Patents

Literature

229 results about "Thermal wave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

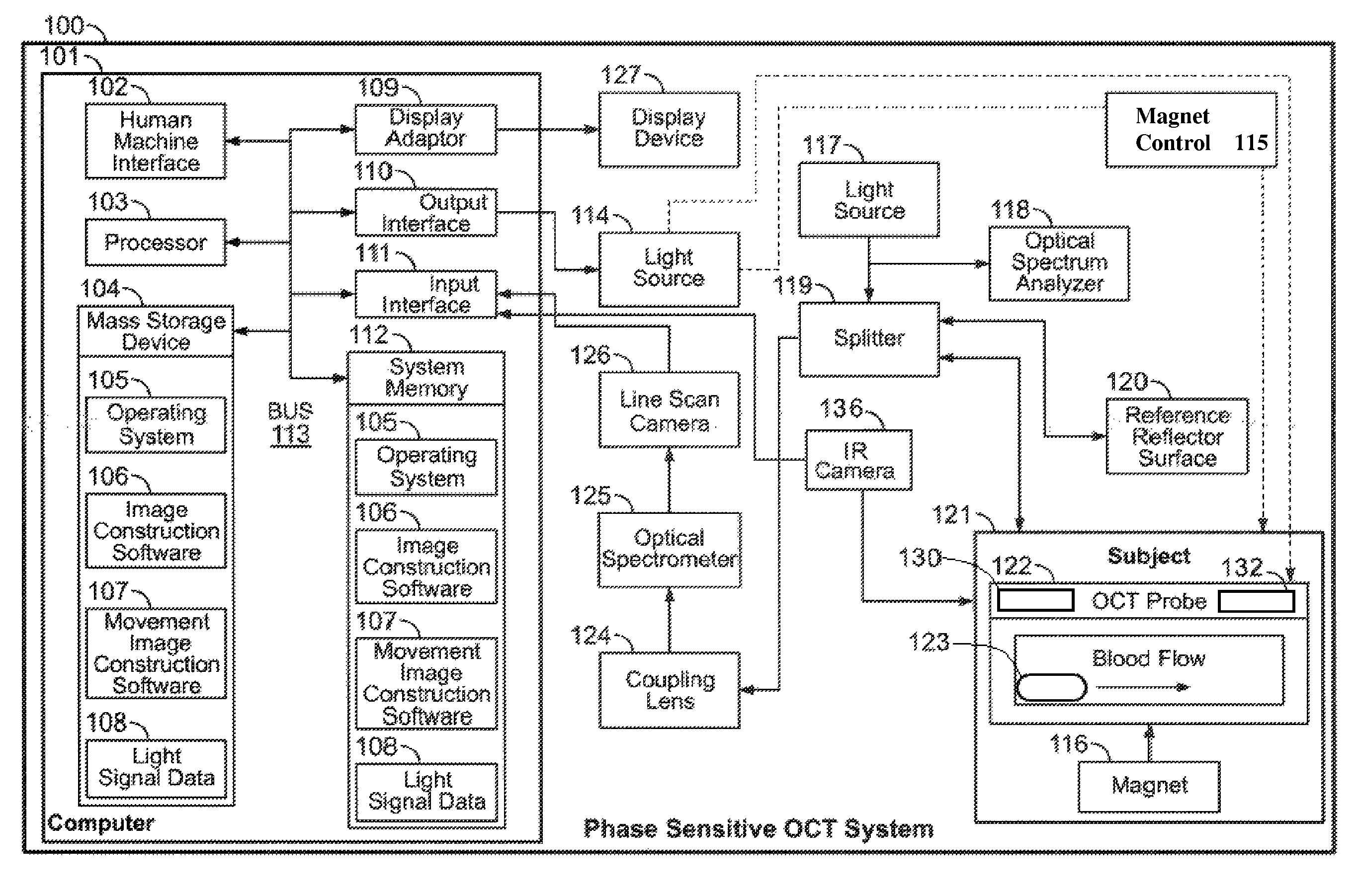

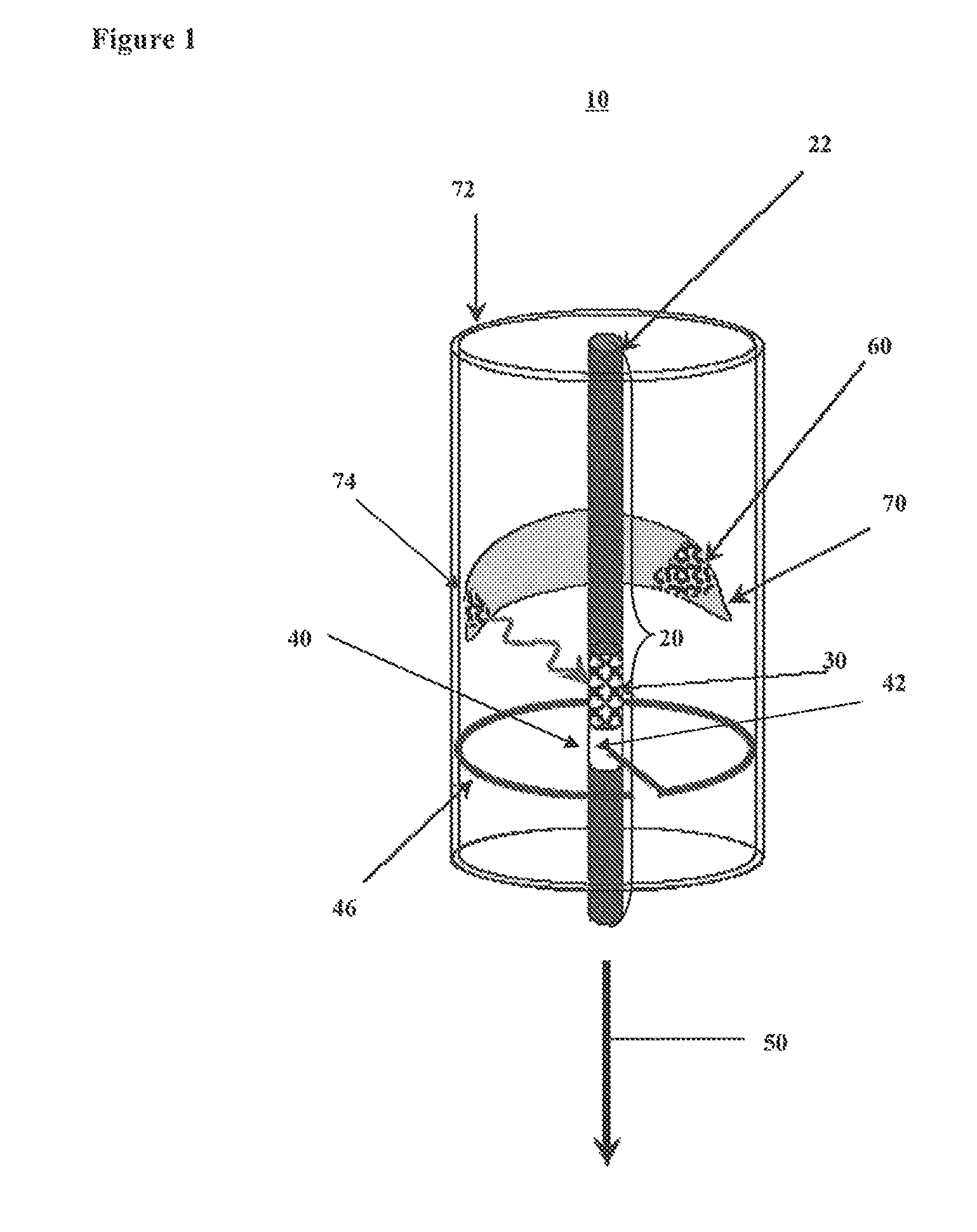

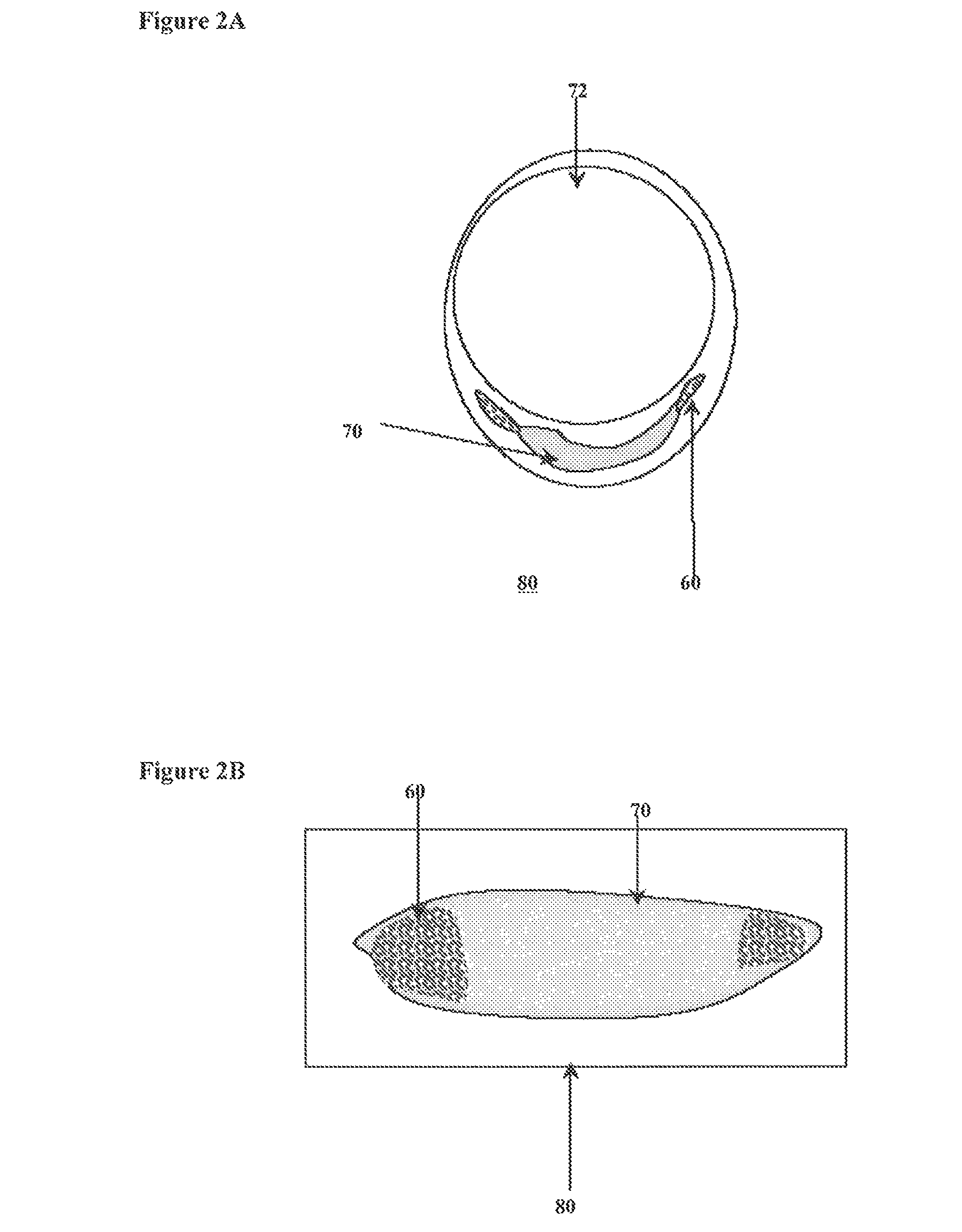

Method and apparatus to identify vulnerable plaques with thermal wave imaging of heated nanoparticles

Owner:BOARD OF REGENTS THE TEXAS UNIV SYST +1

Process for removing a target gas from a mixture of gases by thermal swing adsorption

The separation of a target gas from a mixture of gases using a thermal swing adsorption process wherein a thermal wave is used, primarily in the desorption step. The process of this invention enables one to separately remove multiple contaminants from a treated gaseous stream.

Owner:EXXON RES & ENG CO

Thermal Flow Meter

ActiveUS20100116048A1Volume/mass flow by thermal effectsSuction devicesThermodynamicsPhase difference

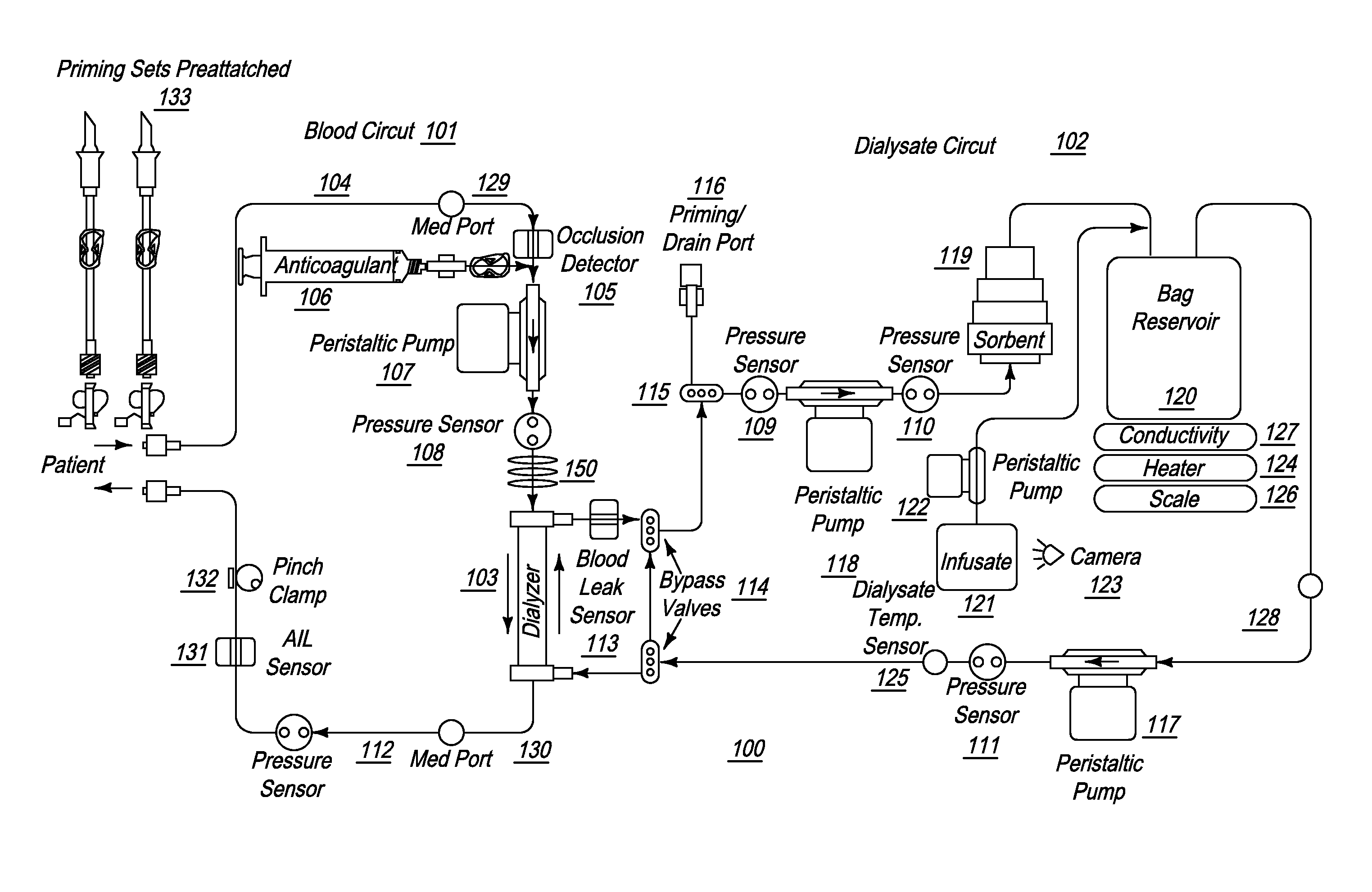

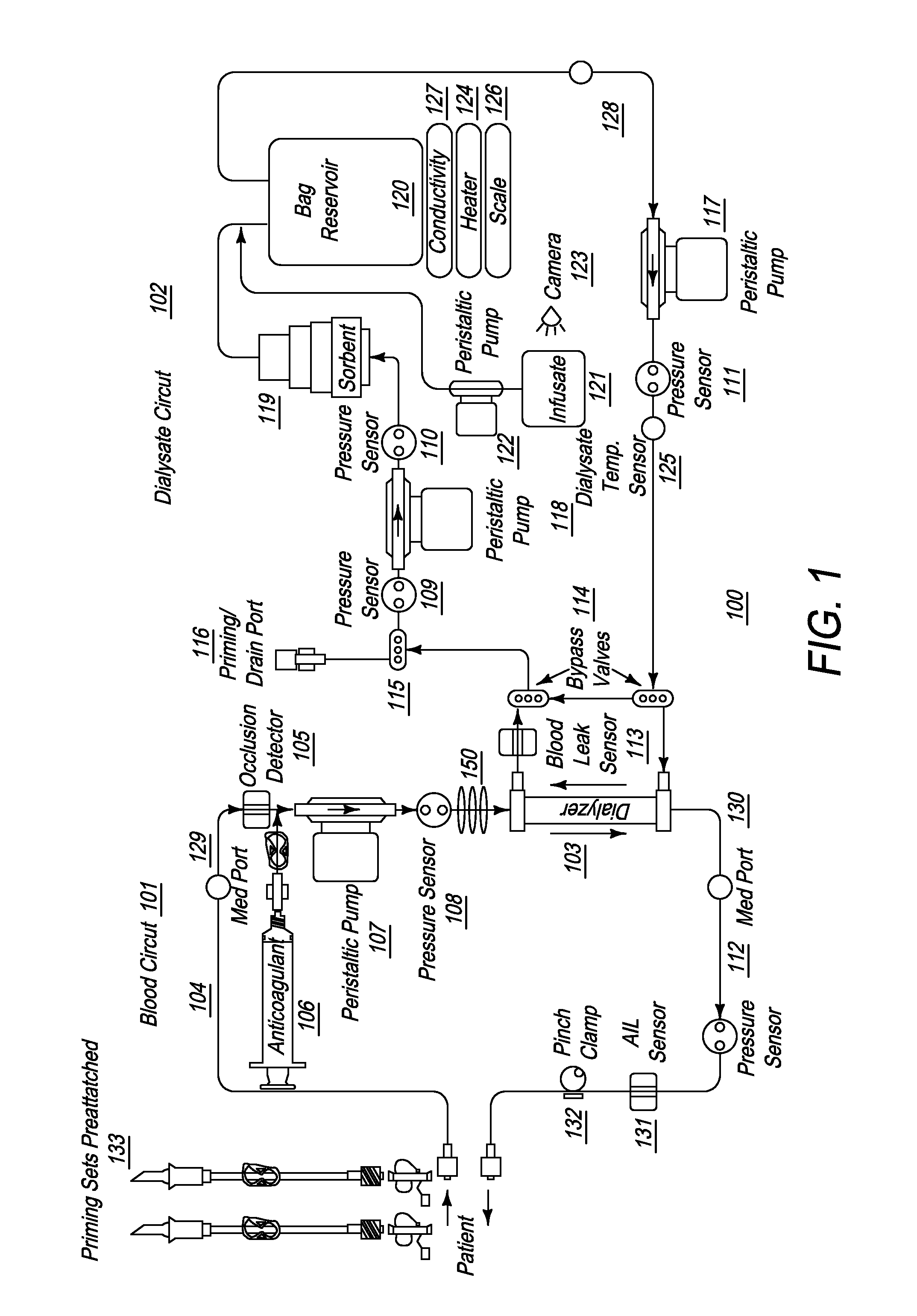

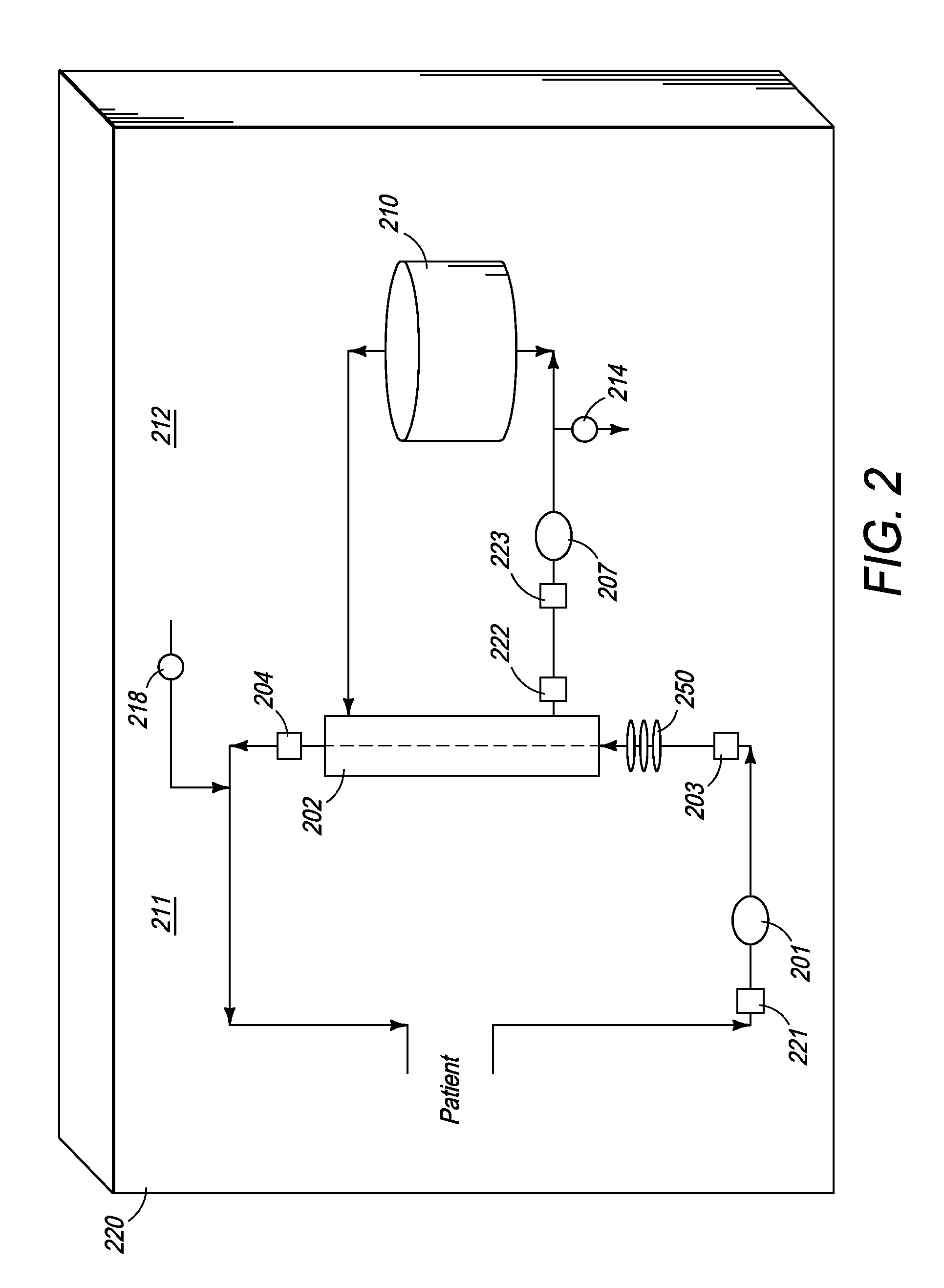

A thermal flow meter for use in dialysis is described, that uses a thermal wave to generate a signal in the fluid for which the flow rate is to be measured. The phase angle of the thermal wave signal changes when traversing downstream. The phase difference between the signals received downstream, compared with a reference excitation source signal is measured, and used to determine the flow rate of the fluid.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Systems and methods for thermophotonic dynamic imaging

