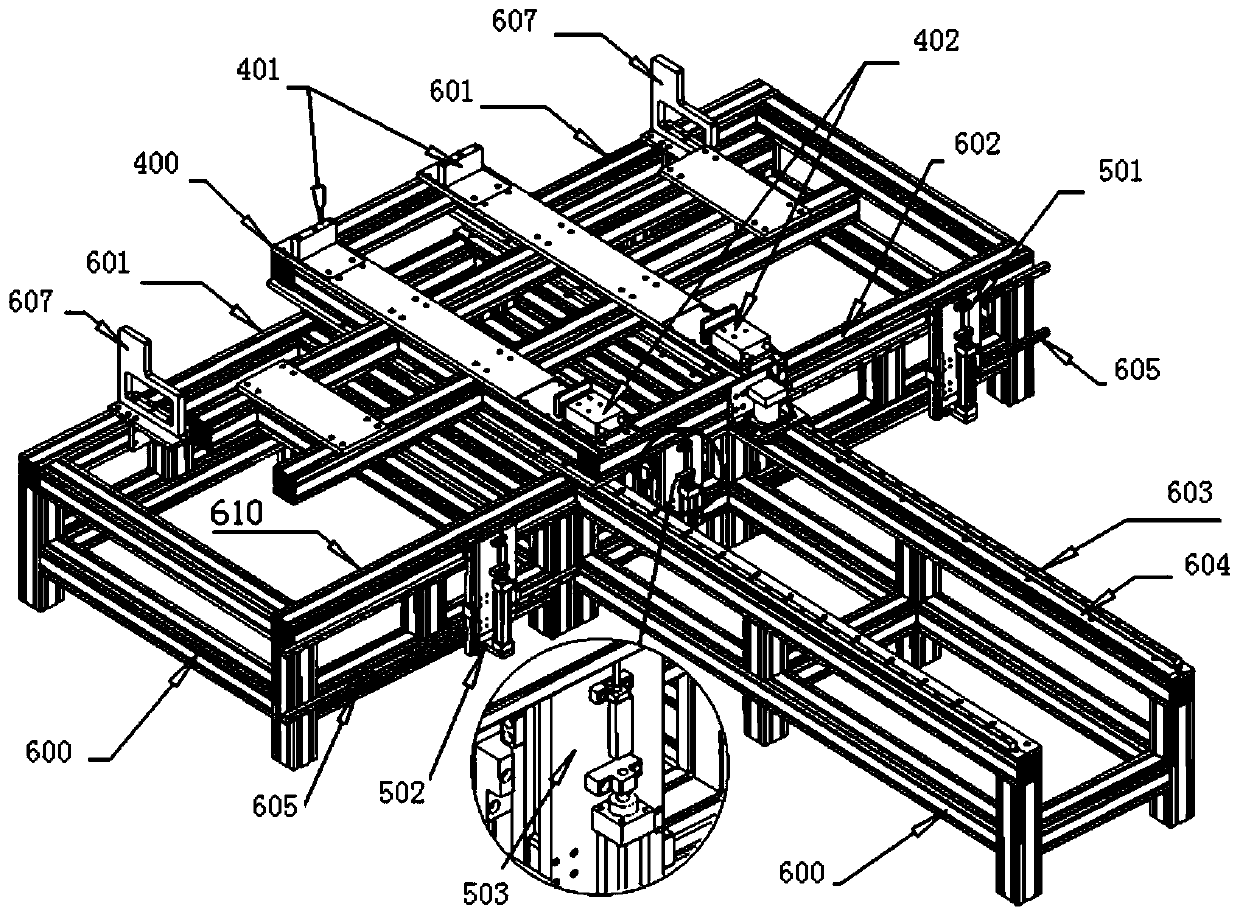

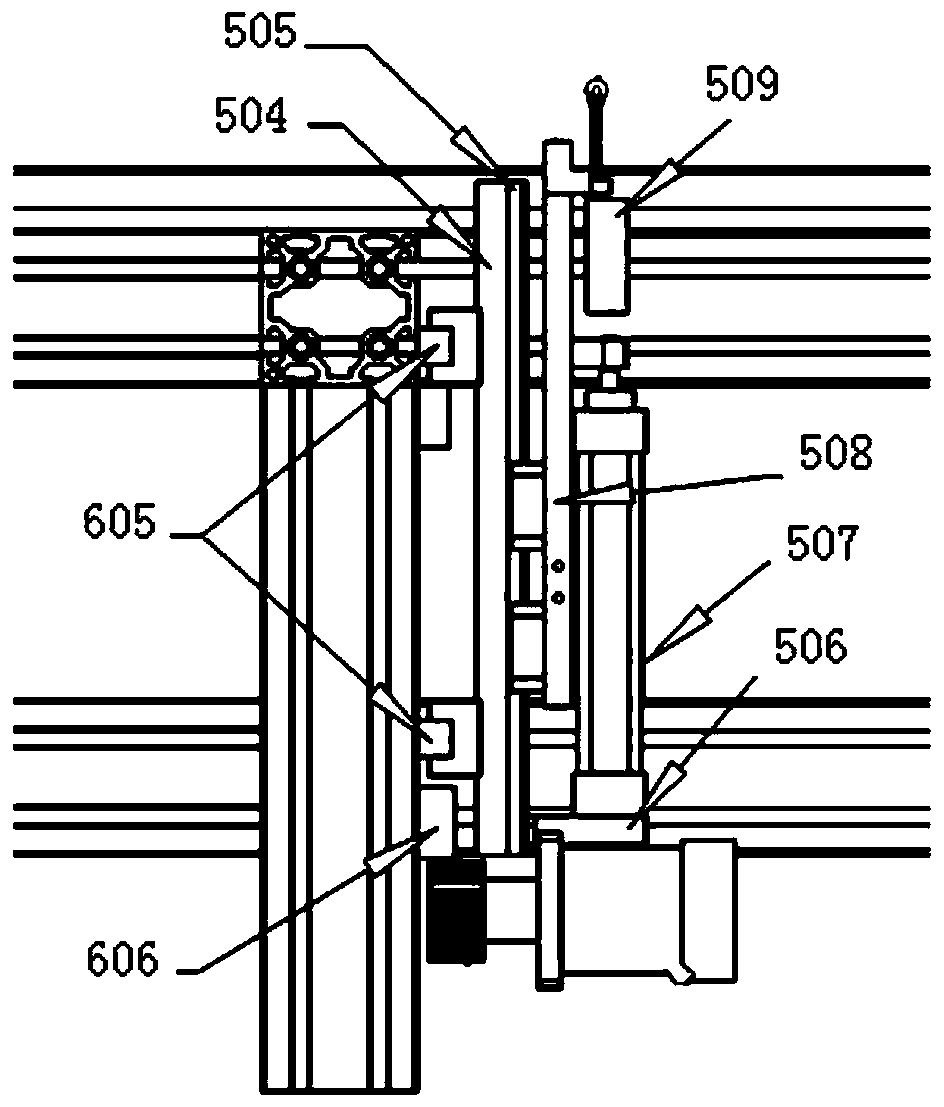

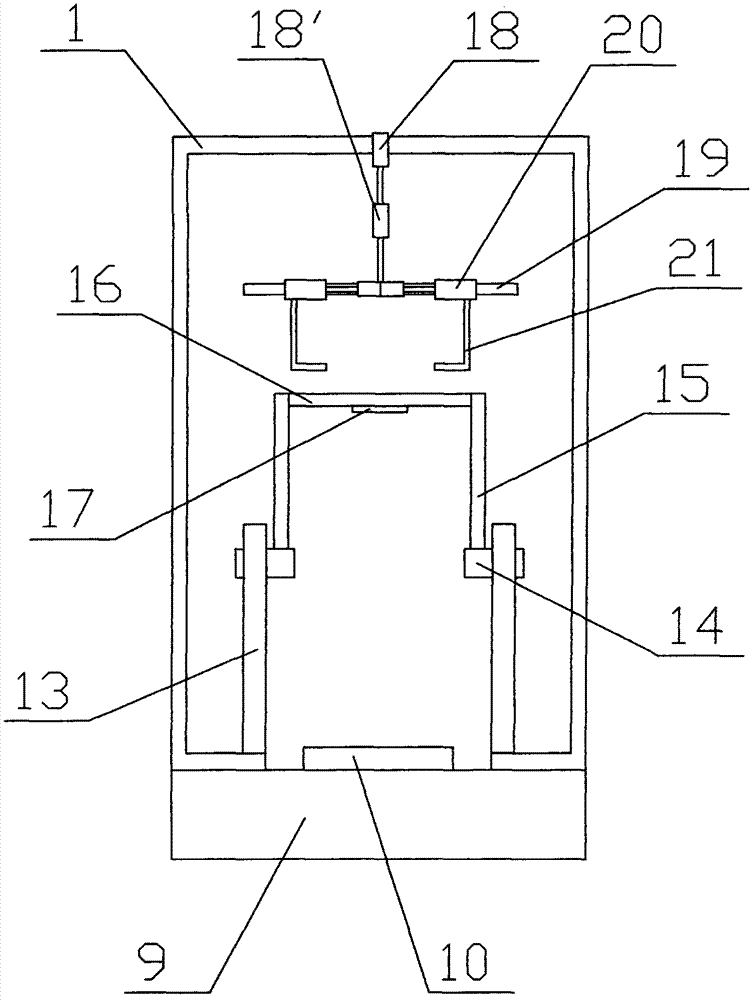

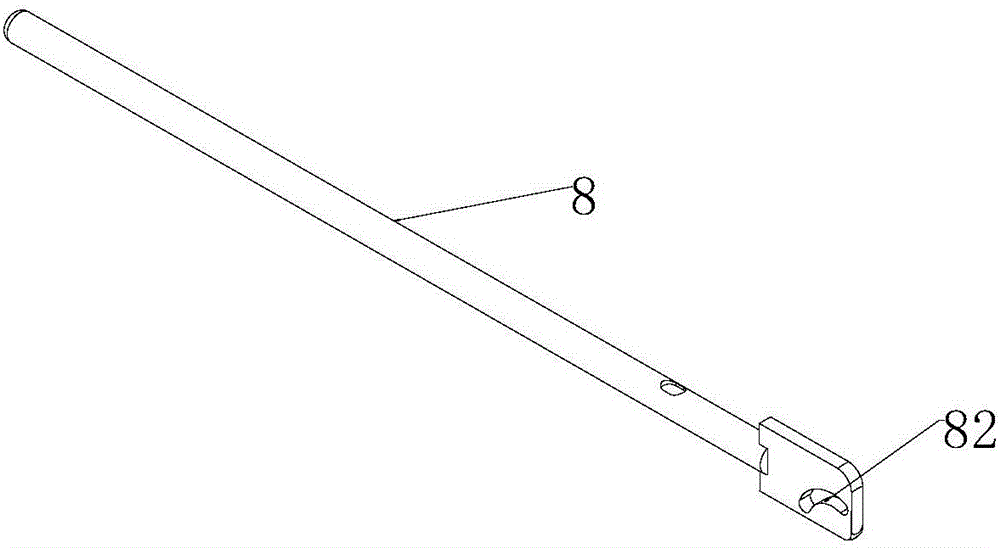

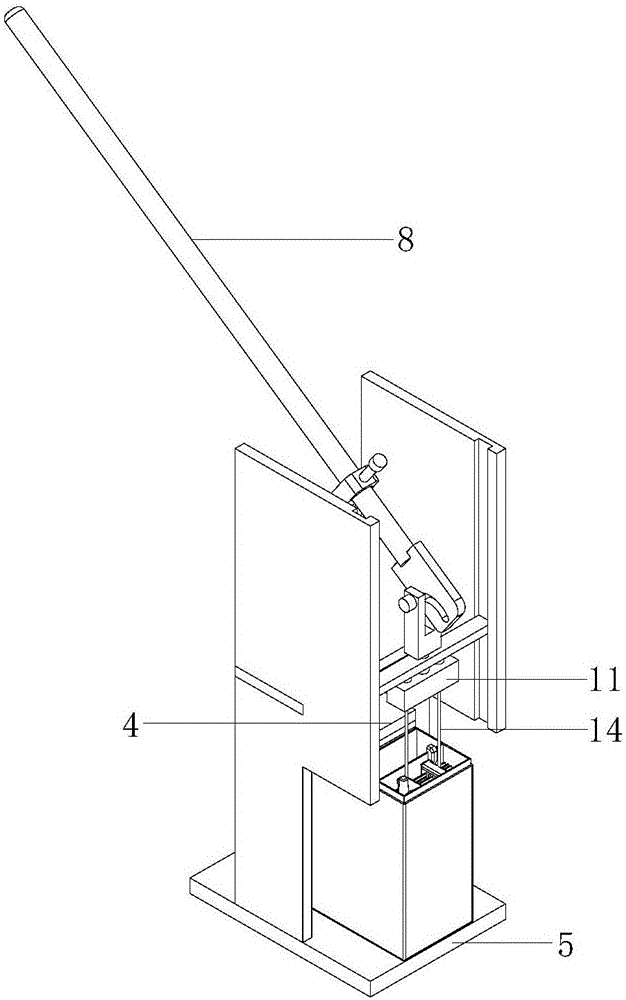

The invention discloses a bolt assembly and disassembly manipulator capable of moving with three degrees of freedom. Moving elements of body, shoulders and arms are connected one another through guide rail sliding blocks, the movement of each element in a specified direction is limited, and the movement of a motor is transferred through a lead screw nut. A spring of a spanner head and a baffle plate are used for limiting the position of a bolt, a pressure sensor is used for measuring the axial force of the bolt, and the measured axial force is a basis for next operation. During disassembling or assembling the bolt, the pressure value detected by the pressure sensor arranged in the spanner head is used as the basis, the three moving elements are driven to ensure the precise positioning of the spanner head, and an elastic coupling for connecting the motor and a lead screw can ensure that the arms successfully realize flexible guide and positioning under the condition of certain butting error. The manipulator has the characteristics of compact structure and wide application range; and the manipulator has low positioning requirement of the bolt position so as to reduce the complexity of equipment and broaden the space of automatic application.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

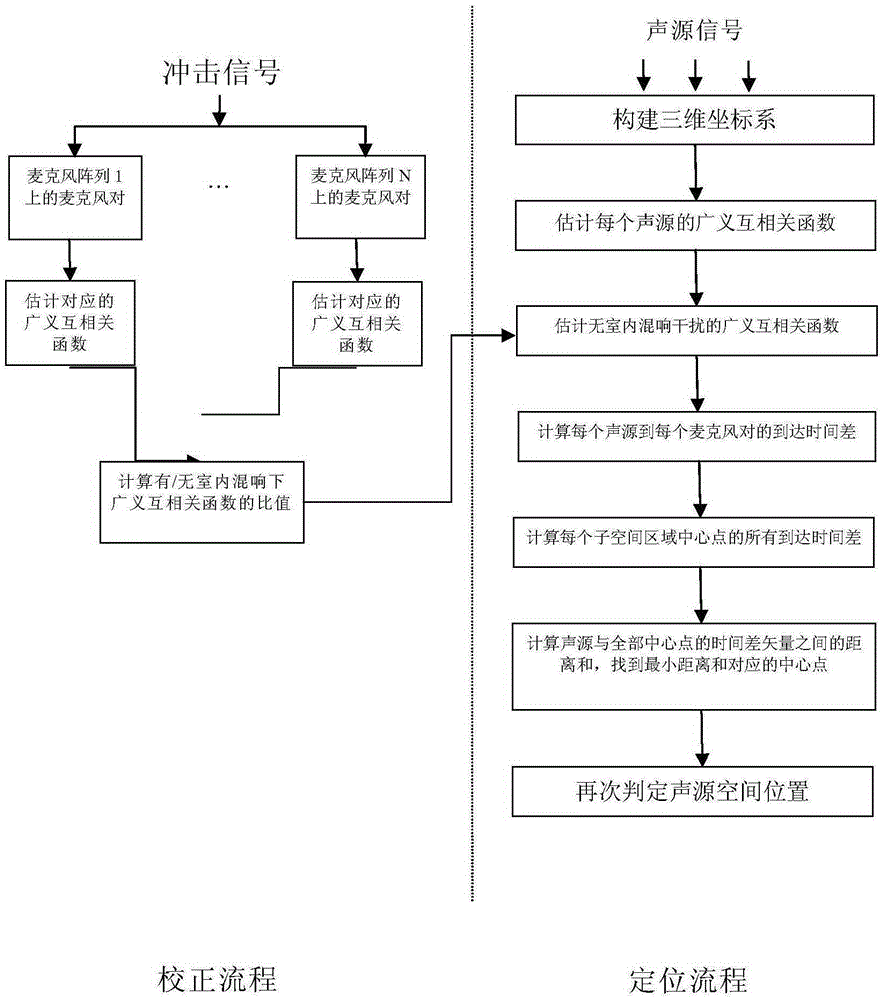

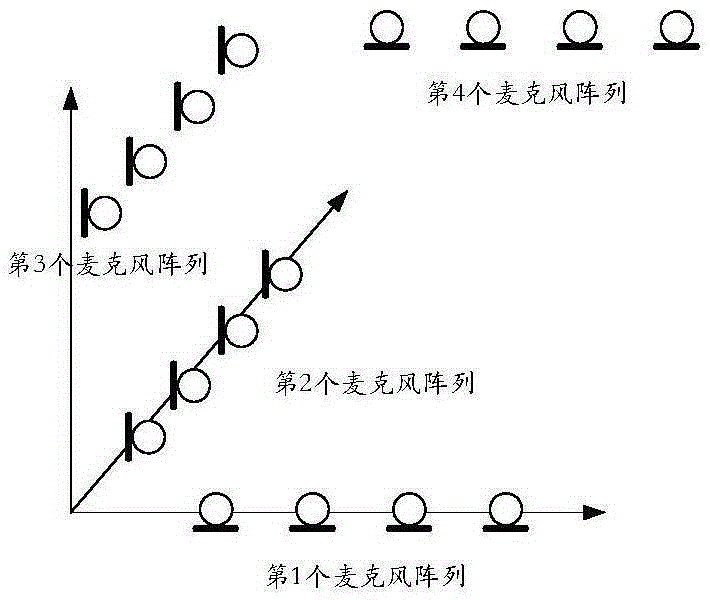

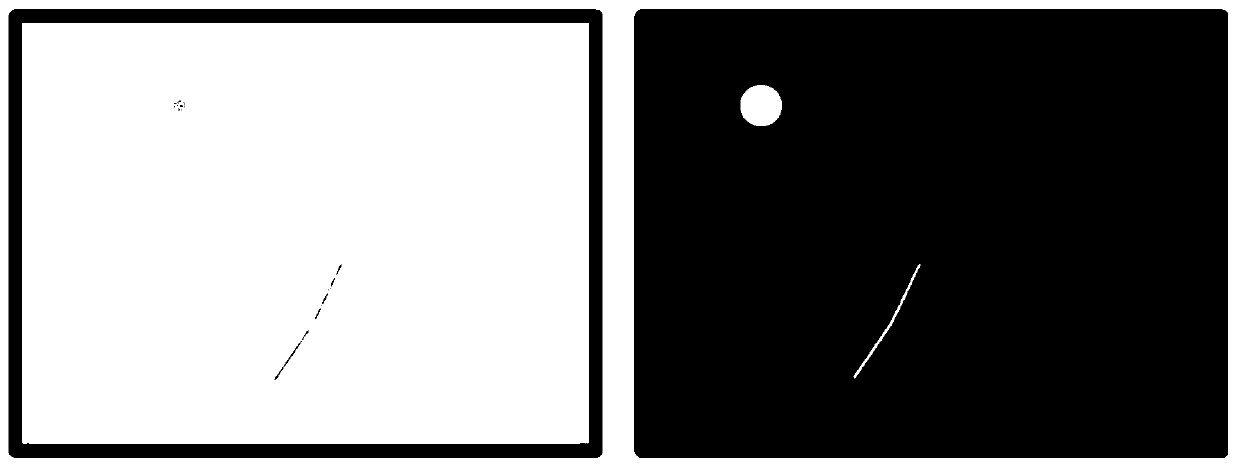

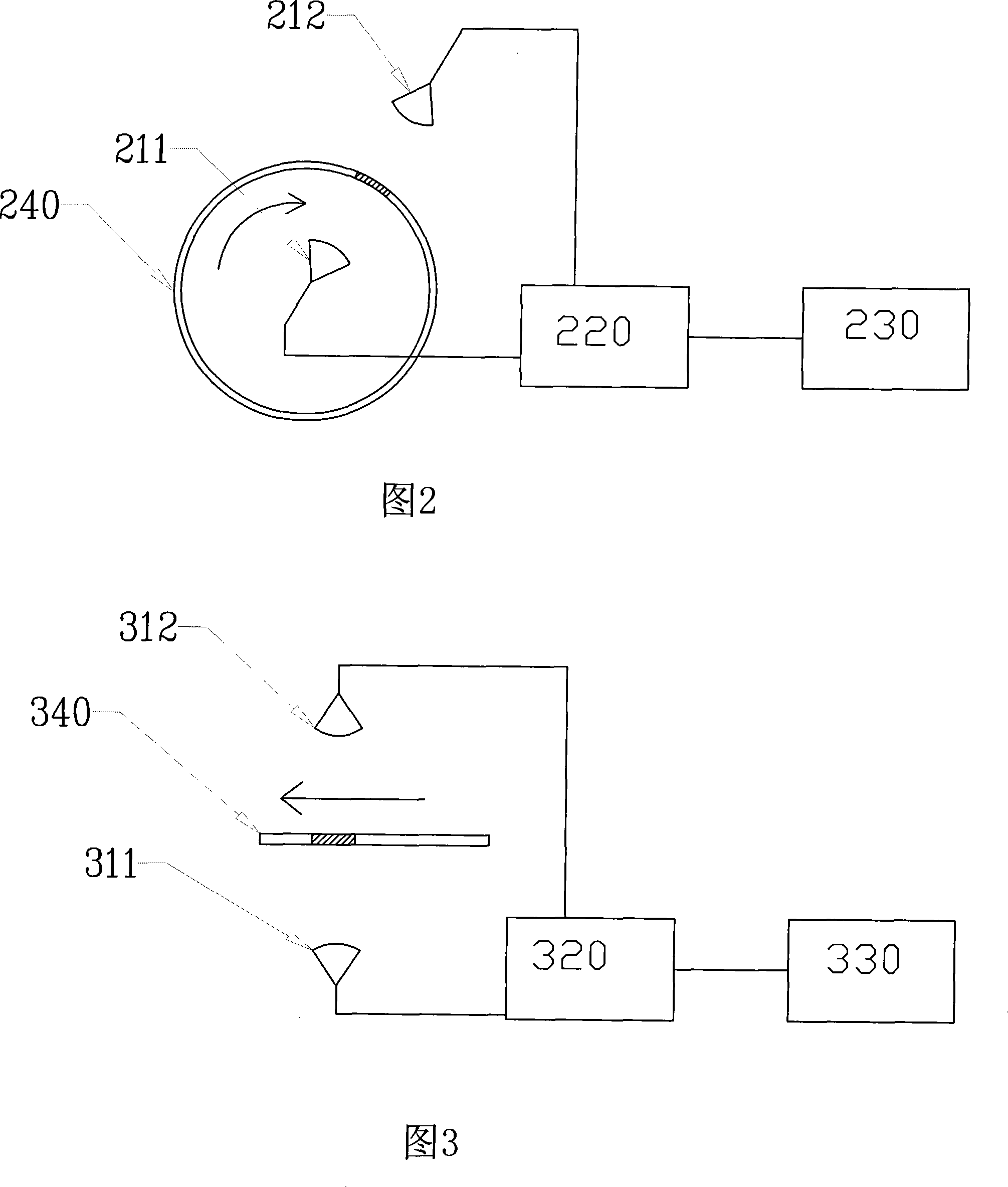

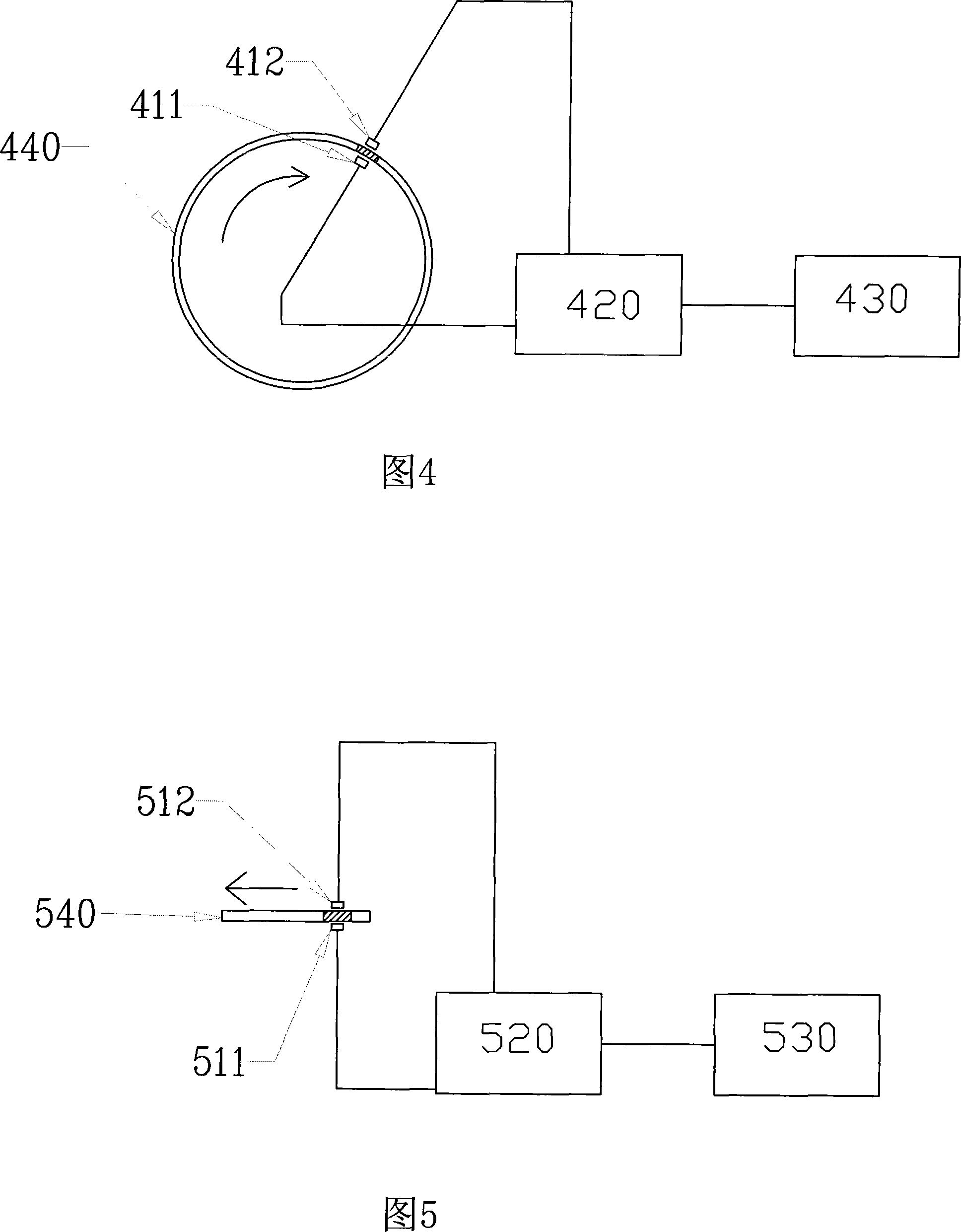

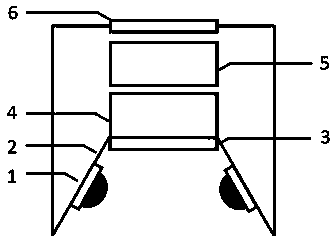

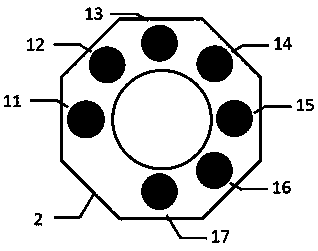

Robustness sound source space positioning method of distributed microphone array network

