Ellipsoidal-reflector-based material complex dielectric constant high temperature testing device and method

A technology of ellipsoidal reflector and complex dielectric constant, which is applied in the direction of measuring device, dielectric property measurement, electric variable measurement, etc., can solve the problems of high test cost, inconvenient maintenance, processing accuracy of volatile samples, etc., and achieve guaranteed test Effects of stability and precision, low cost of use and maintenance, and low sample placement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

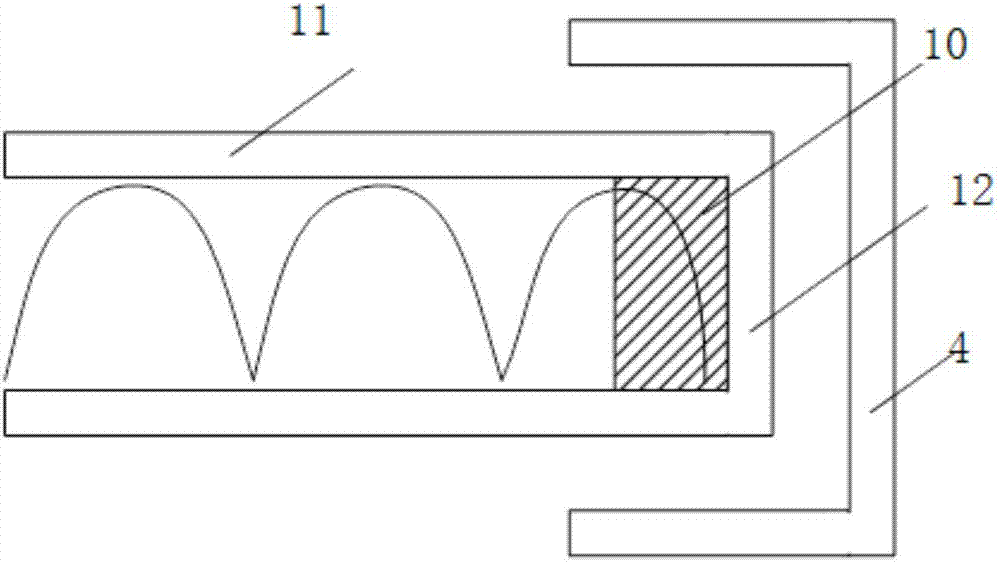

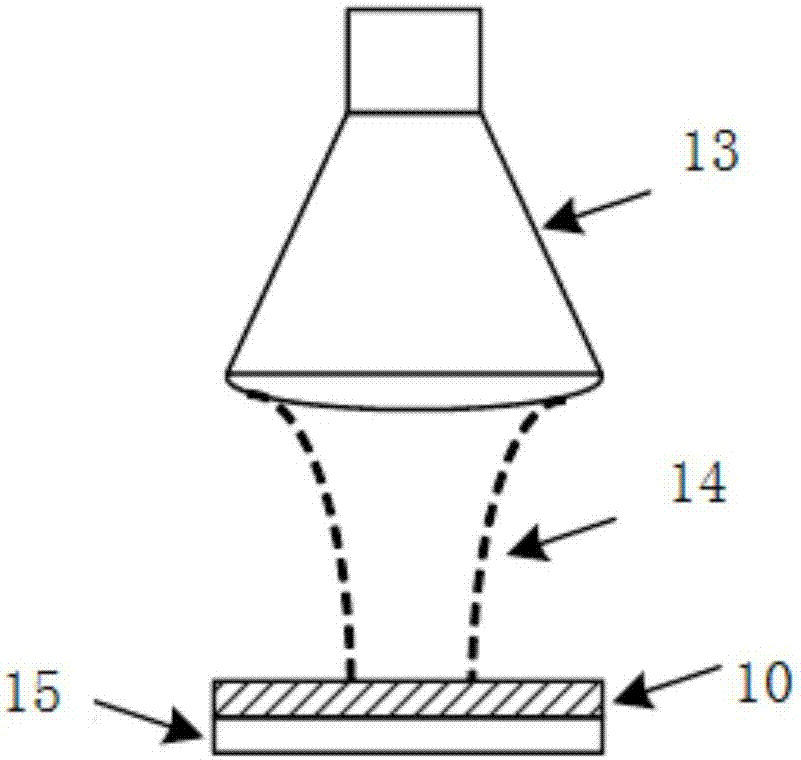

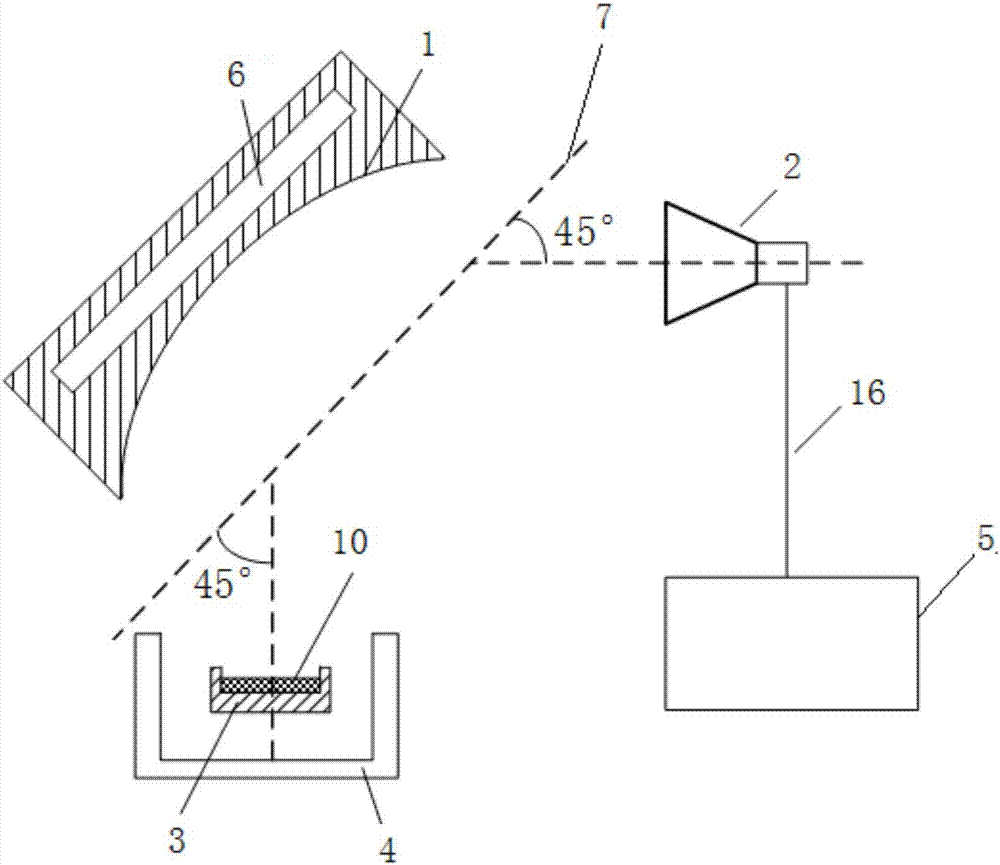

[0036] Such as image 3 As shown, the material complex permittivity high-temperature test device based on the ellipsoid reflector includes a metal ellipsoid reflector 1, a horn antenna 2, a metal crucible 3, a high-temperature furnace 4 and a vector network analyzer 5, and the horn antenna 2. Connect to the vector network analyzer 5 through a microwave cable 16; the aperture field of the horn antenna 2 is evenly distributed and the side lobe level is more than 20dB smaller than the main lobe level, and has a lower side lobe level; as Figure 4 As shown, the reflection surface 9 of the ellipsoid reflector 1 is a part of the spheroid, such as Figure 5 and Figure 6 As shown, the reflective surface 9 of the ellipsoid reflector 1 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com