Owner:MANDELIS ANDREAS +2

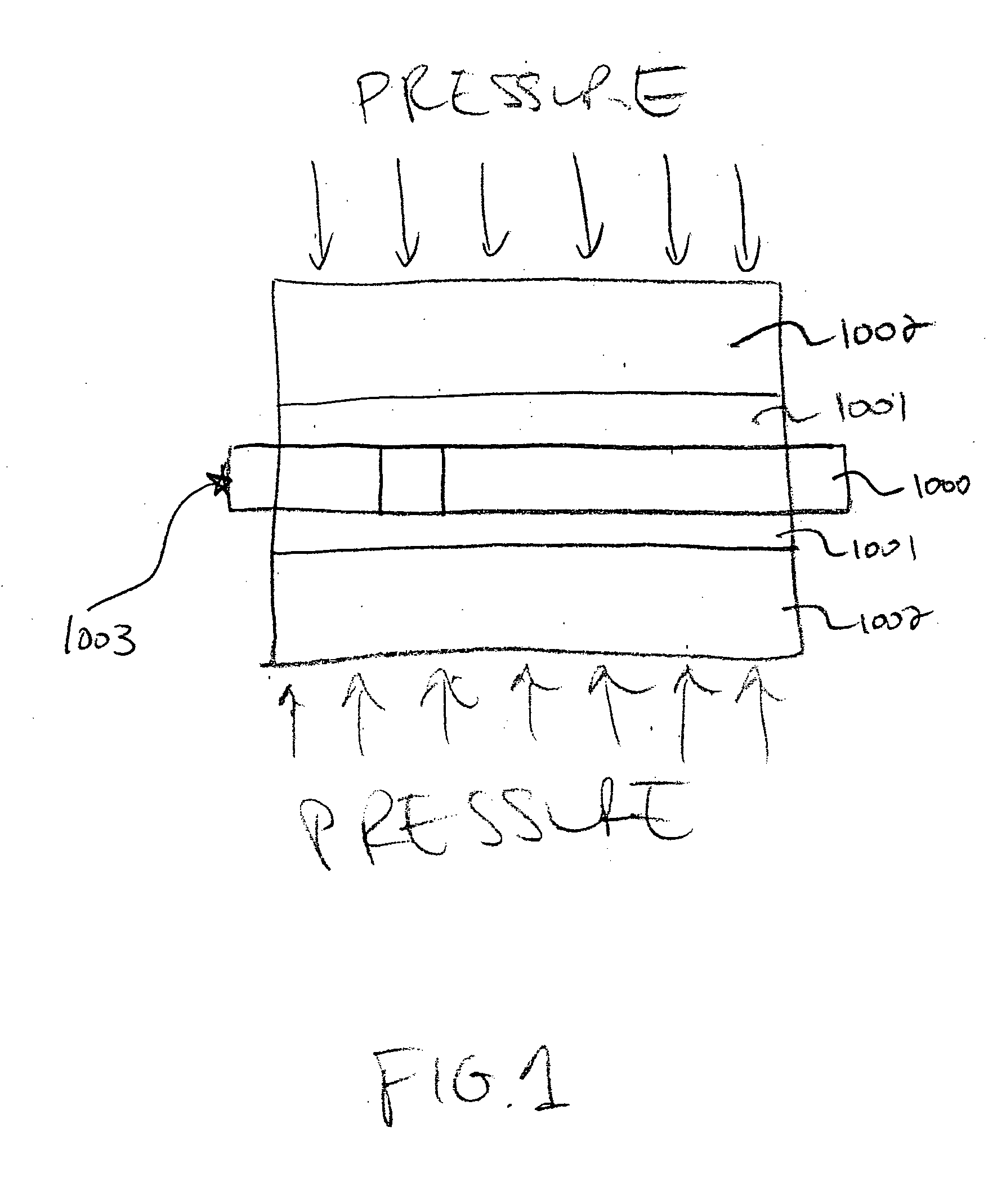

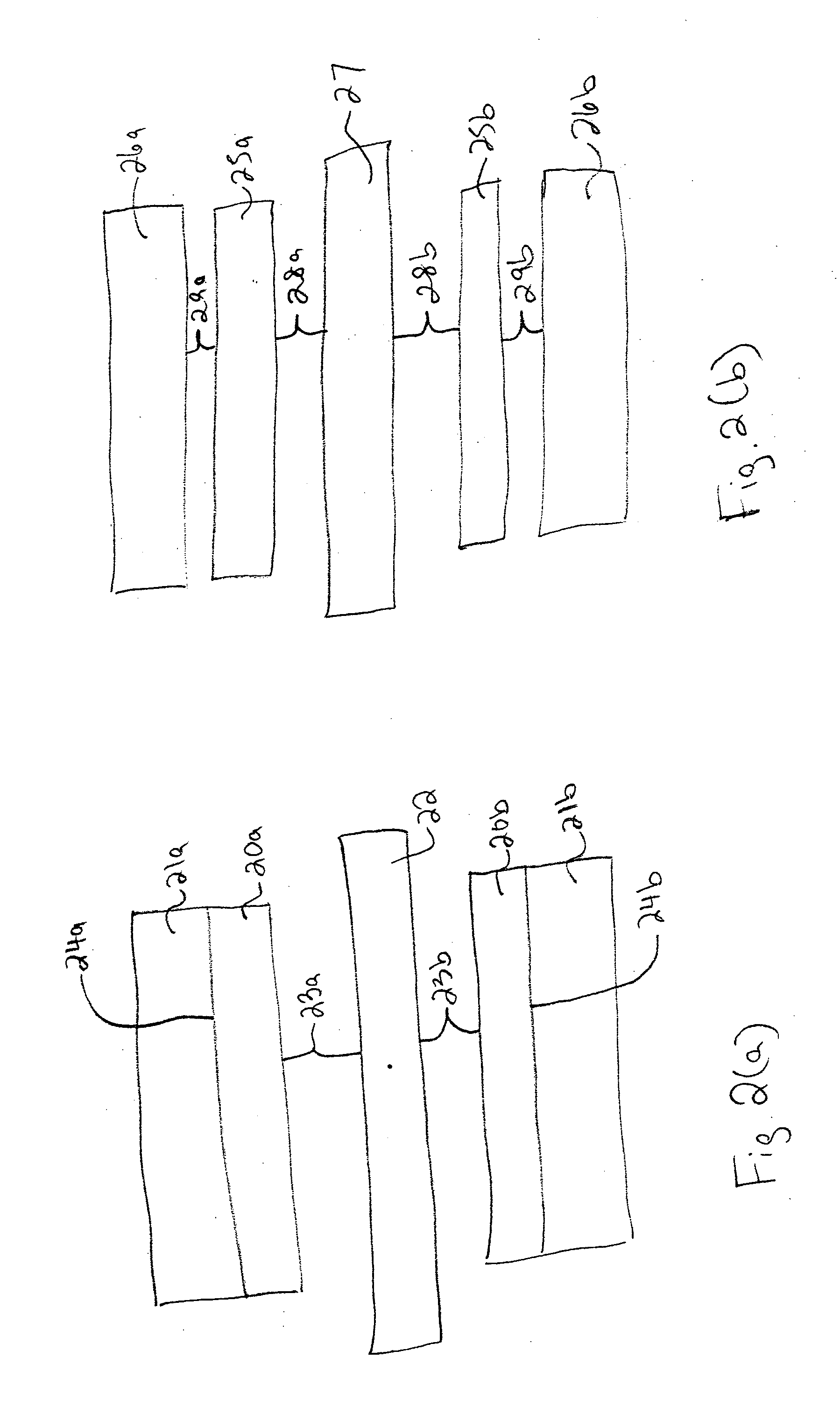

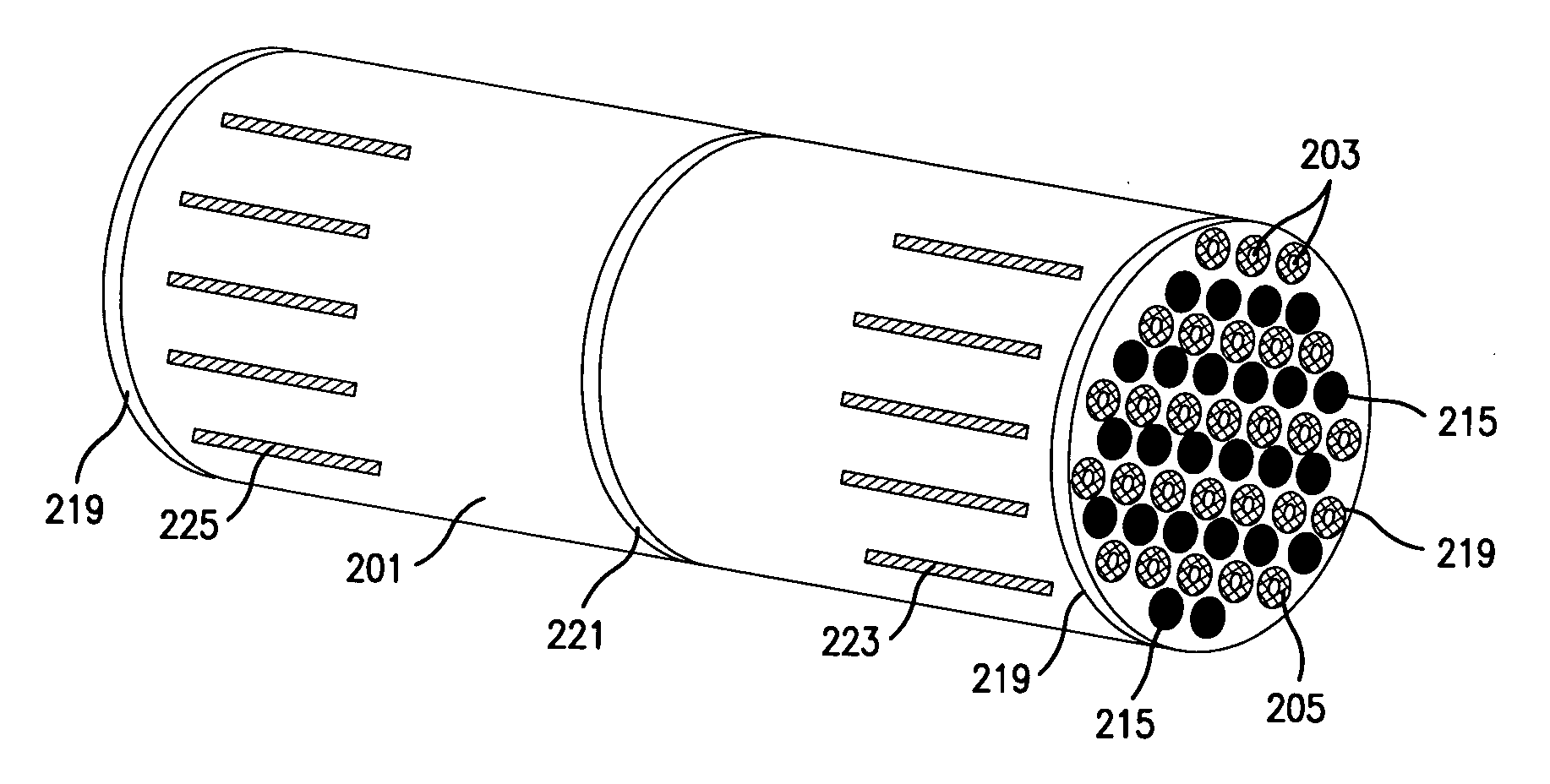

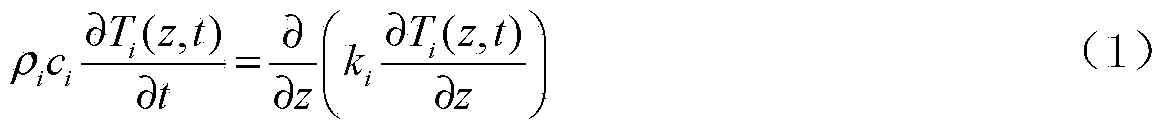

Method of controlling thermal waves in reactive multilayer joining and resulting product

An embodiment of the invention includes a method of simulating a behavior of an energy distribution within a soldered or brazed assembly to predict various physical parameters of the assembly. The assembly typically includes a reactive multilayer material. The method comprises the steps of providing an energy evolution equation having an energy source term associated with a self-propagating reaction that originates within the reactive multilayer material. The method also includes the steps of discretizing the energy evolution equation, and determining the behavior of the energy distribution in the assembly by integrating the discretized energy evolution equation using other parameters associated with the assembly.

Owner:REACTIVE NANOTECH

Process for removing a target gas from a mixture of gases by thermal swing adsorption

The separation of a target gas from a mixture of gases using a thermal swing adsorption process wherein a thermal wave is used, primarily in the desorption step. The process of this invention enables one to separately remove multiple contaminants from a treated gaseous stream.

Owner:EXXON RES & ENG CO

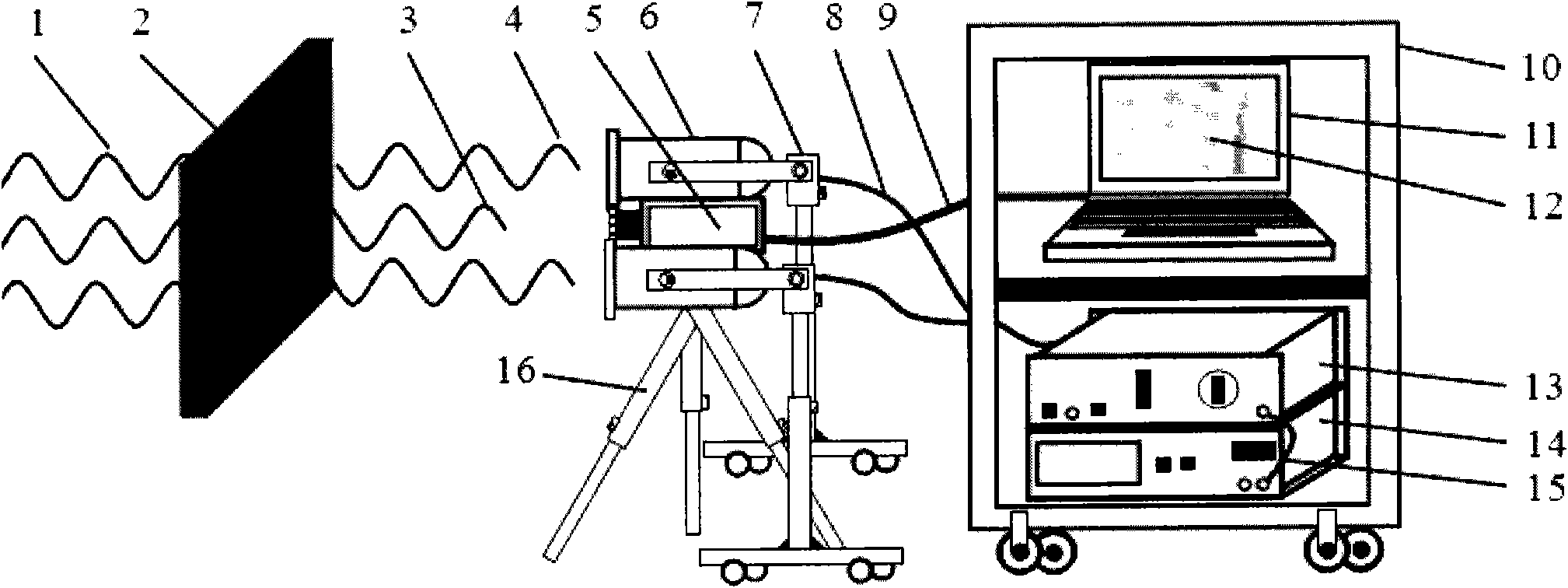

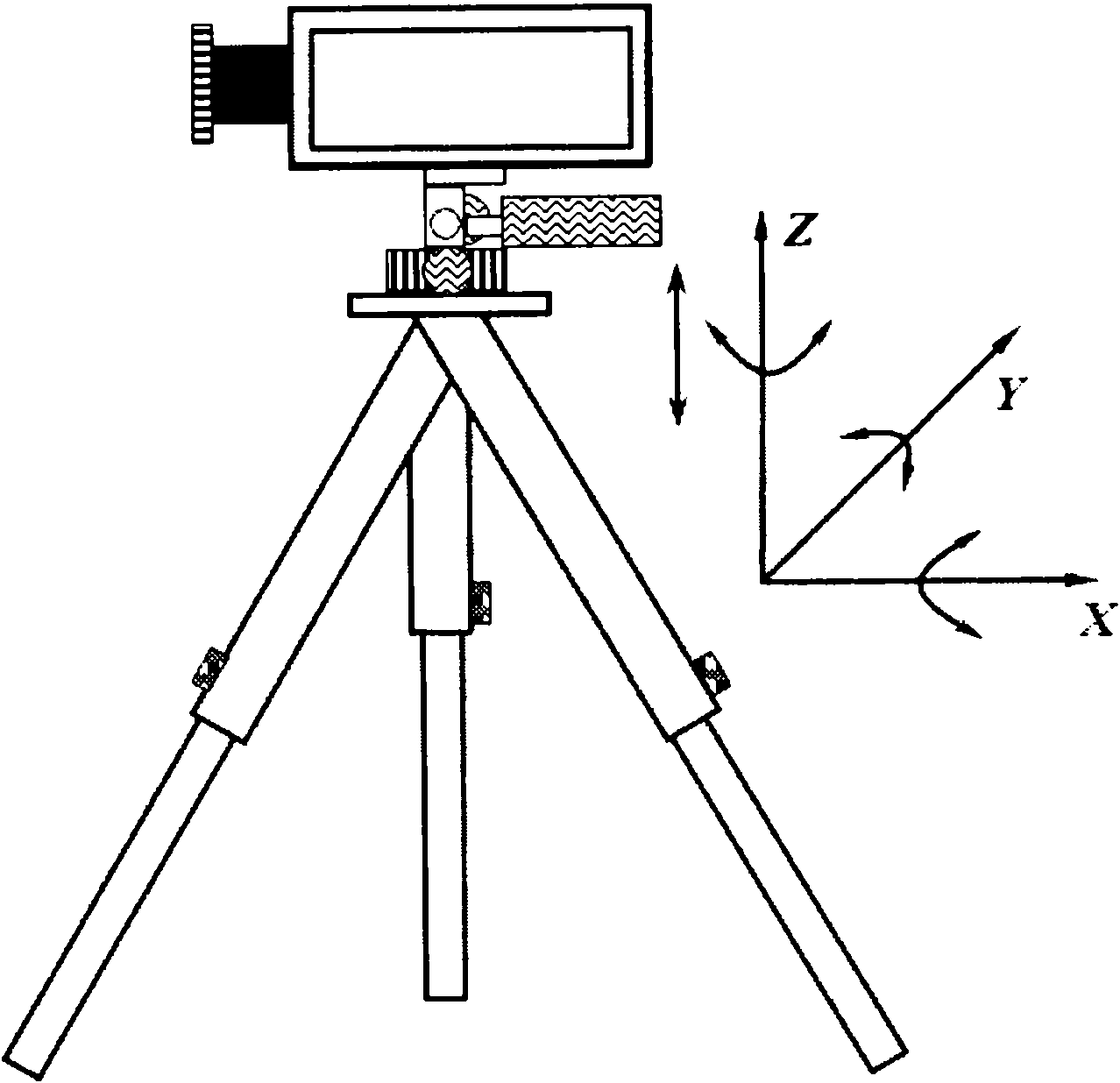

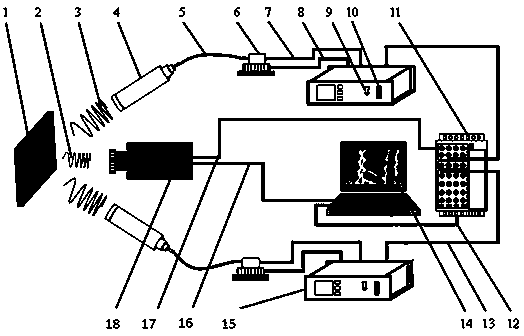

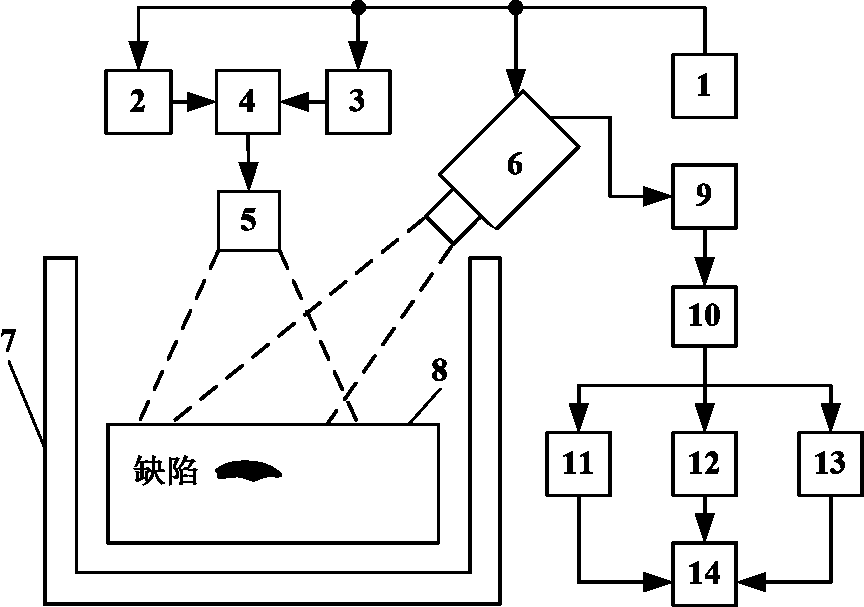

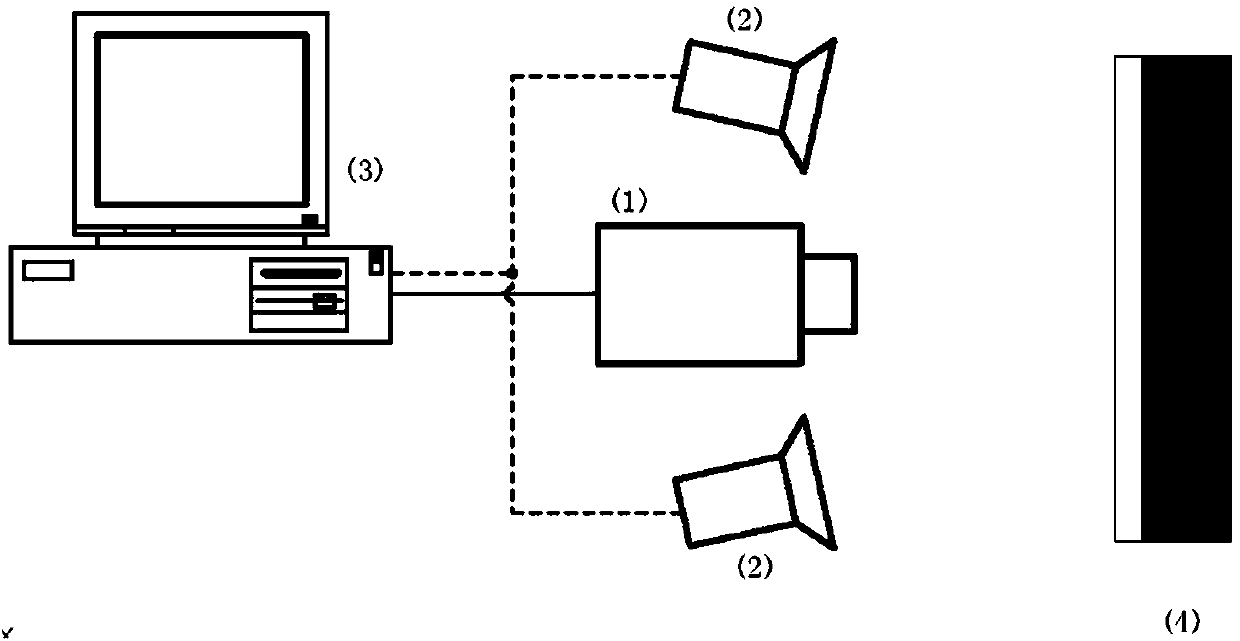

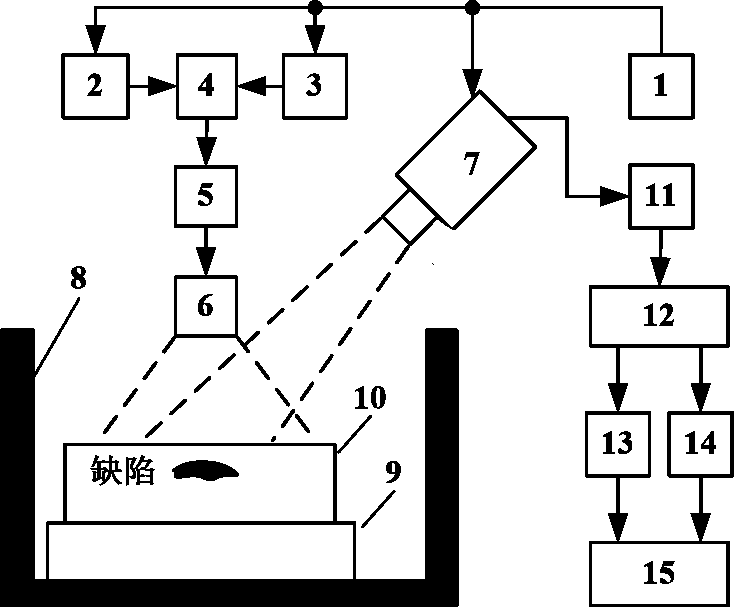

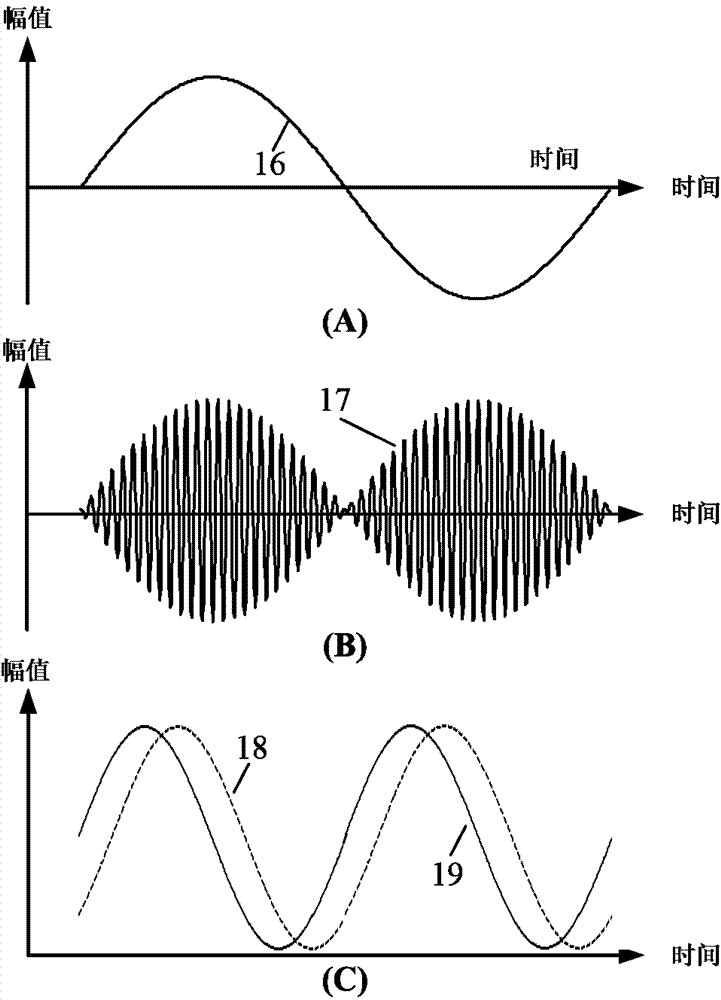

Infrared lock-in thermal wave non-destructive detection method based on image sequence processing

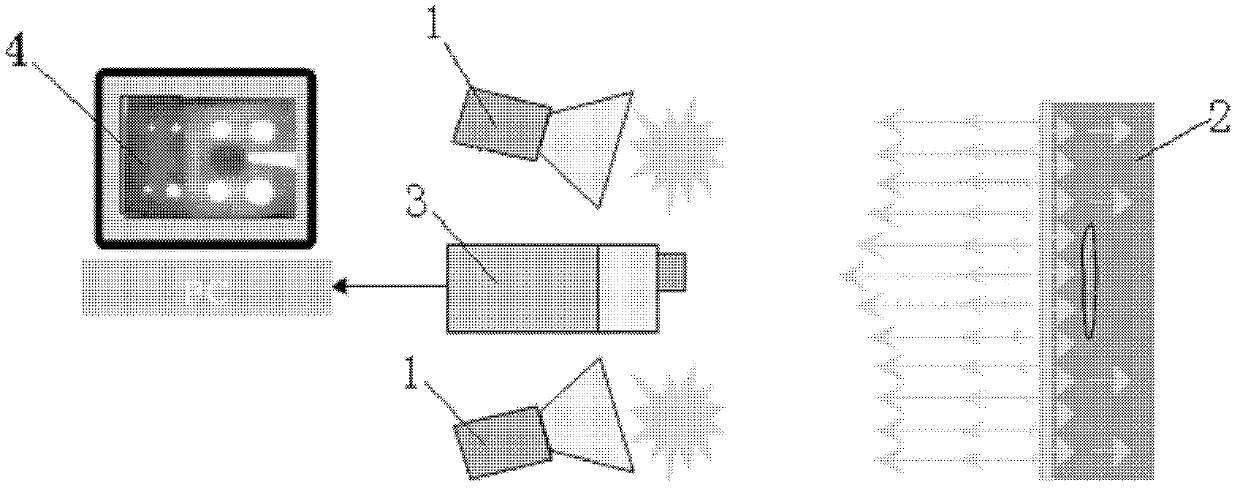

InactiveCN102033081AGuaranteed to be clearly visibleShort Spectral Power DistributionMaterial flaws investigationData acquisitionFunction generator

The invention discloses an infrared lock-in heat wave non-destructive detection method based on image sequence processing, which is a new method for realizing infrared lock-in heat wave non-destructive detection by using computer software to process the sequence of infrared images. The method comprises the following implementation steps: using a focal plane infrared heat imager to collect the image sequence of heat wave signals, using a halogen light source modulated by sine law to excite, carrying out digital lock-in processing on heat wave signals and analysis of feature images. When the method is used for non-destructive detection, the focal plane infrared heat imager 5 is fixed on a tripod 16 and connected with a data acquisition card of a computer 11, and infrared lock-in processing software 12 based on the image sequence is used for finishing initialization and image display of the infrared heat imager. The halogen light source 6 is fixed on a special support 7 to ensure that incident light is irradiated in an area to be detected of a sample piece 2 as far as possible, a function generator 14 is connected with a light source power amplifier 13 through a signal wire 15, and light intensity of the halogen light source 6 is controlled to change by the sine law. The incident light of the halogen light source 6 is irradiated to the surface of the sample piece 2 to generate excited heat waves 4. The infrared lock-in processing software 12 based on the image sequence records reflected heat waves 3 or transmitted heat waves 1 generated on the surface of the sample piece 2, a lock-in processing module is used for extracting feature information of the heat wave signals and forming the feature images, an image processing and analyzing module processes and analyzes the heat wave feature images, and inner defect features of the sample piece 2 are extracted, so as to realize fast and accurate non-destructive detection of inner defects and damages of the sample piece 2.

Owner:HARBIN INST OF TECH

Non-destructive detection method of pulse-excited infrared thermal wave phase of fixed viewing field

InactiveCN104359944AEasy to detectFlexible useMaterial flaws investigationFrequency spectrumImage sequence

The invention relates to a non-destructive detection method of pulse-excited infrared thermal wave phase of a fixed viewing field. The non-destructive detection method comprises the following steps: comprehensively applying a multiple-modulation Zoom-FFT refining spectrum method, a thermal-wave data fitting extension method and a zero-phase digital filter method, and carrying out high-accuracy spectral analysis on acquired continuous equally-spaced infrared thermal-wave image sequences before and after thermal excitation, thus quickly obtaining precise ultralow-frequency thermal-image phase diagram and amplitude diagram, and further realizing detection and recognition for defects or damages of equipment. Compared with the prior art, the non-destructive detection method has the beneficial effects that not only can the acquisition frequency, the acquisition time, the acquisition frame number and the refining degree of analysis of thermal images be flexibly set, but also the detection speed, the refining degree and the precision degree can be increased by ten times respectively, the multiplied increase of the detection effect and the detection depth of the defects also can be realized, simultaneously the requirement for computer hardware is also reduced, so that the method is flexible in use, is especially suitable for non-destructive detection of the infrared thermal wave on site and has a wide application prospect.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

Method for automatic identification and detection of defect in composite material

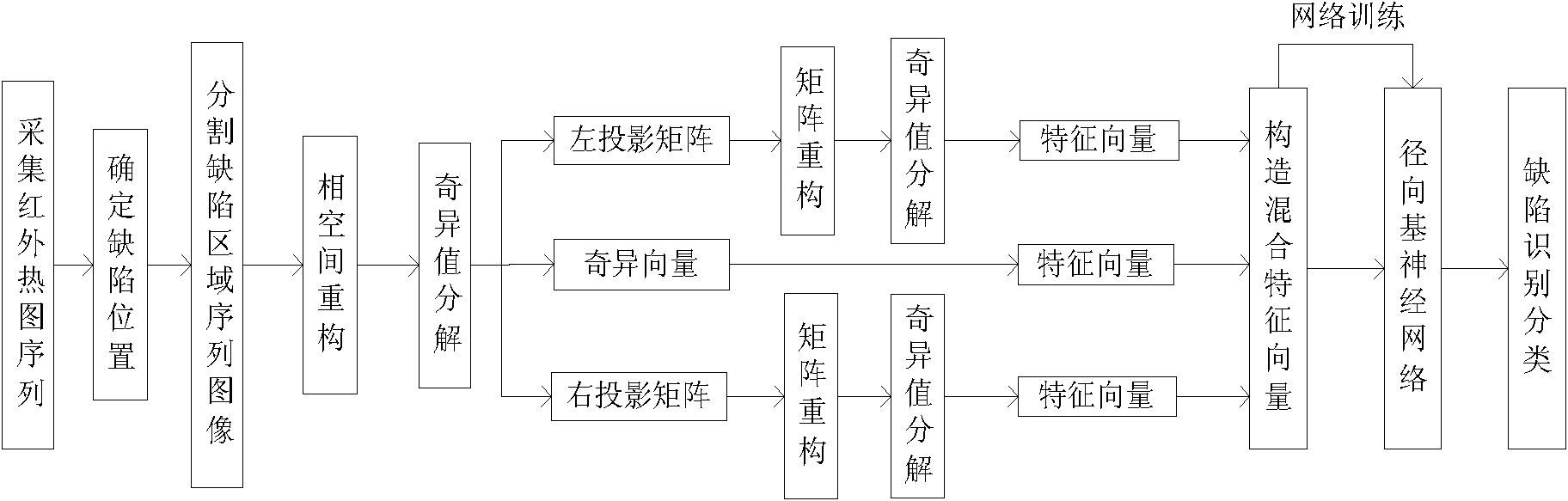

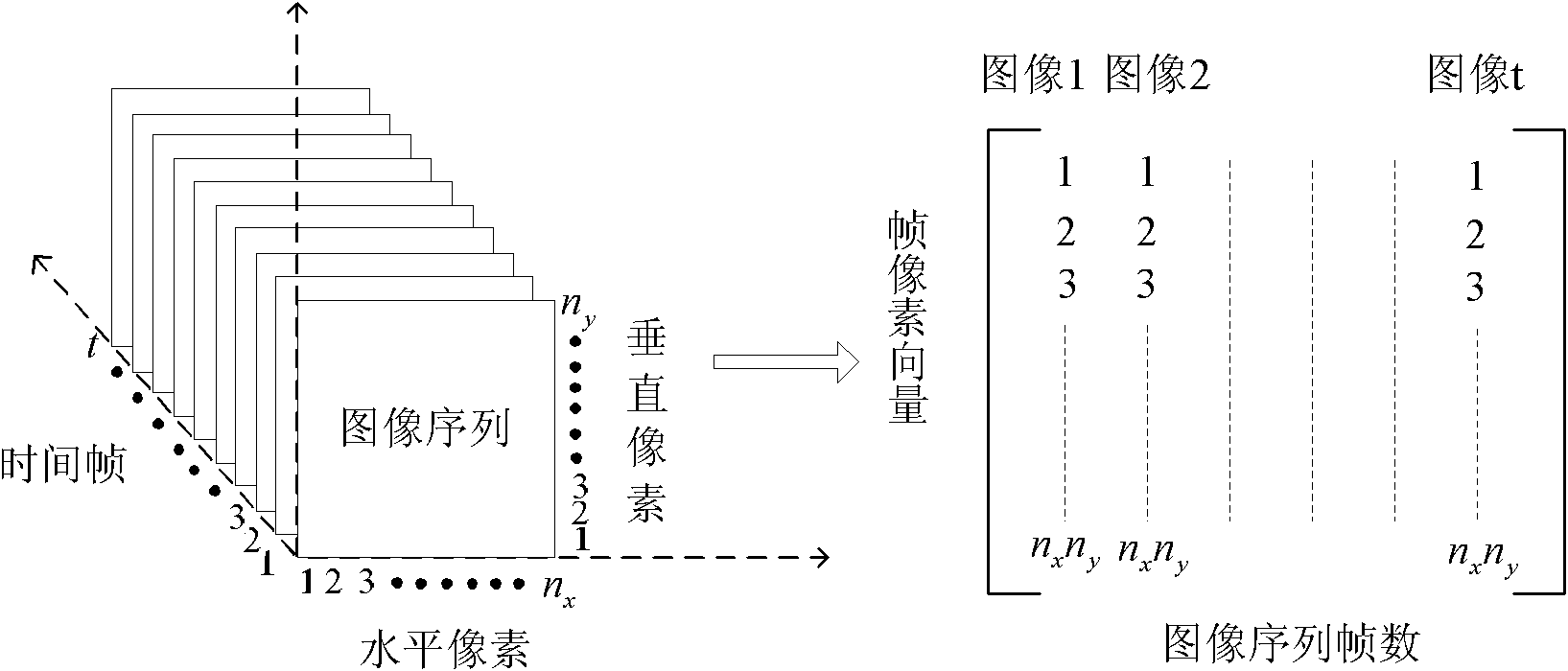

InactiveCN102692429ARealize automatic identification and detectionImprove performanceMaterial flaws investigationNeural learning methodsTime informationSingular value decomposition