ActiveCN105388459AReduce distractionsReduce placement requirementsPosition fixationSound source locationSound sources

The invention provides a robustness sound source space positioning method of a distributed microphone array network. The method comprises the steps of: constructing a three-dimensional spatial coordinate system, estimating an arriving time difference and reducing reverberation interference, estimating a sound source position, and finally determining the sound source position. According to the invention, two microphone arrays are used for determining three-dimensional spatial coordinates, and time delay information in the microphone array network is fully utilized for reducing interference caused by indoor reverberation; and a spatial coordinate area is divided, and the spatial position of a sound source is finally determined by means of twice estimation. The robustness sound source space positioning method has the advantages that the performance and the calculation cost are superior to an existing technology, the application is wide, the structure is simple, the cost is low, and the method is applicable to intelligent household and intelligent monitoring scenes utilizing the distributed microphone array network.

Owner:TSINGHUA UNIV

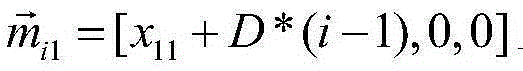

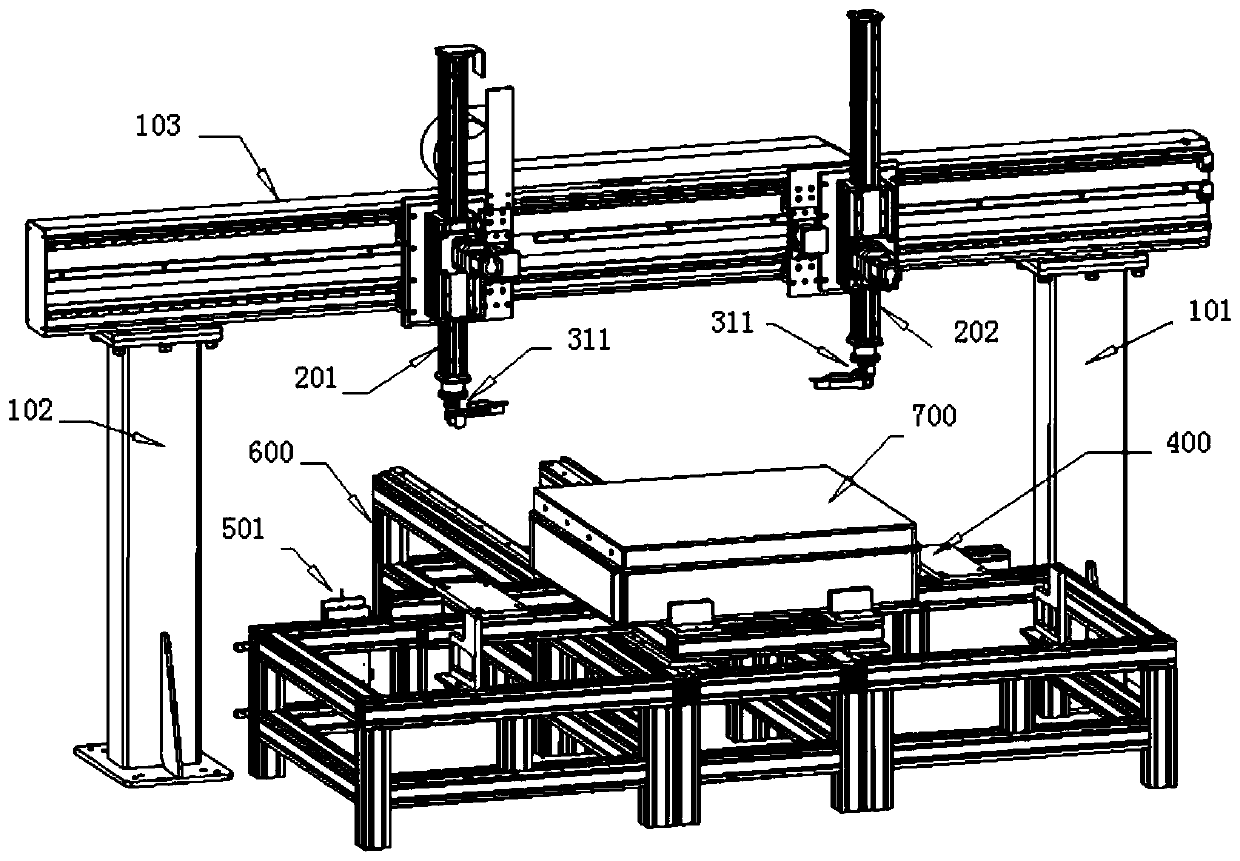

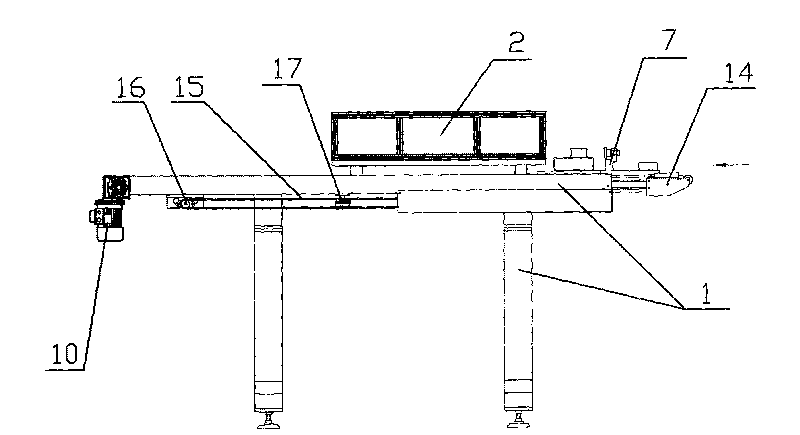

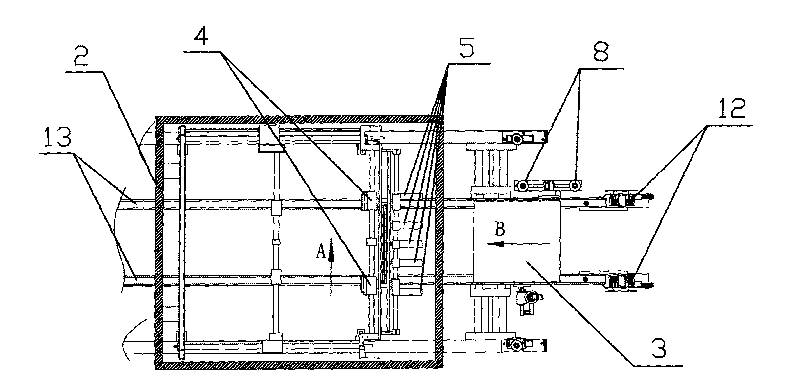

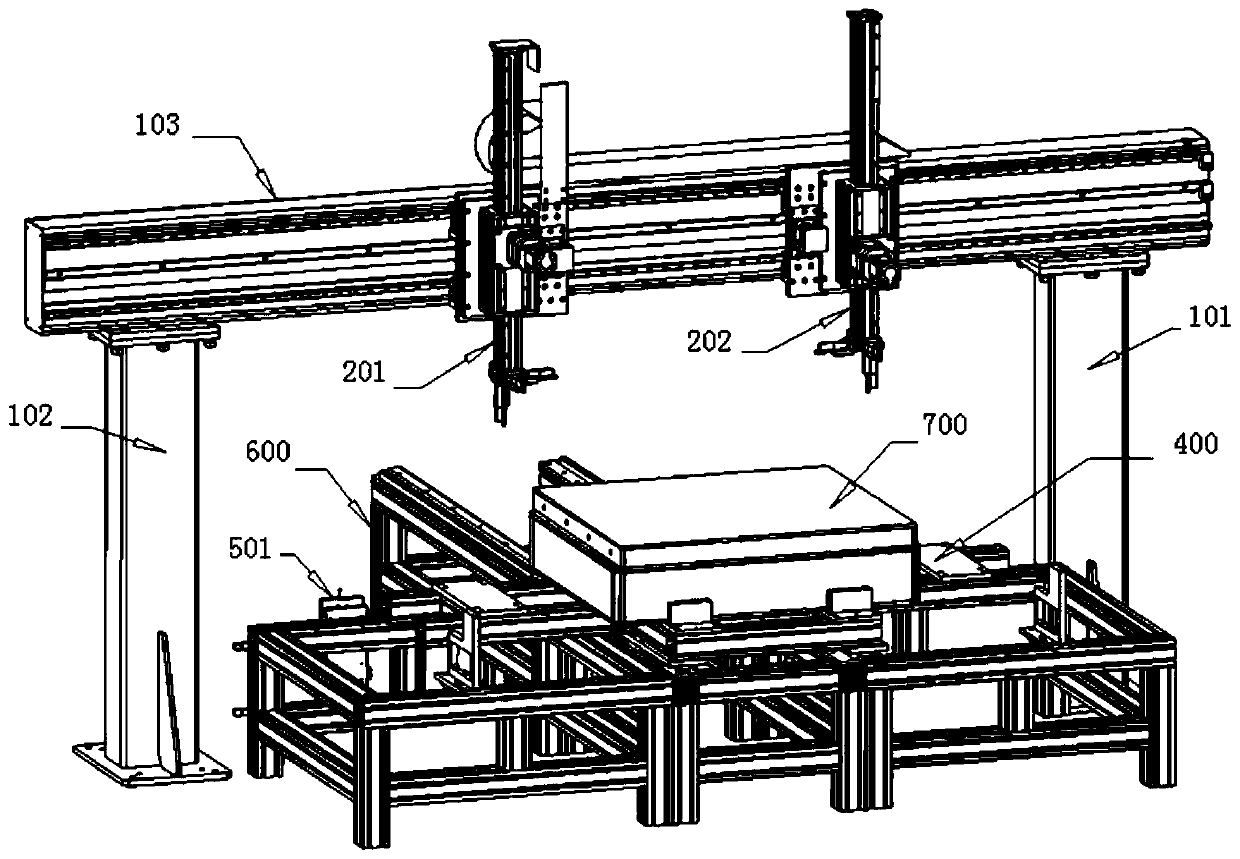

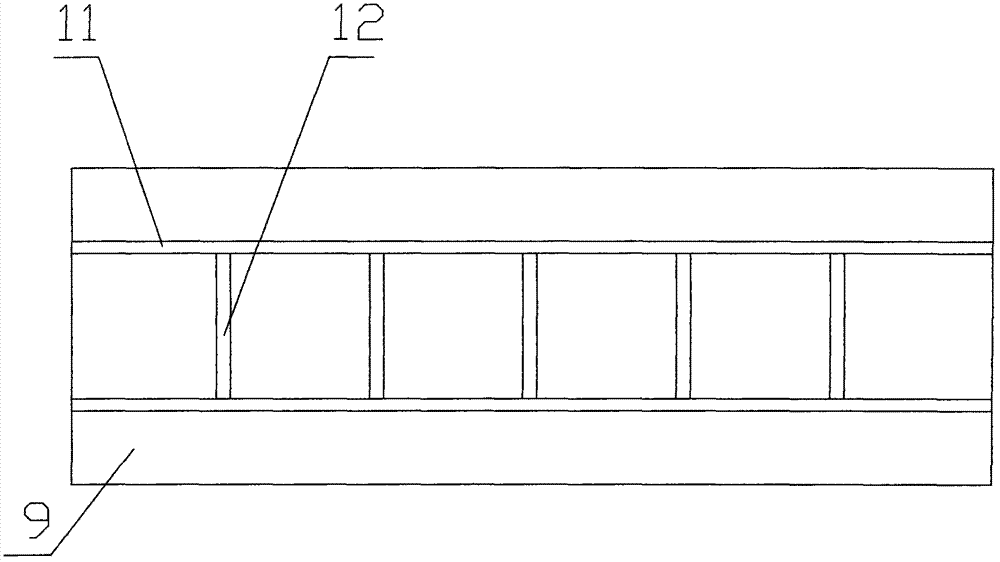

Full-automatic contact type measuring equipment and method

ActiveCN110307813AHigh measurement accuracyReduced precision requirementsMeasurement devicesMeasurement deviceContact type

The invention relates to full-automatic contact type measuring equipment and method. The full-automatic contact type measuring equipment comprises a test bench, a longitudinal sliding table and a cross beam, wherein the longitudinal sliding table is longitudinally and slidably arranged on the test bench and can be used for fixedly placing a measured workpiece, the cross beam is suspended above thetest bench, and at least one measuring arm which can move back and forth along the cross beam is arranged on the cross beam. Compared with the prior art, the equipment in the invention is the equipment specially for rapid and high-precision measurement of the geometric dimension of the large-size workpieces with pores and burrs on the surface, the size of the workpiece is measured by means of a contact type displacement sensor, the defects of the existing measuring method are avoided, so that the influence of the pores and burrs on the surface of the workpiece on precision can be avoided by the measuring equipment, the measurement of the large-size workpiece is more efficient and accurate, relatively complicated workpiece shapes can be adapted to, various dimensions of the thickness, theperpendicularity, the parallelism, the flatness and the like can be measured; meanwhile, the cost of the measuring equipment is lower, and the maintenance and the calibration are simpler and more convenient.

Owner:SHANGHAI JIAO TONG UNIV +1

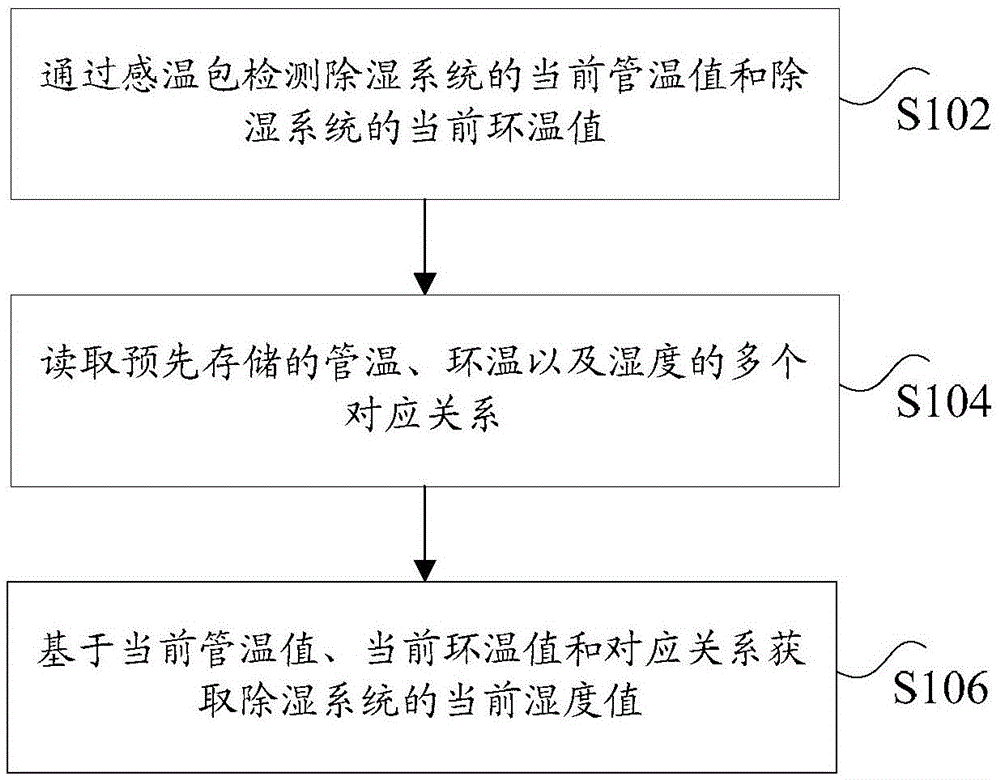

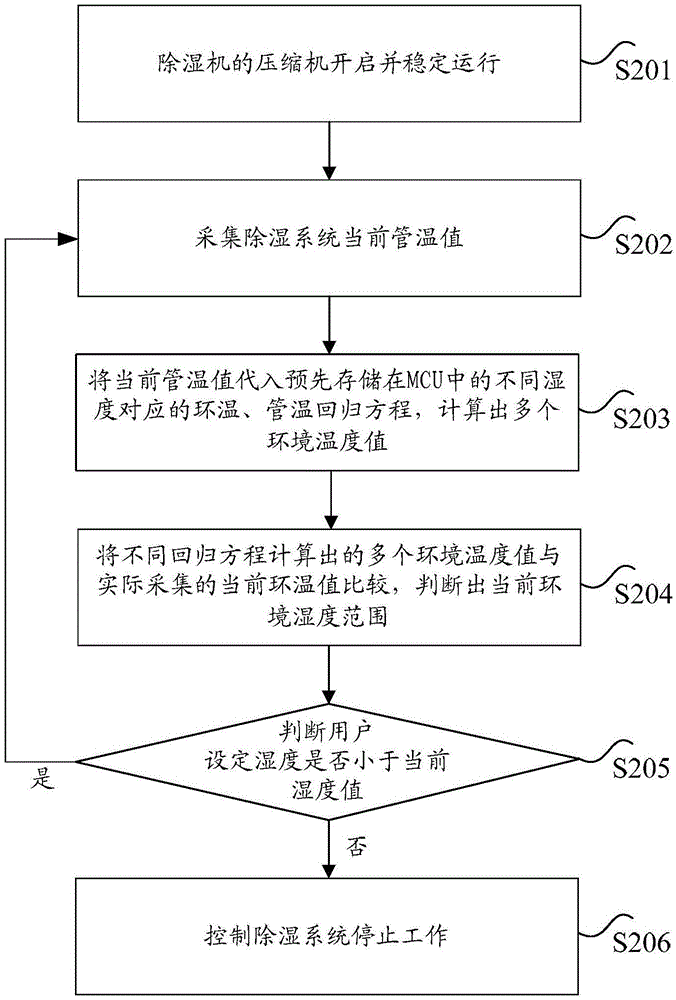

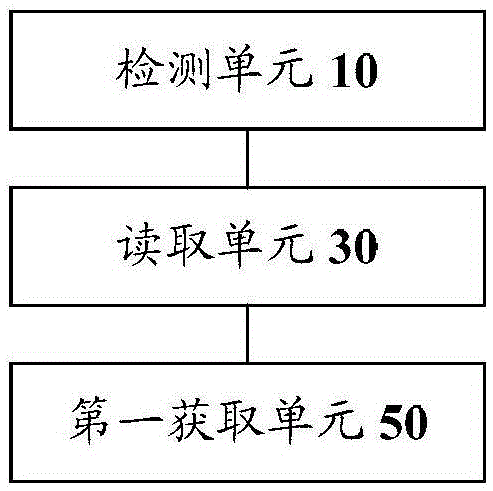

Humidity detection method, device and system for dehumidifier

InactiveCN105546712AReduce placement requirementsSimple structural designMechanical apparatusSpace heating and ventilation safety systemsEngineeringMoisture sensor

The invention discloses a humidity detection method, device and system for a dehumidifier. The humidity detection method comprises the steps that the current pipe temperature value of a dehumidification system and the current environment temperature value of the dehumidification system are detected through a thermometer bulb; pre-stored multiple pipe temperature, environment temperature and humidity corresponding relations are read, and the different corresponding relations are used for describing the corresponding relations of different humidity values, pipe temperatures and environment temperature; and the current humidity value of the dehumidification system is obtained based on the current pipe temperature value, the current environment temperature value and the corresponding relations. By the adoption of the humidity detection method, device and system for the dehumidifier, the technical problem that starting and stopping anomalies of the dehumidifier occur frequently due to the fact that the placing position of a humidity sensor is unreasonable is solved.

