Bolt assembly and disassembly manipulator capable of moving with three degrees of freedom

A technology of manipulators and degrees of freedom, applied in the field of manipulators, can solve the problems of manual operation, not an automatic tool, and the inability to complete bolt loading and unloading tasks, and achieve the effects of reducing the placement position, compact structure, increasing work space and independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Implementation of the present invention will be further explained below in conjunction with accompanying drawing:

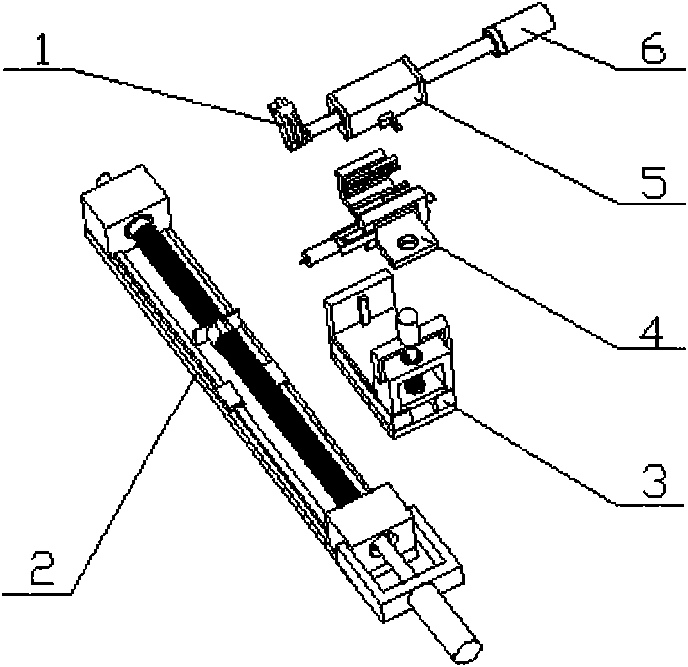

[0033] figure 1 A perspective view showing the overall model of the manipulator in use. exist figure 1 Middle: 1 is the hydraulic rotating motor, 2 is the base of the manipulator, 3 is the torso part of the manipulator, 4 is the shoulder part of the manipulator, 5 is the part of the manipulator arm, and 6 is the socket wrench head.

[0034] The base, torso, shoulder, and arm parts of the manipulator are connected by a combination of sliders and guide rails. On the one hand, unnecessary movement between parts is restricted, and on the other hand, flexible movement in the specified direction is guaranteed. The motor of each component is fixed on the motor bracket with four bolts, the screw rod is supported by bearings at both ends, and the nut and slider are used to transmit the motion of the motor.

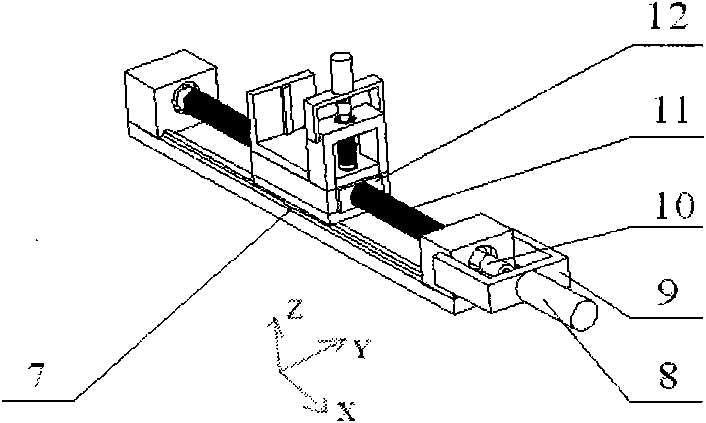

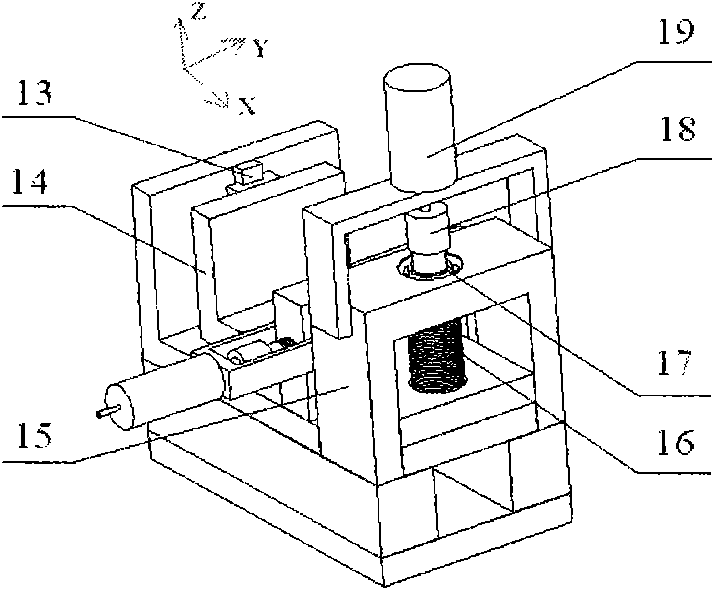

[0035] figure 2 It is a three-dimensional compositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com