The invention relates to a method for automatic identification and detection of defects in a composite material. The method comprises steps of: detecting the composite material to generate an infrared image by using infrared thermal wave nondestructive testing equipment; conducting phase space reconstruction on the infrared sequence image to determine defect position of the composite material and segment defect area of the image; conducting phase space reconstruction on the infrared sequence image with defect area and carrying out singular value decomposition to obtain a singular matrix, and left and right projection matrixes; carrying out matrix reconstruction again on the two projection matrixes; extracting algebraic characteristics of time information and space information of the defect through singular value decomposition; constructing mixing characteristic vector as characteristic symptom of the defect; and utilizing results from a nerve network classifier to complete the identification and classification determination. The method of the invention can realize automatic identification and detection on defect in the composite material, carry out rapid detection on damage type of the composite material and provide rapid detection means according to usage condition of the composite material, and has critical reality meaning and research value.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

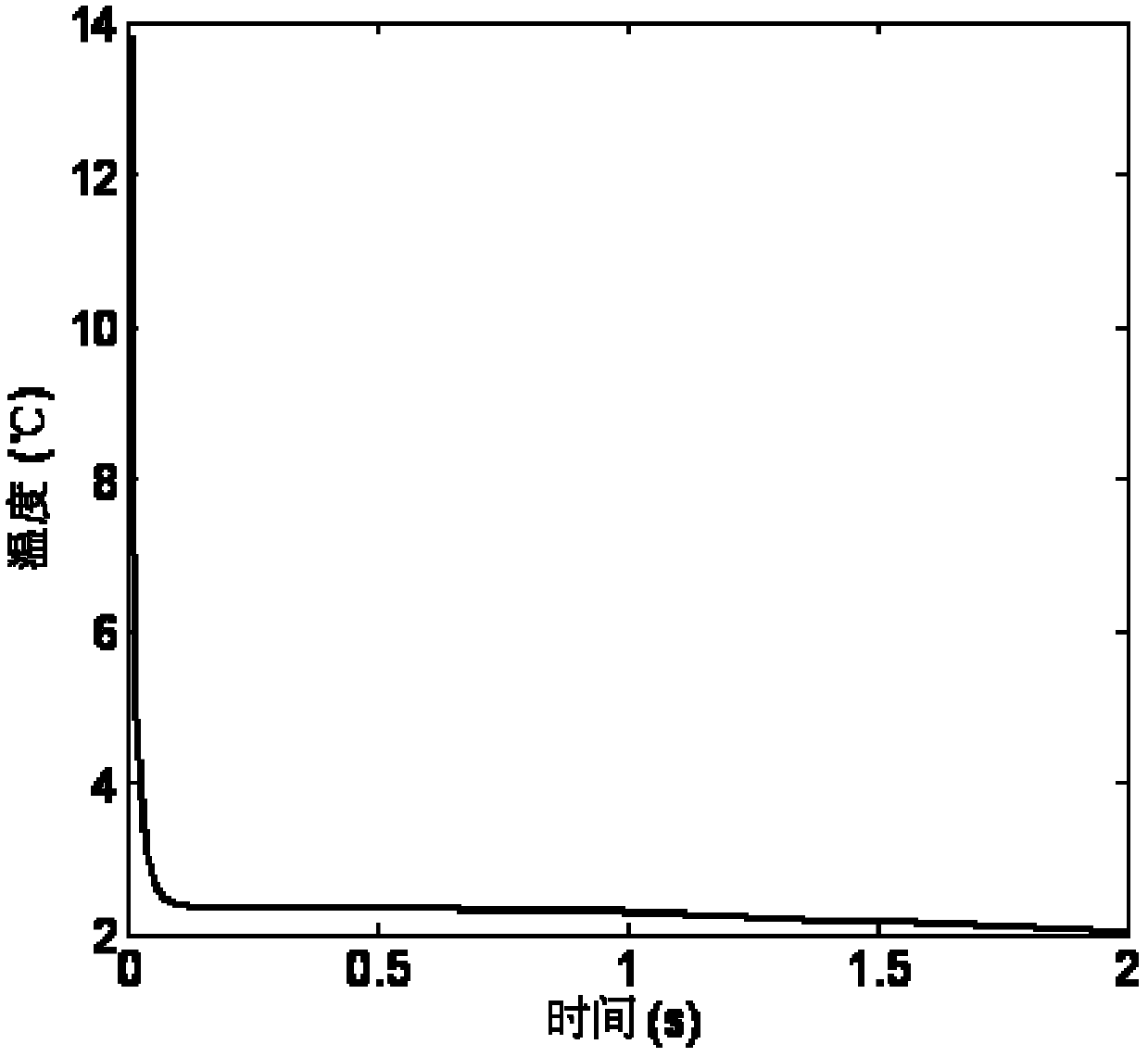

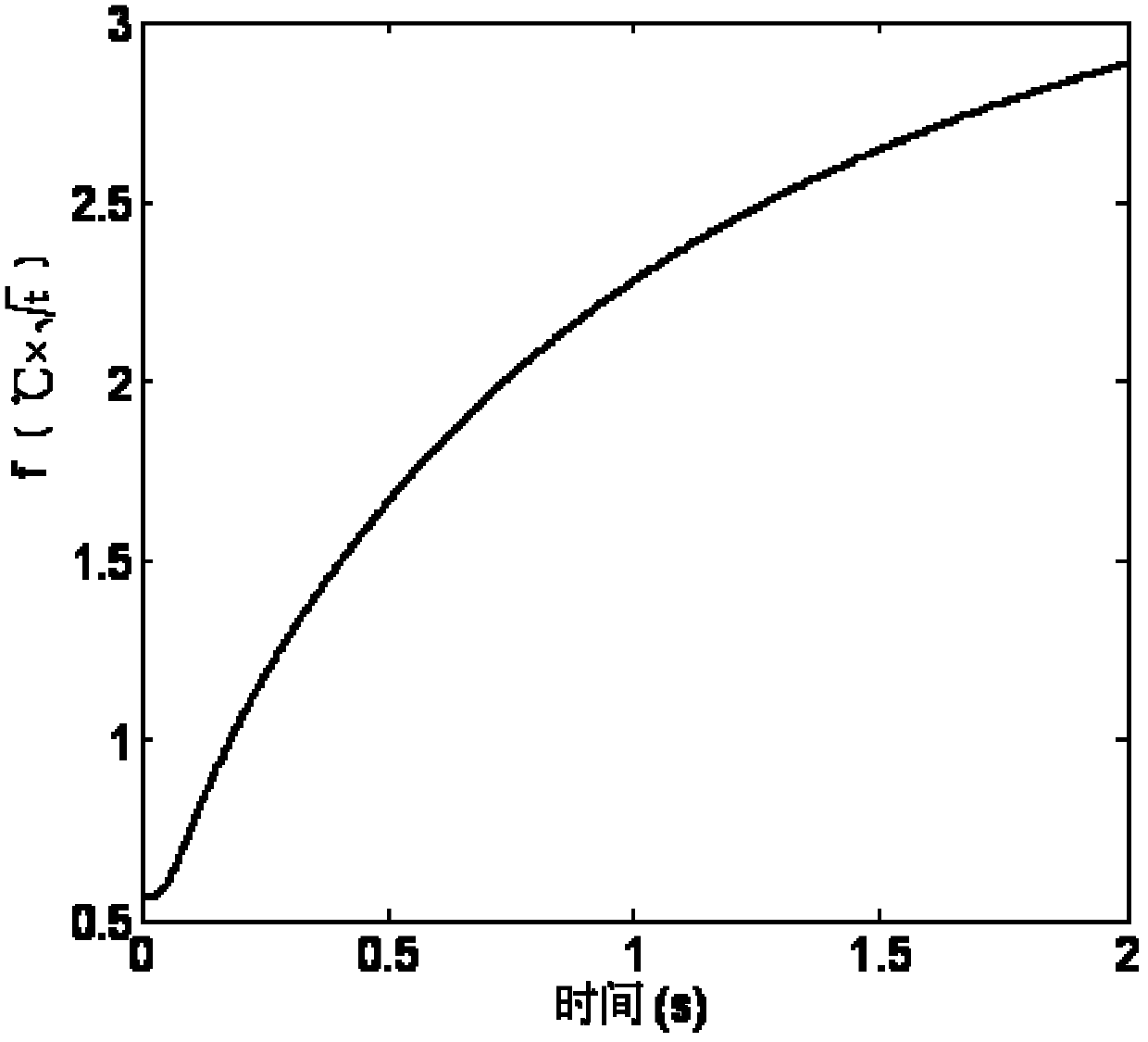

Method for measuring thickness by pulse infrared thermal wave technology

ActiveCN102221339ASimple processing methodMaterial flaws investigationUsing optical meansThermal diffusion coefficientThermodynamics

The invention provides a method for measuring thickness or defect depth by a pulse infrared thermal wave technology, comprising the following steps of (1) heating an object to be measured by pulse heating equipment; obtaining a thermographic sequence on the surface of the object to be measured by an infrared thermal imaging device; memorizing the thermographic sequence in a general memory; (2) multiplying a temperature-time curve of each point in the thermaographic sequence with corresponding time, thus obtaining a new curve f; (3) working out first-order differential on the f; and obtaining a peak time tapst; (4) working out L by a formula, wherein Alpha is thermal diffusion coefficient and L is the thickness or the defect depth of the object to be measured. By adopting the technical scheme, the thickness or detect depth of a part to be measured can be measured, a reference curve is not needed, and only one-order differential treatment is needed for the measurement, so that the processing method is simpler.

Owner:CAPITAL NORMAL UNIVERSITY +1

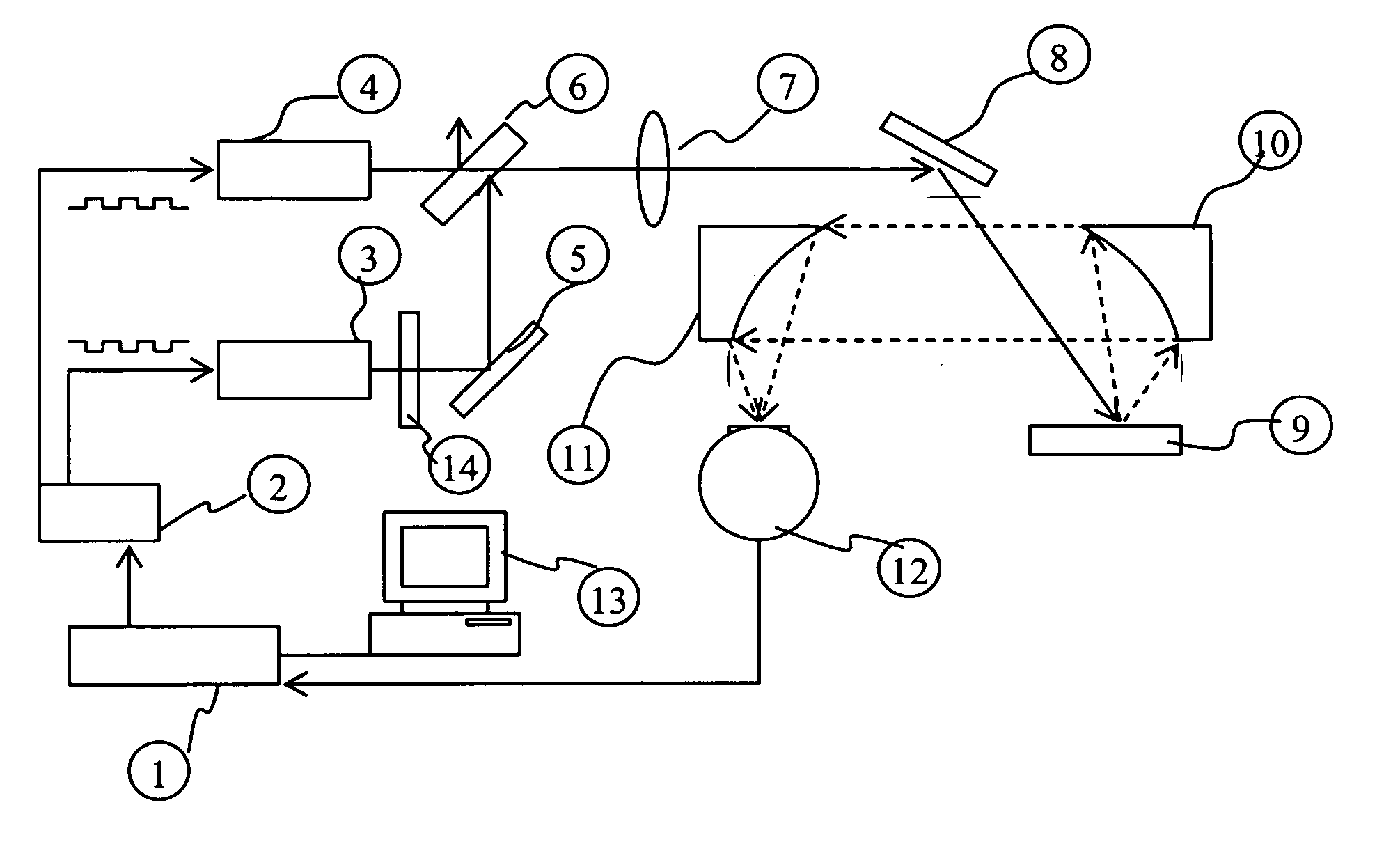

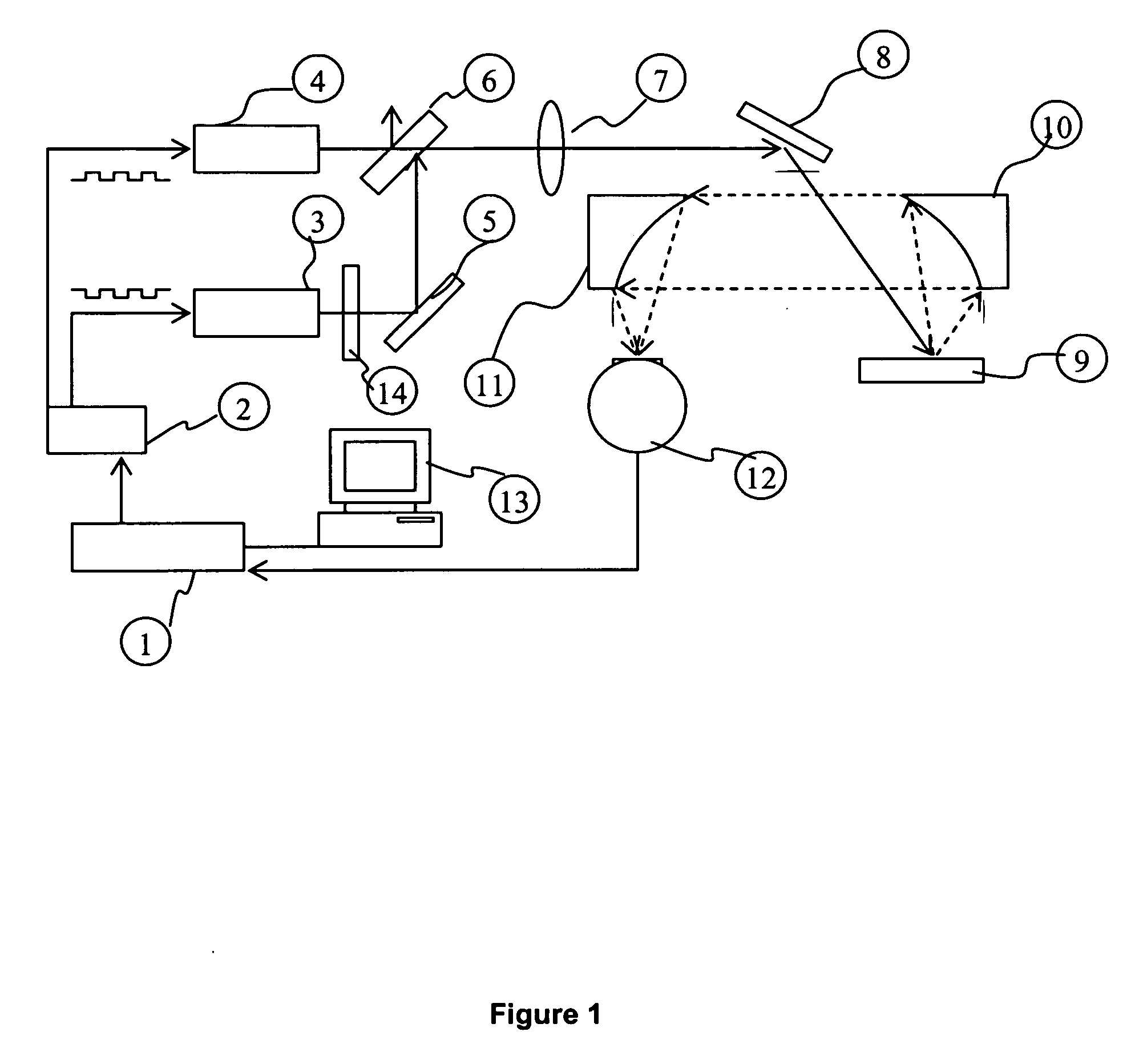

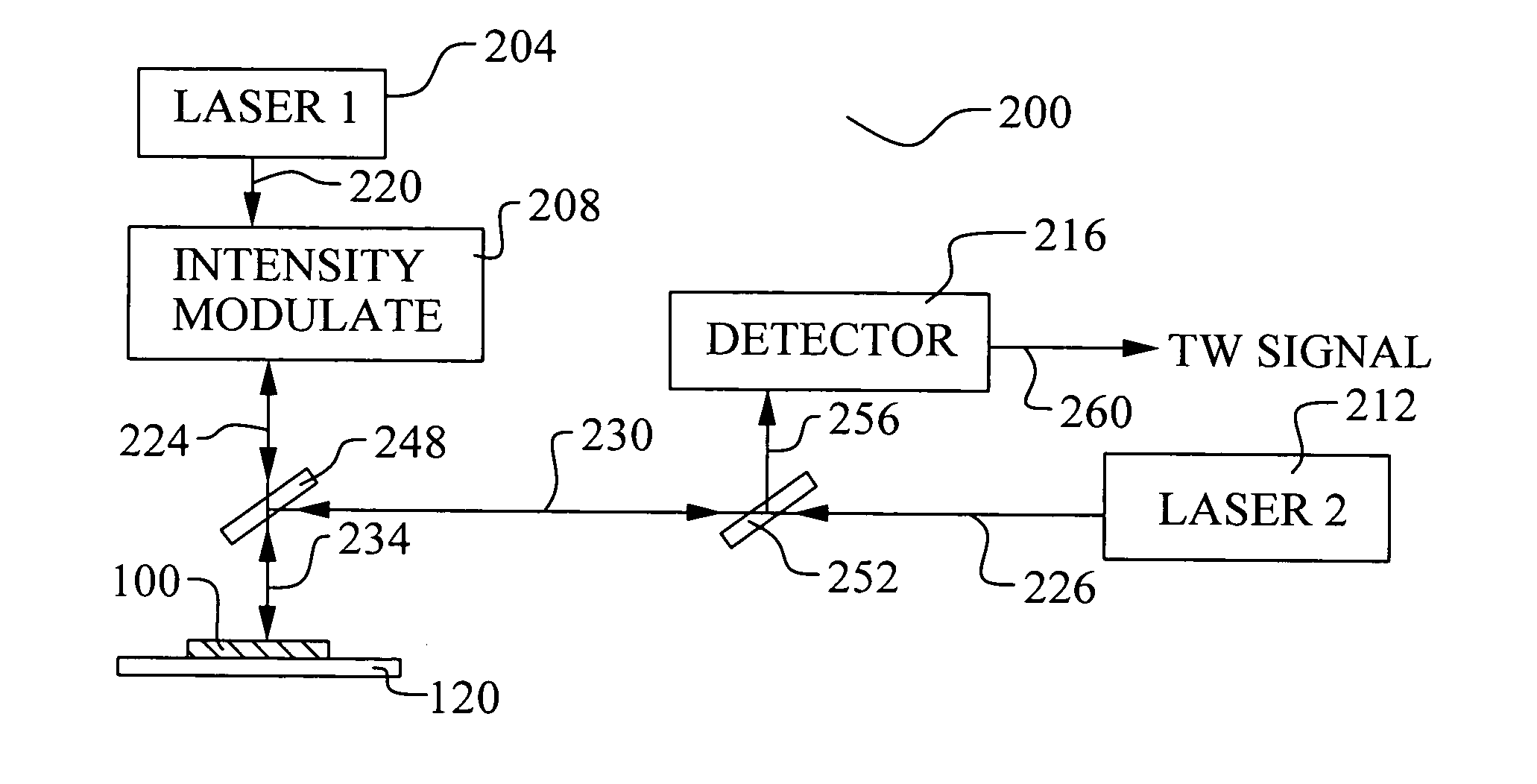

Non-invasive biothermophotonic sensor for blood glucose monitoring

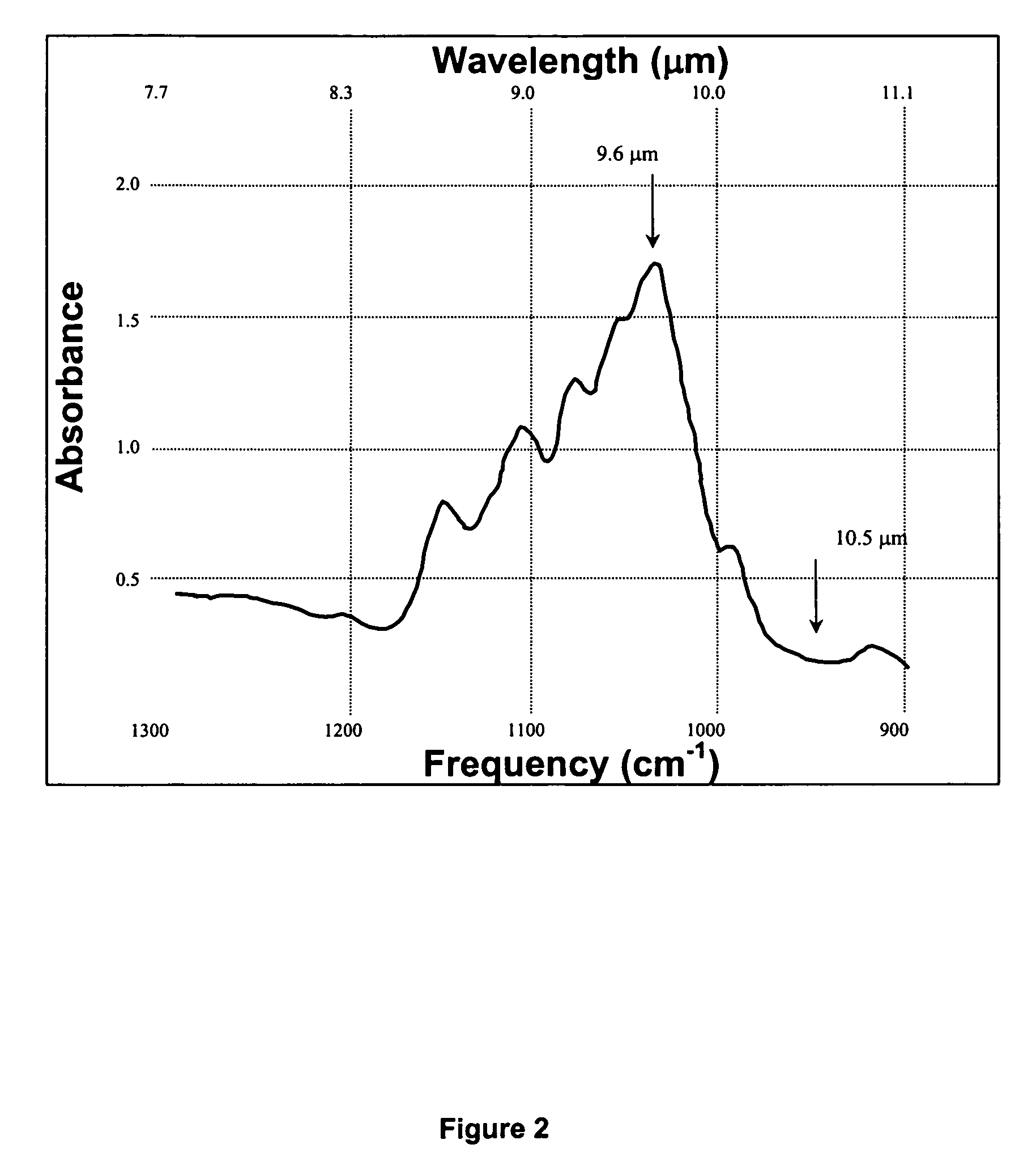

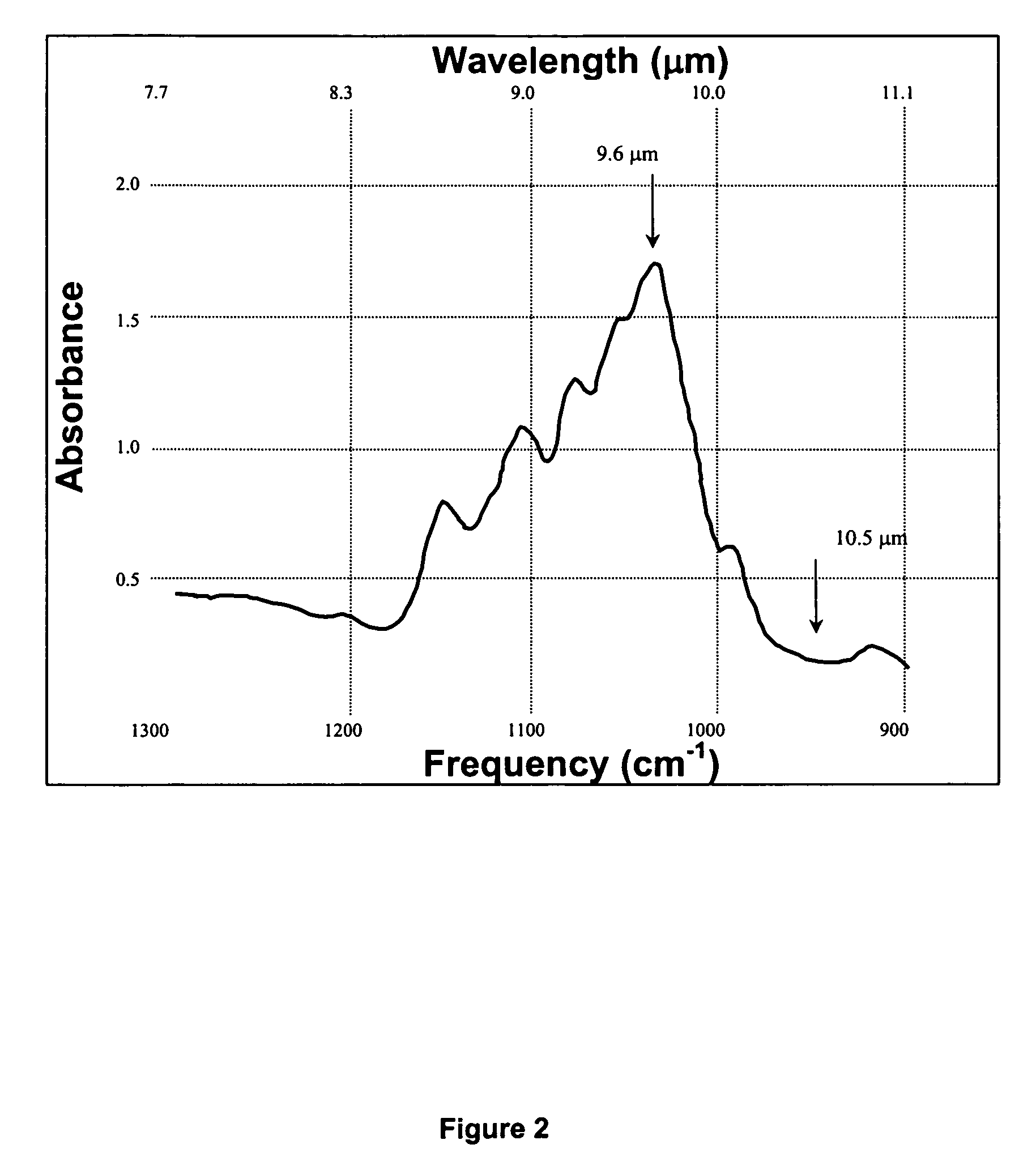

There is provided a glucose monitoring method and apparatus based on the principle of Wavelength-Modulated Differential Laser Photothermal Radiometry (WM-DPTR). Two intensity modulated laser beams operating in tandem at specific mid-infrared (IR) wavelengths and current-modulated synchronously by two electrical waveforms 180 degrees out-of-phase, are used to interrogate the tissue surface. The laser wavelengths are selected to absorb in the mid infrared range (8.5-10.5 μm) where the glucose spectrum exhibits a discrete absorption band. The differential thermal-wave signal generated by the tissue sample through modulated absorption between two specific wavelengths within the band (for example, the peak at 9.6 and the nearest baseline at 10.5 μm) lead to minute changes in sample temperature and to non-equilibrium blackbody radiation emission. This modulated emission is measured with a broadband infrared detector. The detector is coupled to a lock-in amplifier for signal demodulation. Any glucose concentration increases will be registered as differential photothermal signals above the fully suppressed signal baseline due to increased absorption at the probed peak or near-peak of the band at 9.6 μm at the selected wavelength modulation frequency. The emphasis is on the ability to monitor blood glucose levels in diabetic patients in a non-invasive, non-contacting manner with differential signal generation methods for real-time baseline corrections, a crucial feature toward precise and universal calibration (independent of person-to-person contact, skin, temperature or IR-emission variations) in order to offer accurate absolute glucose concentration readings.