Owner:GREE ELECTRIC APPLIANCES INC

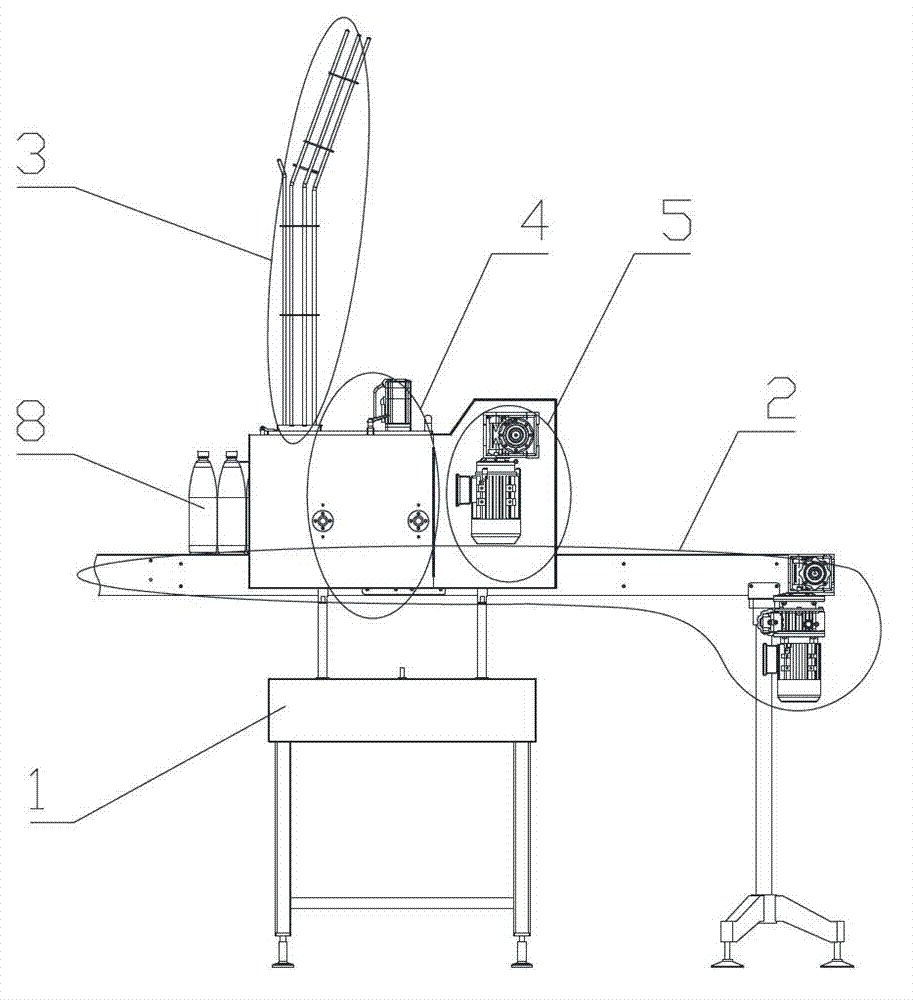

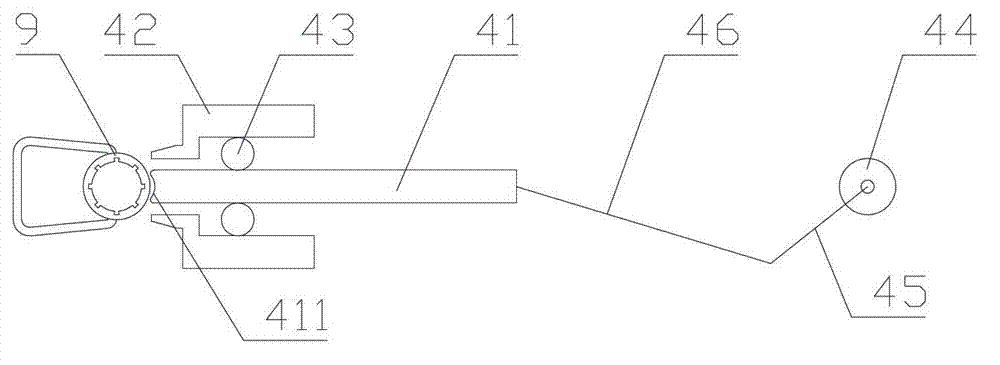

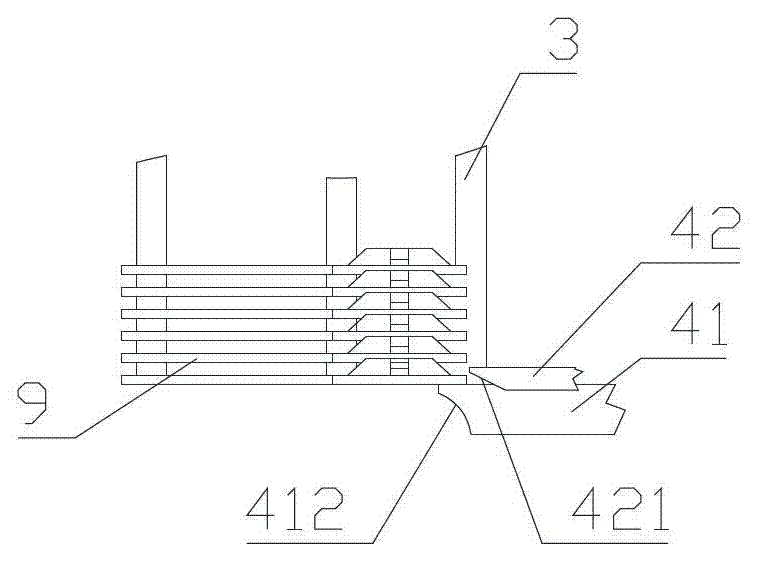

Lifting ring assembling device

ActiveCN103112624ARealize mechanical automation assemblyAvoid direct contactPackagingEngineeringBottle

The invention discloses a lifting ring assembling device, and belongs to automatic production machines. The lifting ring assembling device is convenient to use, and has a wide range of application. The lifting ring assembling device comprises a frame, a conveying part, a storing part, a ring separating part and a ring pressing part, and the conveying part, the storing part, the ring separating part and the ring pressing part are arranged on the frame. The storing part, the ring separating part and the ring pressing part are arranged from front to back sequentially and above the feeding part. The lifting ring separating part is corresponding to the lower end of the storing part. The lifting ring assembling device is used for assembling lifting rings on bottle containers.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

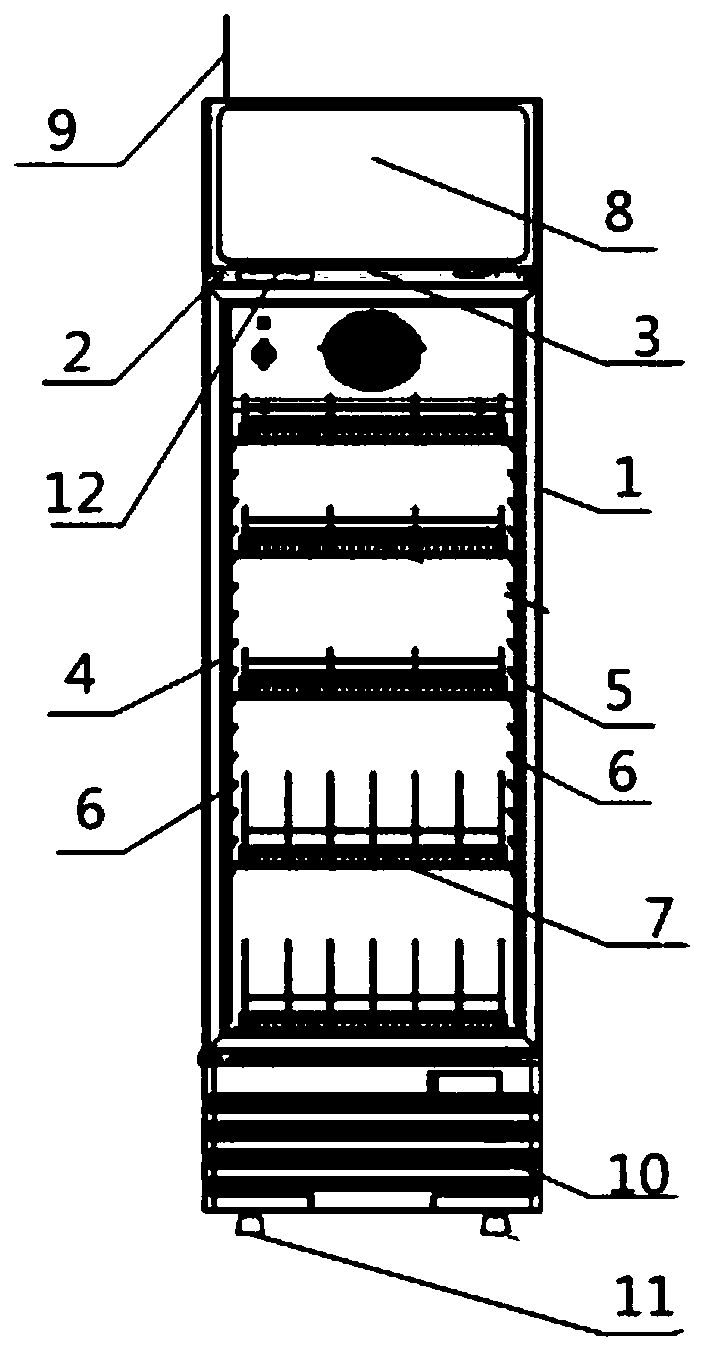

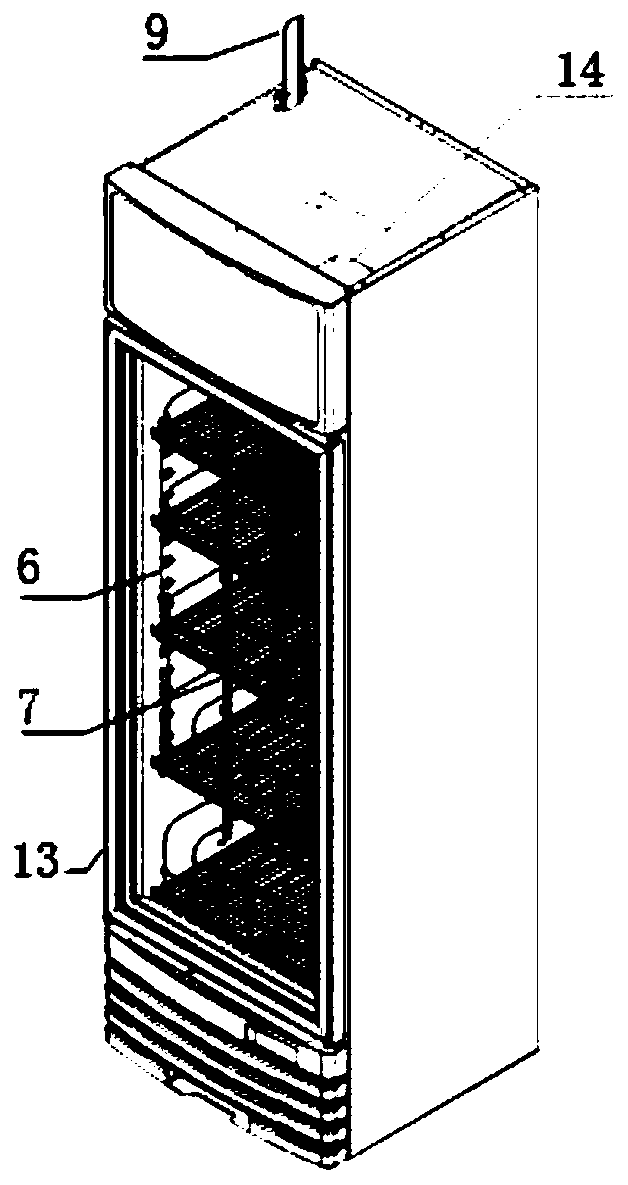

AI (Artificial Intelligence) intelligent vending cabinet based on dynamic visual recognition

PendingCN110136328AImprove accuracyReduced Lighting Intensity RequirementsTelevision system detailsCoin-freed apparatus detailsWireless transmissionComputer graphics (images)

The invention discloses an AI (Artificial Intelligence) intelligent vending cabinet based on dynamic visual recognition. The vending cabinet is communicatively connected with a cloud server. The vending cabinet comprises a cabinet body provided with at least one shelf, a camera disposed on the cabinet body, and a control module connected with the camera and a wireless transmission module; the cloud server includes a dynamic visual recognition algorithm processing module and a storage space; the camera shoots the whole process that an object departs away the cabinet body into a video and the video is uploaded to the cloud server through the wireless transmission module; video processing calculation recognition is performed by the dynamic visual recognition algorithm; and the recognized result is sent to a user payment terminal through a network for fee deduction. According to the AI intelligent vending cabinet based on dynamic visual recognition disclosed by the invention, the number ofhardware components of the vending cabinet can be decreased, the assembly of the hardware is simplified, the superposition placement of multiple commodities in the vending cabinet is implemented, thus the cost of the whole machine is reduced, the space utilization rate of the vending cabinet is improved, the unmanned retail is implemented and the retail labor cost and the site rental cost are greatly reduced.

Owner:武汉市哈哈便利科技有限公司

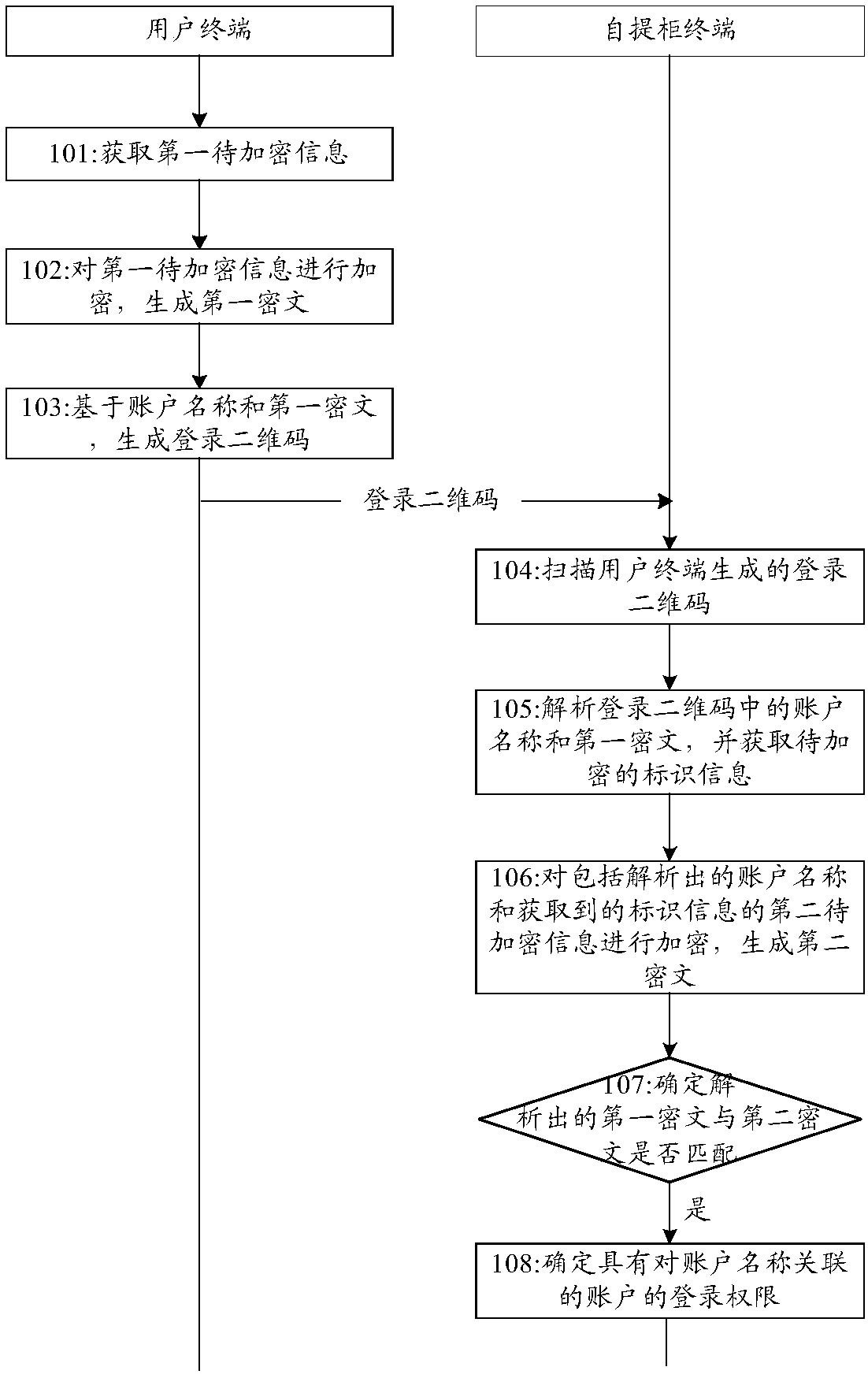

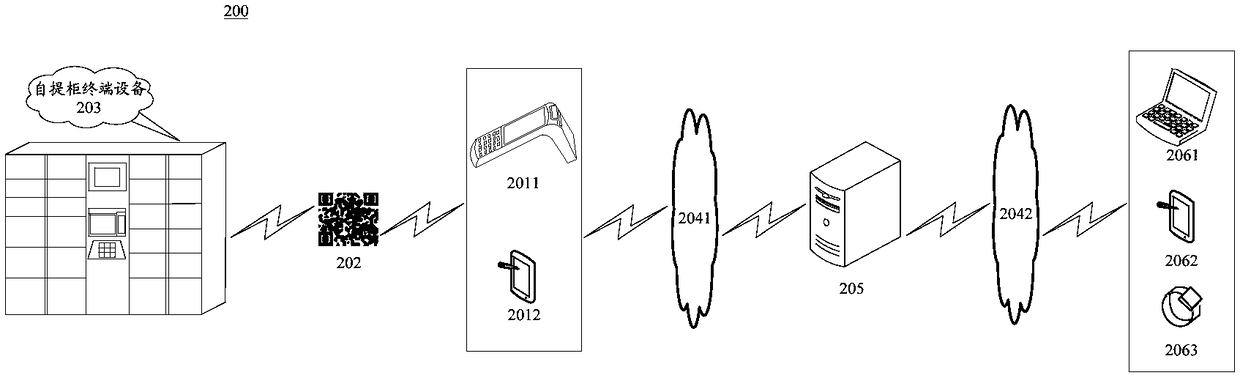

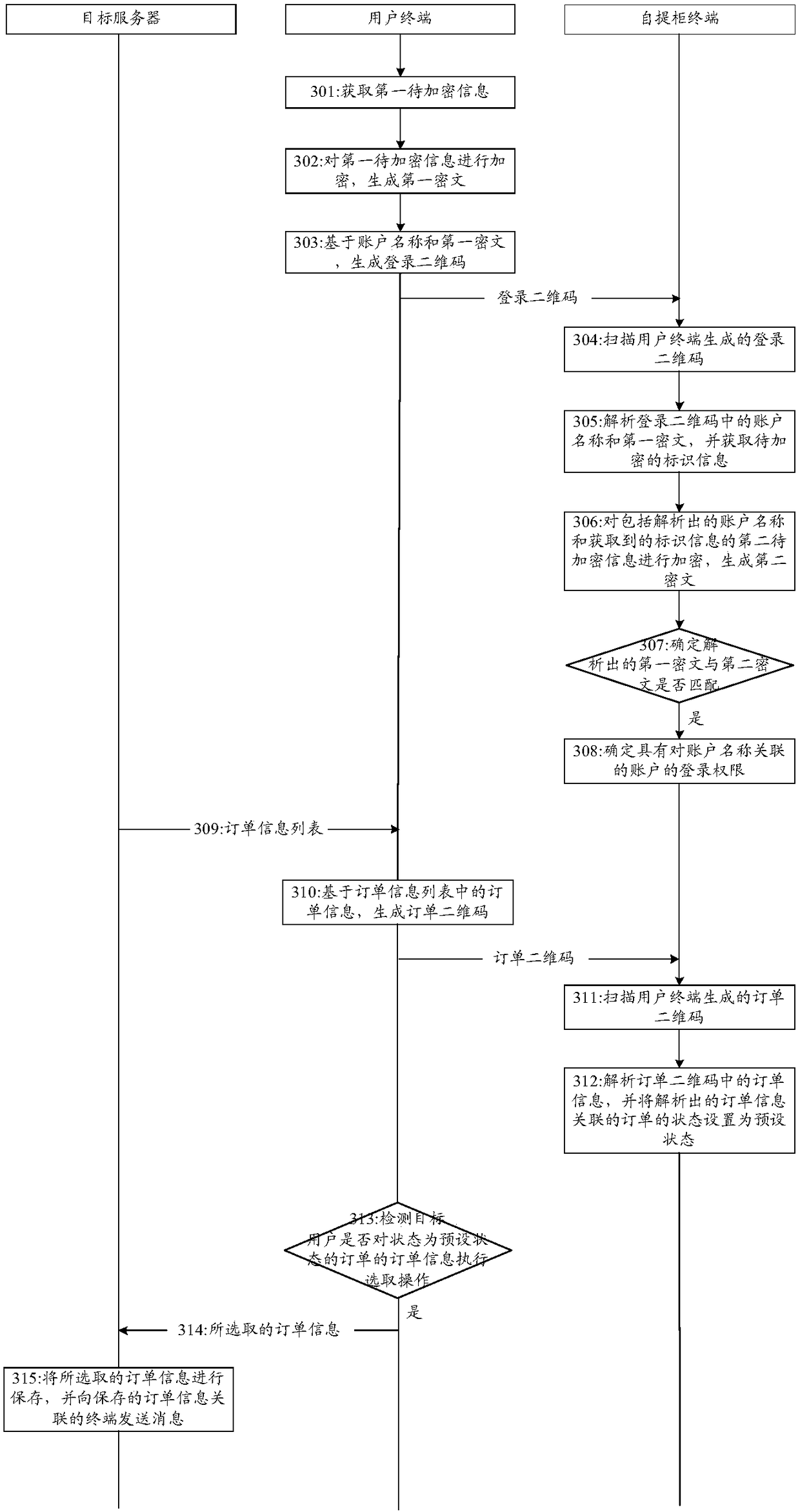

Method, apparatus and system for determining authority

ActiveCN108805640AReduce placement requirementsImprove network securityCo-operative working arrangementsComputer security arrangementsCiphertextNetwork security

A method, system and apparatus for determining an authority are disclosed. A specific embodiment of the method includes: acquiring first information to be encrypted, wherein the first information to be encrypted comprises an account name of a target user and identification information of a pick-up cabinet terminal selected by the target user; encrypting the first information to be encrypted to generate a first ciphertext; based on the account name and the first ciphertext, generating login two-dimensional code, so that the pick-up cabinet terminal can analyze the account name and the first ciphertext in the login two-dimensional code by scanning the login two-dimensional code, and encrypting second information to be encrypted including the analyzed account name and the obtained identification information to be encrypted to generate a second ciphertext, determining whether the first ciphertext matches the second ciphertext, and if yes, determining the login authority of an account associated with the account name. The implementation mode reduces the requirement of placing a pick-up cabinet, and improves the network security of a pick-up cabinet system.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

Automatic ceramic tile detector

The invention discloses an automatic ceramic tile detector. The detector comprises a worktable, a tile clamping mechanism, a distance adjusting mechanism, a tile delivering mechanism and a detection mechanism, wherein the tile delivering mechanism is arranged on the worktable; the tile clamping mechanism is arranged at the head end of the tile delivering mechanism; the distance adjusting mechanism is arranged below the tile delivering structure; and the detection mechanism is positioned above the tile delivering mechanism and is fixedly connected with the worktable. The ceramic tile automatic detector is characterized in that: the detection mechanism consists of a shell and a sensor arranged in the shell; the sensor comprises an outline dimension sensor for detecting the outline dimension of a ceramic tile and a planeness sensor for detecting the planeness of the ceramic tile; the outline dimension sensor is arranged at the upper and lower edges along a ceramic tile delivering direction; and the planeness sensor is connected in series above the upper surface of the ceramic tile by a cross rod of the shell. The automatic ceramic tile detector not only can detect the size and surface quality of the ceramic tile in a fully automatic way, but also has the characteristics of high accuracy, high efficiency and simple structure and saves a large amount of time, labor power, financial power and physical resources.