Owner:MANDELIS ANDREAS +1

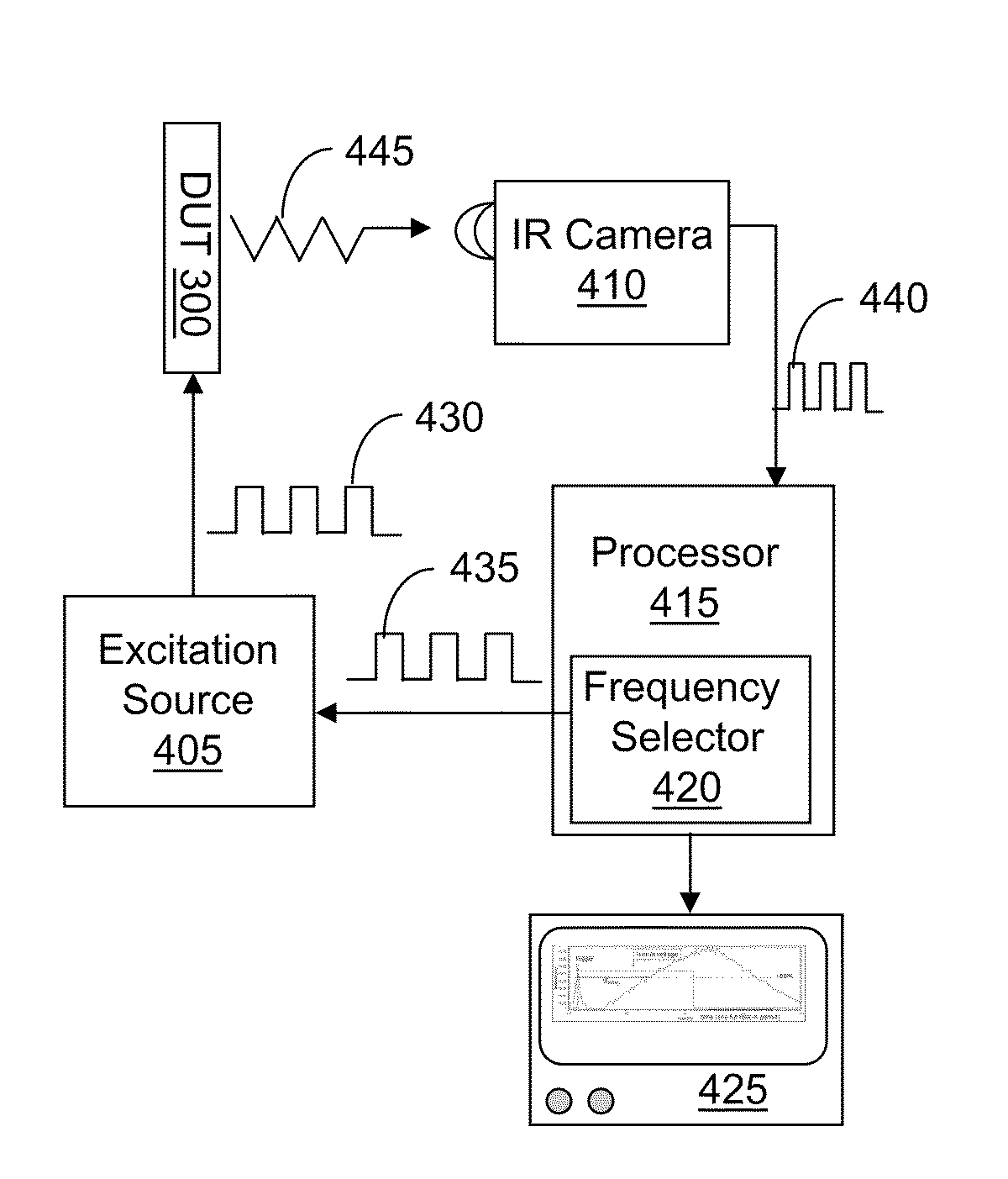

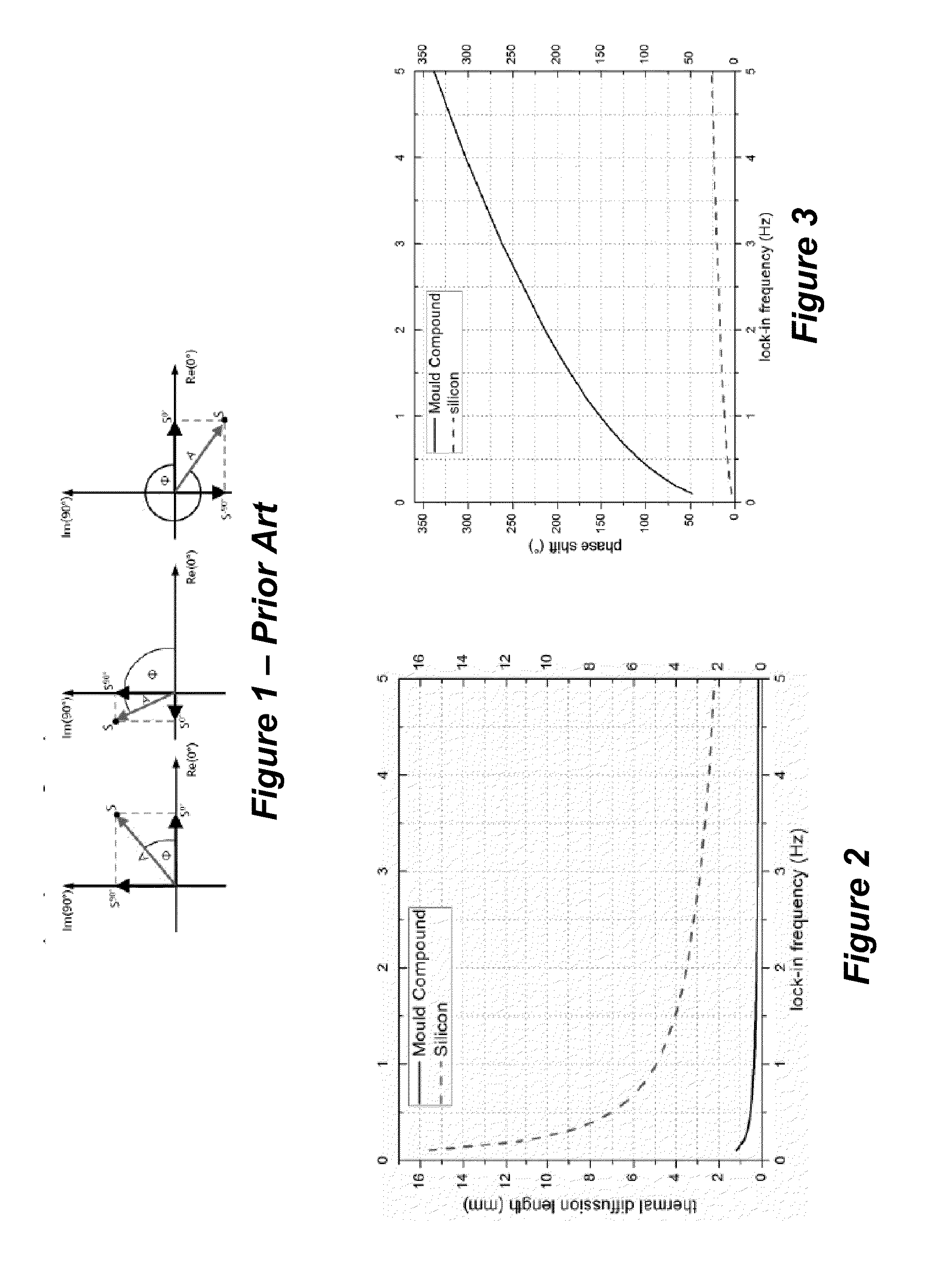

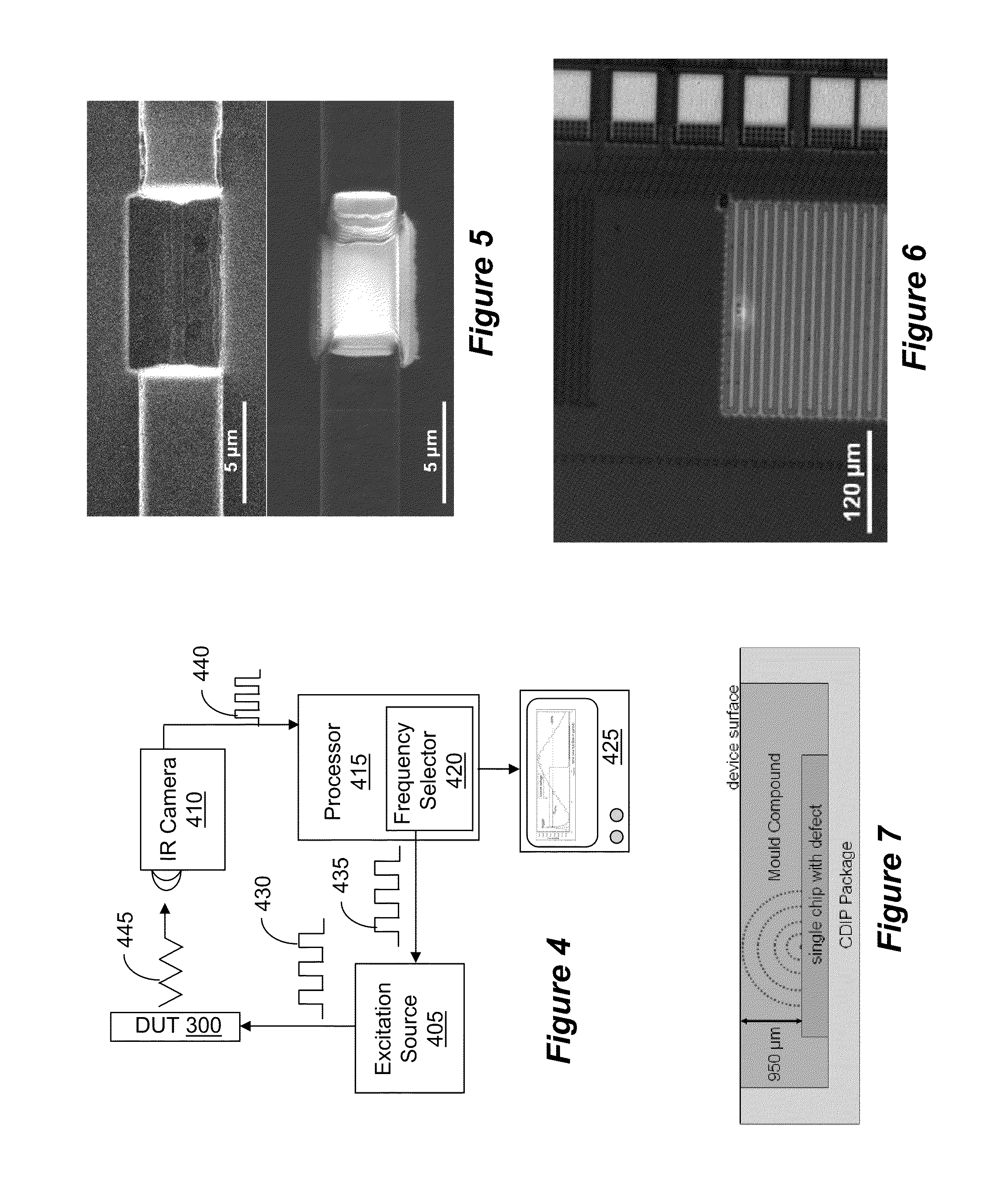

Three-dimensional hot spot localization

ActiveUS20110297829A1Improve depth resolutionImprove measurement reliabilityInvestigating semiconductor impuritiesSamplingTime delaysData acquisition

A non-destructive approach for the 3D localization of buried hot spots in electronic device architectures by use of Lock-in Thermography (LIT). The 3D analysis is based on the principles of thermal wave propagation through different material layers and the resulting phase shift / thermal time delay. With more complex multi level stacked die architectures it is necessary to acquire multiple LIT results at different excitation frequencies for precise hot spot depth localization. Additionally, the use of multiple time-resolved thermal waveforms, measured in a minimized field of view on top of the hot spot location, can be used to speed up the data acquisition. The shape of the resulting waveforms can be analyzed to further increase the detection accuracy and confidence level.

Owner:DCG SYST +1

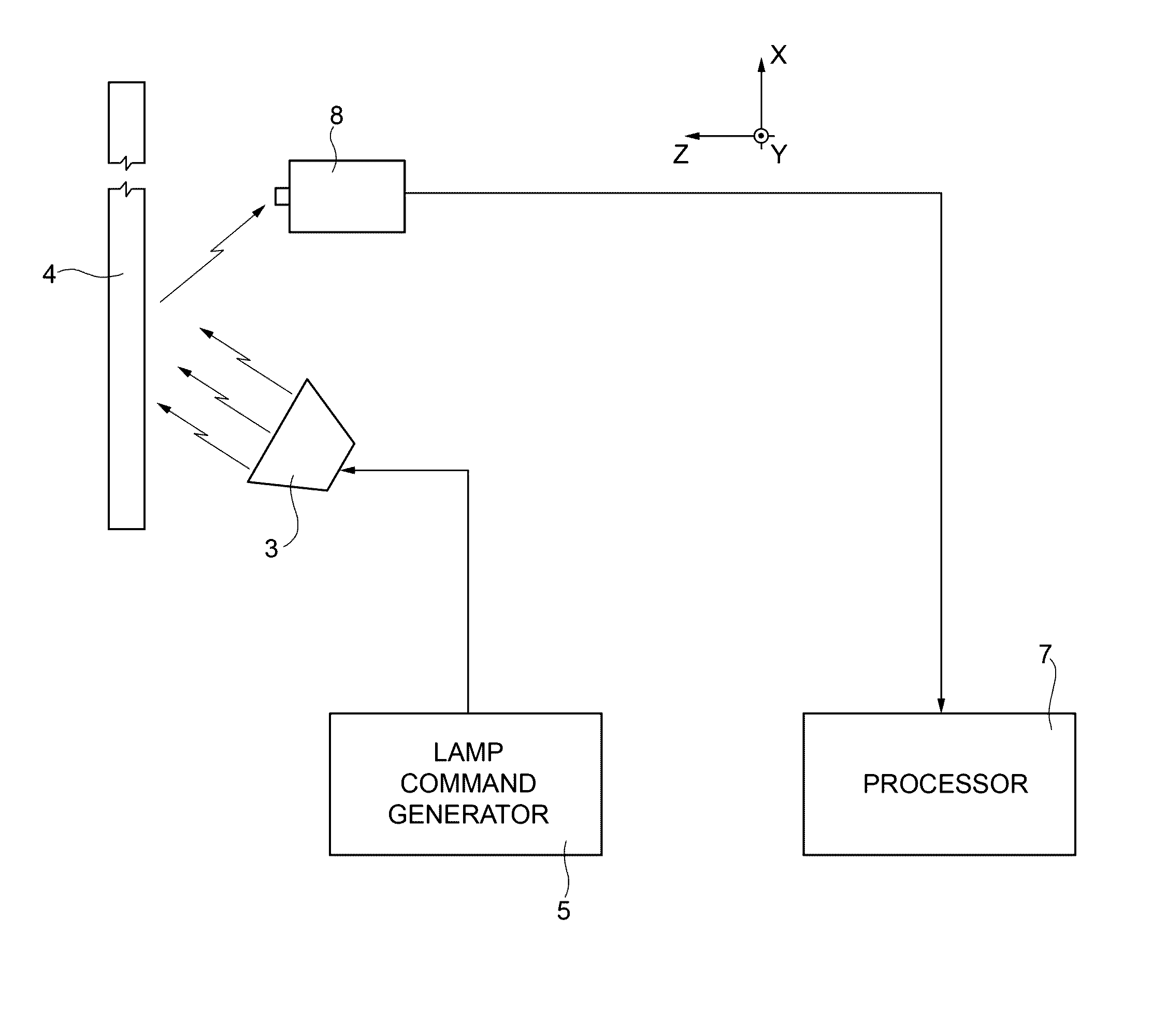

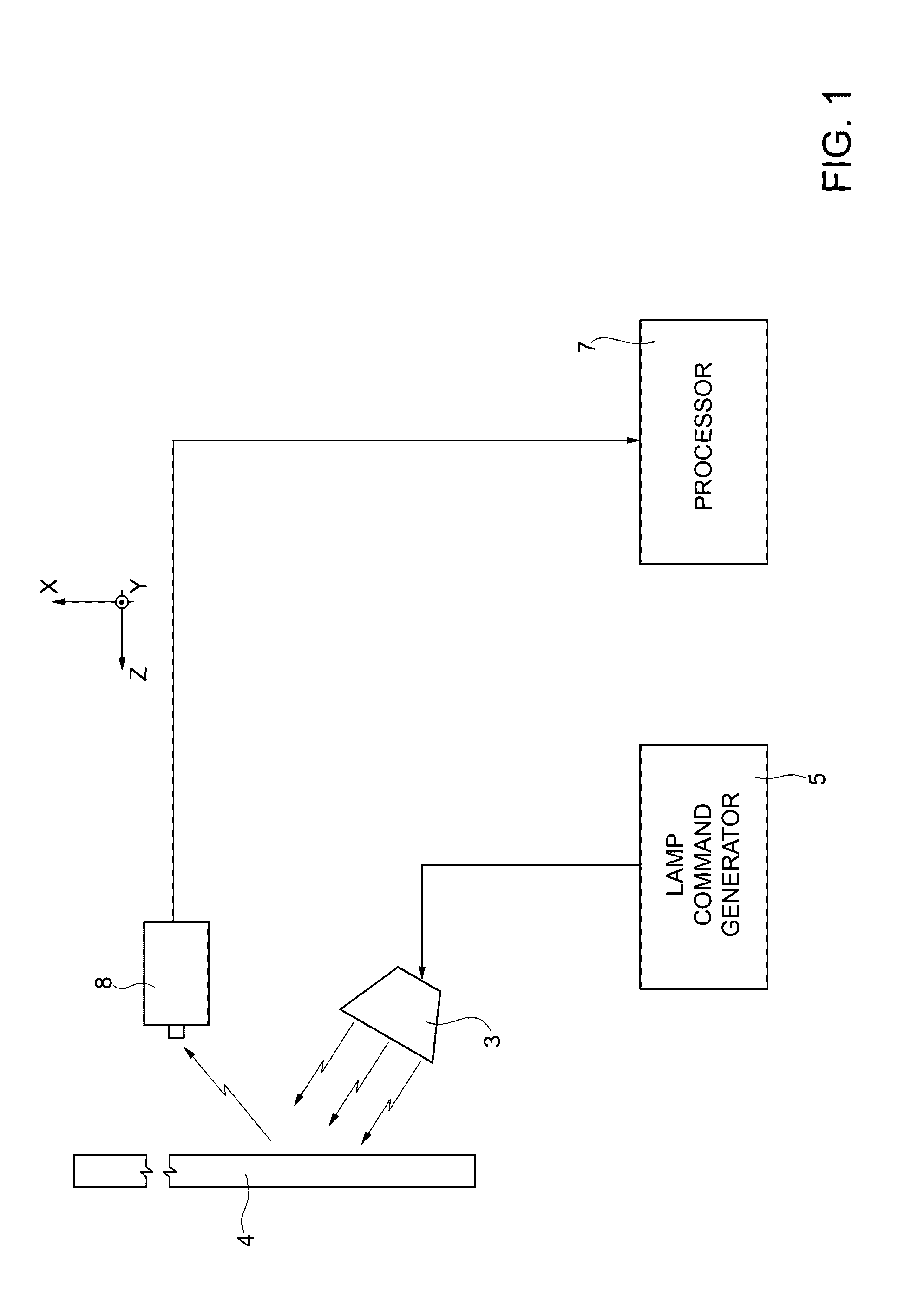

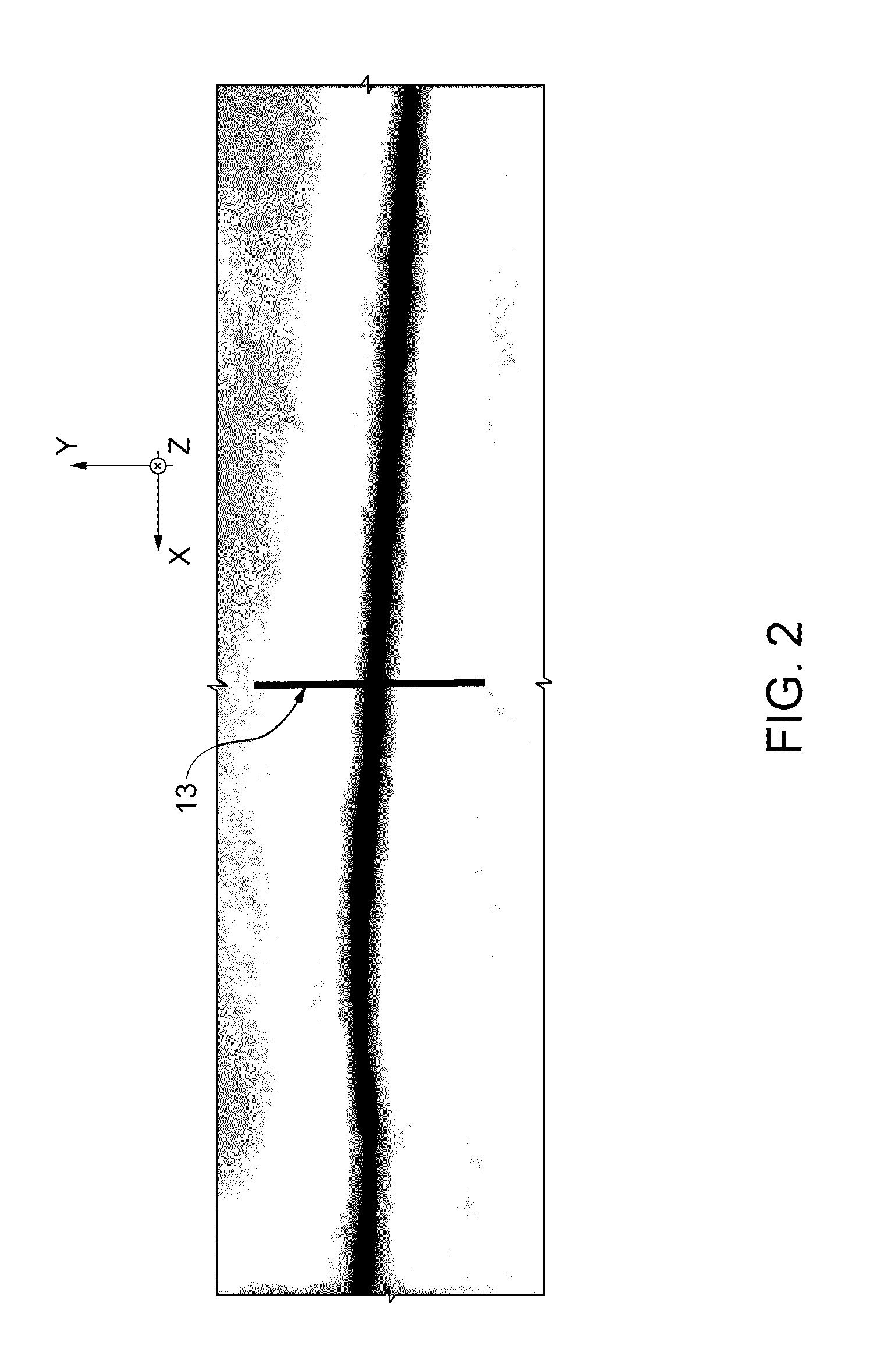

Method and system of thermographic non-destructive inspection for detecting and measuring volumetric defects in composite material structures

A thermographic non-destructive inspection method of a structure, comprising the steps of: generating a modulated thermal wave in the direction of the structure; generating a temperature signal identifying a phase shift between the modulated thermal wave and a return thermal wave emitted from the structure; processing the temperature signal to obtain a first sub-signal related to the phase of the first harmonic of the temperature signal; identifying a first dimension of said defect as a function of the phase of the first harmonic of the temperature signal; calculating a first and a second intermediate parameter, ΔΦ1 for the first harmonic and ΔΦ2 for the third harmonic of the temperature signal, by calculating the difference, in degrees, between the phase value inside the zone with a defect and the phase value, absolute or mean of a plurality of points, of the undamaged zone close to the defect; and identifying a second dimension of the defect as a function of the first dimension and of the intermediate parameters ΔΦ1 and ΔΦ2.

Owner:LEONARDO SPA

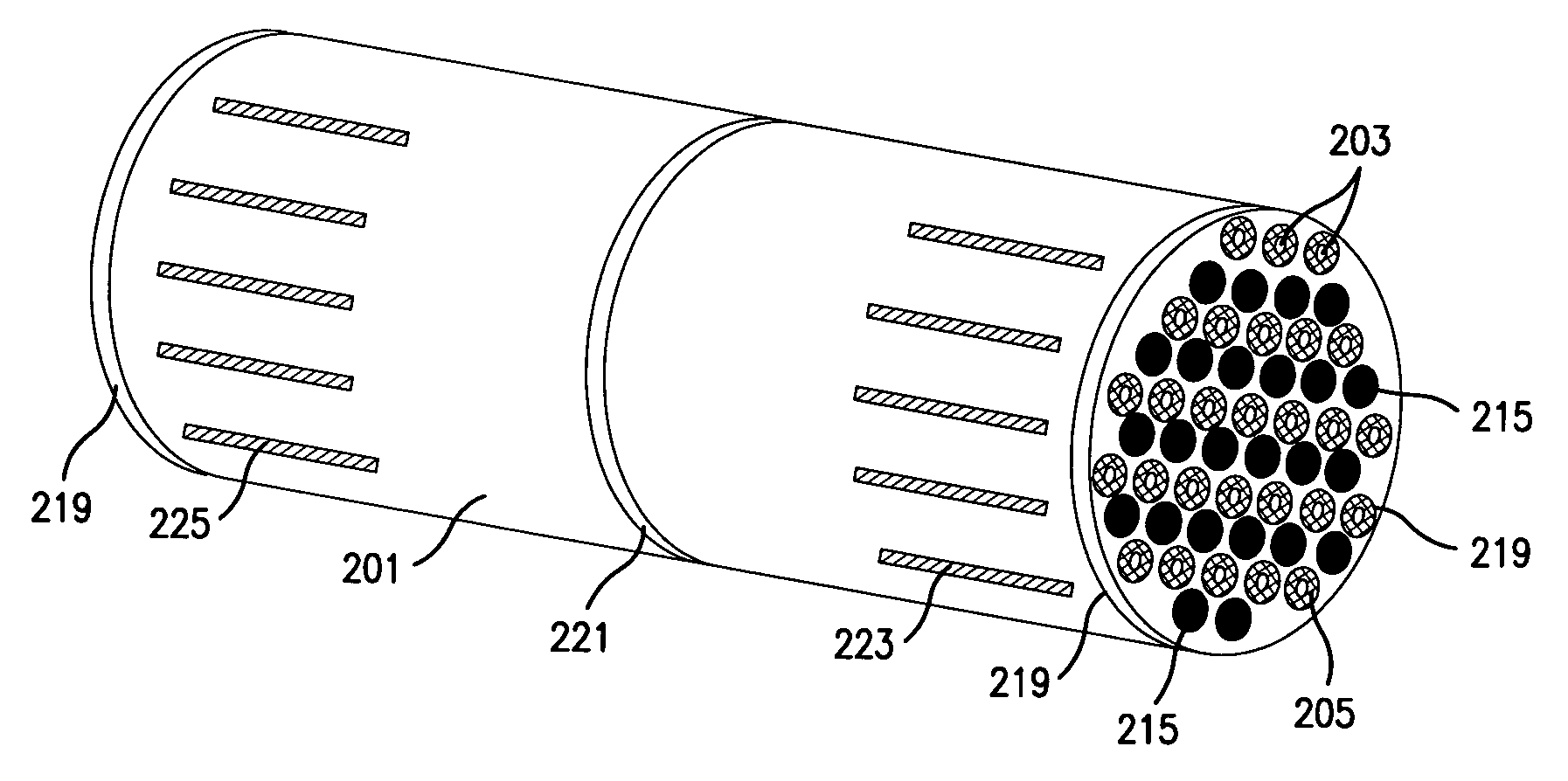

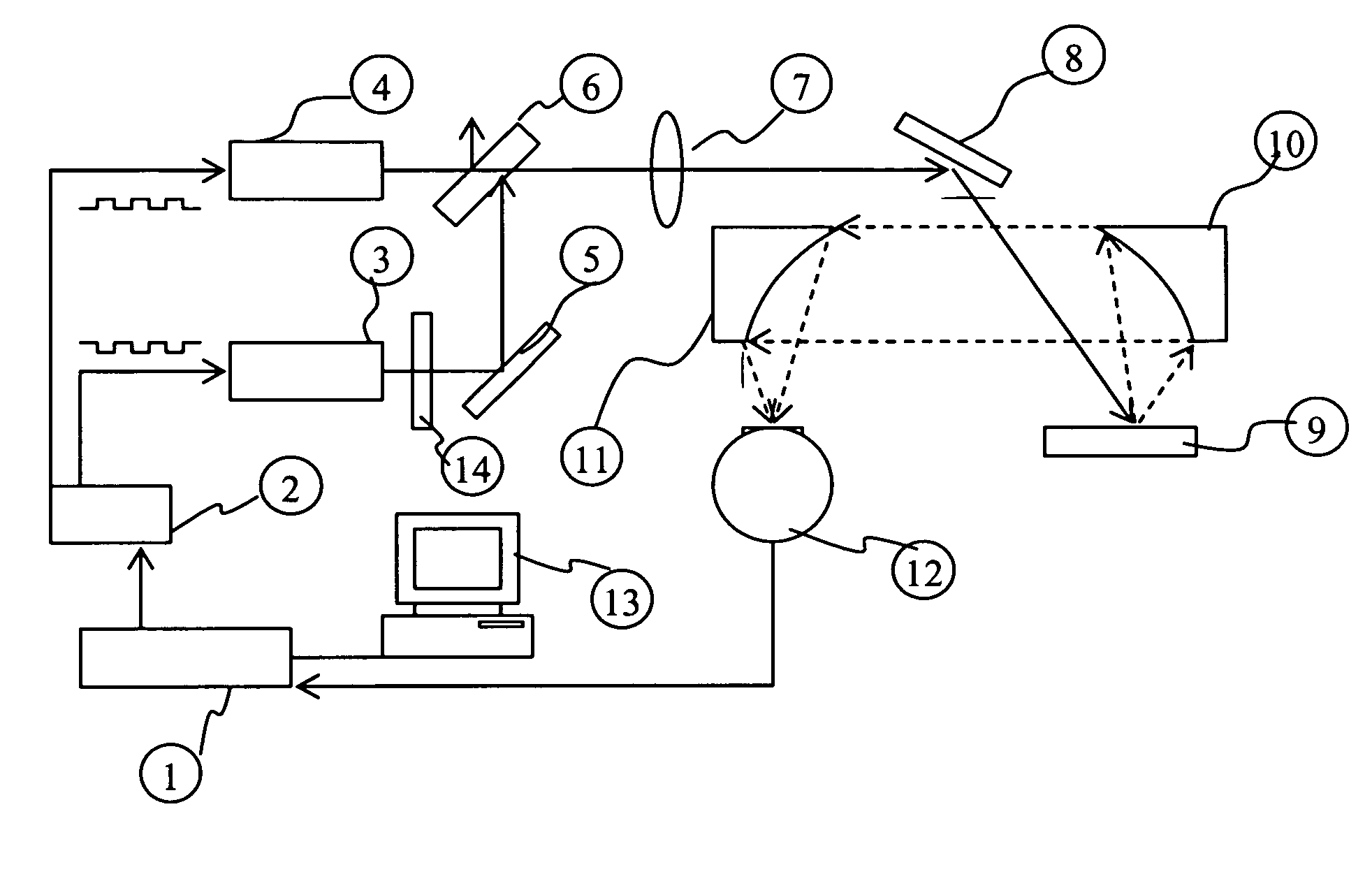

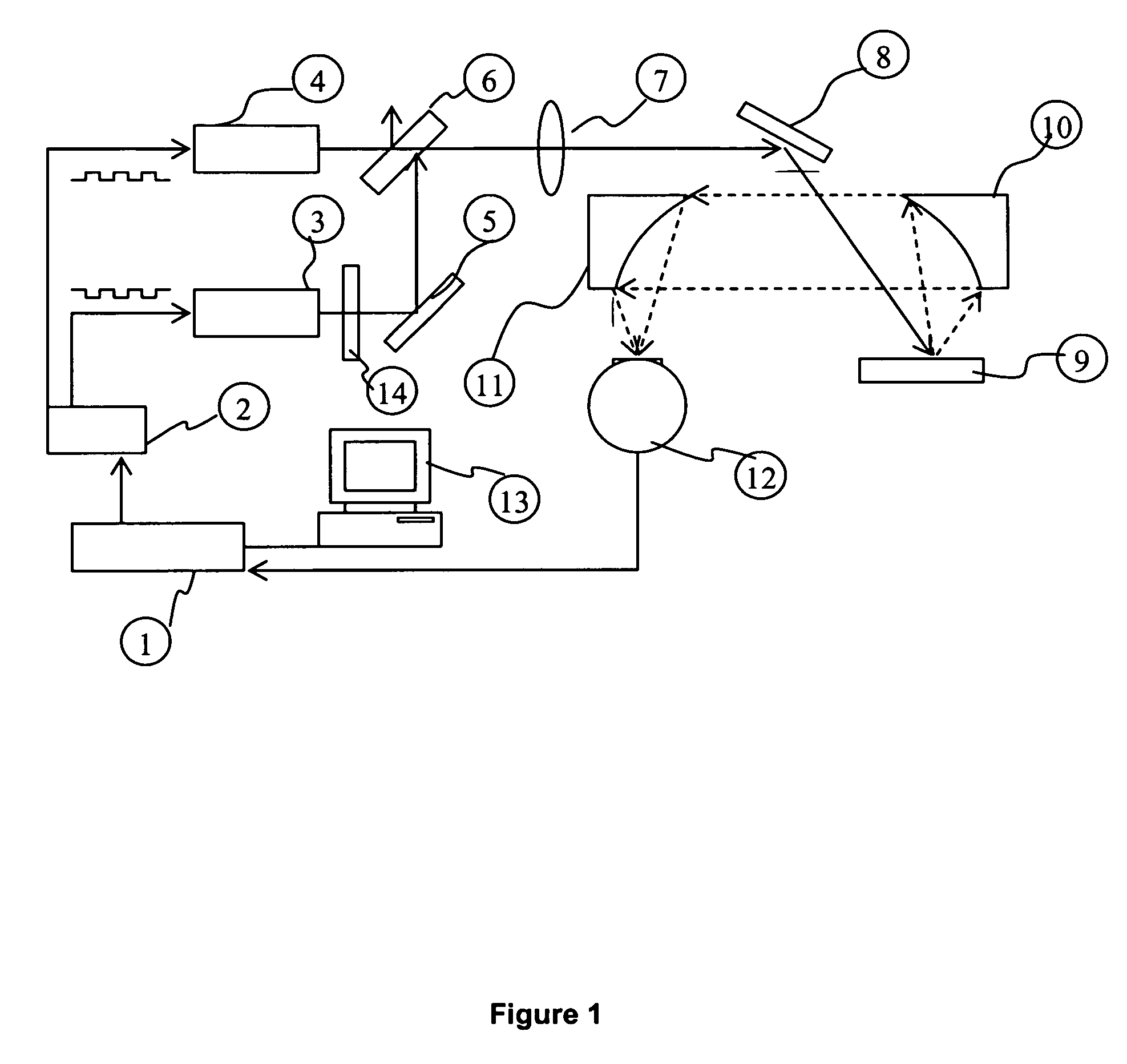

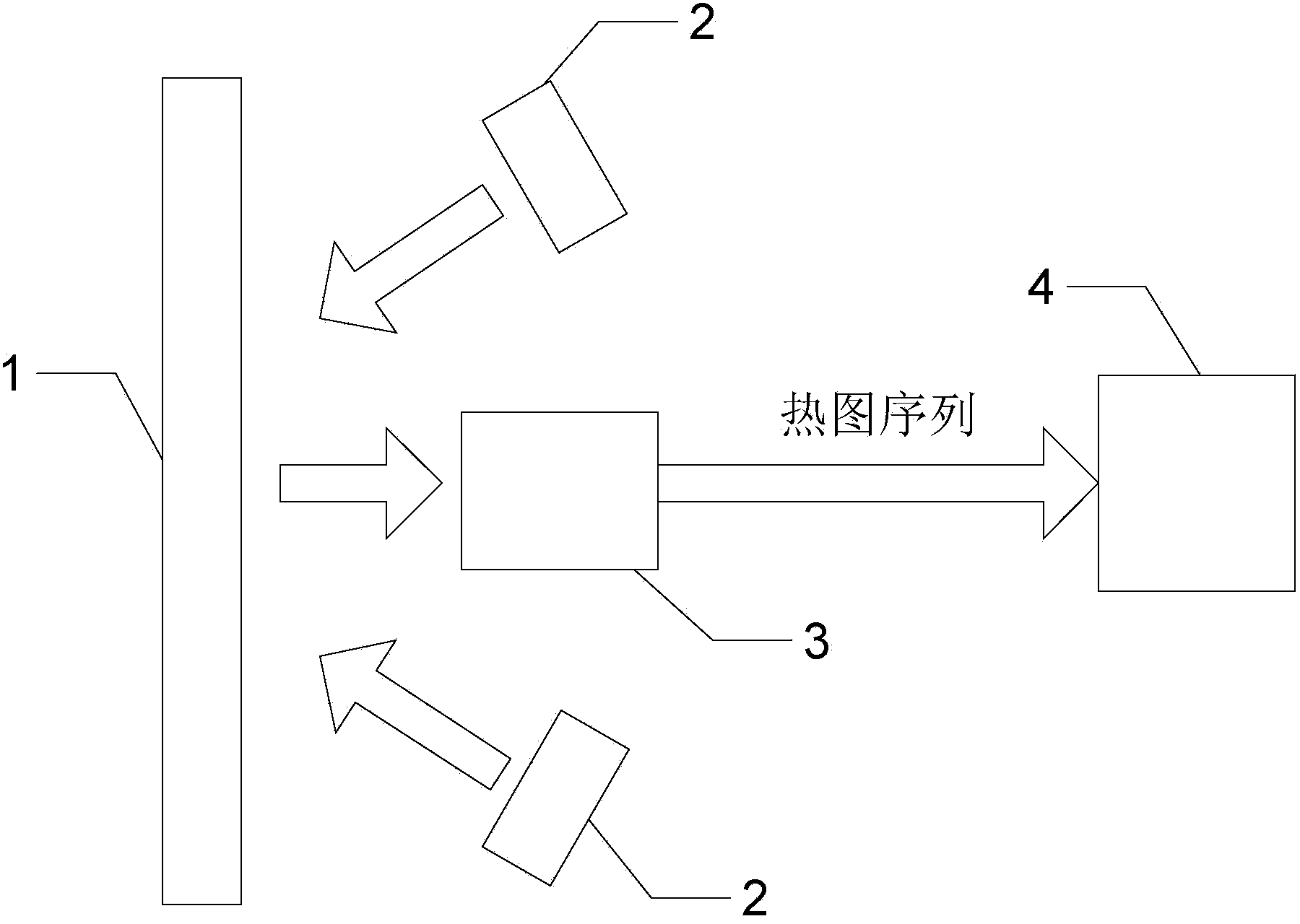

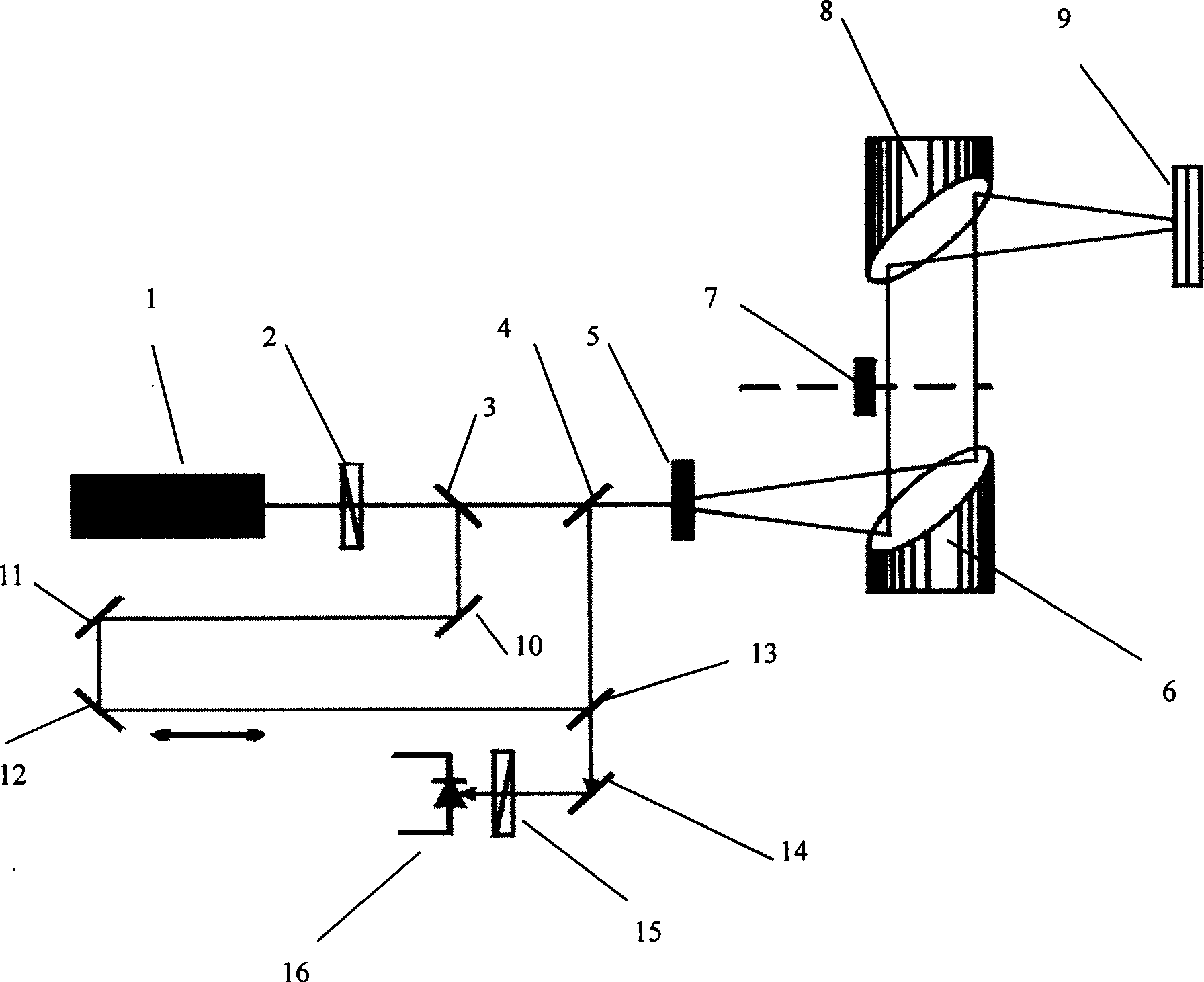

Infrared thermal wave radar imaging nondestructive testing method and system for defects of carbon fiber reinforced plastic (CFRP) plywood

ActiveCN103926274ARealize imaging non-destructive testingFast and accurate non-destructive testingMaterial flaws investigationData acquisitionLaser light

The invention discloses an infrared thermal wave radar imaging nondestructive testing method and an infrared thermal wave radar imaging nondestructive testing system for defects of a carbon fiber reinforced plastic (CFRP) plywood. The method comprises the following steps: adjusting space positions of a laser light source beam expanding and shaping device and a to-be-tested sample, so that the laser evenly irradiates the surface of the sample; controlling a data collection card to generate a linear frequency modulation pulse signal; driving a laser powder driver, so that the power of an optical fiber laser device changes according to the law of the linear frequency modulation pulse signal; collecting a thermal wave radar signal on the surface of the to-be-tested CFRP sample; processing the collected surface thermal wave radar signal; extracting time and frequency domain feature information of the thermal wave radar signal; extracting characteristic parameter of internal defects of the sample by treatment and analysis of the characteristic information images, so as to achieve nondestructive testing of the internal defects and damages of the sample. The system comprises an optical fiber laser device, a laser power driver, a data collection card, a laser light source beam expanding and shaping device, a focal plane infrared thermal imager and a computer. By adopting the method and the system, the defects of the CFRP plywood are quickly and accurately detected.

Owner:HARBIN INST OF TECH

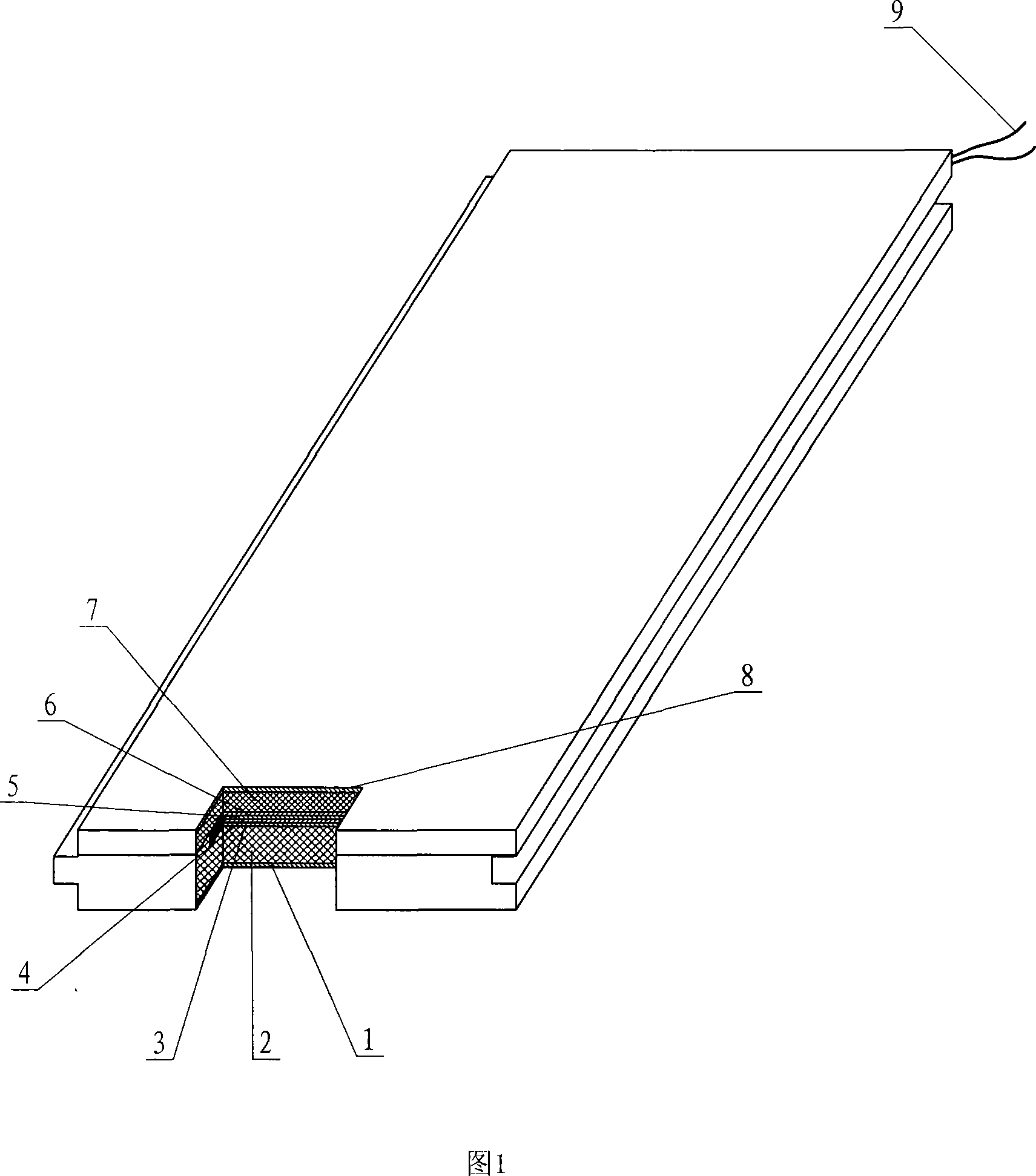

Electric heat floor

The invention relates to a wood electro-thermal floor with far infrared electro-thermal wave of health physiotherapy, which is installed conveniently and quickly. It comprises floor base and electrical heating layer. The technical point is that insulation thermal reflecting layer, far infrared electrical heating layer, insulation heat-transferring layer and solid-wood panel layer with face paint layer are set in turn upwards from the floor base. Because electro-thermal physiotherapy structure with far infrared electro-thermal wave of health physiotherapy is added on prior solid-wood floor, characteristics are shown as follows. Because the physiotherapy far infrared electro-thermal structure is set in the interlayer of floor, the thermal efficiency is high. The room is heated while physiotherapy wave absorbed by foot is provided for human. It is provided with high thermal efficiency, small starting current, no pollution, no noise, energy saving, good anti-aging performance and long service life. It also has the action that by infrared ray radiation of carbon fiber, human blood cycle is promoted; cell viability is strengthened and human health function is improved. It is killing two birds with one stone.

Owner:庞志忠

Non-invasive biothermophotonic sensor for blood glucose monitoring

There is provided a glucose monitoring method and apparatus based on the principle of Wavelength-Modulated Differential Laser Photothermal Radiometry (WM-DPTR). Two intensity modulated laser beams operating in tandem at specific mid-infrared (IR) wavelengths and current-modulated synchronously by two electrical waveforms 180 degrees out-of-phase, are used to interrogate the tissue surface. The laser wavelengths are selected to absorb in the mid infrared range (8.5-10.5 μm) where the glucose spectrum exhibits a discrete absorption band. The differential thermal-wave signal generated by the tissue sample through modulated absorption between two specific wavelengths within the band (for example, the peak at 9.6 and the nearest baseline at 10.5 μm) lead to minute changes in sample temperature and to non-equilibrium blackbody radiation emission. This modulated emission is measured with a broadband infrared detector. The detector is coupled to a lock-in amplifier for signal demodulation. Any glucose concentration increases will be registered as differential photothermal signals above the fully suppressed signal baseline due to increased absorption at the probed peak or near-peak of the band at 9.6 μm at the selected wavelength modulation frequency. The emphasis is on the ability to monitor blood glucose levels in diabetic patients in a non-invasive, non-contacting manner with differential signal generation methods for real-time baseline corrections, a crucial feature toward precise and universal calibration (independent of person-to-person contact, skin, temperature or IR-emission variations) in order to offer accurate absolute glucose concentration readings.

Owner:MANDELIS ANDREAS +1

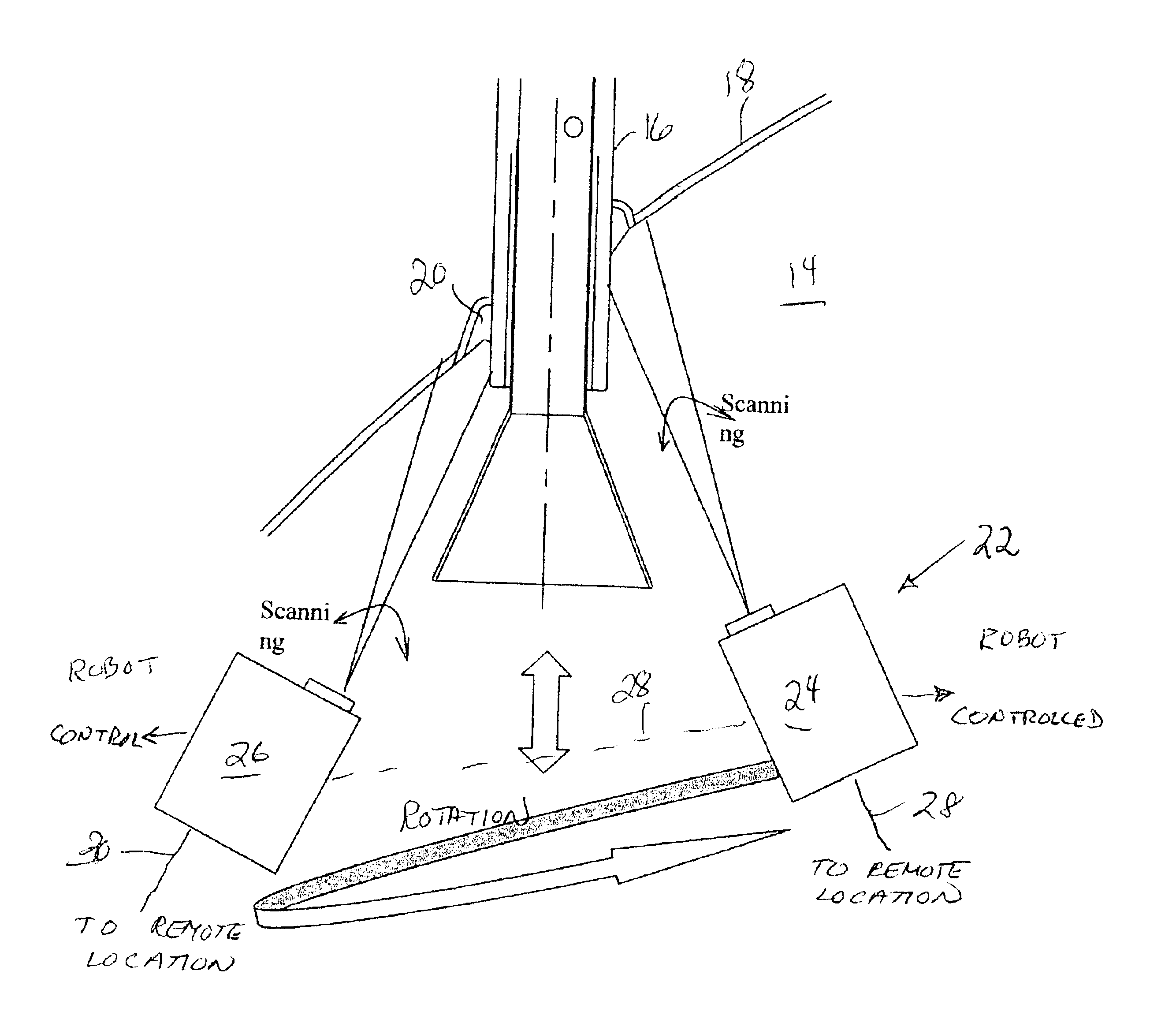

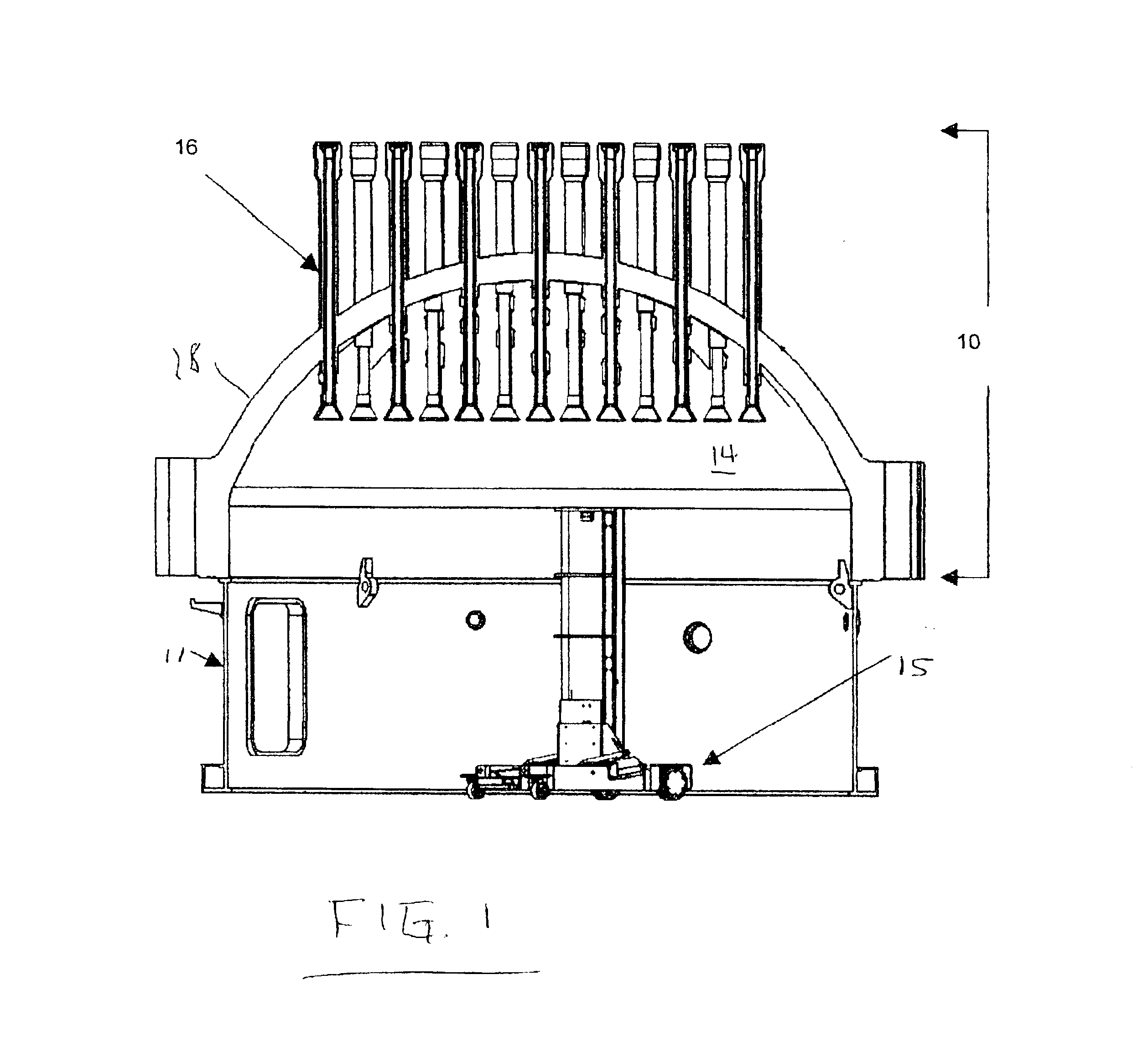

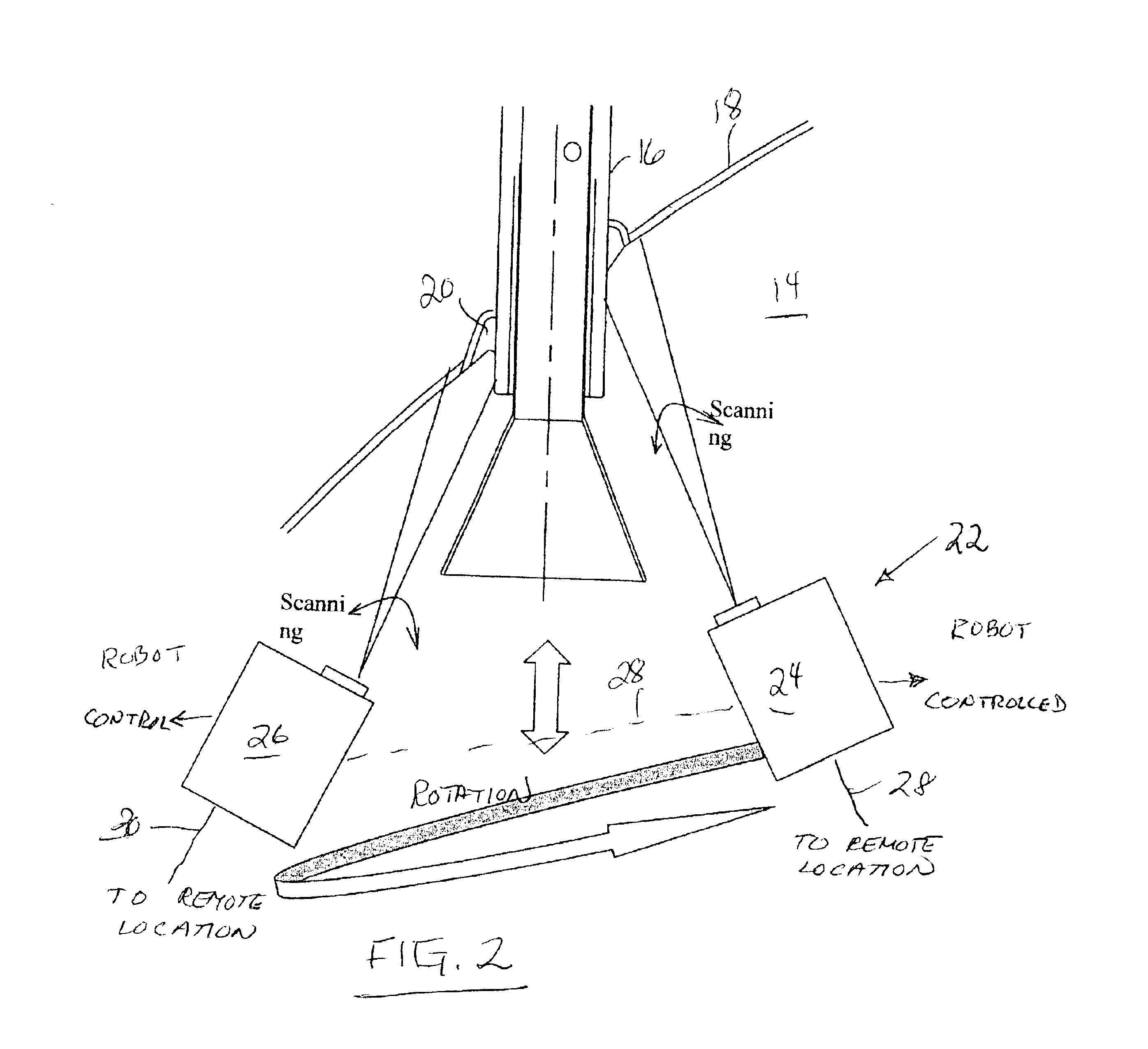

Remote examination of reactor nozzle J-groove welds

InactiveUS6856662B2Easy to understandMinimize difficultyNuclear energy generationNuclear monitoringGraphicsScan conversion

A combined laser and infra red sensing camera is located beneath the reactor head in the vicinity of the closure head tube welds by manipulating known robotic device handling the laser which is used to heat a line along the surface thereby generating a thermal wave that propagates over the one to two square inch test area where the increased thermal resistance of cracks and anomalies makes the surface temperature profile gradient greater at a crack or anomaly. An IR camera captures the test area image of interest as the thermal wave propagates across the target inspection area and the image is processed and enhanced to show cracks and other anomalies as a sharp drop in the thermal scan at the point of the crack using known Photo Thermal NDE technology to convert the scan into a pictorial representation of the scanned surface clearly showing any cracks therein. This process is repeated sequentially until the entire circumference of the weld is scanned.