Owner:FOSHAN SANSHUI YINGJIE PRECISION MACHINERY

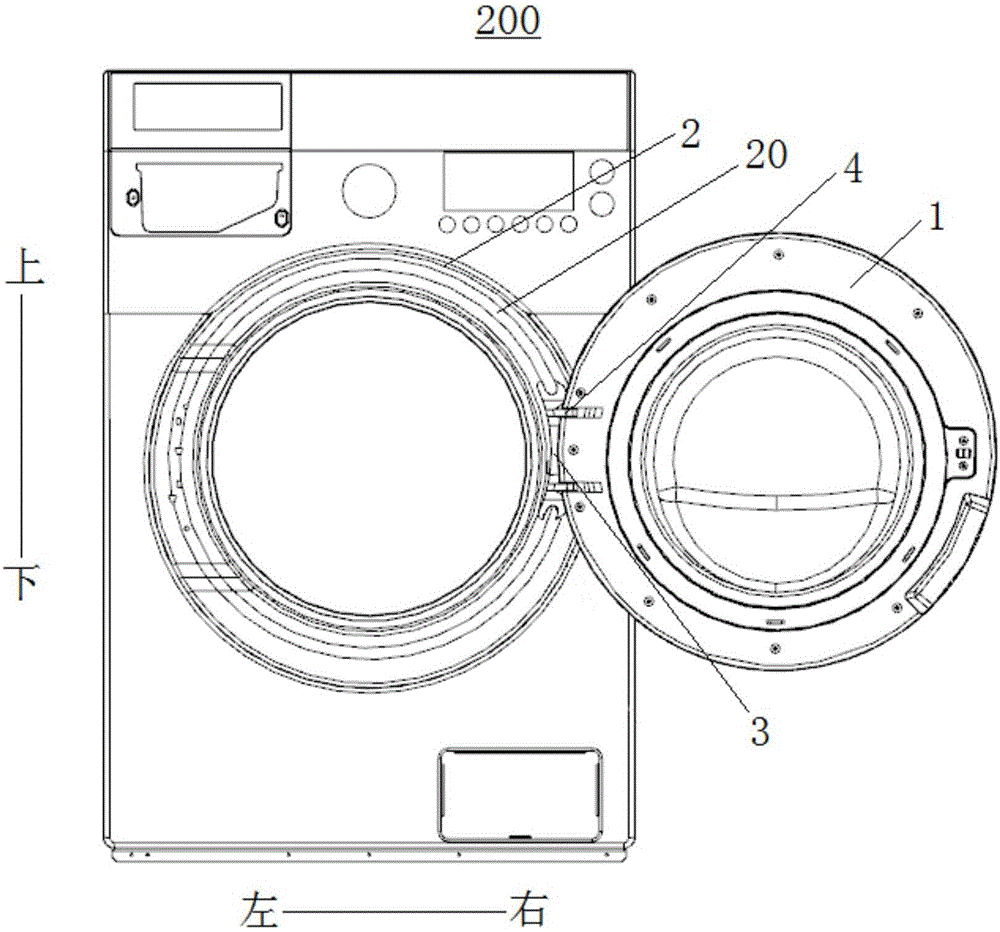

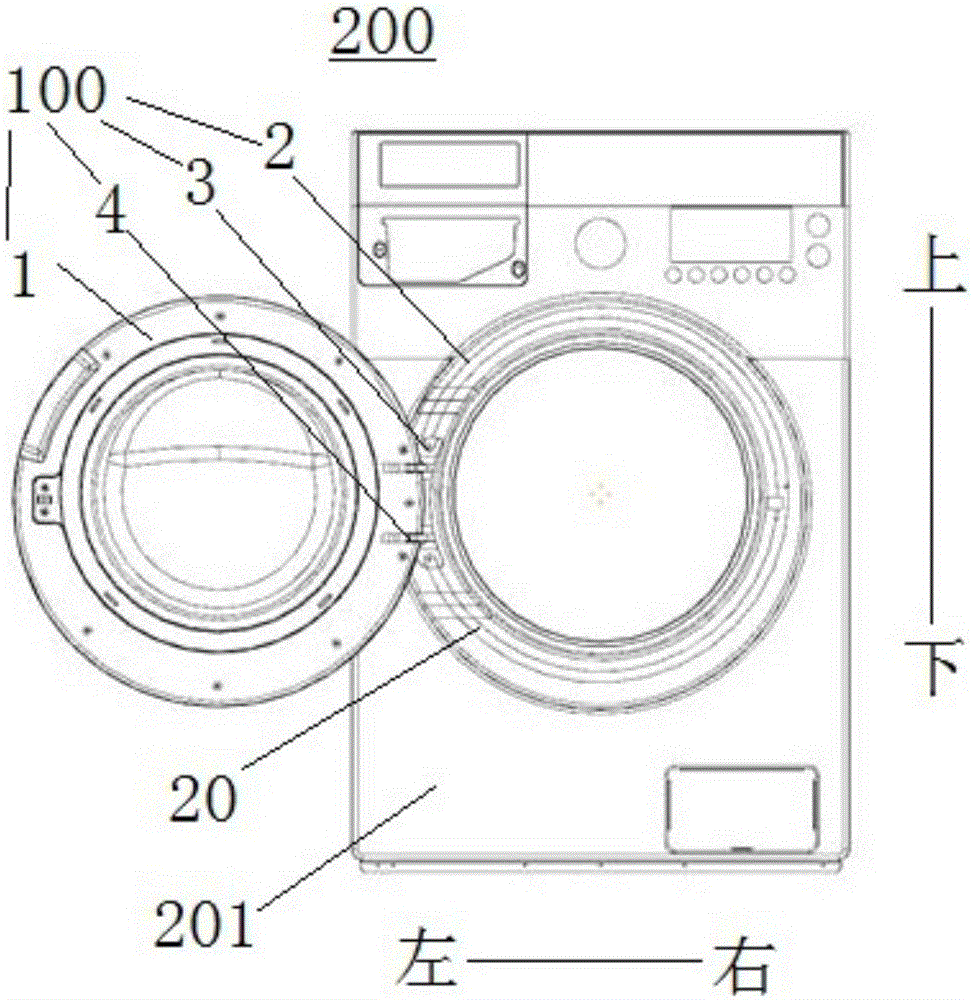

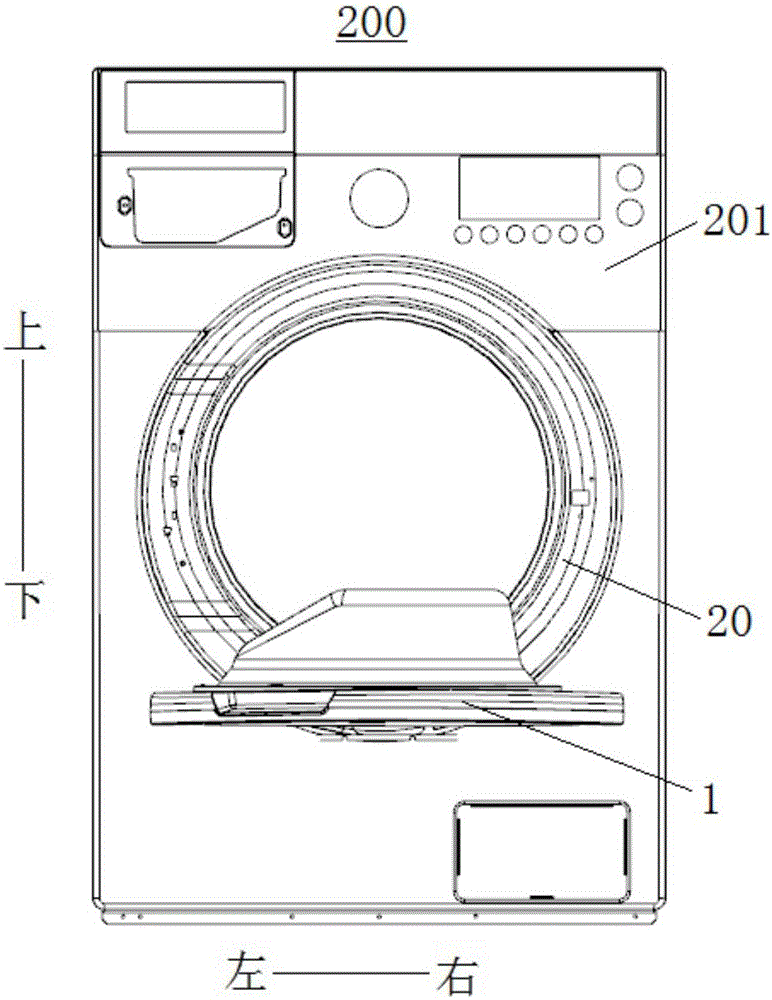

Door body assembly for clothes processor and clothes processor with door body assembly

ActiveCN105937150AReduce placement requirementsFlexible and convenient to useOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a door body assembly for a clothes processor and the clothes processor with the door body assembly. The door body assembly comprises a door body, a seal ring suitable for being installed on a machine shell of the clothes processor, a sliding piece arranged in a slide groove in a slidable mode and connected with the door body in a pivoting mode, and a fixed piece arranged on the sliding piece and detachably connected with the seal ring so that the sliding piece can be fixed to the seal ring, wherein the slide groove extending in the circumferential direction of the seal ring is formed in the front side face of the seal ring. According to the door body assembly, the door body opened direction can be changed, the requirement for arrangement sites is low, and use is convenient and flexible.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Full-automatic contact type measuring device and method

ActiveCN110307814AImprove efficiencyHigh measurement accuracyMeasurement devicesMeasurement deviceContact type

The invention relates to a full-automatic contact type measuring device and method. The measuring device comprises a test bench, a longitudinal sliding table and a cross beam, wherein the longitudinalsliding table is longitudinally arranged on the test bench in a sliding mode and can be used for fixedly placing a measured workpiece, the cross beam is suspended above the test bench, and a measuring arm which can move back and forth along the cross beam is arranged on the cross beam. Compared with the prior art, the device in the invention is the device specially for rapid and high-precision measurement of the geometric dimension of large-size workpieces with pores and burrs on the surface, a contact type displacement sensor is used for measuring the size of the workpiece, and the defects of the existing measuring method are avoided, so that the influence of the pores and burrs on the surface of the workpiece on the precision can be avoided by the measuring device, the measurement of the large-size workpiece is more efficient and accurate, relatively complex workpiece shapes can be adapted to, and various dimensions of the thickness, the perpendicularity, the parallelism, the flatness and the like can be measured; meanwhile, the cost of the measuring device is lower, and the maintenance and the calibration are simpler and more convenient.

Owner:SHANGHAI JIAO TONG UNIV +1

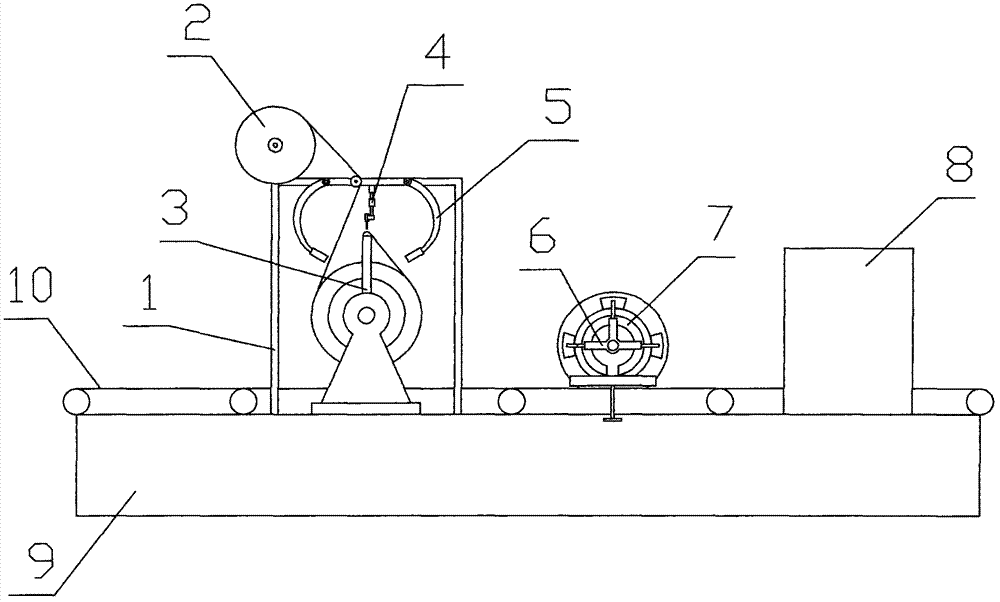

Tyre packing machine and packing method

InactiveCN102730223AShorten the lengthImprove aestheticsWrappers shrinkageWrappingCooking & bakingUtilization rate

The invention discloses a tyre packing machine, which comprises a vertical tyre feeding device. A tyre surface wrapping device, a tyre inner ring bonding device and a baking and tightening device are sequentially arranged on the vertical tyre feeding device along the tyre feeding direction. A tyre lifting device of the tyre packing machine can be used for positioning a tyre, the requirement for the placing position of a material fed by a feeding device is low, the joint of packing tapes on the surface of the tyre is short, and the joint is only positioned at a certain position on the outer periphery of the tyre; the probability of breakage of the tyre in the carrying process is reduced, packing aesthetic feeling is promoted, little packing waste is produced, the utilization rate of a packing material is high, and the packing cost is low; by adjusting the height of the tyre packing device, the tyre packing machine can be used for packing tyres with different sizes and is strong in compatibility; through two heating bonding plates on a tool rest and an annular hot knife in the inner ring bonding device, attractiveness of the bonding surface is ensured; and through the baking and tightening device, the packing tapes are tightly attached to the surface of the tyre, and packing tightness and firmness are improved.

Owner:青岛科力达机械制造有限公司

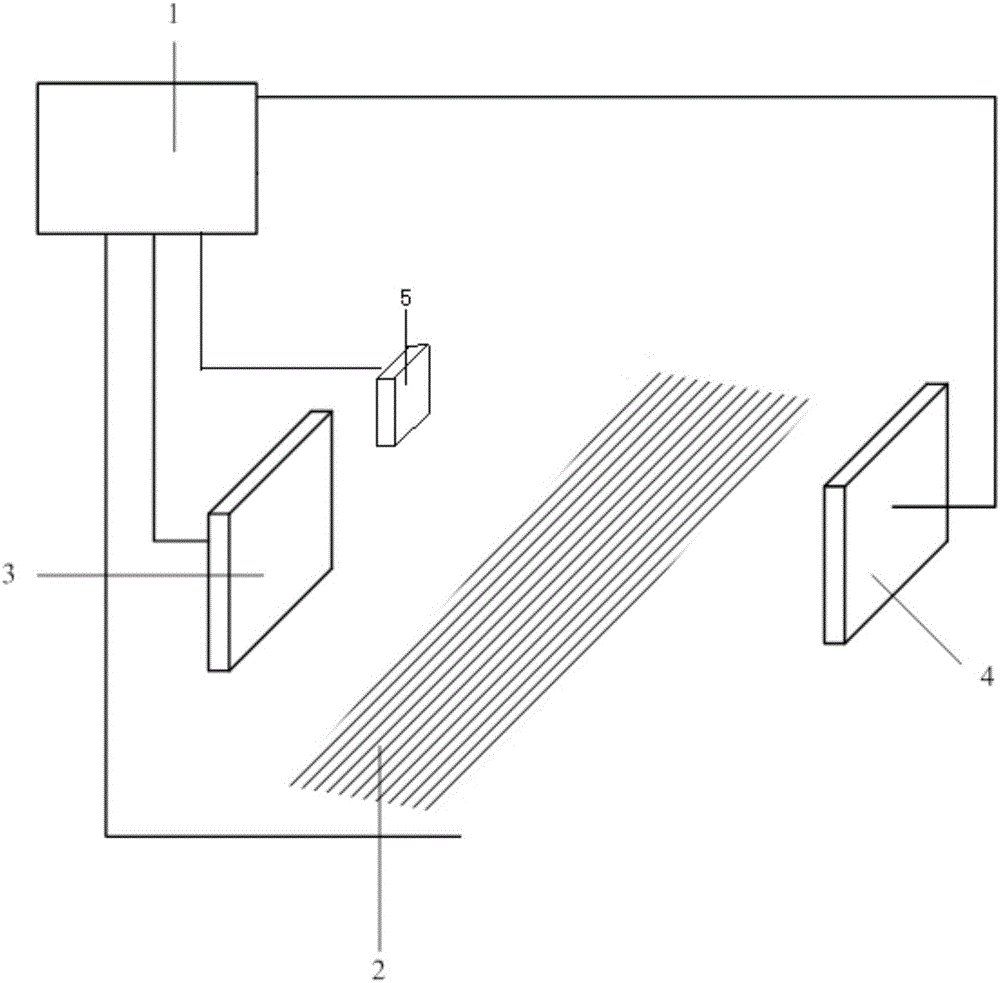

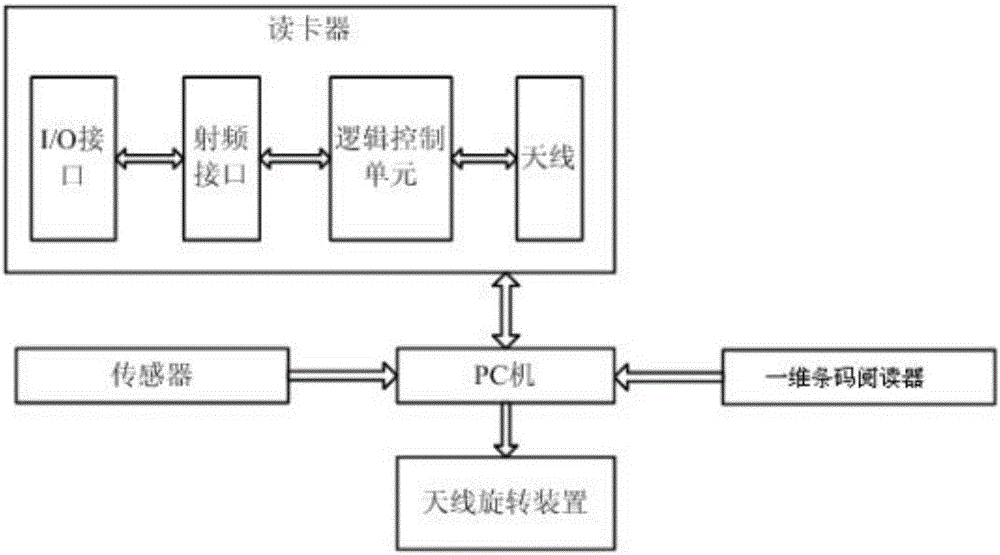

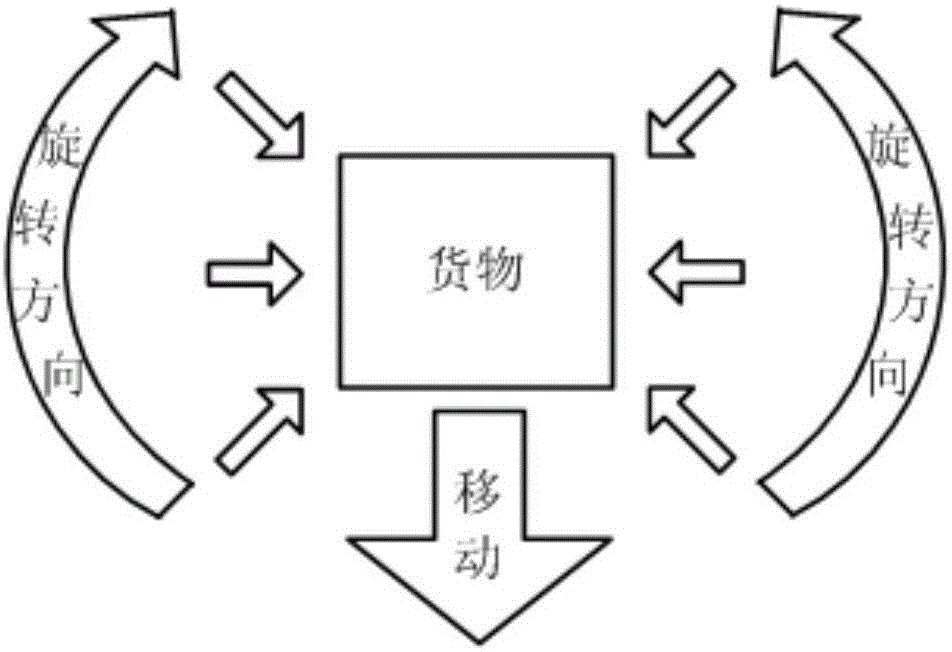

Barcode reading and locating based tracking locking RFID fusion system and method

InactiveCN105868801AReduce placement requirementsExtend signal coverageCo-operative working arrangementsBarcode readerPosition sensor

The invention relates to the technical field of radio-frequency identification (RFID), in particular to a one-dimensional barcode reading and locating based tracking locking RFID fusion system and method. The system comprises a cargo channel, sensors, a barcode reader, antenna rotation apparatuses and an antenna gate, wherein the cargo channel penetrates through the antenna gate; the sensors are in communication connection with the antenna rotation apparatuses and are used for detecting the cargo channel and sending a detection result to the antenna rotation apparatuses; the antenna gate comprises a plurality of antennae; the antennae are connected with the antenna rotation apparatuses in a one-to-one correspondence manner; and the antenna rotation apparatuses are used for rotating and driving the antennae when the sensors detect that cargos exist on the cargo channel. According to the system, initial position information of the cargos is obtained through the position sensors on the channel, the moving speed of the cargos is calculated, and the rotating angular speed of each antenna is dynamically controlled, so that antenna signals can be always aligned to the cargos; and while the barcode reader reads one-dimensional code information, RFID tag information is read and bound by fusion.

Owner:SHANGHAI SHENTENG INFORMATION TECH CO LTD

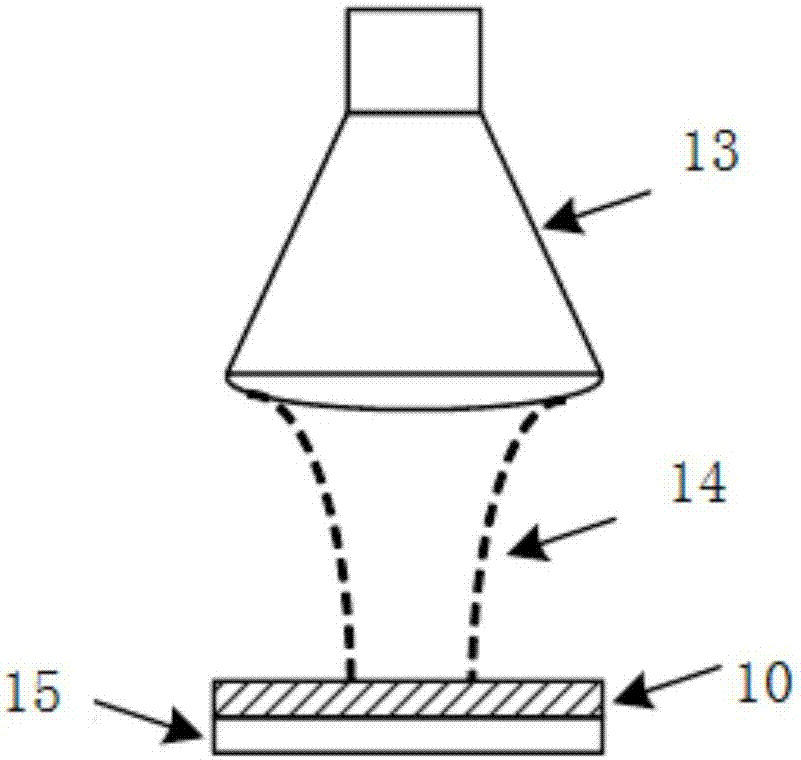

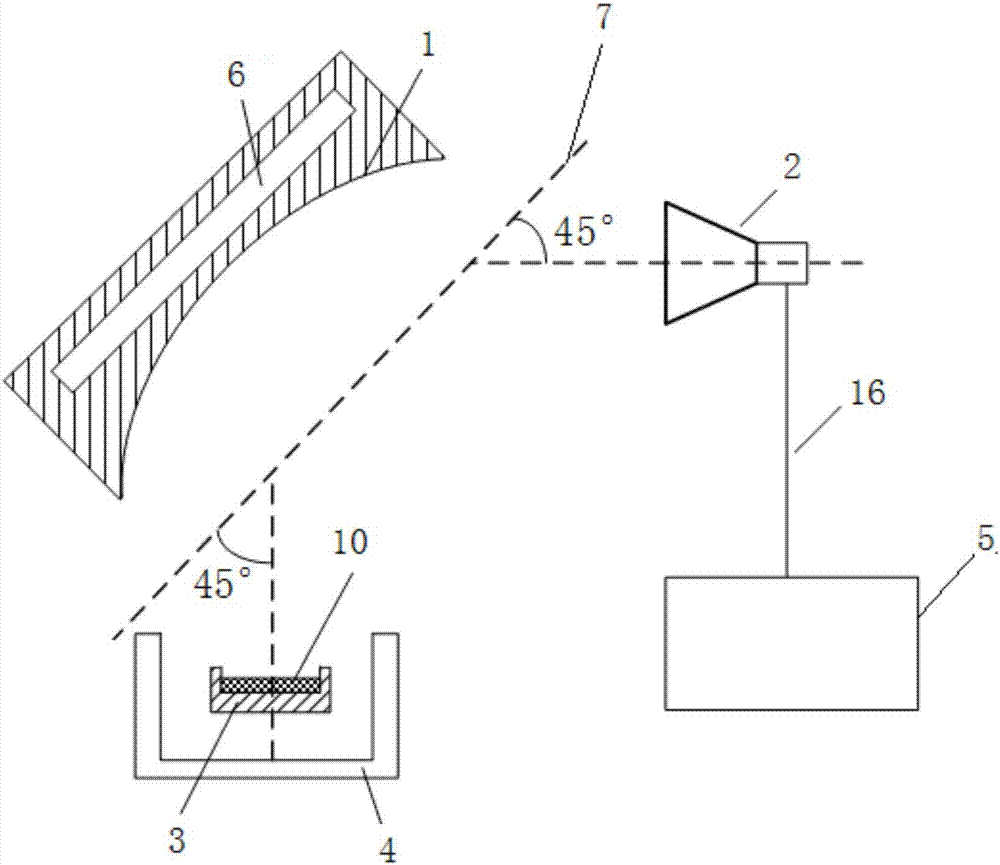

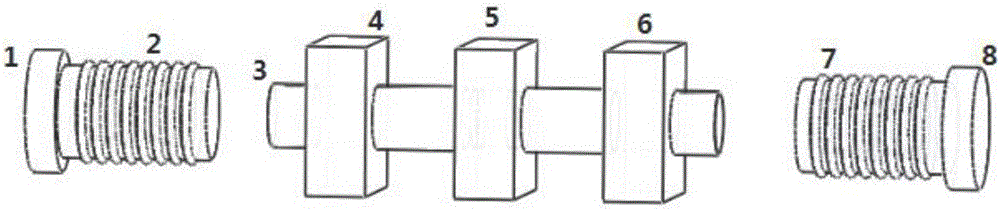

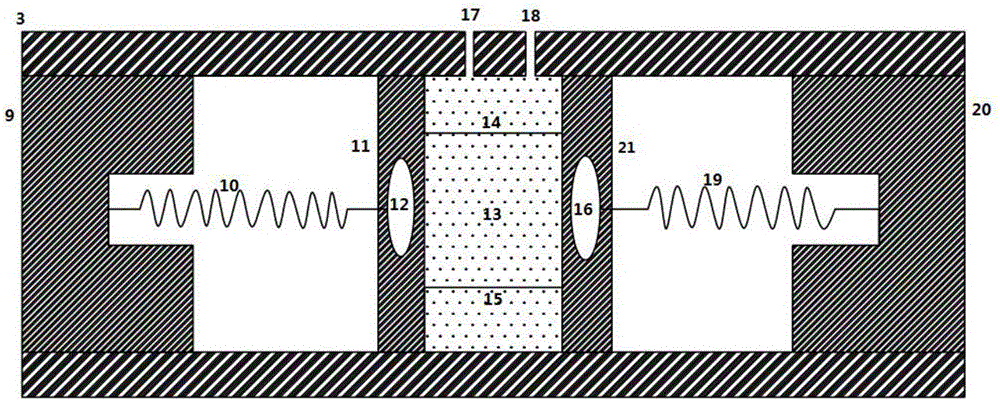

Ellipsoidal-reflector-based material complex dielectric constant high temperature testing device and method

ActiveCN107290595AImprove test accuracyImprove test stabilityDielectric property measurementsDielectricLow demand

The invention provides an ellipsoidal-reflector-based material complex dielectric constant high temperature testing device and testing method. The ellipsoidal-reflector-based material complex dielectric constant high temperature testing device includes an ellipsoidal reflector, a horn antenna, a metal crucible, a high temperature furnace and a vector network analyzer, wherein the vector network analyzer is connected with the horn antenna through a microwave cable; the reflection plane of the ellipsoidal reflector is one part of a rotation ellipsoid; a long axis of the rotation ellipsoid and the axis of the horn antenna form a 45DEG included angle, and the long axis of the rotation ellipsoid and the normal of the metal crucible form a 45DEG included angle; the phase center of the horn antenna is located at one focus of the ellipsoidal reflector; and the center of the upper surface of the metal crucible is located at the other focus of the ellipsoidal reflector. The ellipsoidal-reflector-based material complex dielectric constant high temperature testing device has the advantages of high testing accuracy, high testing stability, low usage and maintenance cost and low demand for sample arrangement. Besides, the ellipsoidal-reflector-based material complex dielectric constant high temperature testing device can guarantee stability of the focusing wave beam amplitude and phase during the high temperature testing process as the ellipsoidal reflector is used, so that the accuracy of the test result can be guaranteed.

Owner:成都恩驰微波科技有限公司

Artificial eel hatching box and artificial eel hatching method

InactiveCN103960186AIncrease heightWater level does not affectClimate change adaptationPisciculture and aquariaAnimal scienceMedicine

The invention discloses an artificial eel hatching box which comprises a box body and a sponge placed at the bottom of the box body. A water outlet is formed in the lateral wall of the box body, and the horizontal position of the water outlet is lower than the upper plane position of the sponge. The invention further discloses an artificial eel hatching method. The method includes the steps that the hatching box is horizontally placed at the position which cannot be radiated by sunlight directly; the water outlet of the latching box is blocked, and water is added into the hatching box; fertilized eggs of eels are placed on the sponge, and the box body is waggled horizontally to enable the eggs to be laid on the sponge horizontally; the water outlet is opened to enable the water to flow out naturally; the whole hatching process is completed under the condition of 28 DEG C water temperature. Water is added in the hatching box in a spraying mode twice every day. The sponge and fries are taken out from the hatching box together, and the sponge is placed on the water surface of a fry breeding box in an inverted mode. According to the artificial eel hatching box and the artificial eel hatching method, the height of the water level for fertilized egg hatching can be limited strictly; the placement requirements for the hatching box are greatly reduced; even if the fertilized eggs are completely exposed to the air, the hatching temperature can be guaranteed, and operation is simple and rapid.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

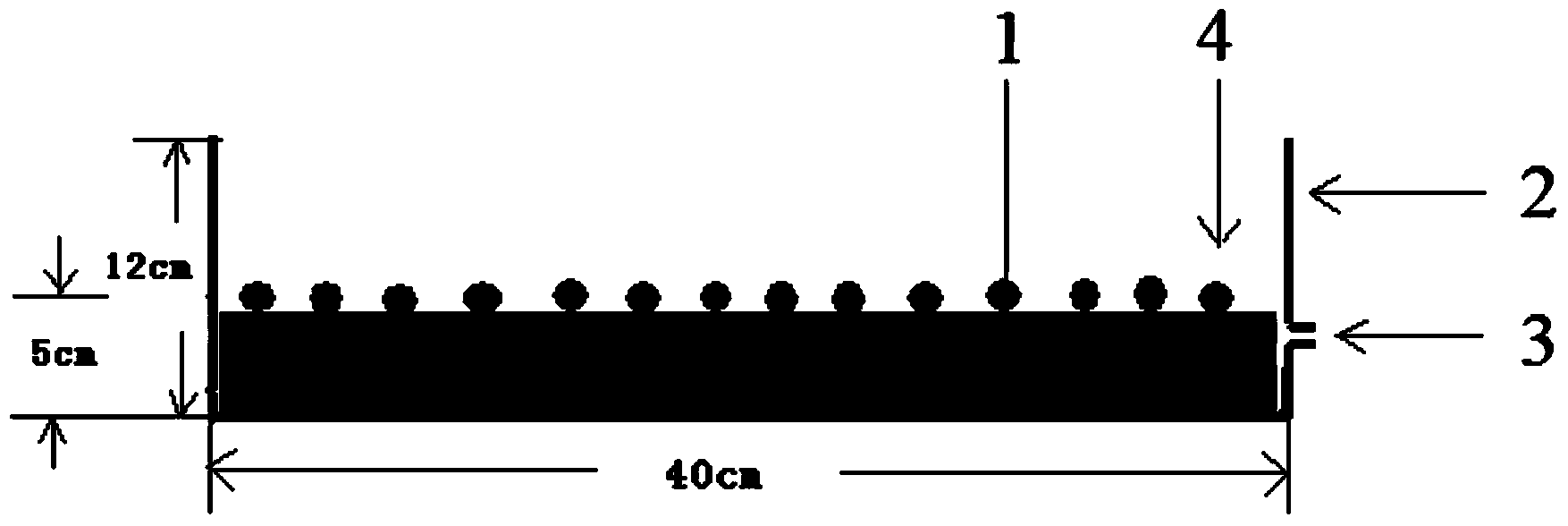

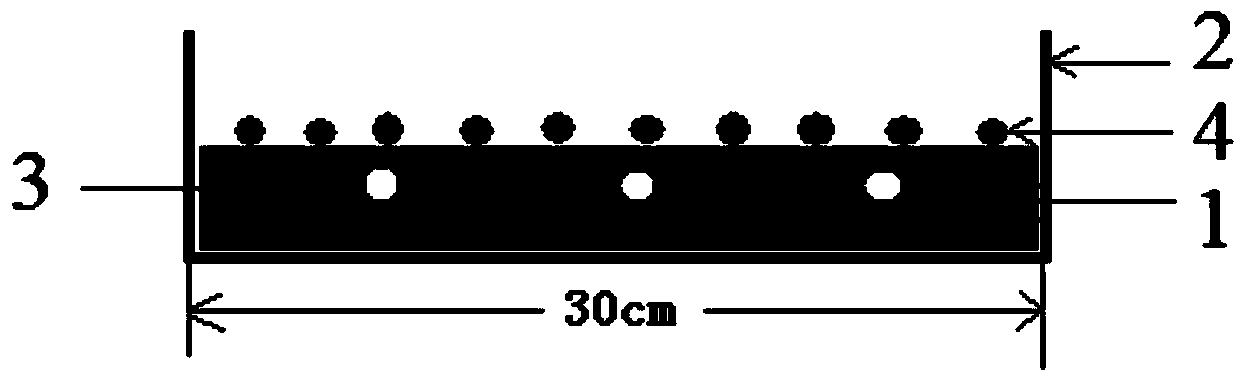

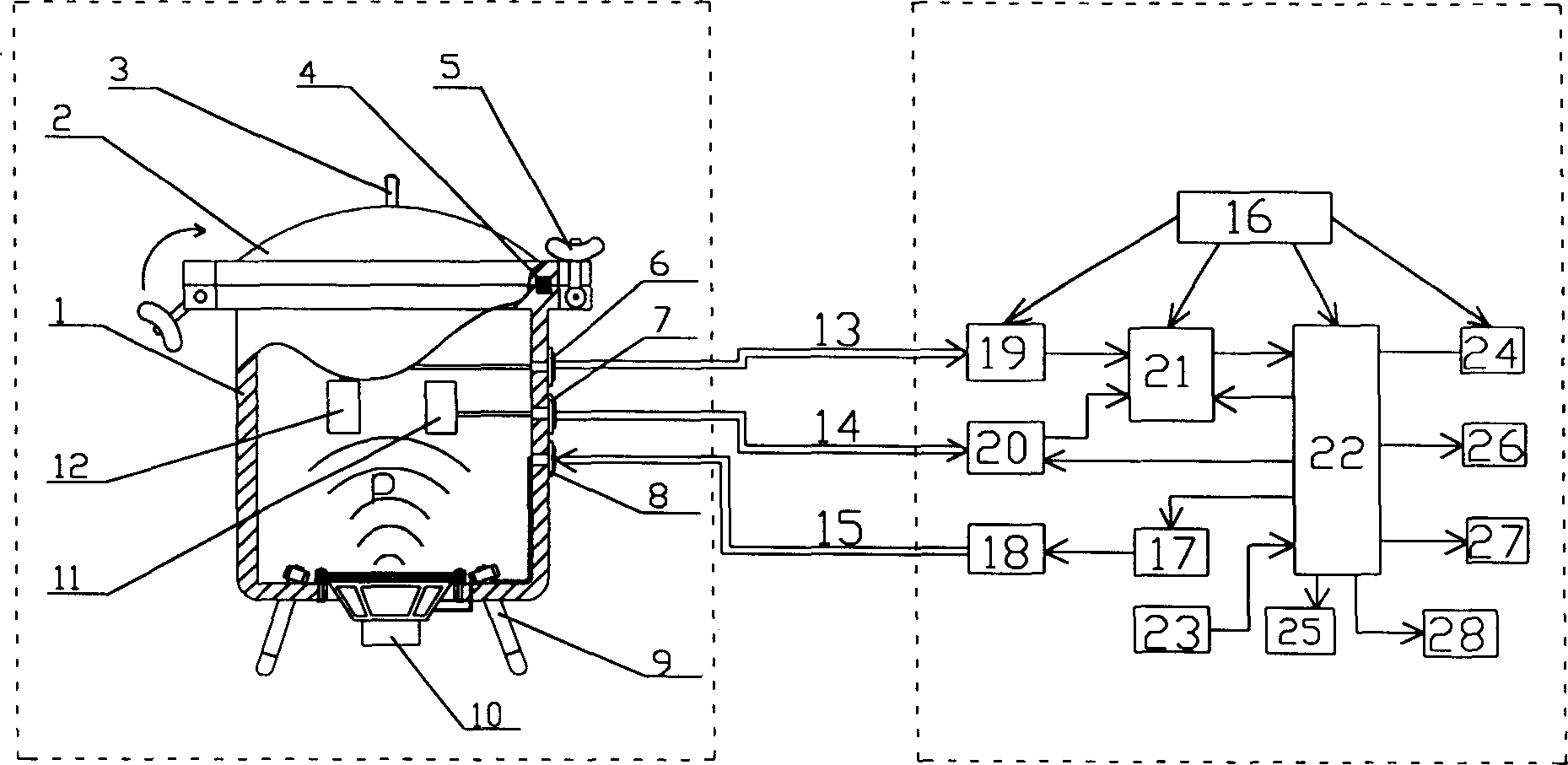

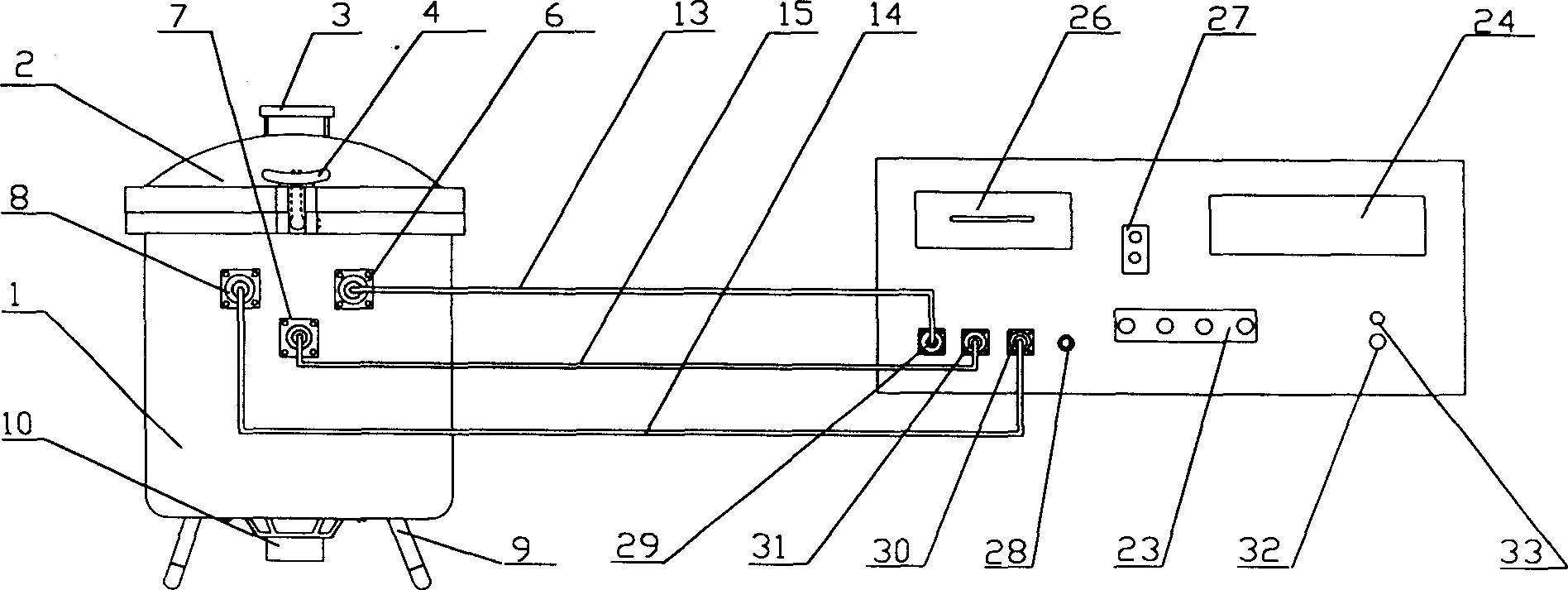

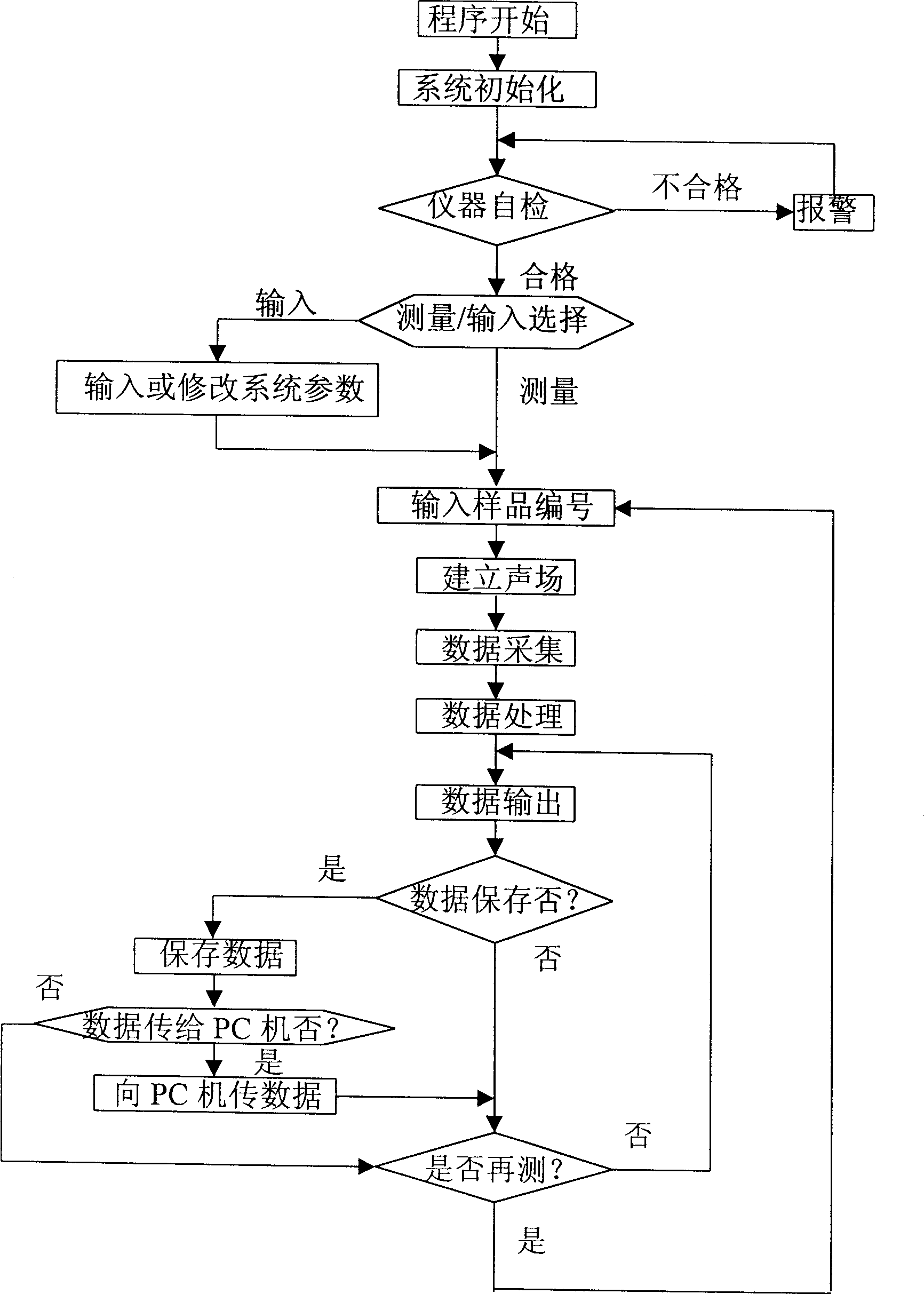

Portable wave detector low frequency receiving voltage sensitivity performance measurer

InactiveCN1425900AEasy to operateEasy to carryElectrical testingSeismic signal receiversBell mouthVoltage

The sensitivity performance measurer for low frequency voltage of portable wave detector includes sound field unit and electric circuit unit. The sound field unit is one sound pressure tank with driving sound source, signal output socket connected via wire to the standard detector and the measured detector inside the tank, and drive input socket connected via wire to the driving sound source, circular opening at the bottom for installing the drive sound source, which has belled mouth towards the openings. The drive input socket is also connected via cable to the output of the power amplifier in the electric circuit unit; and of the two signal output sockets one is connected via cable to the input of fixed gain amplifier in the circuit unit and the other to the input of program controlled amplifier.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

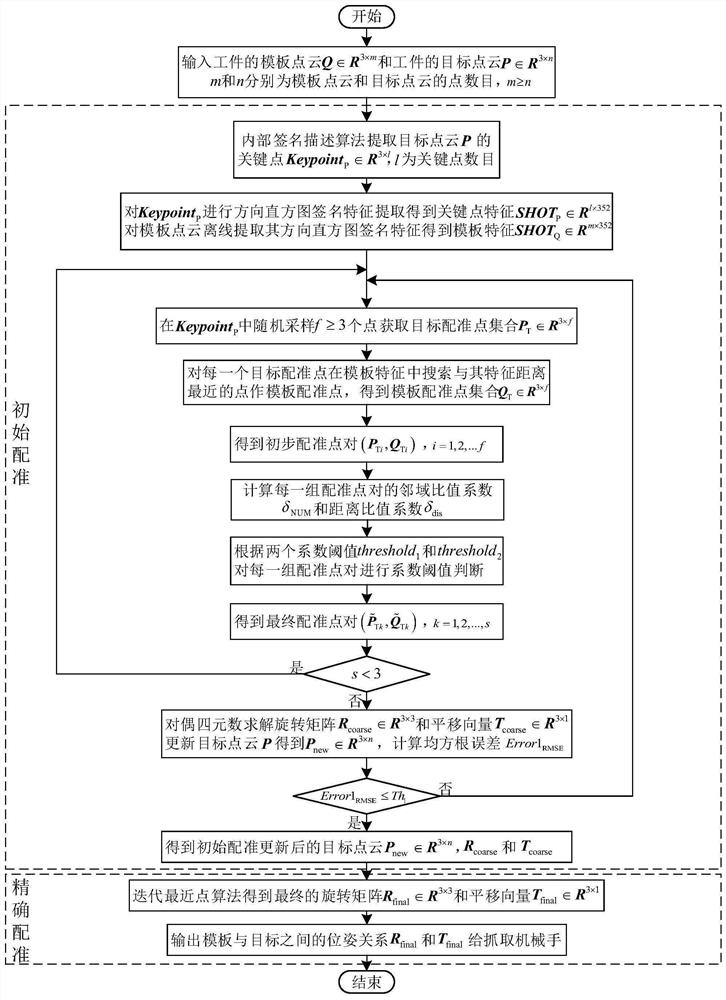

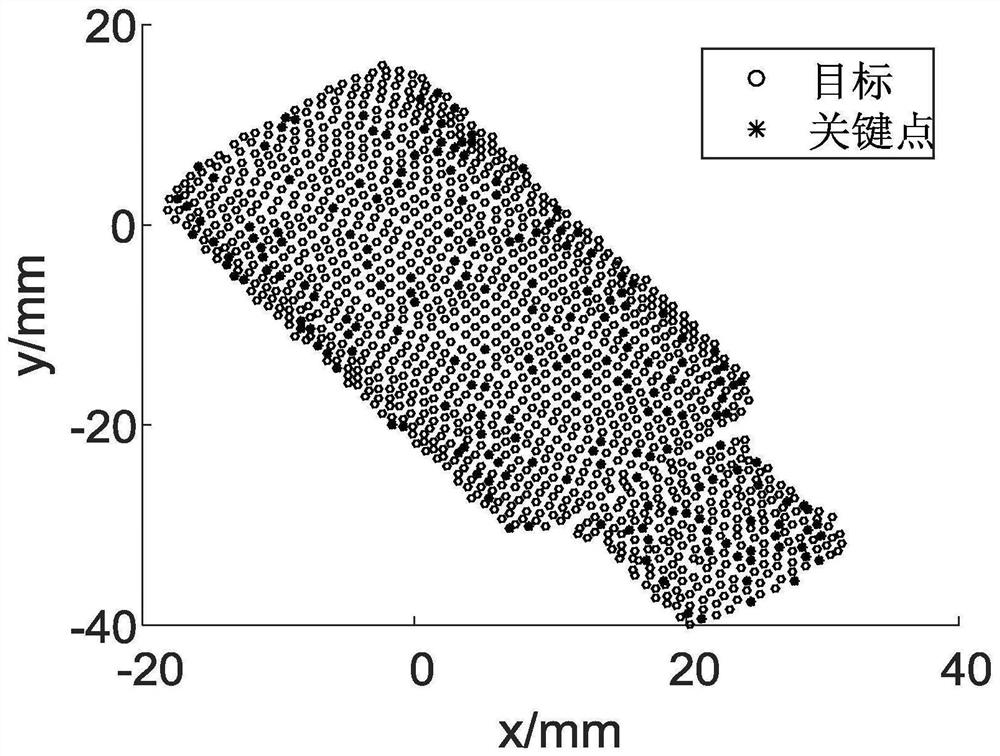

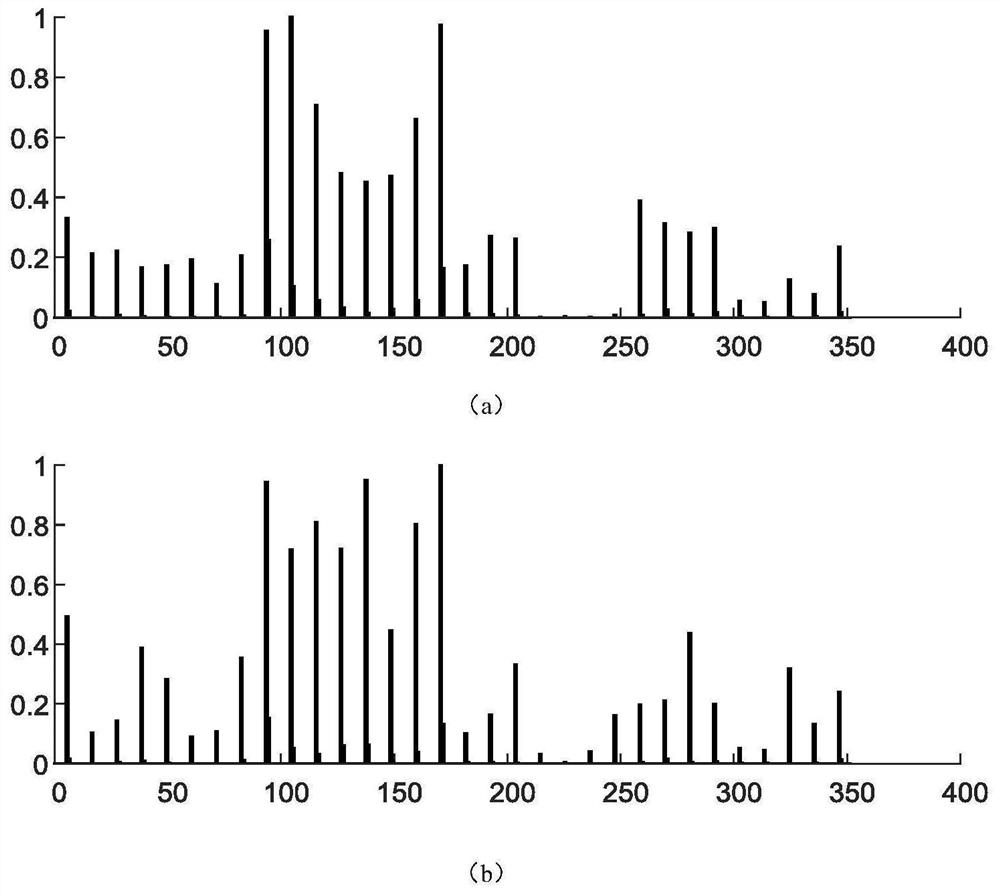

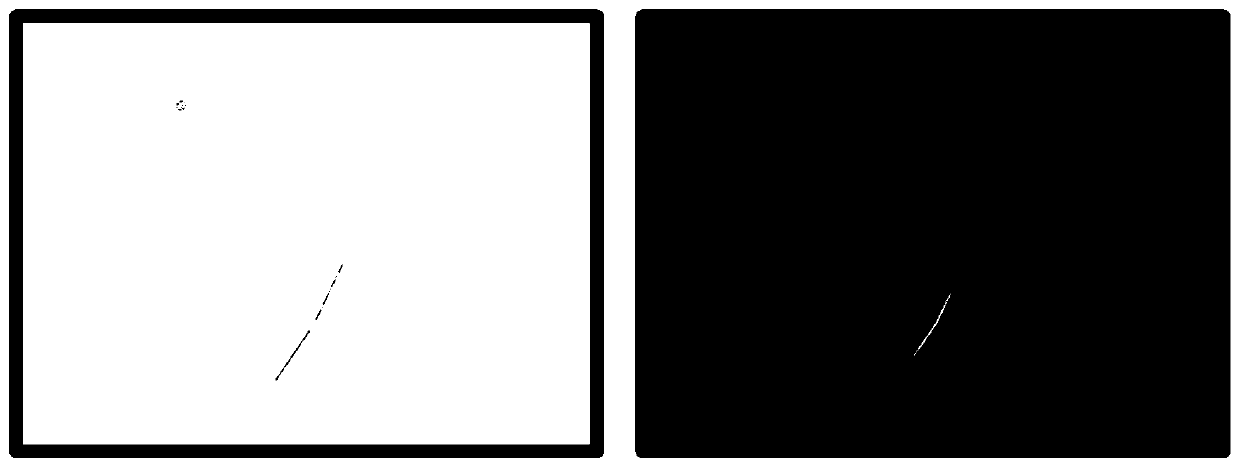

Workpiece three-dimensional point cloud registration method based on direction histogram signature features