Owner:FRAMATOME ANP RICHLAND

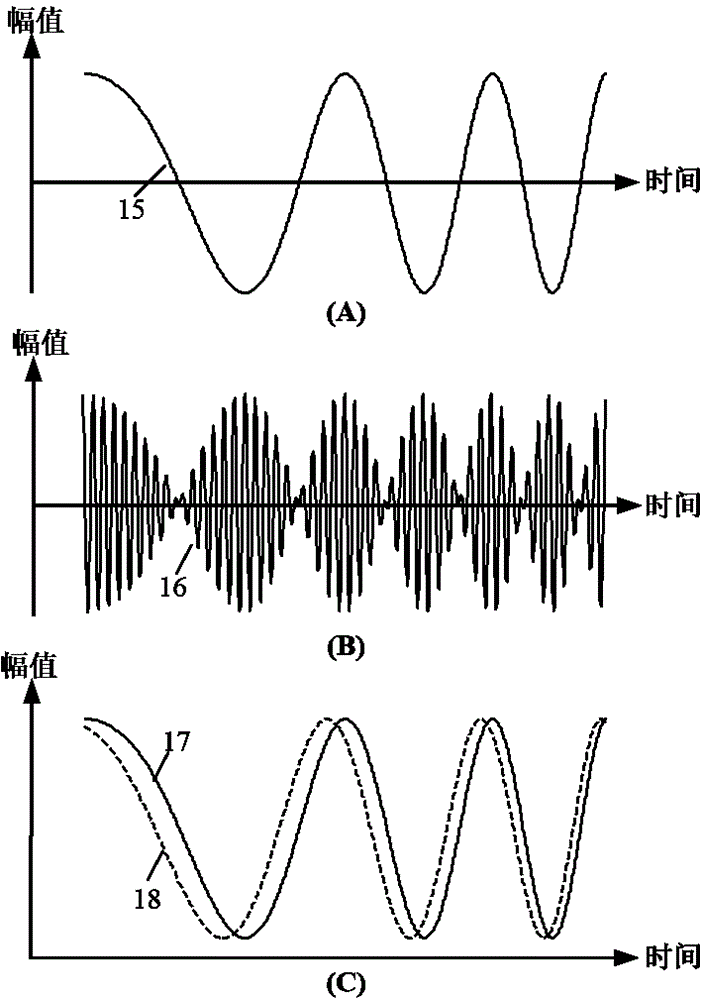

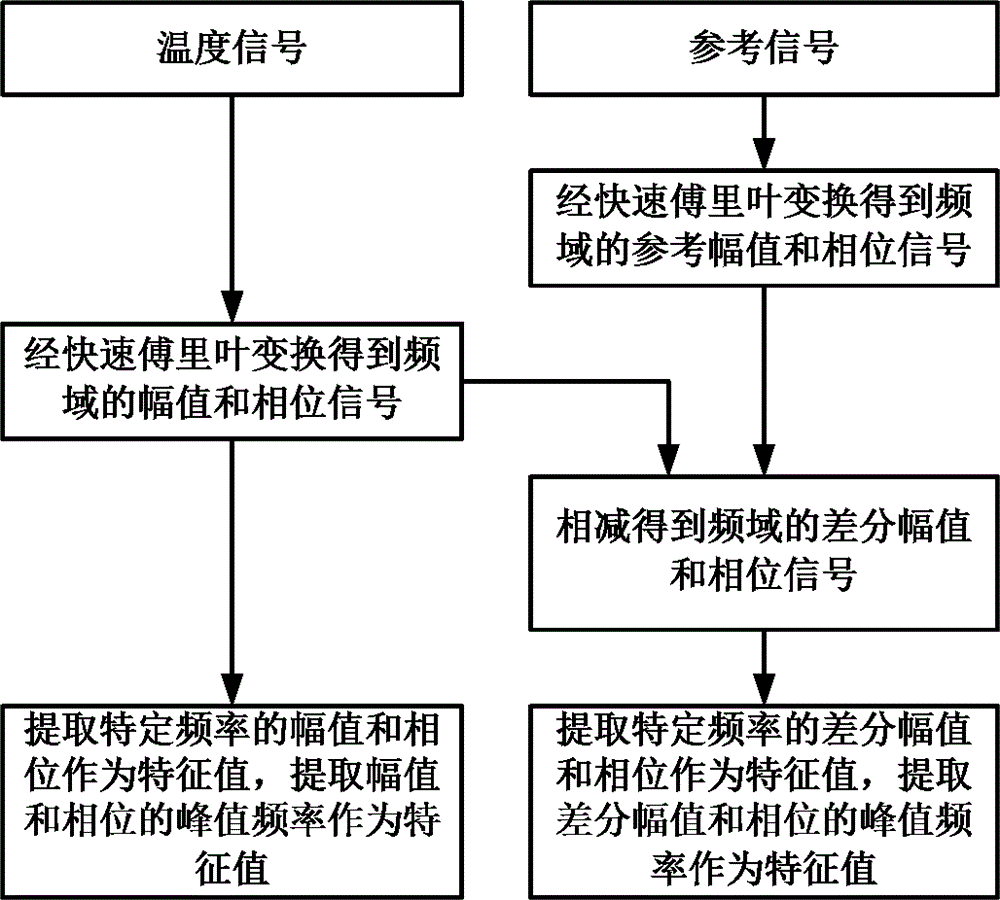

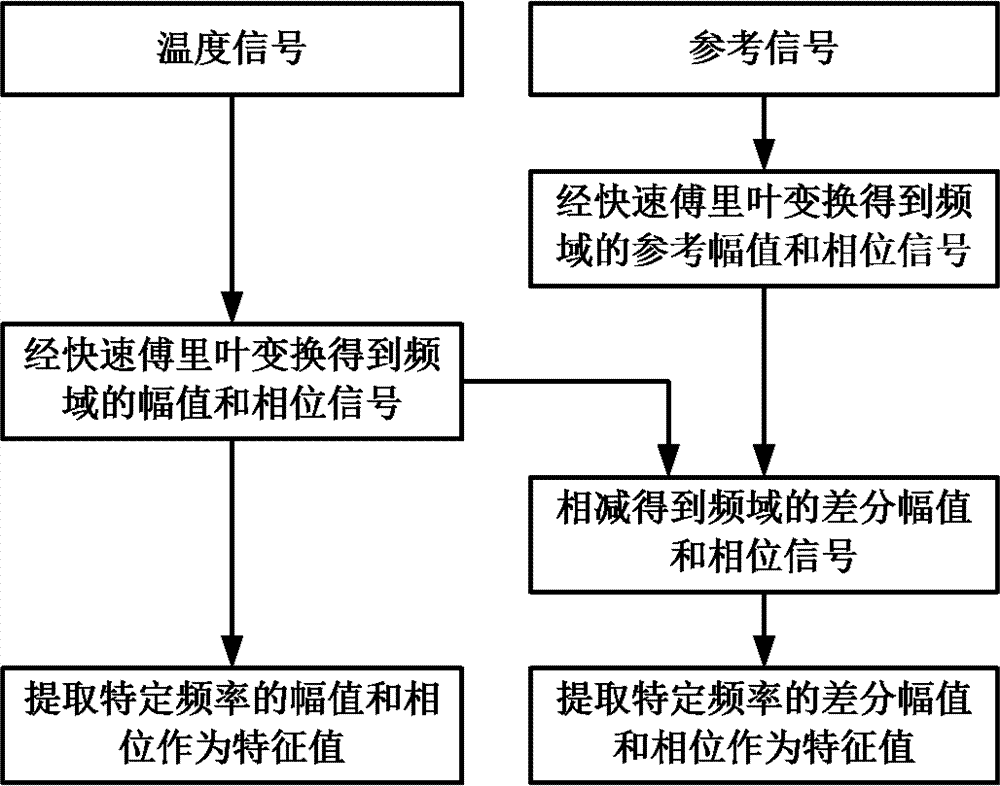

Microwave frequency-modulation thermal wave imaging system and microwave frequency-modulation thermal wave imaging method

ActiveCN104677944AMaterial heat developmentMaterial flaws investigationPeak valueFrequency modulation

The invention discloses a microwave frequency-modulation thermal wave imaging system and a microwave frequency-modulation thermal wave imaging method. The microwave frequency-modulation thermal wave imaging method comprises the following steps: heating a detected object by adopting microwaves subjected to amplitude modulation of a frequency-modulation signal, recording the temperature of the surface of the detected object by adopting a thermal imager, setting the frequency-modulation signal or a temperature signal in an area free from defects as a reference signal, carrying out fast Fourier transform on the temperature signal and the reference signal, and extracting the amplitude and the phase position of a special frequency, a peak frequency and the like as characteristic values; carrying out mutual correlation on the temperature signal and the reference signal, and extracting correlation coefficients at a special delay time and a peak delay time as characteristic values; and carrying out frequency domain mutual correlation on the temperature signal and the reference signal, extracting mutual correlation amplitudes and phase positions at the special delay time and the peak delay time as characteristic values, and imaging by adopting the characteristic values of all pixel points in the detected area. The method and the system disclosed by the invention have the advantages of being high in anti-interference performance, abundant in depth information, short in detection time and the like, and can be applied in the fields of non-destructive detection, medical imaging, target detection and the like.

Owner:何赟泽

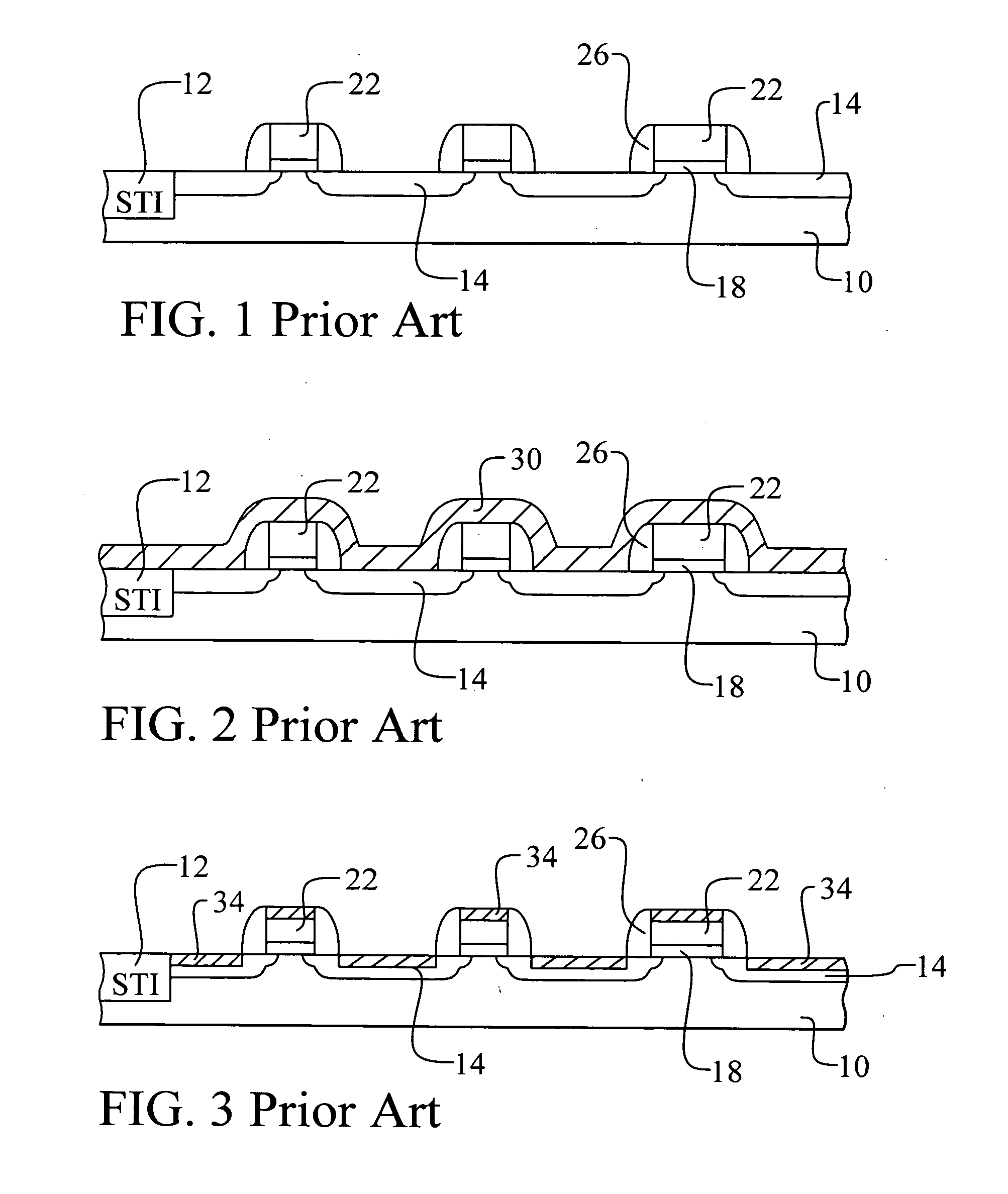

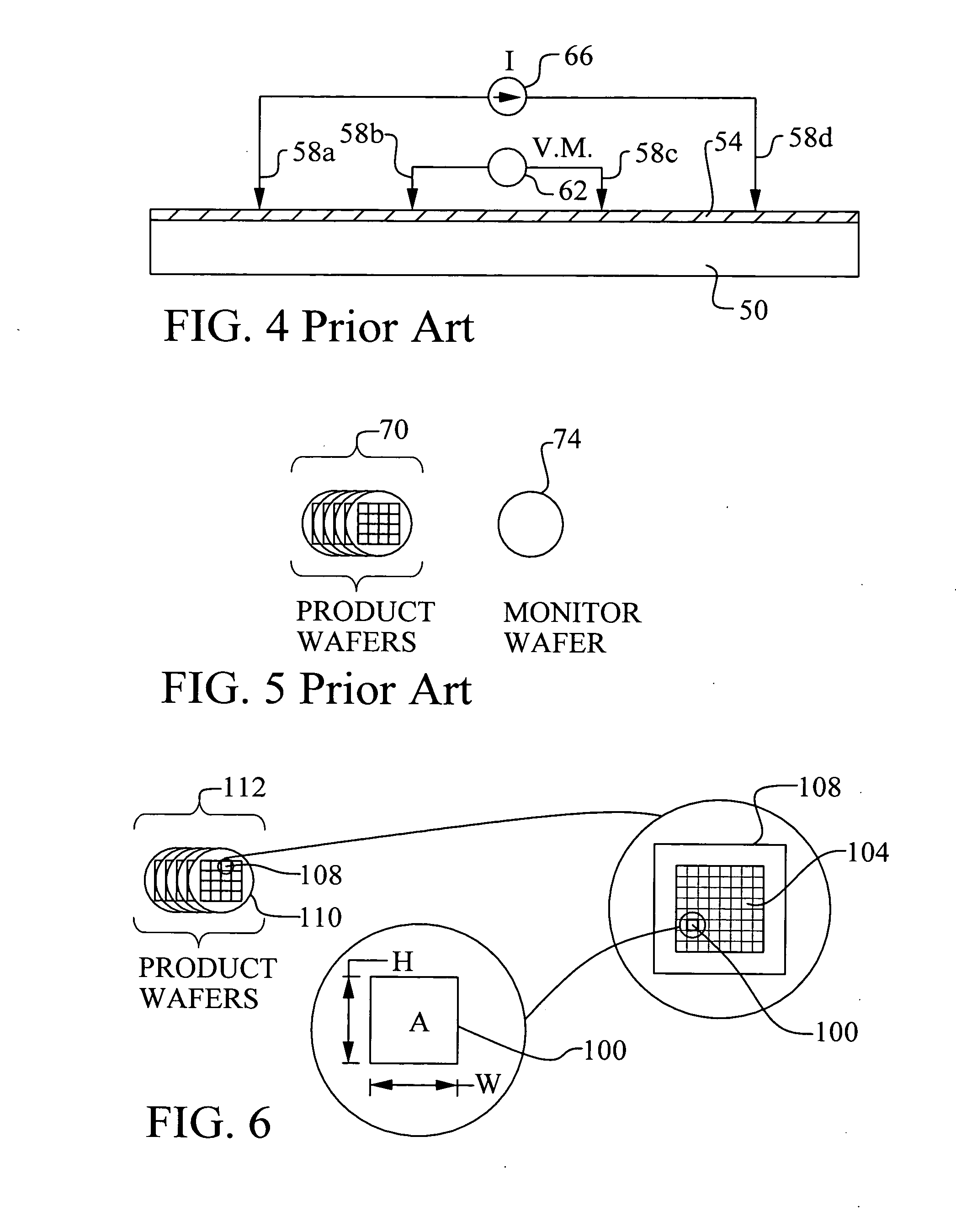

Method to monitor silicide formation on product wafers

InactiveUS20050134857A1Eliminate needEasy to controlSemiconductor/solid-state device testing/measurementElectronic circuit testingElectrical resistance and conductanceMetal silicide

A new method to monitor sheet resistance of a metal silicide layer in the manufacture of an integrated circuit device is achieved. The method comprises providing a metal silicide layer overlying an exposed silicon layer on a substrate. A thermal wave intensity signal is generated for the metal silicide layer by an optical measurement system. The optical measurement system comprises a first laser beam that is intensity modulated and a second laser beam. The first and second laser beams comprise different wavelengths. A dichroic mirror is used to combine the first and second laser beams and to project the first and second laser beams onto the metal silicide layer. A detector is used to gather the second laser beam reflected from the metal silicide layer and to generate a thermal wave intensity signal based on the reflected second laser beam. Sheet resistance of the metal silicide layer is calculated by a linear equation based on the thermal wave intensity signal.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

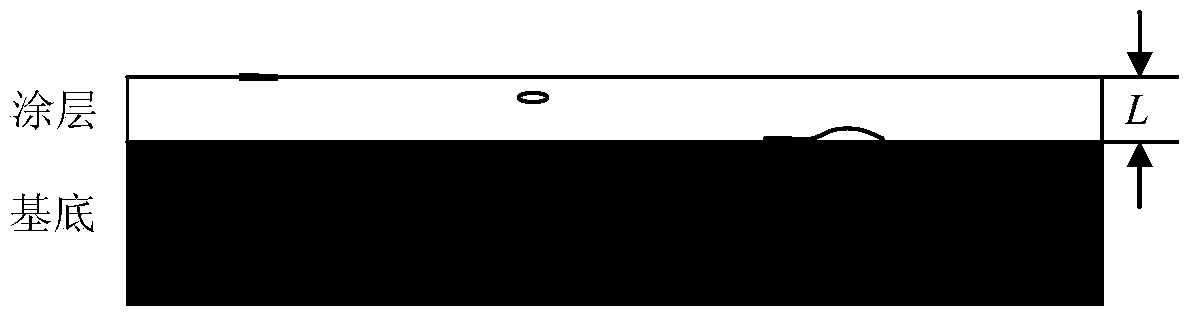

Judgment method for detecting defects of wave absorption coating by using pulse infrared thermal waves

The invention relates to a judgment method for detecting defects of a wave absorption coating by using pulse infrared thermal waves and belongs to the technical field of nondestructive inspection. According to the judgment method, heating equipment for stimulating a test piece to be detected can be a high-energy flash lamp or other pulse type heating equipment; a high-energy flash lamp or other pulse type heating equipment with relatively short pulse acting time is suitable for being adopted; the collection frequency of a thermal imaging device is relatively high and the collection time is set according to the specific property of a material of the test piece to be detected. According to the judgment method, firstly, a standard test piece with a common defect type needs to be selected to be subjected to an experiment; thermal diffusion characteristics are extracted and defect judgment criteria are established to realize the judgment on different defect types; when the structure of the coating is changed, such as a coating material and a coating thickness, reconstructed unstuck defect criteria need to be referred.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