PendingCN111862177AExact pose relationshipReduce placement requirementsImage enhancementImage analysisFeature descriptorHistogram

The invention discloses a workpiece three-dimensional point cloud registration method based on direction histogram signature features, and belongs to the field of machine vision. The method comprisesthe steps: extracting the key points of a workpiece target point cloud through an internal signature description algorithm; adopting a direction histogram signature feature descriptor to carry out feature description extraction on the key points; randomly sampling the key points, and searching and extracting registration point pairs by combining secondary constraints, namely neighborhood constraints and distance constraints, in offline calculated template feature description; solving a rotation matrix and a translation vector by utilizing dual quaternion to realize initial registration of thepoint cloud, and realizing accurate registration of the point cloud by utilizing an iterative closest point algorithm on the basis of an initial pose provided by the initial registration. Compared with conventional registration based on a two-dimensional image, the method has the advantages that the influence of illumination can be avoided, the requirement for the placement position of an object is lowered, and the accurate pose relation between the template and the target, namely the rotation matrix and the translation matrix between the template and the target, can be obtained.

Owner:JIANGNAN UNIV

A paper defect detection method based on local brightness invariance priori

ActiveCN109886914AImprove accuracySolve the problem of strobeImage analysisOptically investigating flaws/contaminationColor imageGray level

The invention relates to a paper defect detection method based on the local brightness invariance priori, which comprises the following steps of 1, photographing the surface of paper to be detected byusing a color area array camera, and capturing a frame of color image with a pixel format of RGB components; 2, carrying out nonlinear graying operation on all pixels of the color image in the mask of the convolution template by using a convolution template with local brightness invariance priori, and finally obtaining pixels corresponding to the convolution window; according to the 1*1 convolution operation and the 3 * 3 convolution operation, obtaining two gray level images respectively; 3, carrying out corresponding position pixel division on the two grayscale images to obtain a grayscaleimage; 4, performing 3 * 3 Fourier convolution operation on the grayscale image; 5, performing gradient morphological operation on an operation result; 6, performing thresholding processing to obtaina paper defect detection result. According to the present invention, a common light source and an area array camera can be used for detecting paper defects, and a detection system is low in complexity, high in accuracy and low in cost.

Owner:浙江企银印务科技有限公司

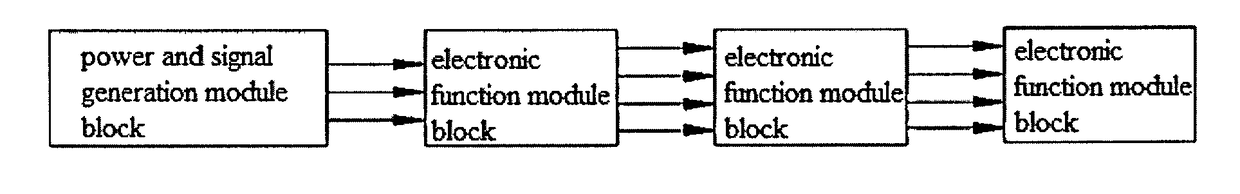

Improved magnetic type electronic bricks system

ActiveCN104043252AImprove multi-functional useIncrease the use of functionsEngagement/disengagement of coupling partsToysBrickMagnetic poles

The invention discloses an improved magnetic type electronic bricks system. The improved magnetic type electronic bricks system is provided with a plurality of module bricks provided with output or input connectors and spliced in an attraction mode. Each connector comprises a main plastic body and a plastic back cover detachably fixed to the main plastic body, wherein the main plastic body is provided with a fool-proof structure, and the plastic back cover is provided with at least one cavity internally provided with a magnet or magnetic attraction metal. Each connector is provided with a one-positive and one-negative power source conducting connecting piece and at least one data signal conducting connecting piece. The setting position of the conducting connecting piece shared by the input and output connectors conforms to the mirror symmetry corresponding relation. The improved magnetic type electronic bricks system is suitable for expanding a data signal line, and more functional applications of the electronic bricks system are improved; the placing requirement of magnetic poles is greatly lowered through an attraction mode for plastic back cover magnet installation, the producing and manufacturing cost can be reduced, the abutting plane of an insulator body cannot be occupied, expansion of more conducting connecting pieces is facilitated, and the magnets are protected extremely well; the space can be fully utilized due to placement of the conducting connecting pieces, and expansion of more conducting connecting pieces is facilitated.

Owner:SHENZHEN BOYUE DOMESTIC GOODS

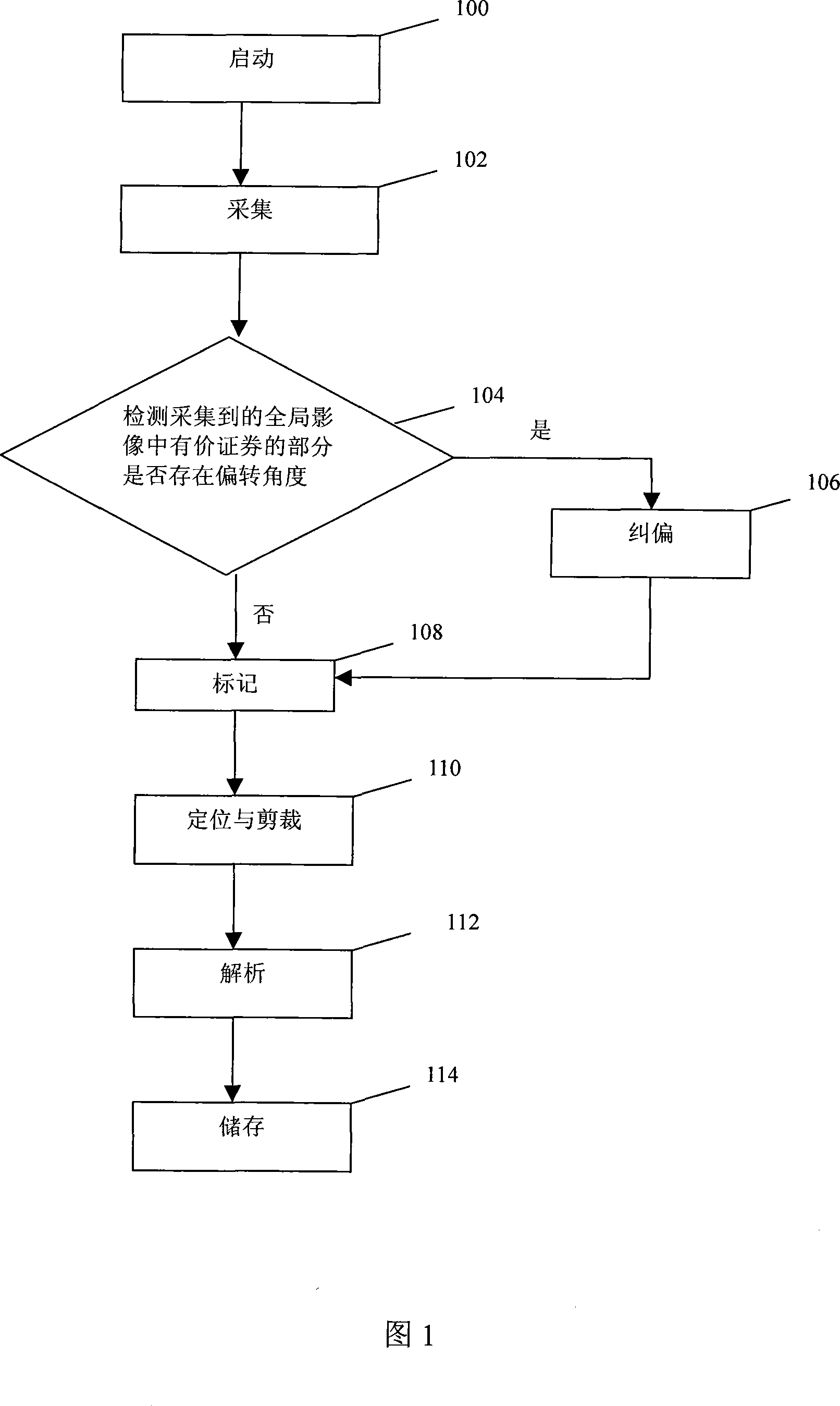

Valuable paper identification code recording analysis method and apparatus for currency counting apparatus

InactiveCN101241616ALower requirementAccurate conversionPaper-money testing devicesCounting objects on conveyorsAnalysis methodComputer science

Owner:北京捷爱特科技有限公司

Modular Block And Electronic Block System

A modular block, including a circuit board, a functional circuit disposed on the circuit board, an input connector and an output connector. The input connector and the output connector are both provided with a plurality of conductive terminals connected to the circuit board. The plurality of conductive terminals are a positive power conductive terminal, a negative power conductive terminal and a data signal conductive terminal respectively. At least one of the input connector and the output connector is provided with a plurality of the data signal conductive terminals. Also provided is an electronic block system. The input connector and the output connector of the modular block can be provided with one or more data signal conductive terminals according to actual needs, data signal lines can be expanded for use, and the modular block has more functions and applications.

Owner:SHENZHENSHI HANTONG TECH CO LTD

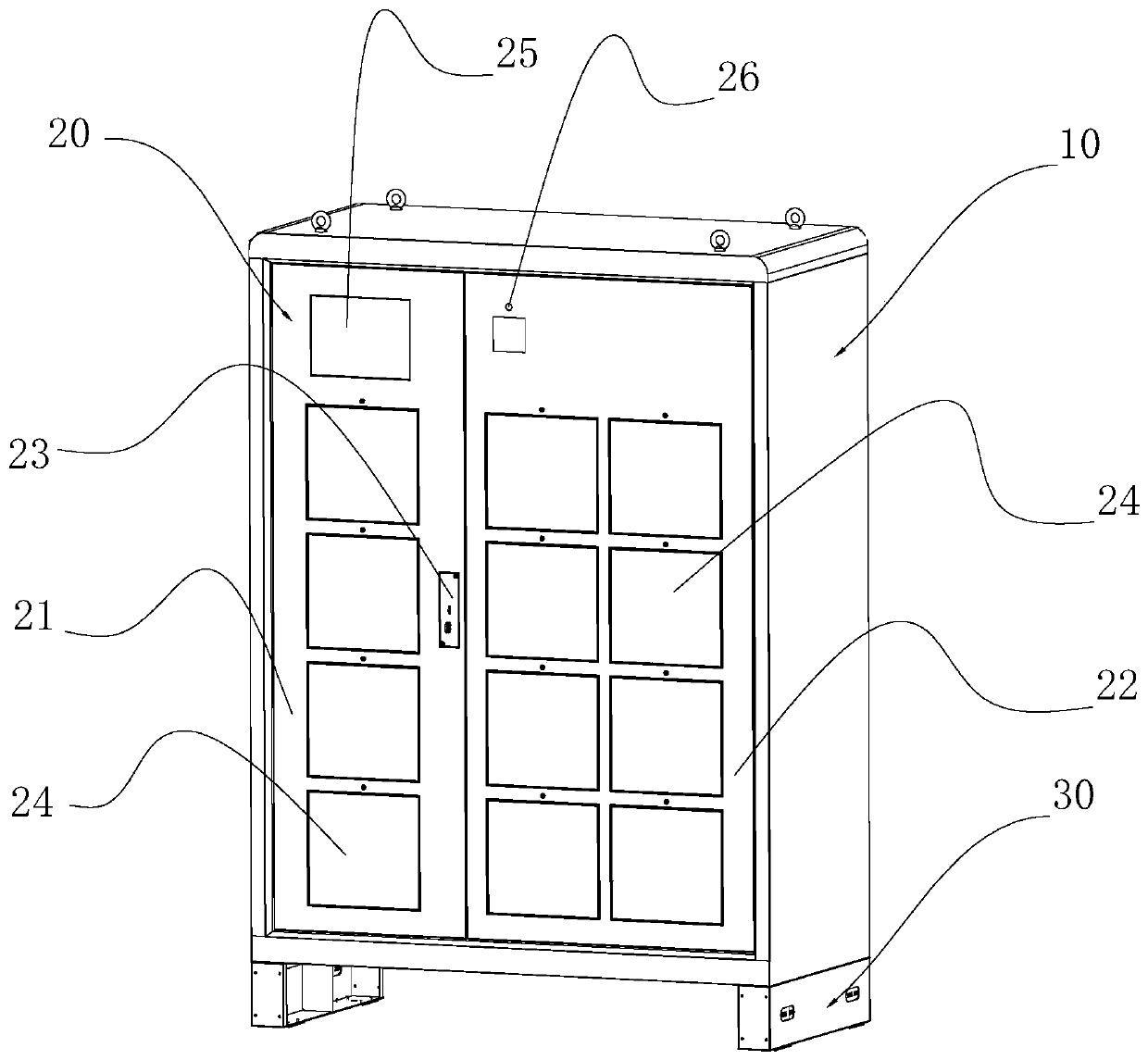

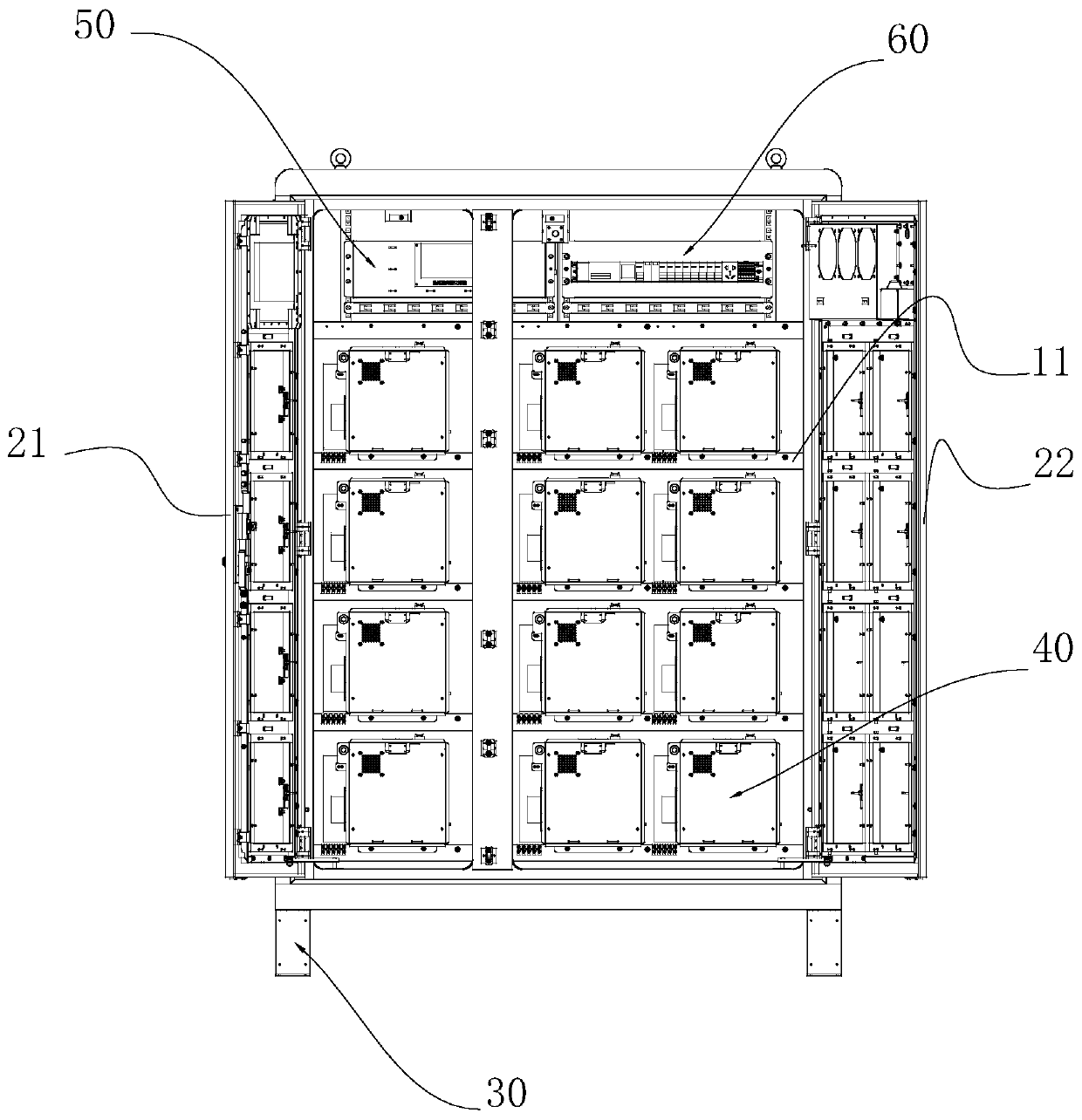

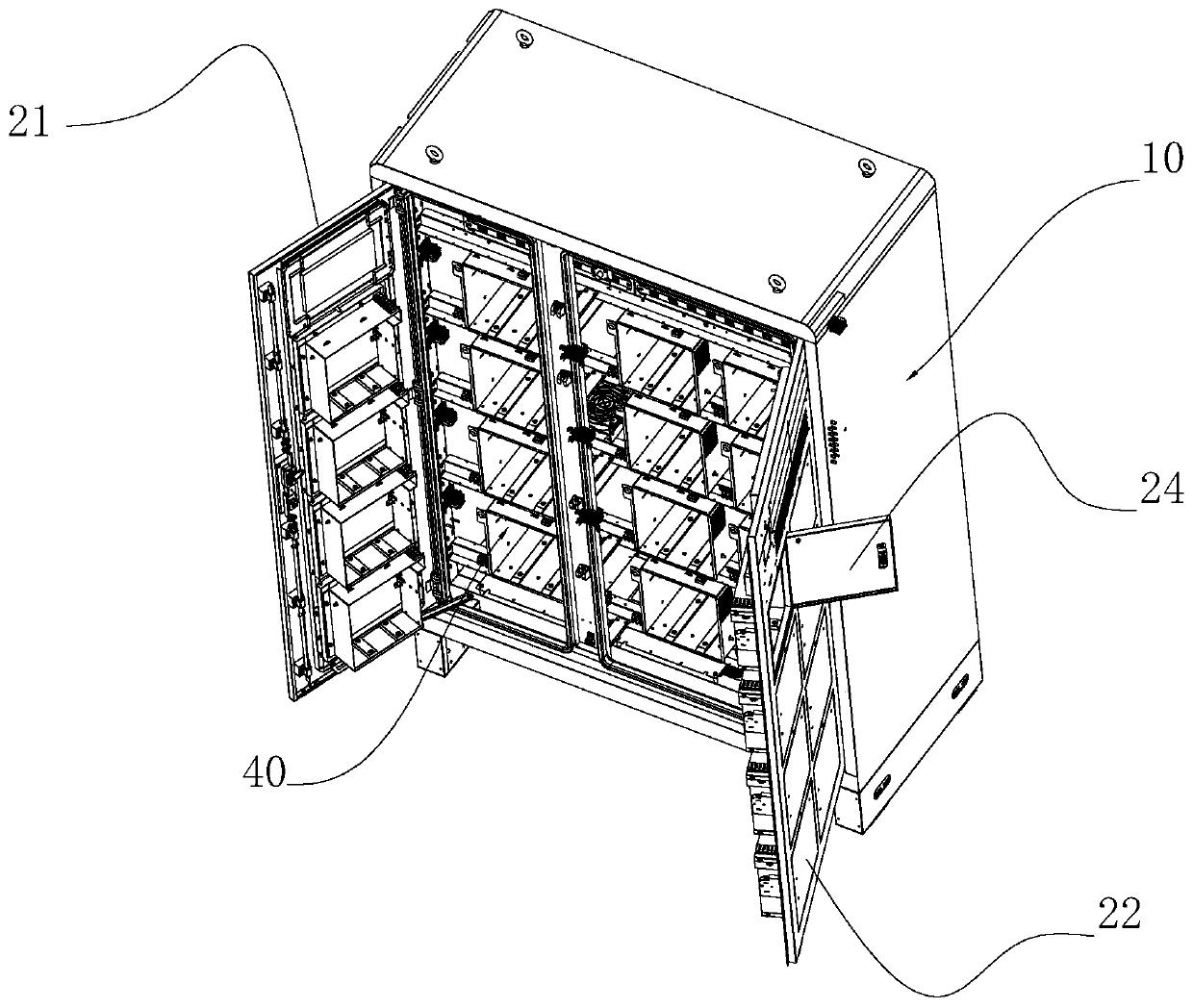

Modular battery replacing cabinet and maintenance method thereof

PendingCN110466371AIncrease productivityImprove assembly efficiencyBatteries circuit arrangementsCharging stationsElectricityModularity

The invention discloses a modular battery replacing cabinet and a maintenance method thereof. The battery replacing cabinet comprises a cabinet body and a plurality of electric changing warehouse receipt units arranged in the cabinet body. The cabinet body is internally provided with a charging bracket, a plurality of power changing card positions are arranged on the charging bracket in array, thepower changing card positions are provided with power changing interfaces, and the electric changing warehouse receipt units are detachably mounted on the power changing card positions and connectedelectrically with the power changing interfaces. According to the electric changing cabinet, through the unitization singly of the electric changing warehouse receipt units, all the electric changingwarehouse receipt units are connected to the cabinet body quickly in a mounted mode through a connection terminal independently, the production and assembly efficiency of the battery replacing cabinetis greatly improved, when the electric changing warehouse receipt units fail, the problematic electric changing warehouse receipt units can be directly taken out for replacement, the maintenance efficiency is improved, and the operation efficiency of the battery replacing cabinet is improved; and a requirement for the location of the battery replacing cabinet is reduced, at the same time, when the battery replacing cabinet needs maintenance, the battery replacing cabinet does not need to be moved, and the maintenance efficiency of the battery replacing cabinet is further improved.

Owner:SHENZHEN COMPTON TECH

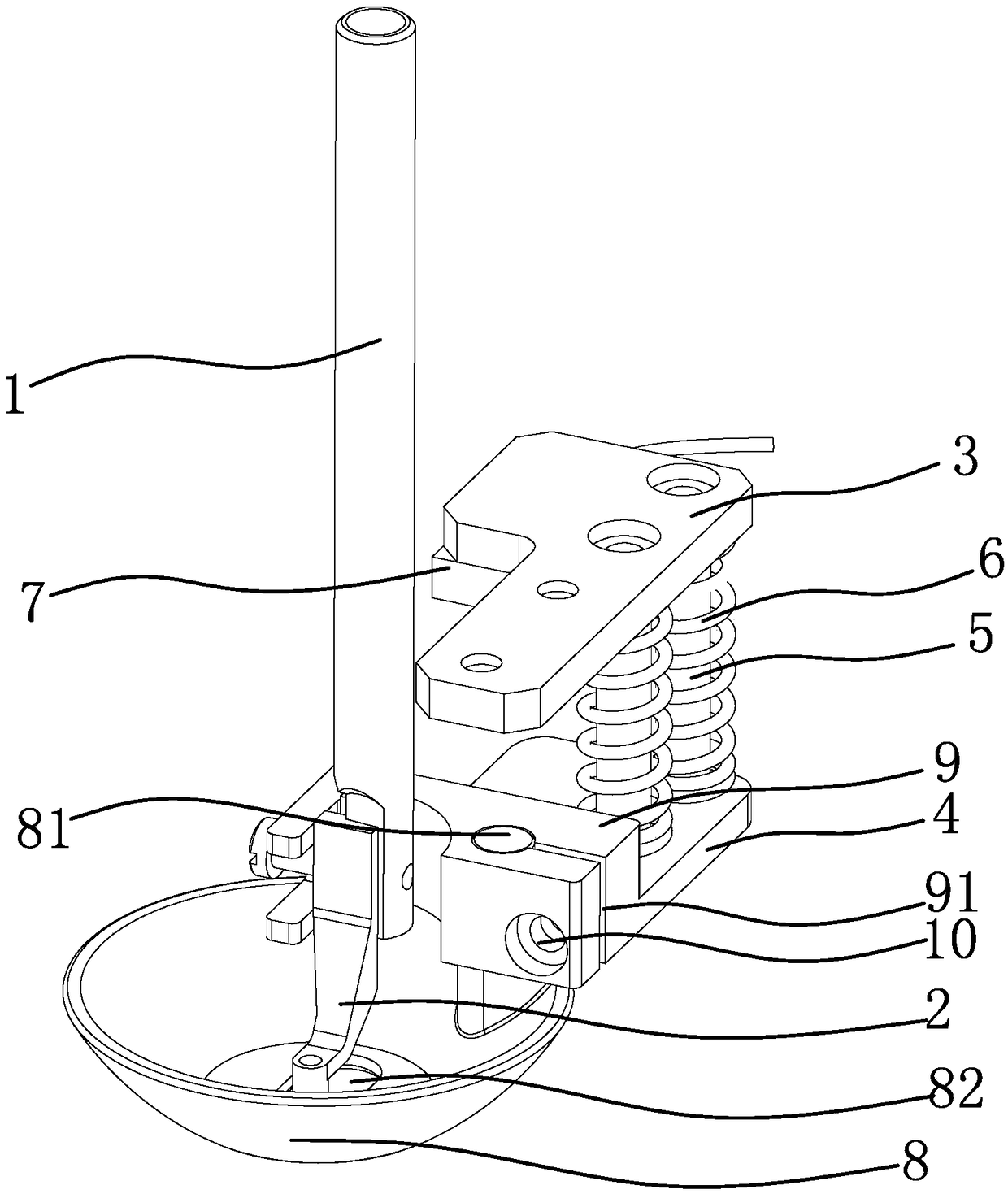

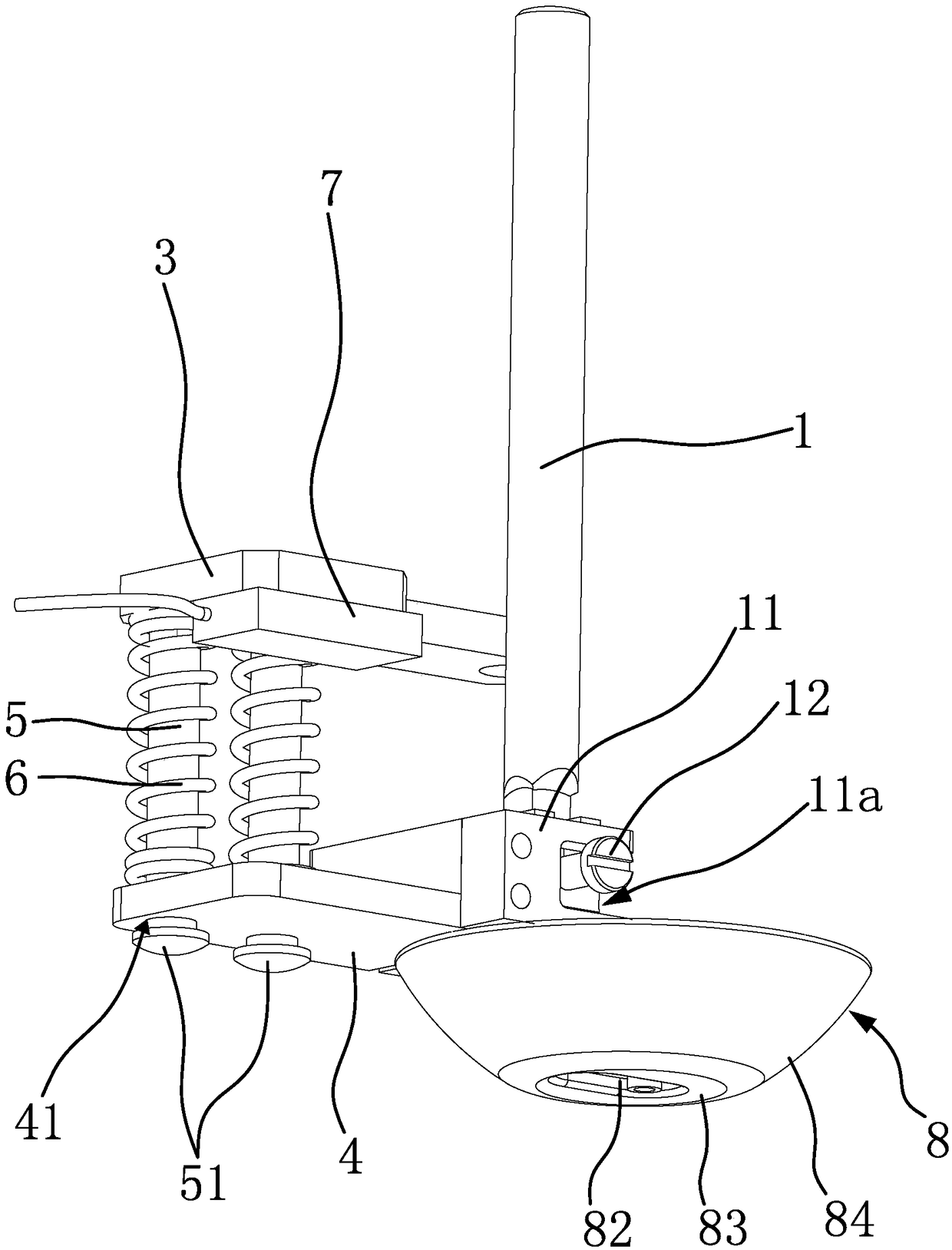

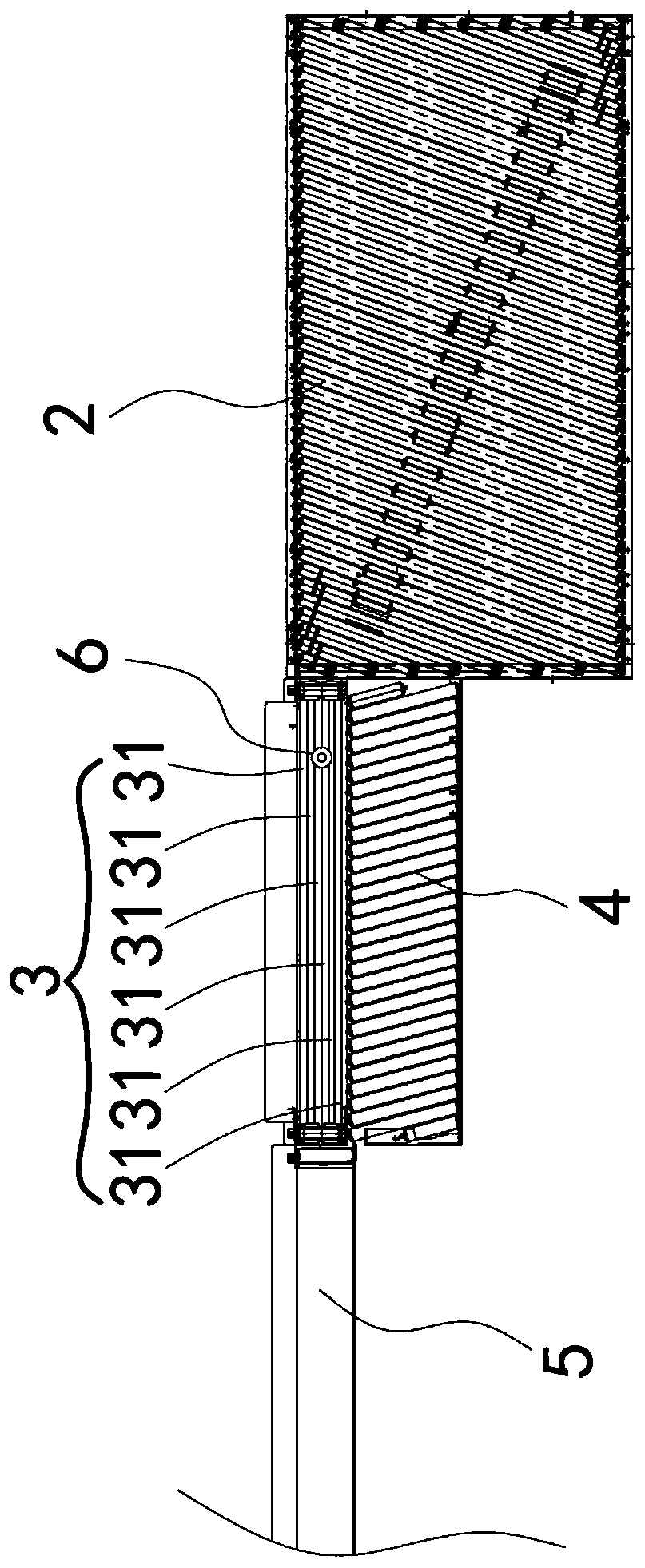

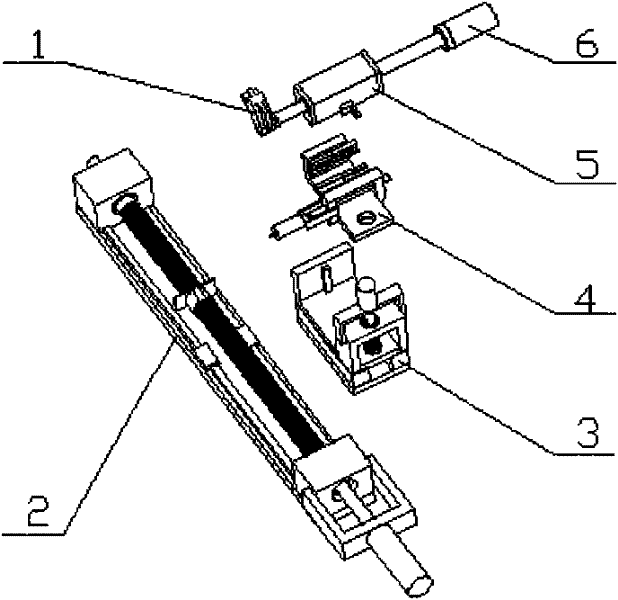

Automatic detecting device of fabric thickness on sewing machine

ActiveCN109112730AReduce placement requirementsHigh-precision detectionMeasurement devicesPressersWire tensionEngineering

The invention provides the detecting device of a fabric thickness on a sewing machine and belongs to the clothing manufacturing equipment technology field. In an existing sewing machine, the adjustingof a middle presser foot height and a surface wire tension is inconvenient and so on. By using the detecting device, the above technical problems are solved. The sewing machine comprises a compactionrod and a middle presser foot arranged on the lower end of the compaction rod. The automatic detecting device comprises a fixing plate and a connection plate which are arranged vertically at intervals. The bottom of the fixing plate is provided with a vertical guide rod. The connection plate slidably sleeves the guide rod. A spring sleeves the guide rod, and the two ends of the spring act on thebottom surface of the fixing plate and the upper surface of the connection plate. The connection plate is fixedly provided with a detection presser foot. The detection presser foot is located below the connection plate. The connection plate and the compaction rod are provided with limiting structures used for limiting the up and down movement of the connection plate. The automatic detecting devicealso comprises a distance sensor. Through the automatic detecting device of the fabric thickness, the middle presser foot height and the surface wire tension can be timely adjusted.

Owner:BULLMER ELECTROMECHANICAL TECH

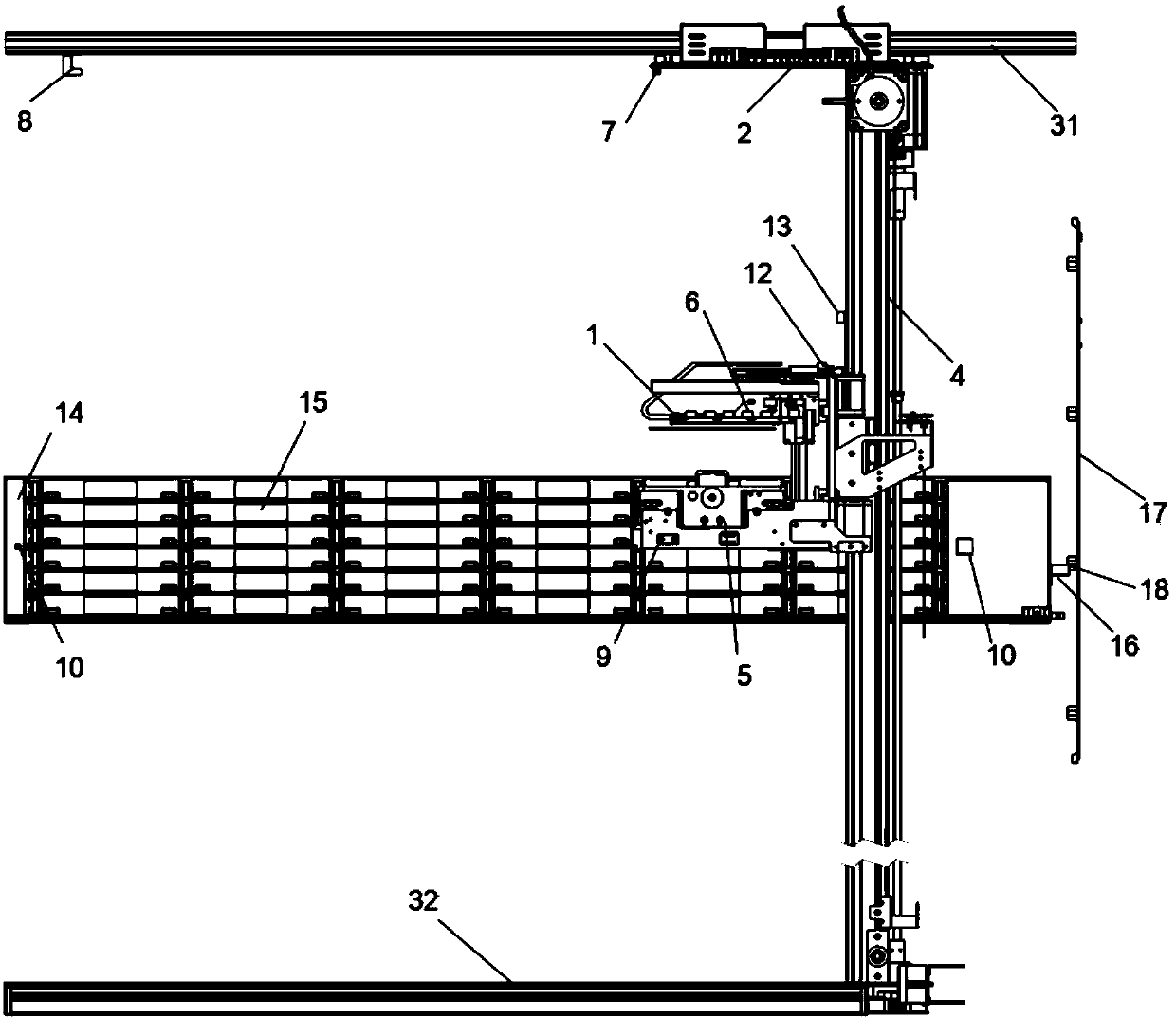

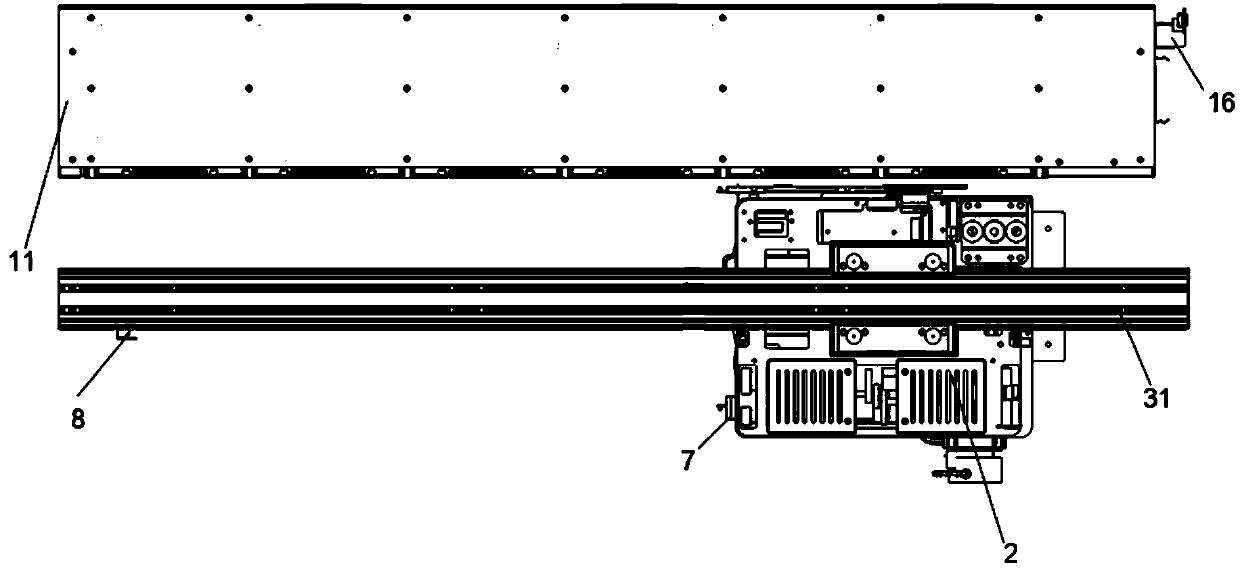

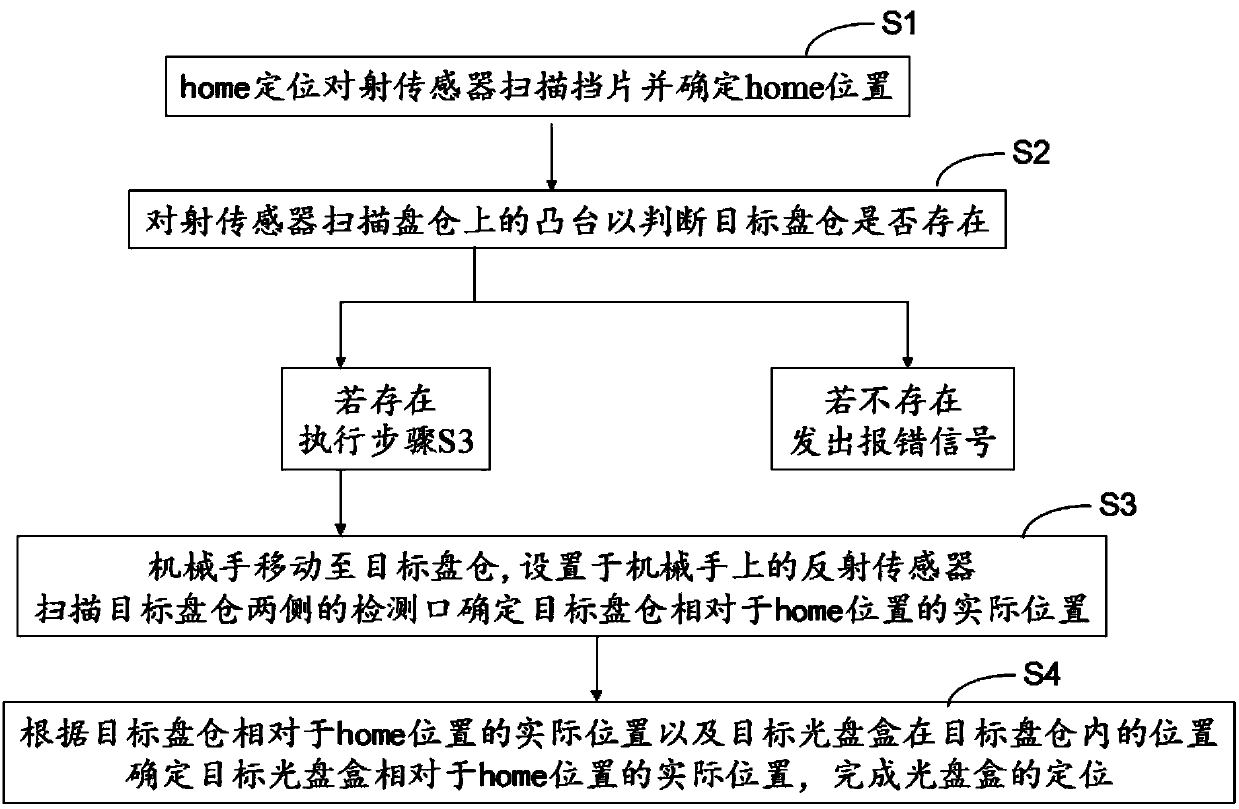

Automatic quick accurate positioning device and method for optical disk cartridge of optical disc juke-box

ActiveCN104200821APrecise positioningHigh speedRecord information storageManipulatorElectrical and Electronics engineering

The invention discloses an automatic quick accurate positioning device for an optical disk cartridge of an optical disc juke-box. The device comprises a manipulator, an actuating unit, horizontal slide rails and vertical slide rails and further comprises two home positioning correlation sensors and a horizontal blocking piece and a vertical blocking piece, wherein the horizontal blocking piece and the blocking piece are matched with the two home positioning correlation sensors and used for limiting a home position. The manipulator is provided with a reflective sensor, and the reflective sensor can move vertically or move horizontally in the direction parallel to the side of an opening of the optical disk juke-box with the manipulator for vertically and horizontally scanning the optical disk cartridge for further achieving accurate positioning in a coordinate system with the home position serving as the origin of the coordinate and a detection opening as a center point. The automatic quick accurate positioning device for the optical disk cartridge of the optical disc juke-box uses the relative position for the positioning, omits manual intervention for debugging and repeatedly drawing for adjusting the position of the optical disk cartridge, and has the advantages of saving the positioning time and improving the accuracy of the positioning.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