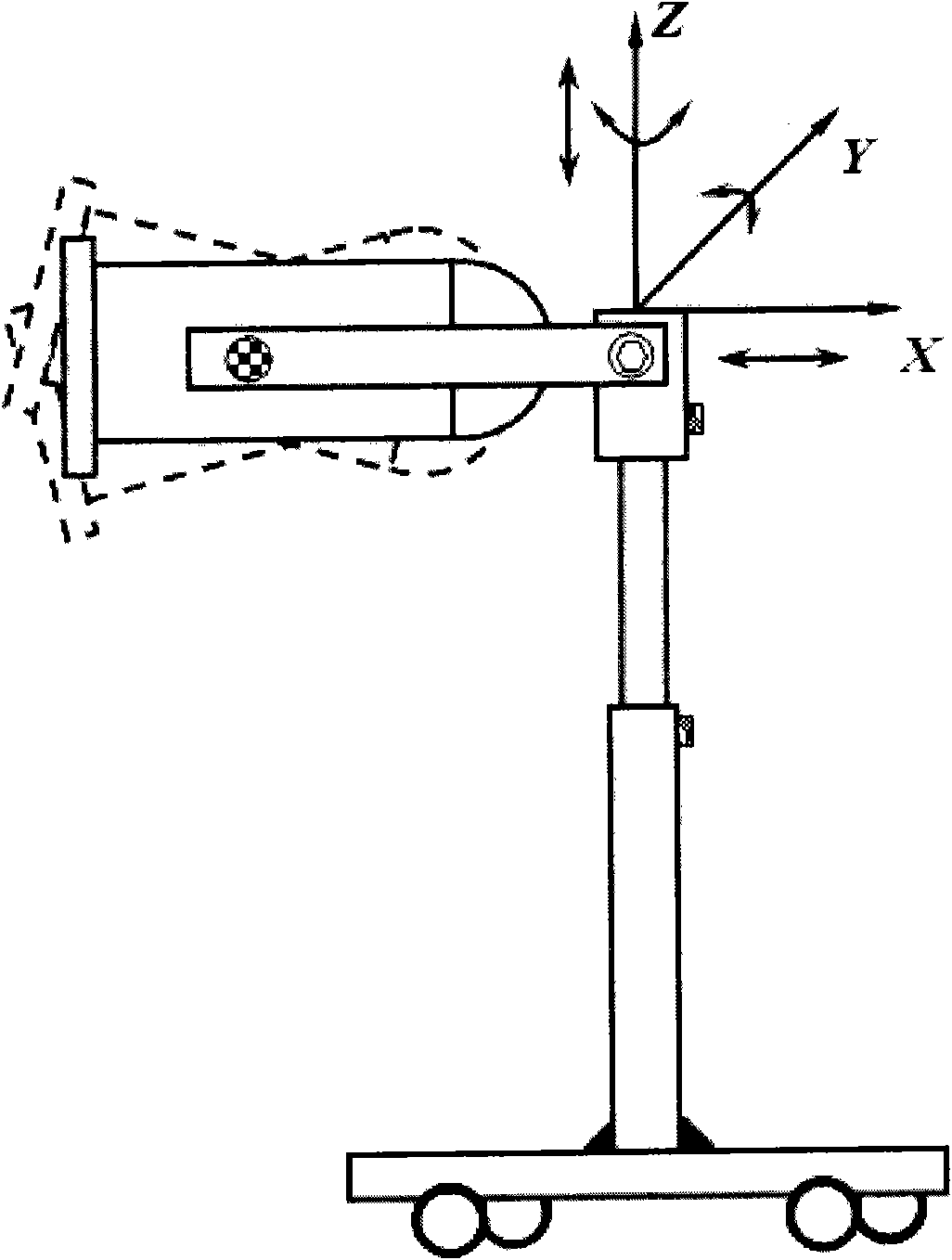

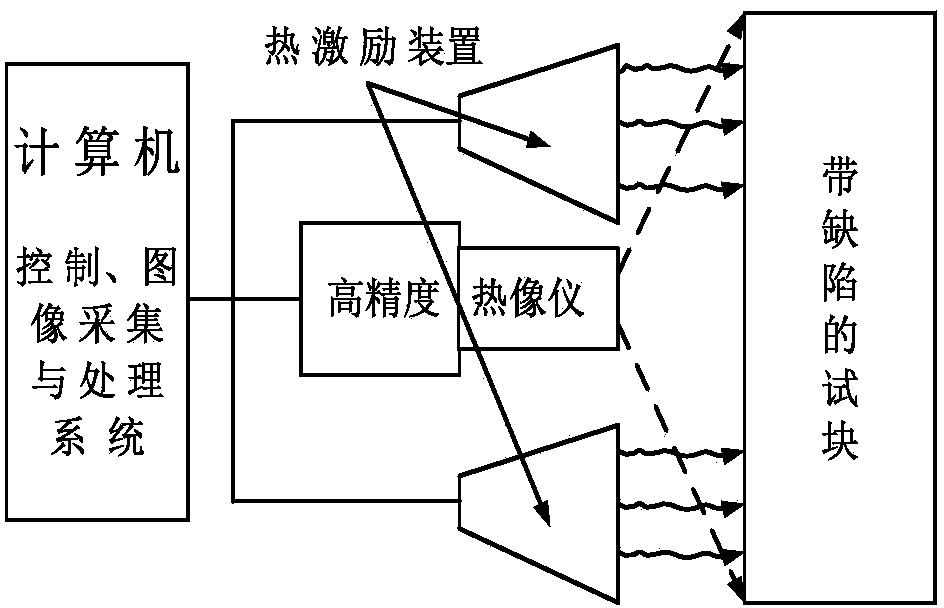

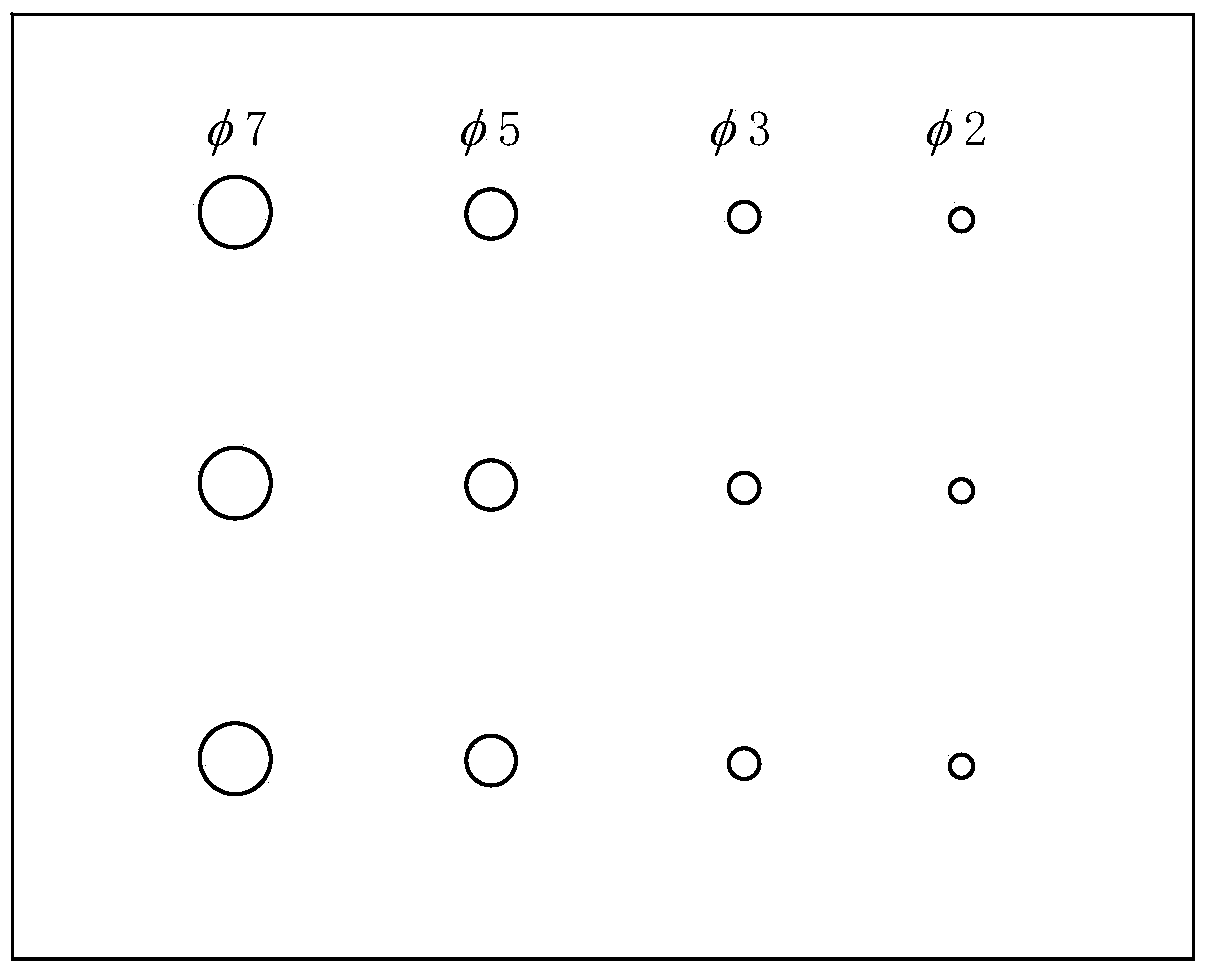

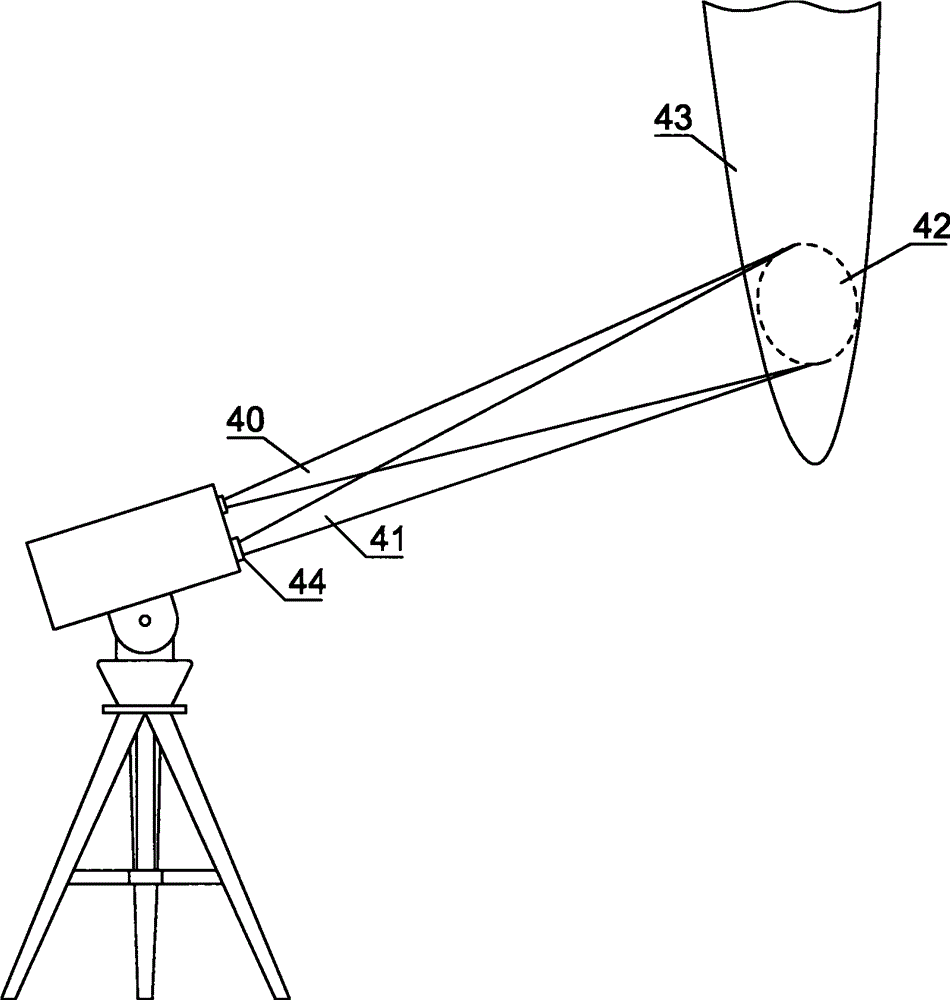

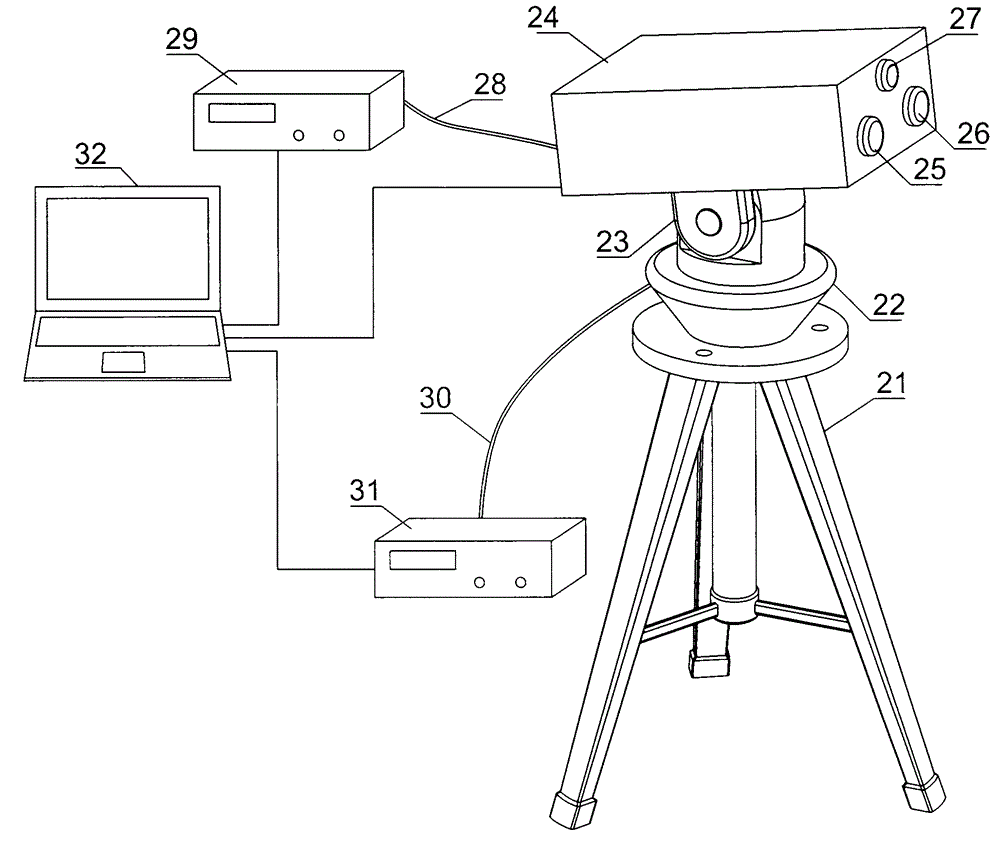

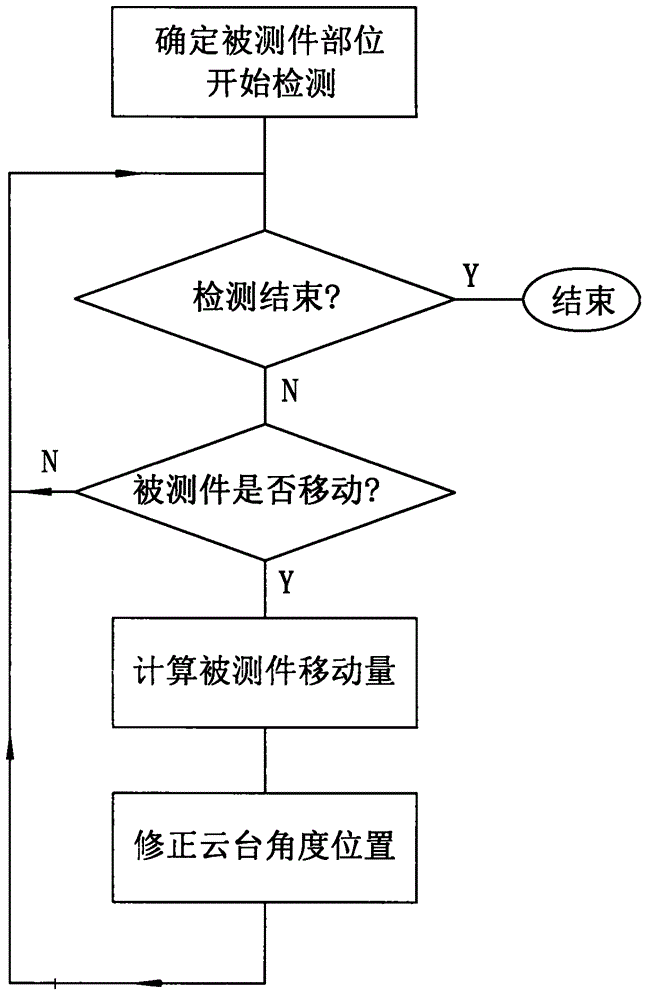

Nondestructive detecting system and method for automatic tracking thermal wave imaging

The invention relates to an on-line nondestructive detecting system for thermal excitation infrared imaging, and the system is used for detecting the internal defects and structures of various metal and non-metal materials. The system comprises an infrared thermal imager, a thermal excitation source, a visible light camera, an automatic fine control cradle head, a control system and a data processor. The system has a function of automatically tracking and locking a detected object, and is applicable applied to the infrared thermal wave nondestructive detection of an object at a nonstatic state.

Owner:NANJING NOVEL PHOTOELECTRIC SYST

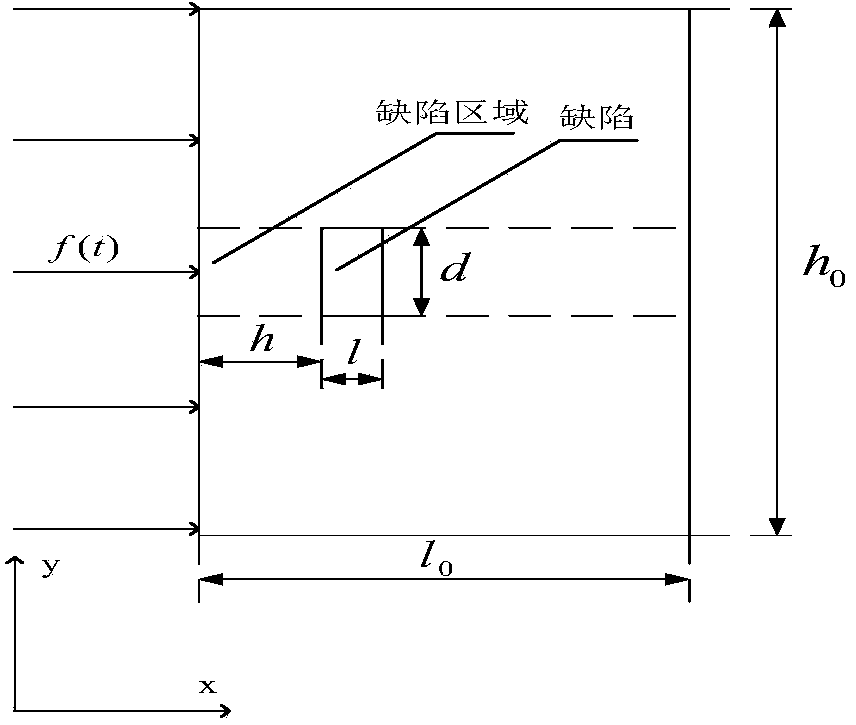

Quantitative measurement method for pulse infrared thermal wave technology

ActiveCN102565124AEasy to measureImprove accuracyMaterial heat developmentMaterial flaws investigationThermodynamicsThermal diffusion coefficient

The invention discloses a quantitative measurement method for a pulse infrared thermal wave technology. The method comprises the following steps of: 1, heating the surface of a measured object by using a pulse heating device, continuously observing and recording the temperature field change of the surface of the measured object by using an infrared thermal image device, and acquiring a time sequence thermal wave signal through a computer control and acquisition system to obtain a thermograph sequence of the surface of the measured object; 2, according to the obtained thermograph sequence, extracting temperature reducing data of a defective area and a non-defective area, and comparing logarithmic temperature-logarithmic time curves; 3, setting a separation time point of defective and non-defective area curves in the logarithmic temperature-logarithmic time curves or a previous time point of the separation time point as t1, setting the maximum temperature difference time point of the two curves as t2, and extracting a temperature value or a radiation energy value delta T (0, t1) and delta T (0, t2) corresponding to the two time points; and 4, when two of an interface thermal reflection coefficient R of the defective area, a thermal diffusion coefficient alpha of the measured object and a defect depth L are given, solving the third coefficient by using a formula (4).