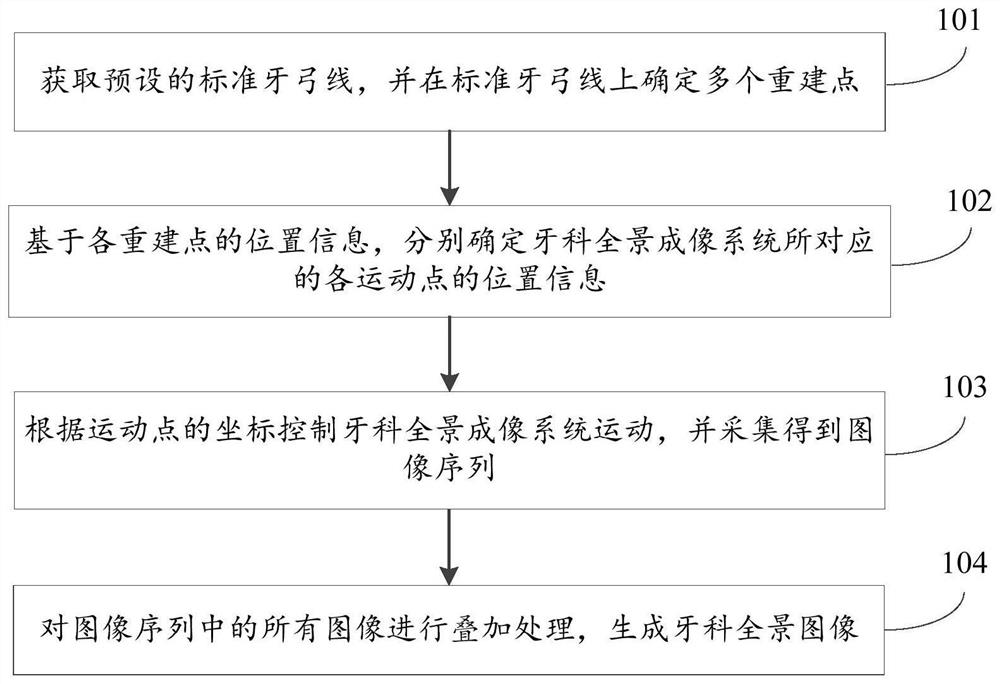

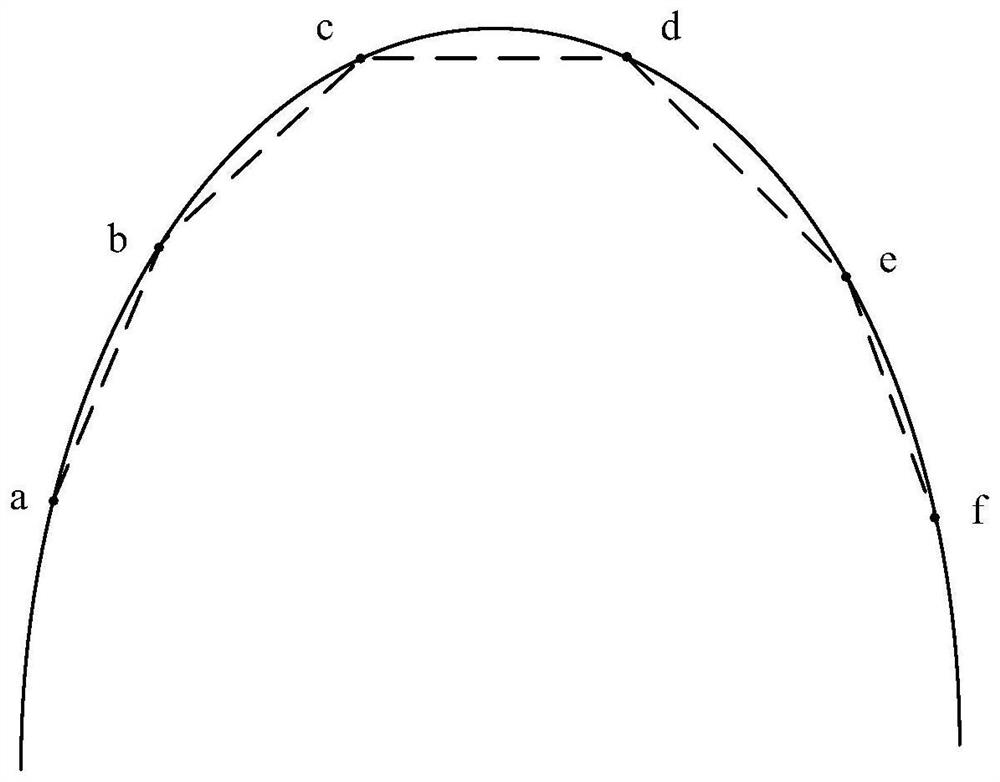

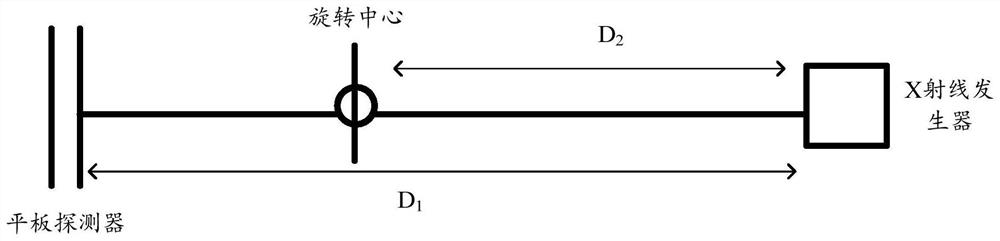

Dental panoramic image generation method and device and computer readable storage medium

PendingCN111833244AReduce placement requirementsReduce image distortionImage enhancementImage analysisComputer scienceBiomedical engineering

The embodiment of the invention discloses a dental panoramic image generation method and device and a computer readable storage medium. The method comprises the steps: obtaining a preset standard dental arch line, and determining a plurality of reconstruction points on the standard dental arch line; based on the position information of each reconstruction point, respectively determining the position information of each movement point corresponding to the dental panoramic imaging system; controlling the dental panoramic imaging system to move according to the coordinates of the movement points,and acquiring an image sequence; and carrying out superposition processing on all images in the image sequence to generate a dental panoramic image. Through the implementation of the invention, the panoramic image of the dental department is reconstructed by adopting a position synchronization mode, the image distortion and the positioning requirement on a patient are reduced, and the clear imaging of a personalized dental arch line can be effectively met.

Owner:深圳市深图医学影像设备有限公司

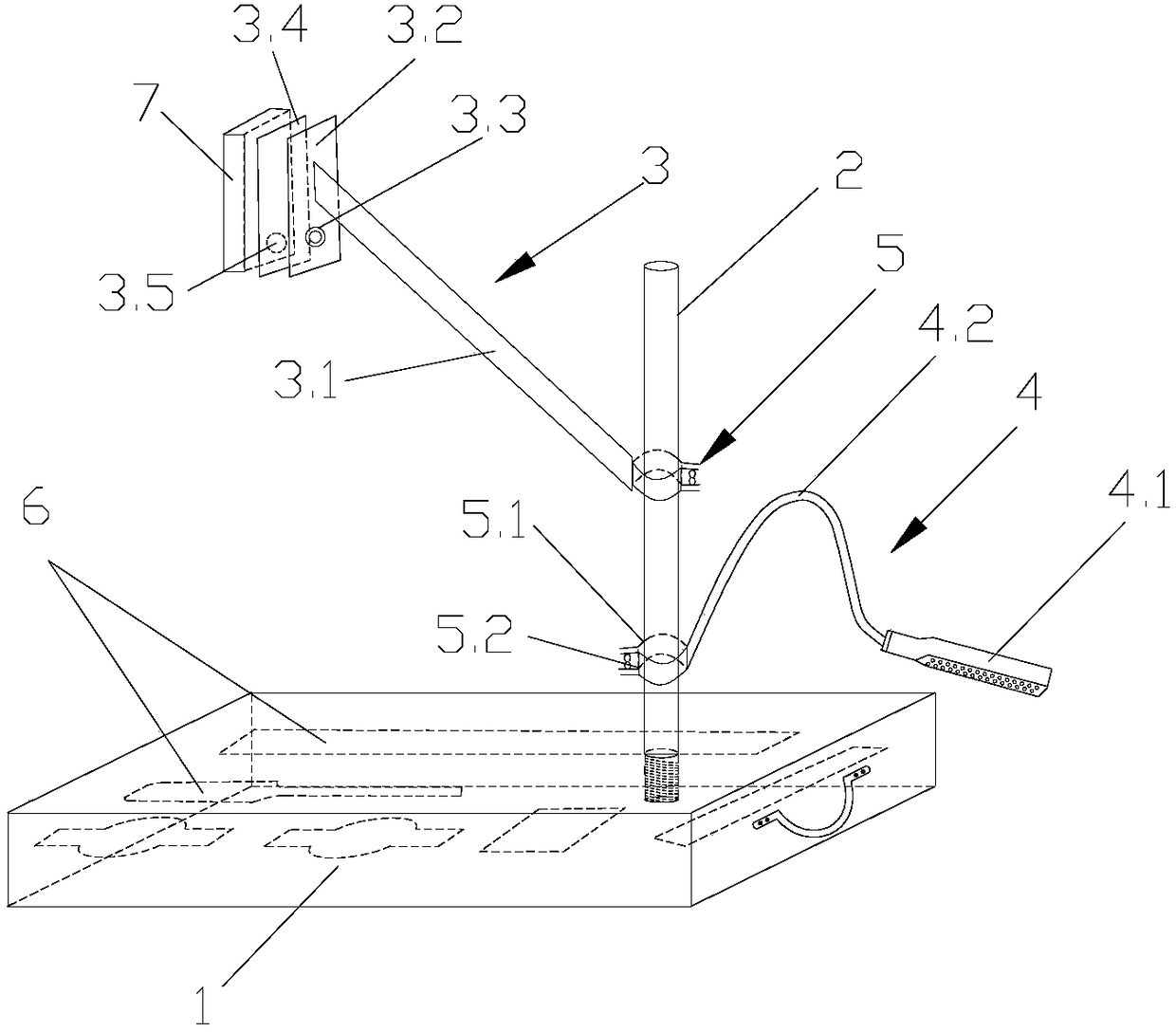

Multi-angle rock core picture taking instrument

PendingCN108132253AImprove stabilityLow placement requirementsMaterial analysis by optical meansStands/trestlesRock coreEngineering

The invention discloses a multi-angle rock core picture taking instrument, which comprises an object carrying table, wherein a support vertical rod detachably connected with the object carrying tableis arranged on the object carrying table; a movable illuminating lamp and a camera installing frame capable of vertically moving and circumferentially rotating in the axial direction are arranged on the support vertical rod. The camera installing frame comprises an installing rod and an installing plate; one end of the installing rod is detachably connected with the support vertical rod through aclamp ring assembly; the other end of the installing rod is fixedly connected with the installing plate; an installing hole for installing a screw assembly is formed in the installing plate; the installing hole is fixedly connected with a screw clamp opening formed in the bottom of a camera through the screw assembly. The movable illuminating lamp and the camera installing frame capable of vertically moving and circumferentially rotating in the axial direction are arranged on the support vertical rod; the picture taking in any angle can be realized; the stability is high; the shot picture is clear.

Owner:YANGTZE UNIVERSITY

Battery disassembling pole group detaching device with vertical guiding function

The invention discloses a battery disassembling pole group detaching device with a vertical guiding function. The device comprises an arch-shaped support and a central shaft vertically penetrating the top of the support and capable of freely sliding; a pressing disc for clamping a battery is arranged at the bottom end of the central shaft, a lever with the hinge point as the fulcrum is hinged to the top end of the central shaft, one end of the lever is hinged to a connecting base, and a plurality of tongs used for pulling out a pole group are arranged at the bottom of the connecting base; an arc-shaped hole is formed in the end of the lever, and the top of the connecting base is matched with the interior of the arc-shaped hole in a sliding manner; a guide rod is mounted on the connecting base, and guide grooves used for guiding the guide rod to vertically ascend and descend are formed in the two sides of the support; and the tongs can freely rotate and have certain elasticity, the device is suitable for detaching storage battery pole groups of different types, the tongs are symmetrically arranged, and therefore during detaching, a pole group bus bar is even in stress and is kept vertical lifting, and the pole groups are not prone to being damaged.

Owner:TIANNENG BATTERY GROUP

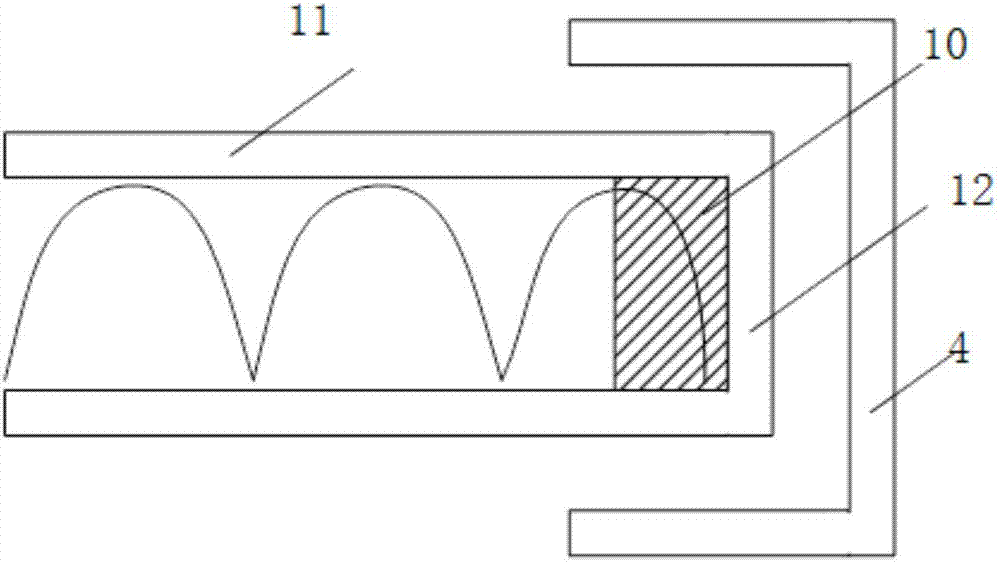

Micro-channel PCR amplification system based on electromagnetic propulsion

ActiveCN106520550ASimple structureEasy to operateBioreactor/fermenter combinationsHeating or cooling apparatusFluorescenceBiology

The invention discloses a micro-channel PCR amplification system based on electromagnetic propulsion, and belongs to the field of biology, analytical chemistry and medical test. The system comprises an annealing low-temperature region, an extending moderate-temperature region, a thermal-change high-temperature region, a PCR reagent and an electromagnetic propulsion module. The micro-channel PCR amplification system based on electromagnetic propulsion is mainly used for PCR amplification operation applied to the inside of a space range under the condition of weight loss and follow-up construction of a real-time fluorescent PCR detection system with a miniature structure; the purpose of integrating a micro-channel circulating PCR amplification module and an electromagnetic propulsion module is achieved; a portable miniaturized PCR fluorescent real-time detection system which meets requirements of space operation is realized; and purposes of function integration, micro-structure, light weight, small size and full-automatic detection are achieved.

Owner:BEIJING UNIV OF TECH

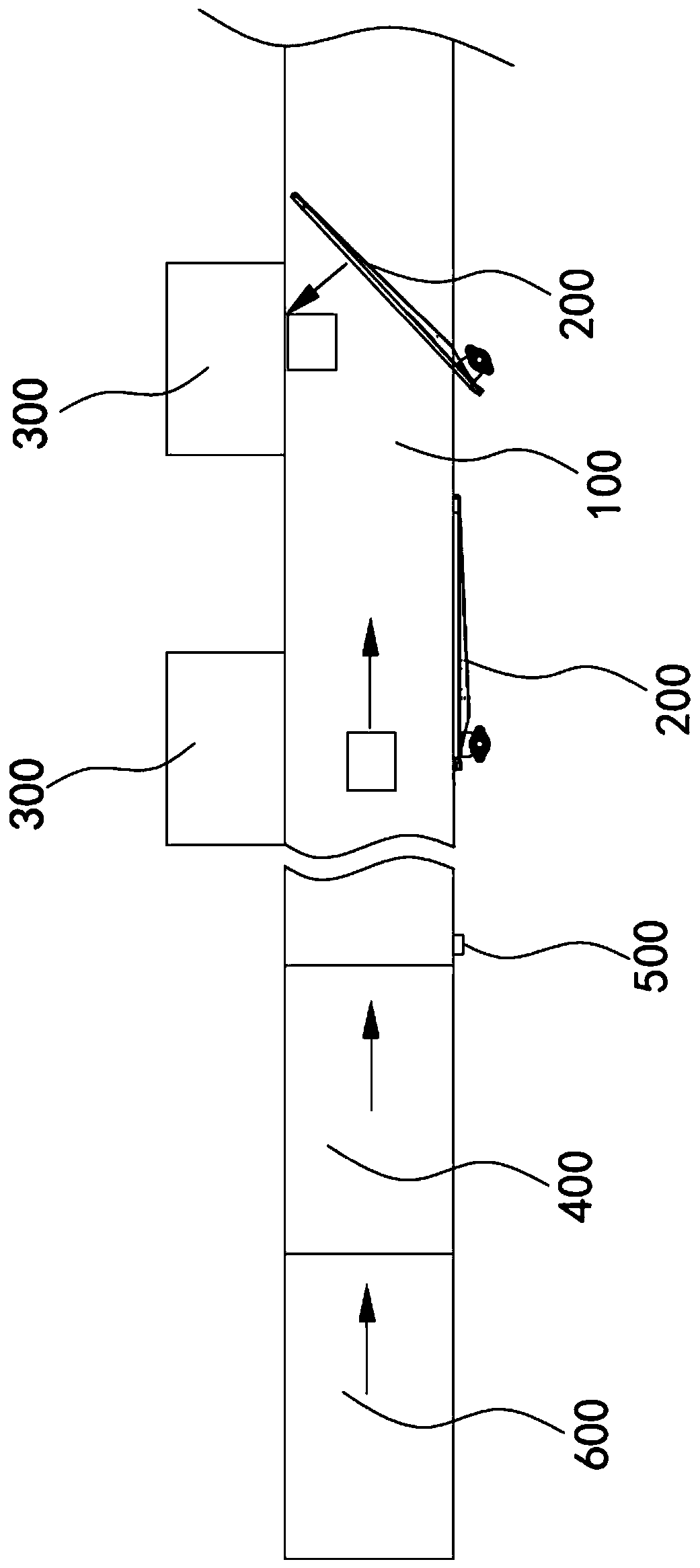

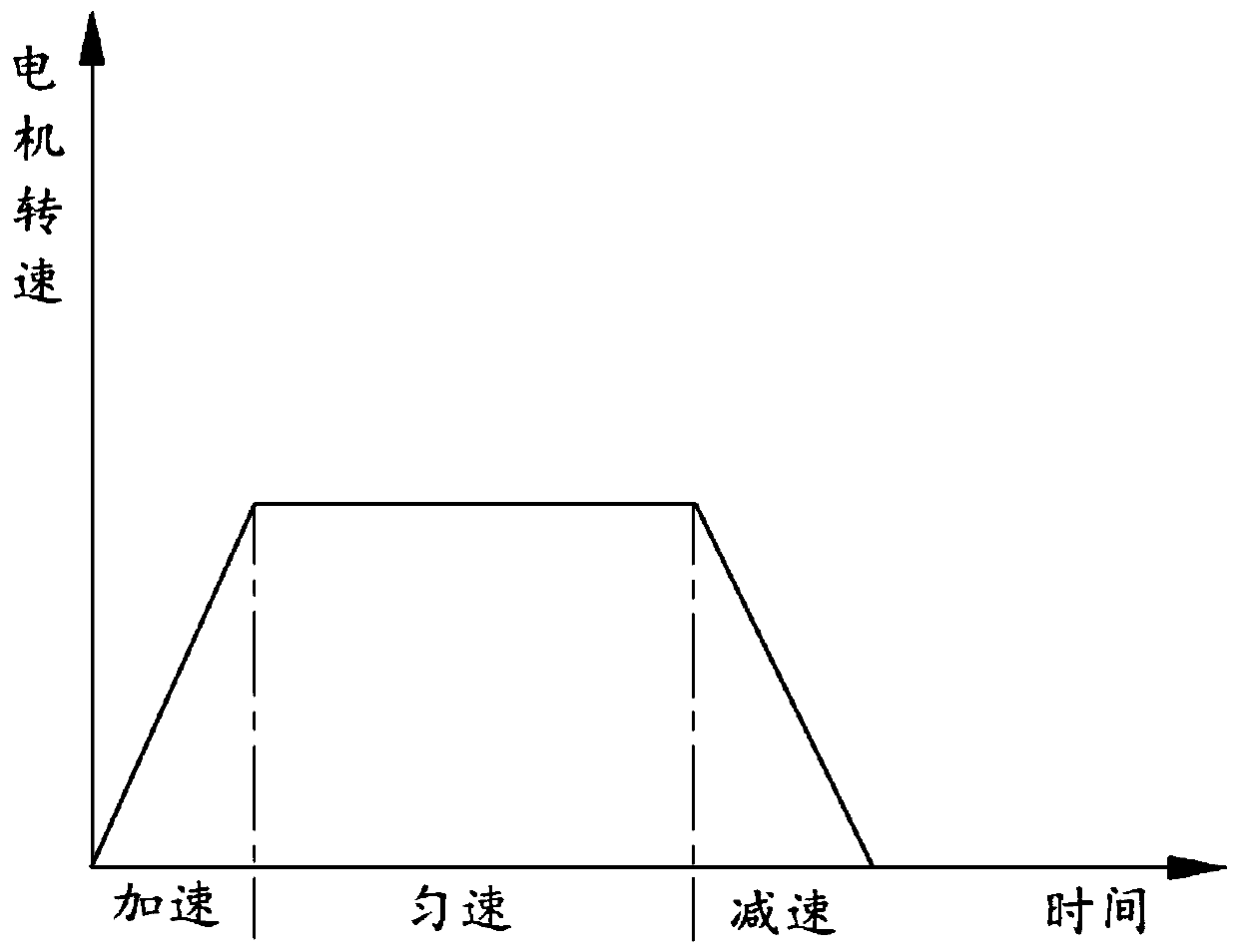

Flexible sorting method of swing arm sorting machine

The invention discloses a flexible sorting method of a swing arm sorting machine. In the process that each swing arm swings from a static state to a maximum opening position, firstly accelerated swinging for a period of time is carried out, and then uniform-speed swinging for a period of time is carried out. According to the scheme of the flexible sorting method of the swing arm sorting machine, the swing arm control mode is adopted, the swing arm can be lifted to a large angular speed at a large angular acceleration, then uniform-speed swinging of the swing arm is carried out at the speed, atthe moment, the driving force borne by the swing arm is far smaller than the driving force needed during acceleration, and therefore according to the force transmission characteristic, the thrust exerted by the swing arm on a parcel can be reduced, and meanwhile, the swing arm swings at a constant speed after moving to the maximum speed, so that a conventional striking mode can be changed into asoft pushing mode, and the breakage rate of the parcel is greatly reduced.

Owner:SUZHOU GP LOGISTICS SYST

Bolt assembly and disassembly manipulator capable of moving with three degrees of freedom

InactiveCN102000970BCompact structureLow costMetal working apparatusThree degrees of freedomCoupling

The invention discloses a bolt assembly and disassembly manipulator capable of moving with three degrees of freedom. Moving elements of body, shoulders and arms are connected one another through guide rail sliding blocks, the movement of each element in a specified direction is limited, and the movement of a motor is transferred through a lead screw nut. A spring of a spanner head and a baffle plate are used for limiting the position of a bolt, a pressure sensor is used for measuring the axial force of the bolt, and the measured axial force is a basis for next operation. During disassembling or assembling the bolt, the pressure value detected by the pressure sensor arranged in the spanner head is used as the basis, the three moving elements are driven to ensure the precise positioning of the spanner head, and an elastic coupling for connecting the motor and a lead screw can ensure that the arms successfully realize flexible guide and positioning under the condition of certain butting error. The manipulator has the characteristics of compact structure and wide application range; and the manipulator has low positioning requirement of the bolt position so as to reduce the complexity of equipment and broaden the space of automatic application.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

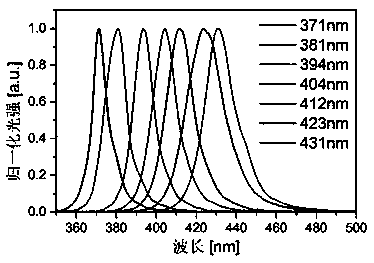

Tea variety identification device and method based on LED array and convolutional neural network

PendingCN110503003AExciting characteristic substancesReduce usageScene recognitionFluorescence/phosphorescenceFluorescencePolyphenol

The invention relates to a tea variety identification device and method based on an LED array and a convolutional neural network. According to the invention, the LED array adopts a plurality of LEDs,wherein the central wavelength of the main LED ranges from 370 nm to 380 nm, the LED with the wavelength can excite fluorescence of tea polyphenol, flavone, anthocyanin and chlorophyll in tea leaves,useful information is provided to the maximum extent, the central wavelength of the auxiliary LED ranges from 360 nm to 500 nm, and the auxiliary LED is controlled by the calculation control unit in an alternate lightening mode. The mini spectrometer is used for collecting spectral data of tea to be identified and sending the spectral data to the calculation control unit. The calculation control unit converts the spectral data into two-dimensional data and sends the two-dimensional data to the trained convolutional neural network to obtain the variety of the tea to be identified. The device islight and portable, can be held by hand, and can be used for quickly and accurately identifying tea varieties.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com