Owner:CAPITAL NORMAL UNIVERSITY +2

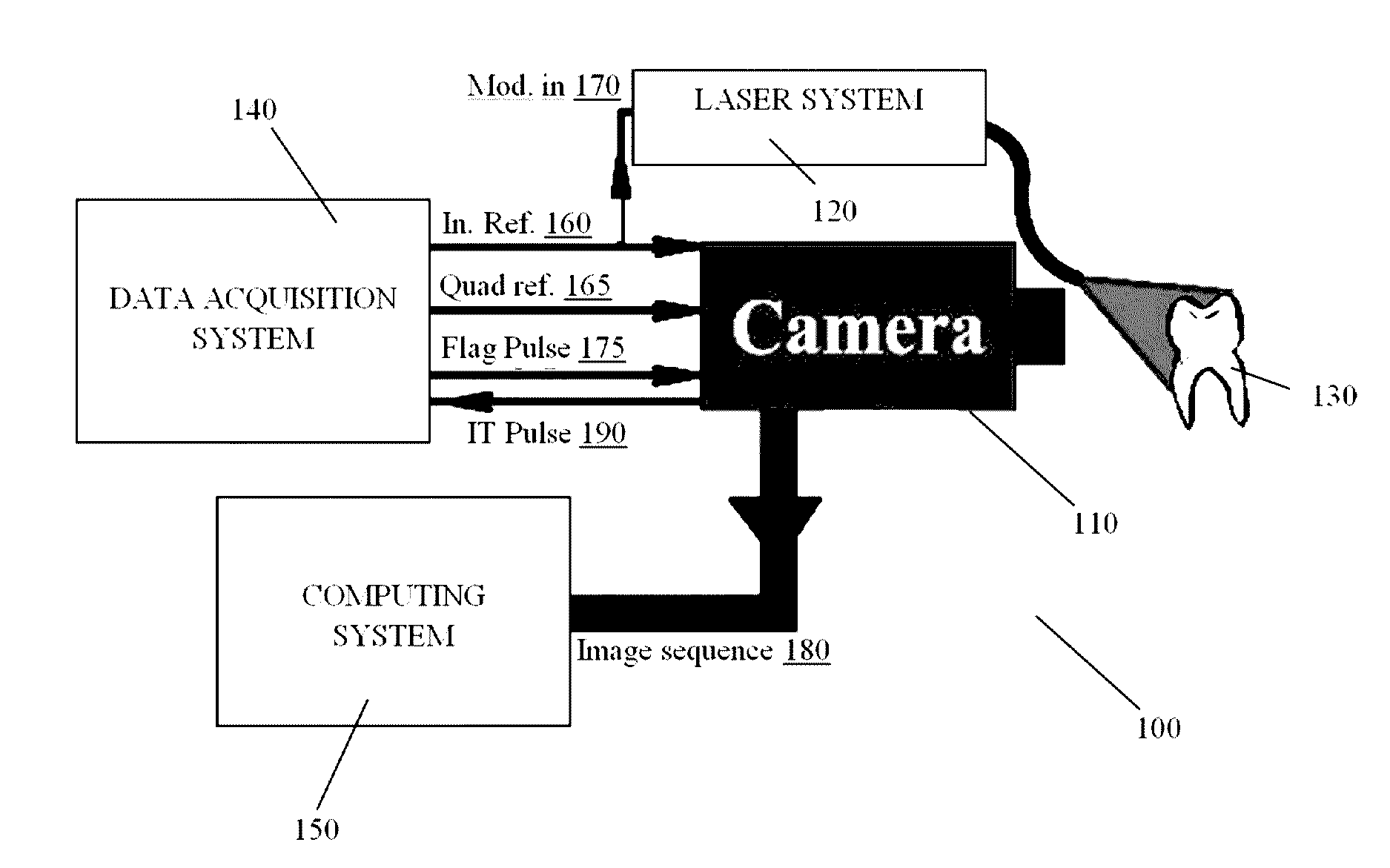

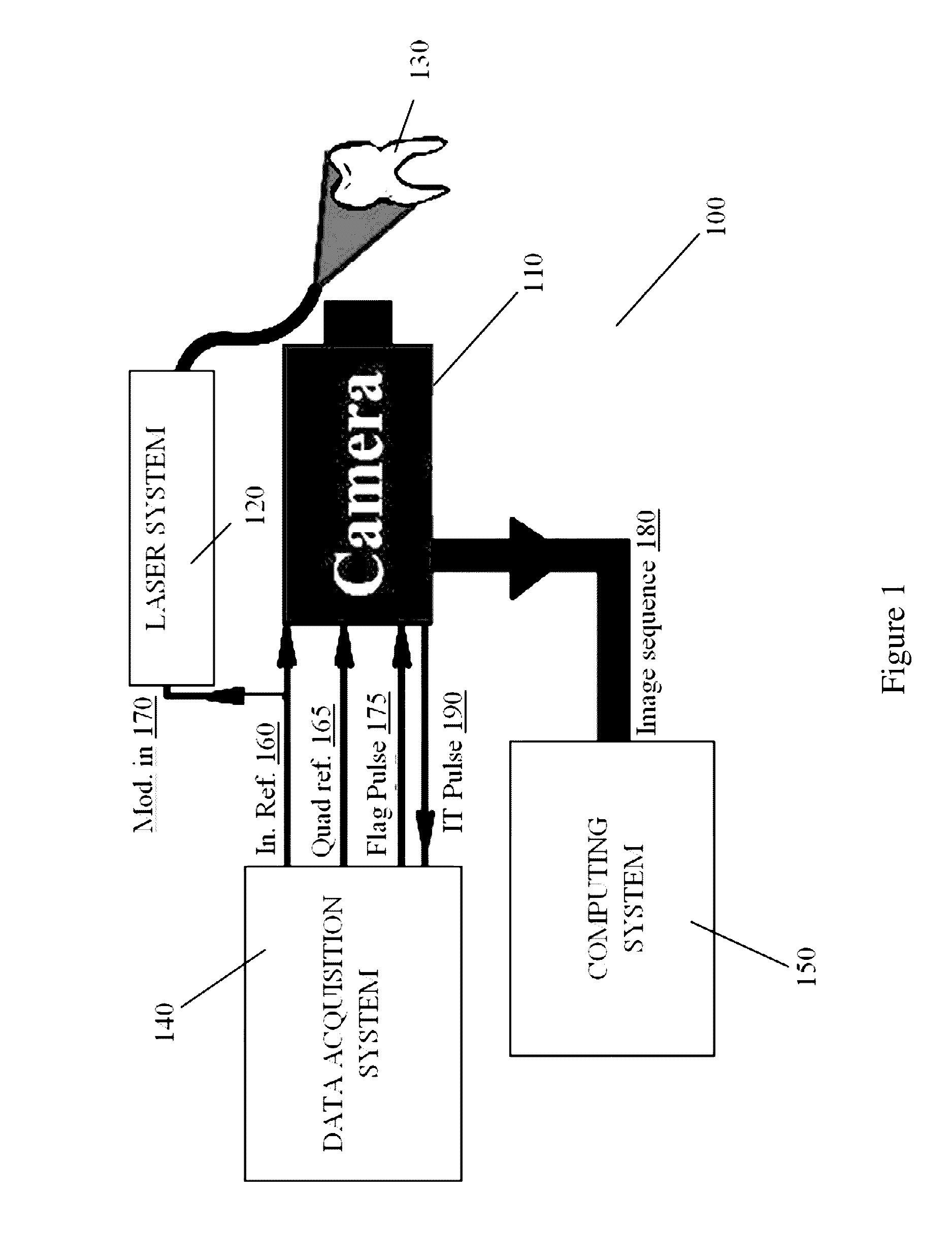

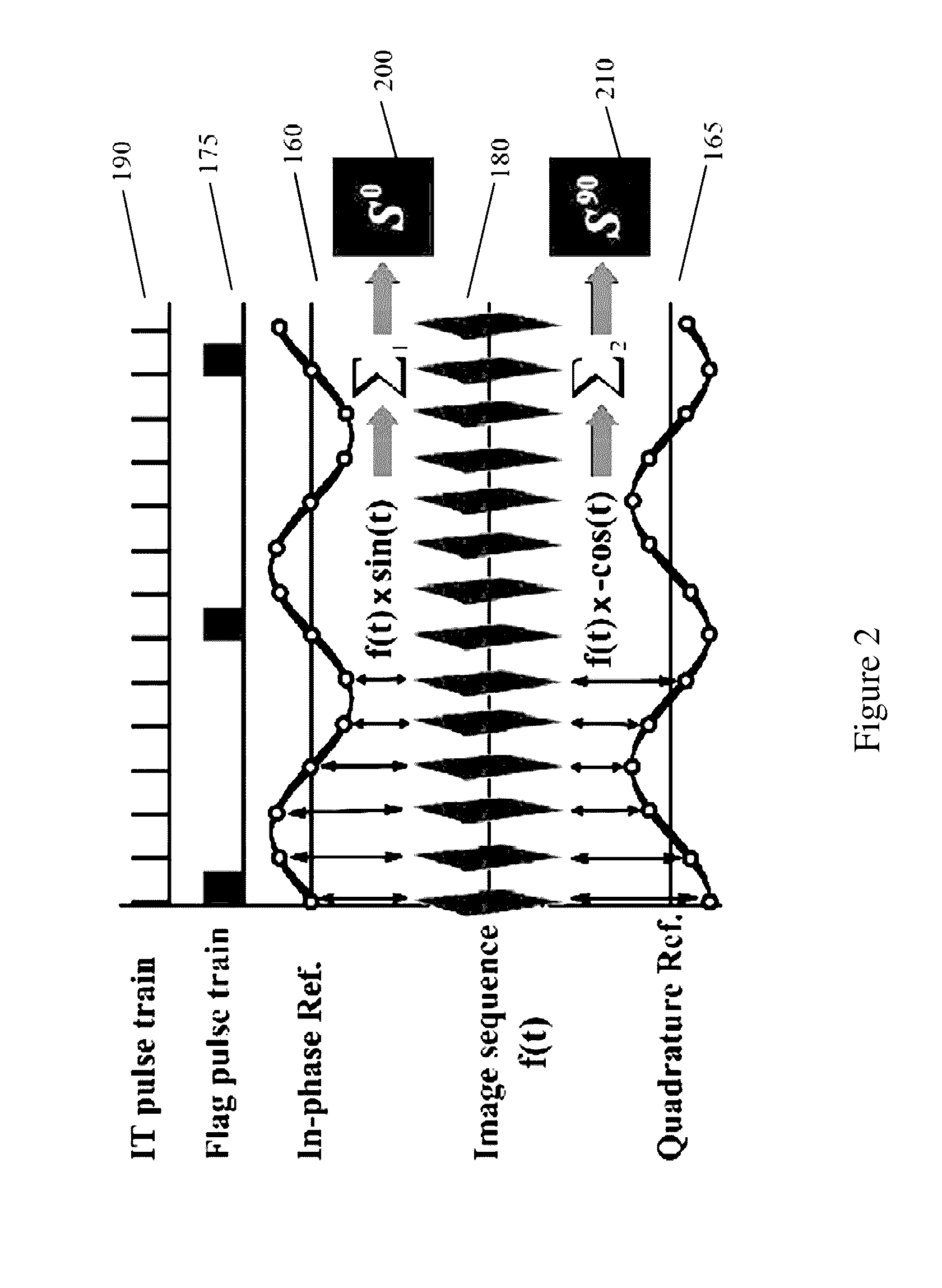

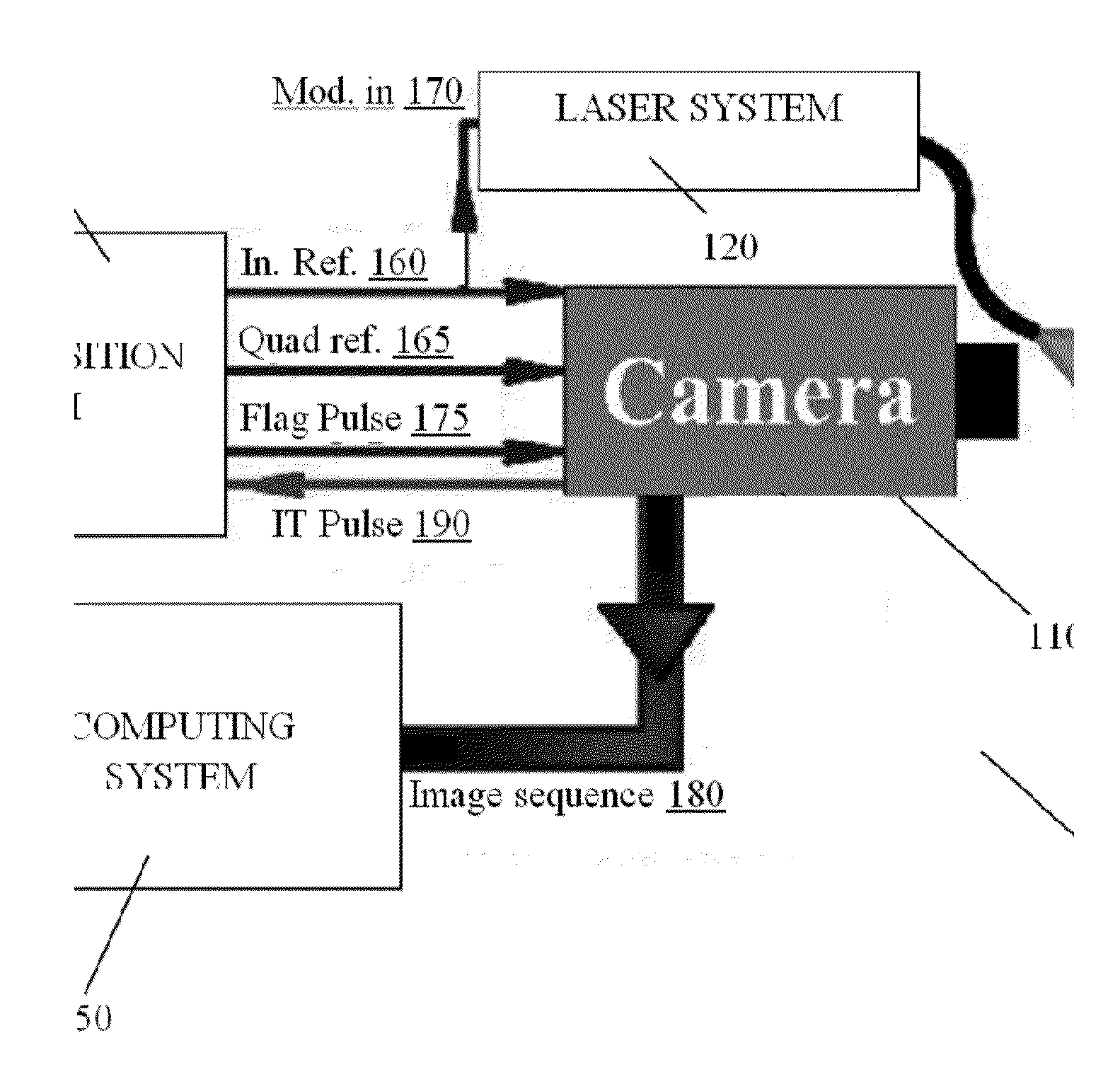

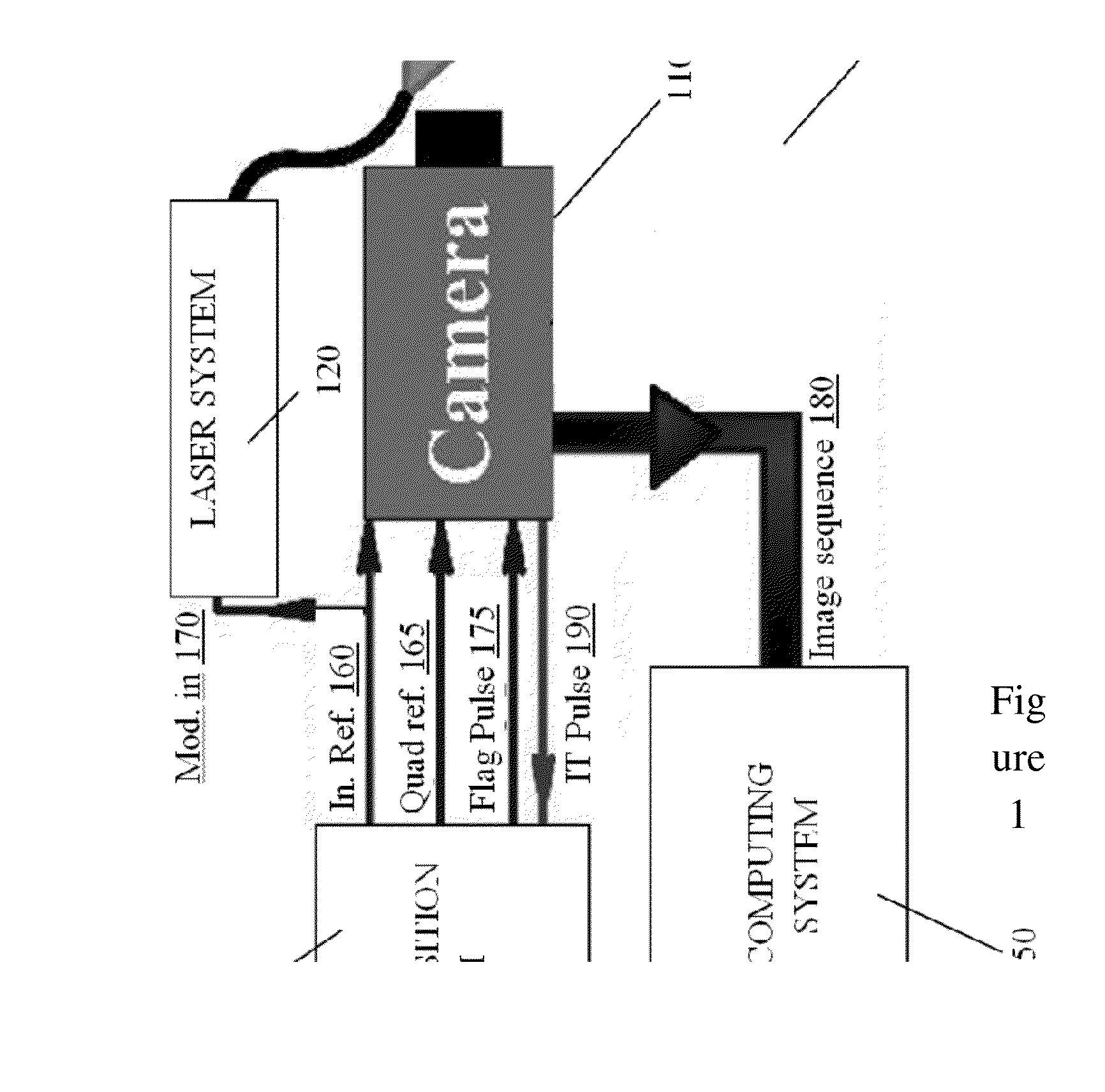

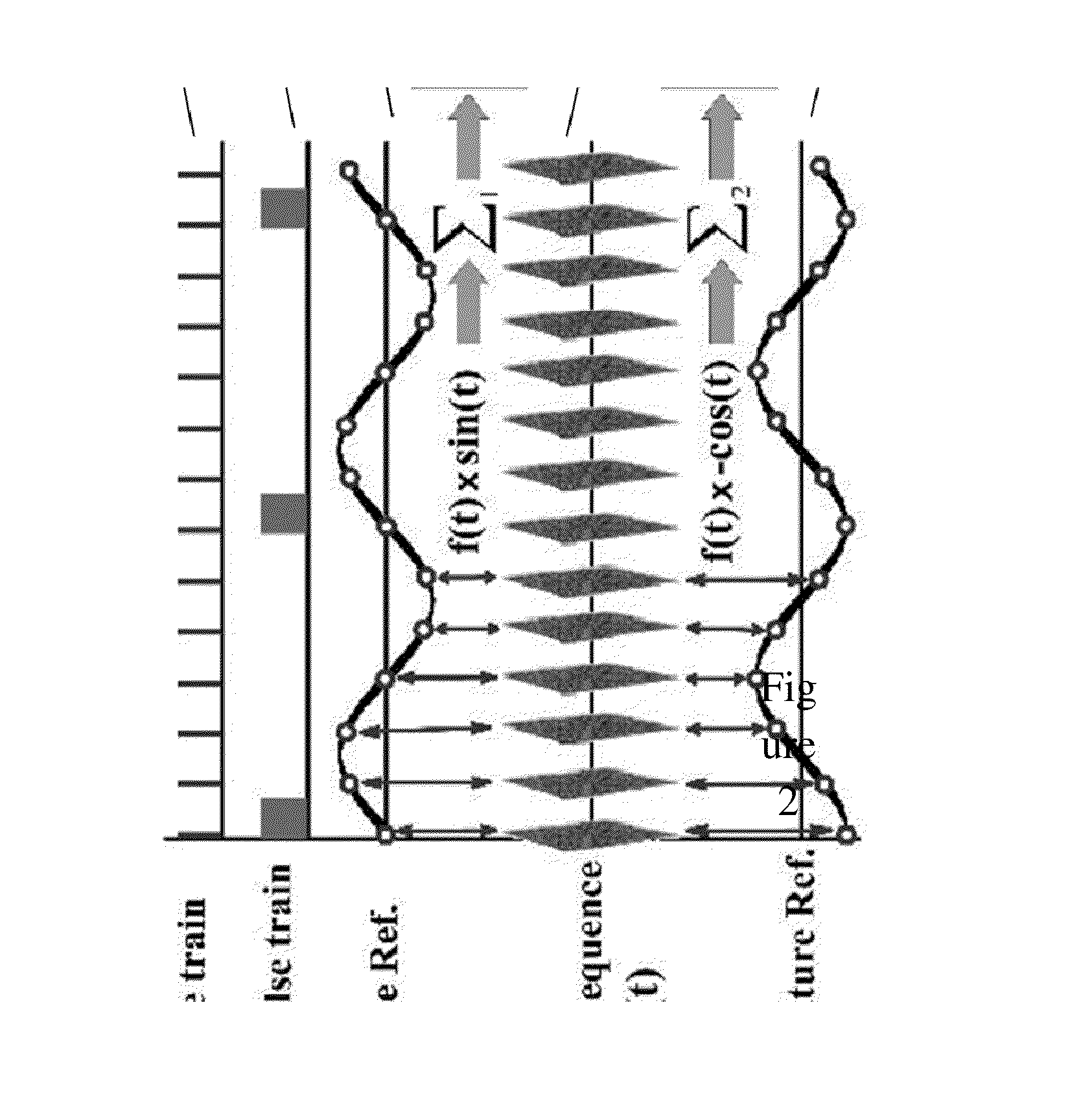

Systems and methods for thermophotonic dynamic imaging

ActiveUS20140085449A1Improve signal-to-noise ratioAnalysis by thermal excitationColor television detailsDiagnostic Radiology ModalityPhase Code

Systems and methods for improved thermophotonic imaging are provided in which both amplitude and phase image information is obtained with a high signal to noise ratio and depth-resolved capabilities. Image data obtained from an imaging camera is dynamically averaged and subsequently processed to extract amplitude and / or phase image data. The system may be configured for a wide range of imaging modalities, including single frequency modulation (thermophotonic lock-in imaging), Thermal-Wave Radar imaging or Thermophotonic Radar imaging involving chirp modulation, and Binary Phase Coded Modulation. Such imaging modalities may find application in many diverse areas, including non-destructive testing and biomedical diagnostic imaging including the imaging of teeth and monitoring changes in the tooth over time which are due to pathology such as dental caries or erosion.

Owner:MANDELIS ANDREAS +2

Microwave phase-locked thermal imaging system and method

ActiveCN104713906AImprove signal-to-noise ratioImprove detection depthMaterial flaws investigationFast Fourier transformMicrowave

The invention discloses a microwave phase-locked thermal imaging system and method. The method comprises the following steps: periodically heating a detected object by adopting continuous microwaves subjected to amplitude modulation by a periodic phase-locked signal, generating thermal waves with periodic change inside the detected object, and recording a temperature signal with the periodic change on the surface of the detected object by adopting a thermal imager, wherein the temperature signal can reflect thermal wave abnormality caused by defects; setting a reference signal according to the phase-locked signal or a temperature signal without a defect area; performing fast Fourier transform on the temperature signal and the reference signal, and extracting the amplitude and the phase of specific frequency such as phase-locked frequency as characteristic values; performing phase-locked association on the temperature signal and the reference signal, and extracting the amplitude and the phase of the phase-locked frequency as characteristic values; and performing reconstruction imaging on the characteristic values of all pixel points of a detected area. The method and the system have the advantages of high signal to noise ratio, capacity of suppressing the emissivity change, large detection depth and the like and can be widely applied to the fields of nondestructive testing, medical imaging, target detection and the like.

Owner:WUXI DOUBLE HORSE DRILLING TOOLS

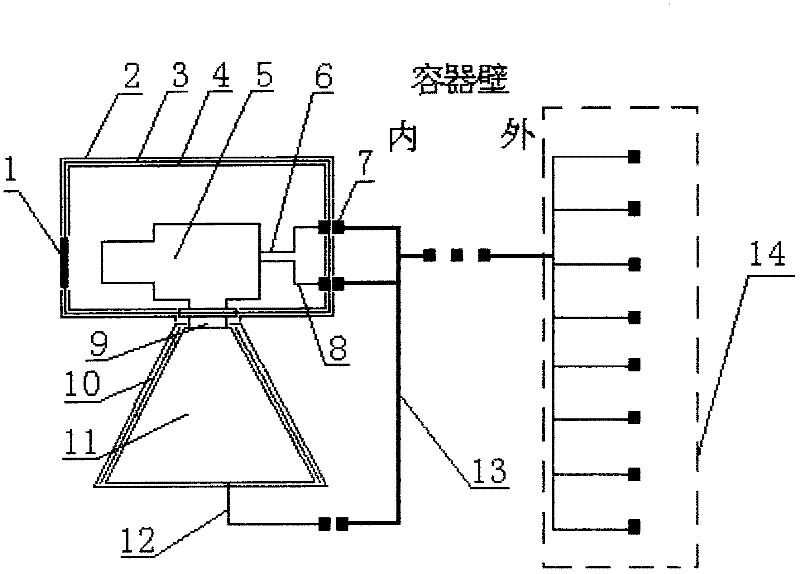

Infrared thermal-wave detecting system for vacuum low-temperature environment

ActiveCN102564595ASolving Non-Contact Temperature Measurement ProblemsGuarantee job securityRadiation pyrometryInfraredElectricity

The invention discloses an infrared thermal-wave detecting system for a vacuum low-temperature environment. The infrared thermal-wave detecting system comprises an internal infrared detecting part, external measuring equipment and power supply equipment, wherein the internal infrared detecting part can be arranged in the vacuum low-temperature environment; the external measuring equipment and the power supply equipment are connected by a network data transmission cable and are arranged outside the vacuum low-temperature environment; the internal infrared detecting part comprises a thermal control cabin, an infrared thermal imager and a cloud platform; the infrared thermal imager is arranged in the thermal control cabin in a sealed manner, and the lower part of the infrared thermal imager is supported on the rotatable cloud platform penetrating through the bottom part of the cloud platform; the cloud platform is coated with heating fins for transferring heat for the infrared thermal imager and a plurality of layers of insulating materials; germanium glass is arranged in a position of the thermal control cabin, which is right opposite to a lens of the infrared thermal imager, so as to receive infrared rays of the vacuum low-temperature environment and carry out temperature measurement, and the measurement result is in electric communication with external measuring equipment by the network data transmission cable. The infrared thermal-wave detecting system has the advantages that not only is the problem of non-contact temperature measurement in a vacuum container solved, but also the reasonable thermal control design ensures working safety of the system in the low-temperature environment.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

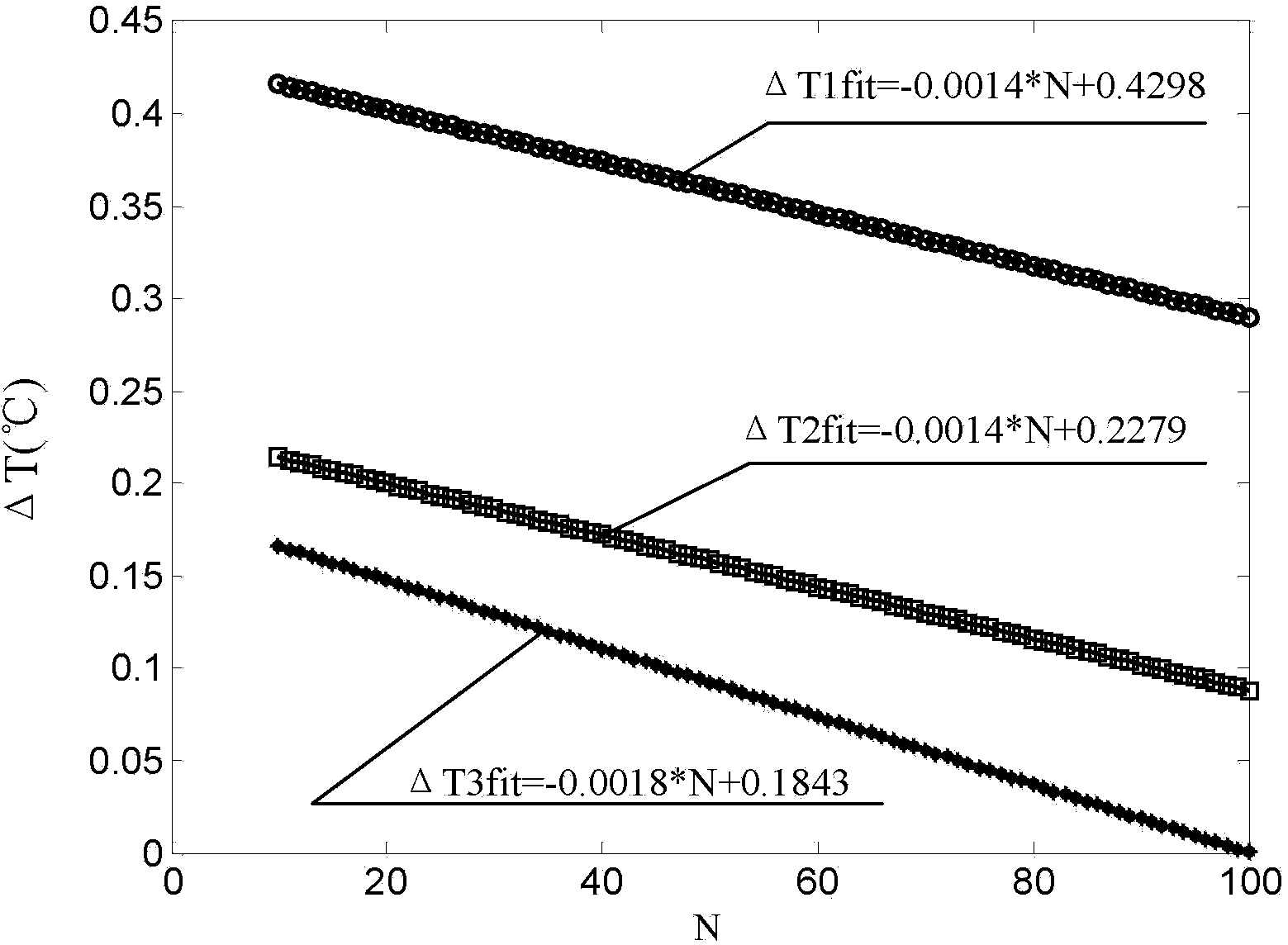

Method for measuring thickness of coating through optical pulse infrared thermal imaging

ActiveCN103471513AOvercoming the problem of limited featuresSimple methodUsing optical meansPyrometry using electric radation detectorsThermodynamicsInfrared thermal imaging

The invention discloses a method for measuring the thickness of a coating through optical pulse infrared thermal imaging, and relates to a method for measuring the thickness of the coating to solve the problem that a current method for measuring the thickness of the coating is limited by the characteristics of measured materials. The method includes the steps of heating a structural element of the measured coating under two different types of pulse strength through a pulse heating device, collecting thermal image sequences T1(x,y,N) and T2(x,y,N) on the surface of the structural element of the measured coating under the same sampling frequency fs through an infrared thermal imager, subtracting the thermal image sequence T1(x,y,N) from the thermal image sequence T2(x,y,N) to obtain a thermal wave signal delta T which is equal to T2(x,y,N) minus T1(x,y,N), conducting linear fitting on the relationships between thermal wave signals of all pixels and collection frame numbers to obtain a delta T(x,y,N) which is equal to aN plus b, and obtaining the coating thickness ec of the structural element of the measured coating according to a formula and according to the obtained a and the obtained b. The method is used for measuring the coating thickness of the structural element of the measured coating.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

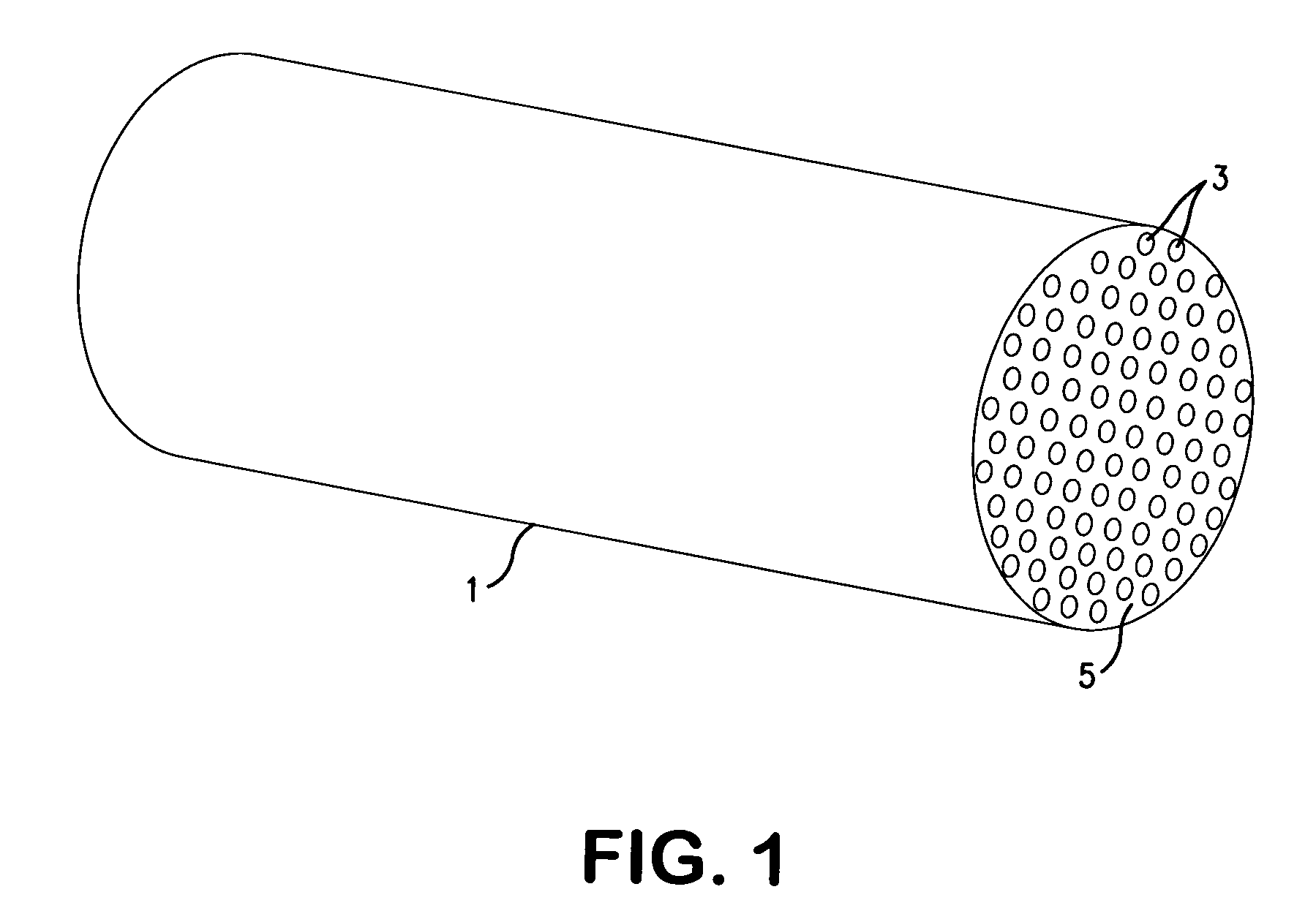

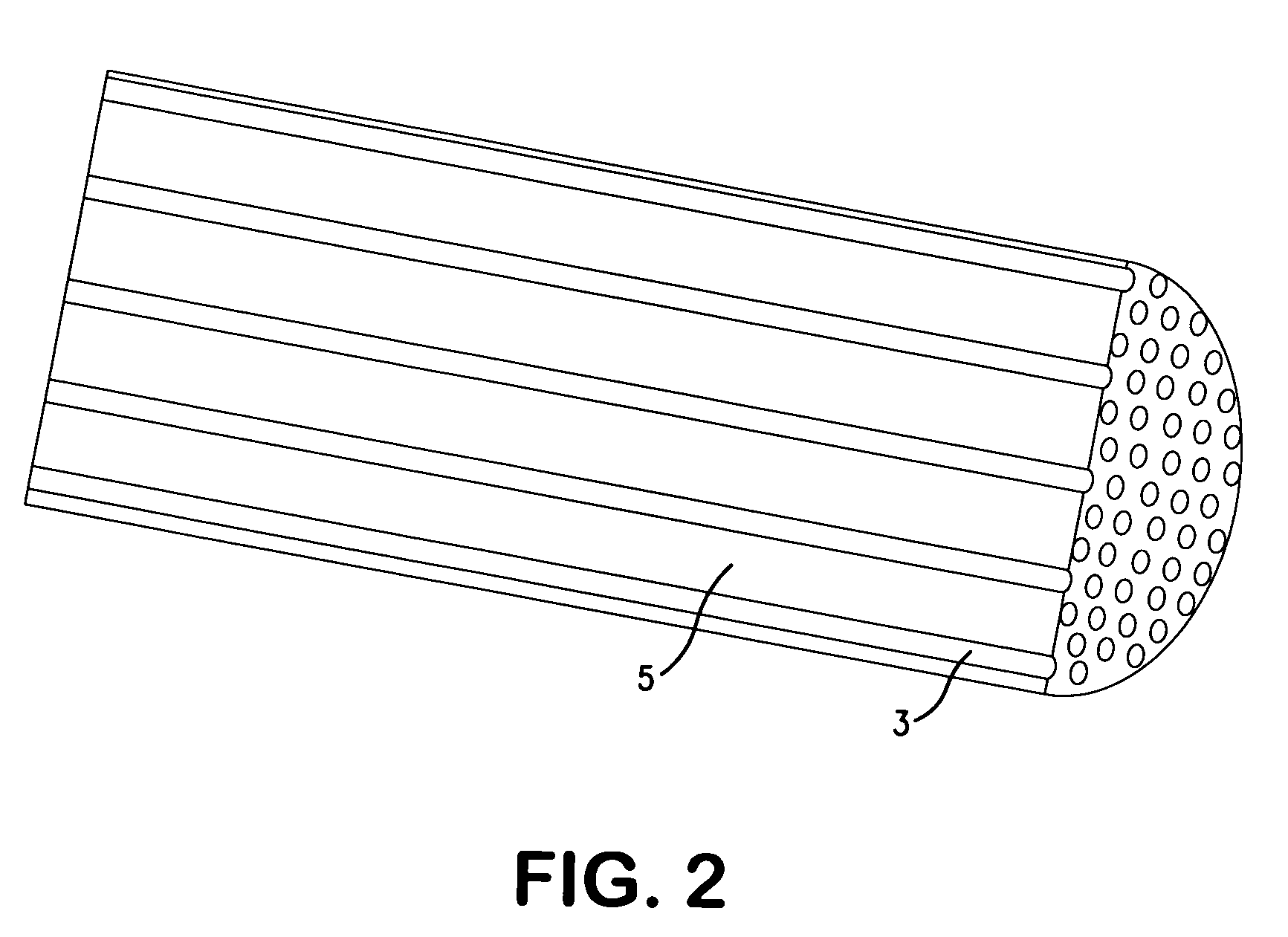

Thermal mangement article having thermal wave guide

Owner:GENERAL ELECTRIC CO

Infrared heat wave detecting system with THZ wave as light source

InactiveCN1548943AOptimize detection resultsMaterial analysis by optical meansMaterial flaws investigationThermodynamicsThermographic camera

The present invention relates to one new kind of thermal wave detecting system. It adopts THz wave as heat source for heating object; thermal imaging instrument to monitor the varying temperature field in the surface of the sample and detect the phase relation between the variance in the temperature field and the heat source applies the THz wave; synchronous or time sequence controller to control the emission of the THz wave and the detection of thermal imaging instrument; and computer for thermal wave transmission calculating processing and data fitting, so as to obtain the inner fault and heterogeneity information from the temperature field variation.

Owner:CAPITAL NORMAL UNIVERSITY +1

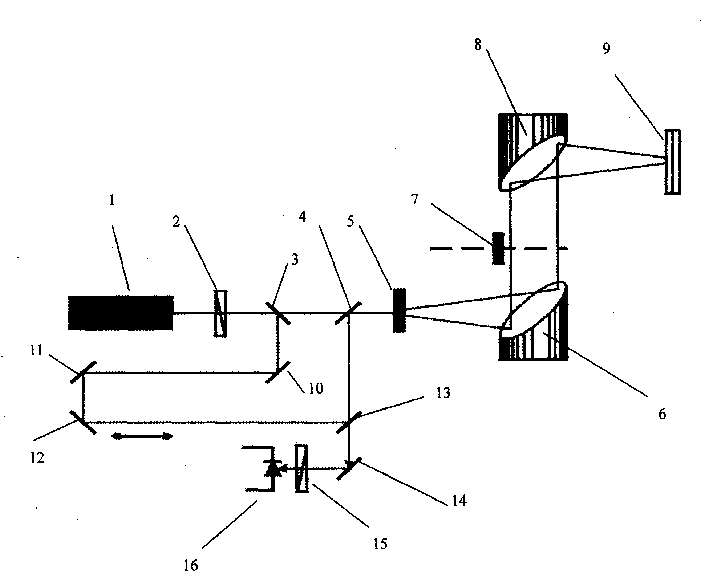

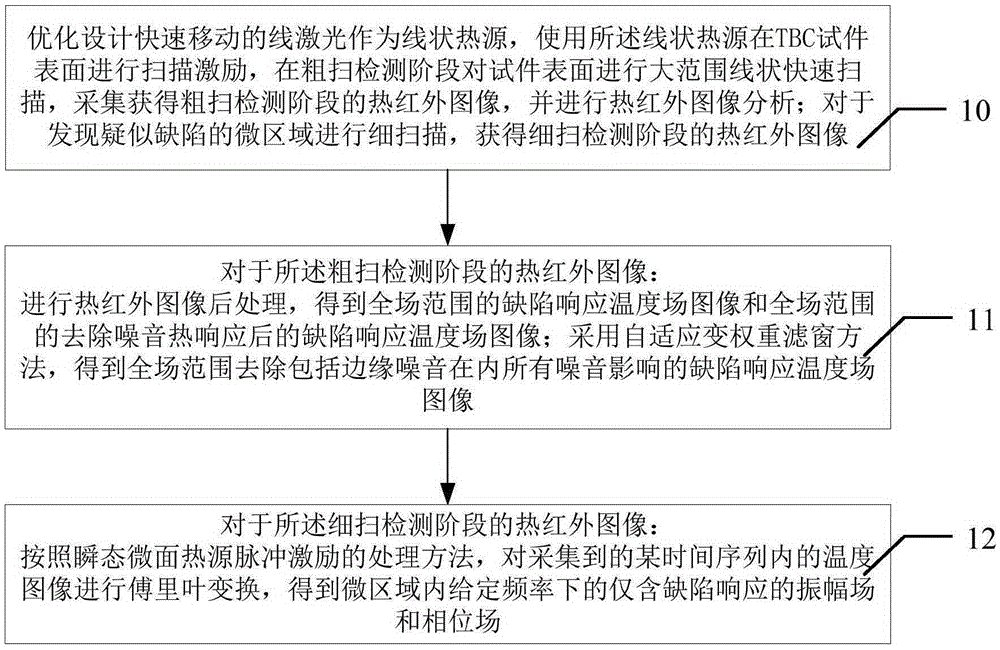

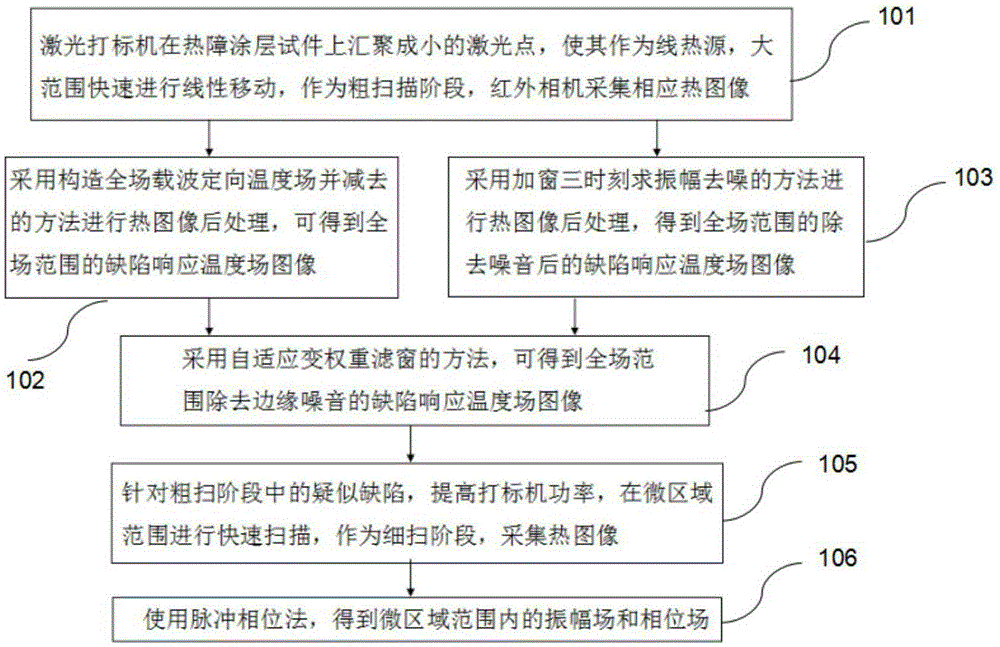

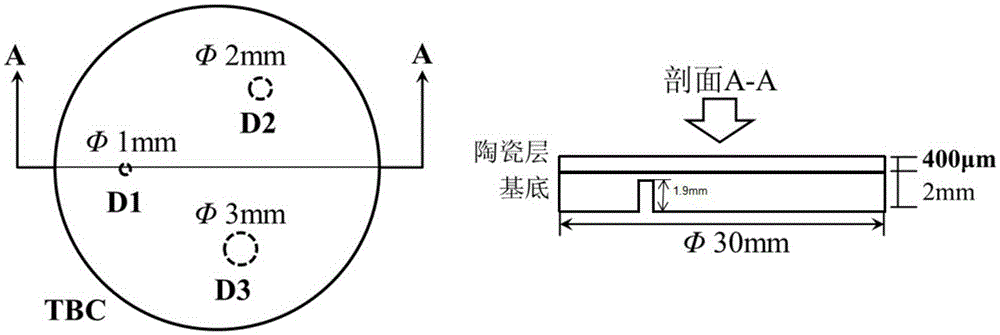

Debonding defect rapid detection line laser scanning thermal wave imaging method for TBC

InactiveCN105301051AEasy to buildEasy to operateMaterial flaws investigationImaging analysisLaser scanning

The present application discloses a debonding defect rapid detection line laser scanning thermal wave imaging method for TBC. The method comprises: optimizing and designing fast-moving line laser line as a linear heat source, carrying out scanning excitation on the surface of a TBC sample by using the linear heat source, carrying out large range linear rapid scanning on the sample surface at a coarse scanning detection stage, collecting to obtain the thermal infrared image at the coarse scanning detection stage, and carrying out thermal infrared image analysis; and carrying out fine scanning on the defect-suspected micro-region to obtain the thermal infrared image at the fine scanning detection stage. With the method of the present invention, the debonding defect of TBC can be detected, the high precision is provided, damage on the TBC during the detection can not be generated, the operation is simple, the high efficiency is provided, and the image collected by the system can be post-treated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

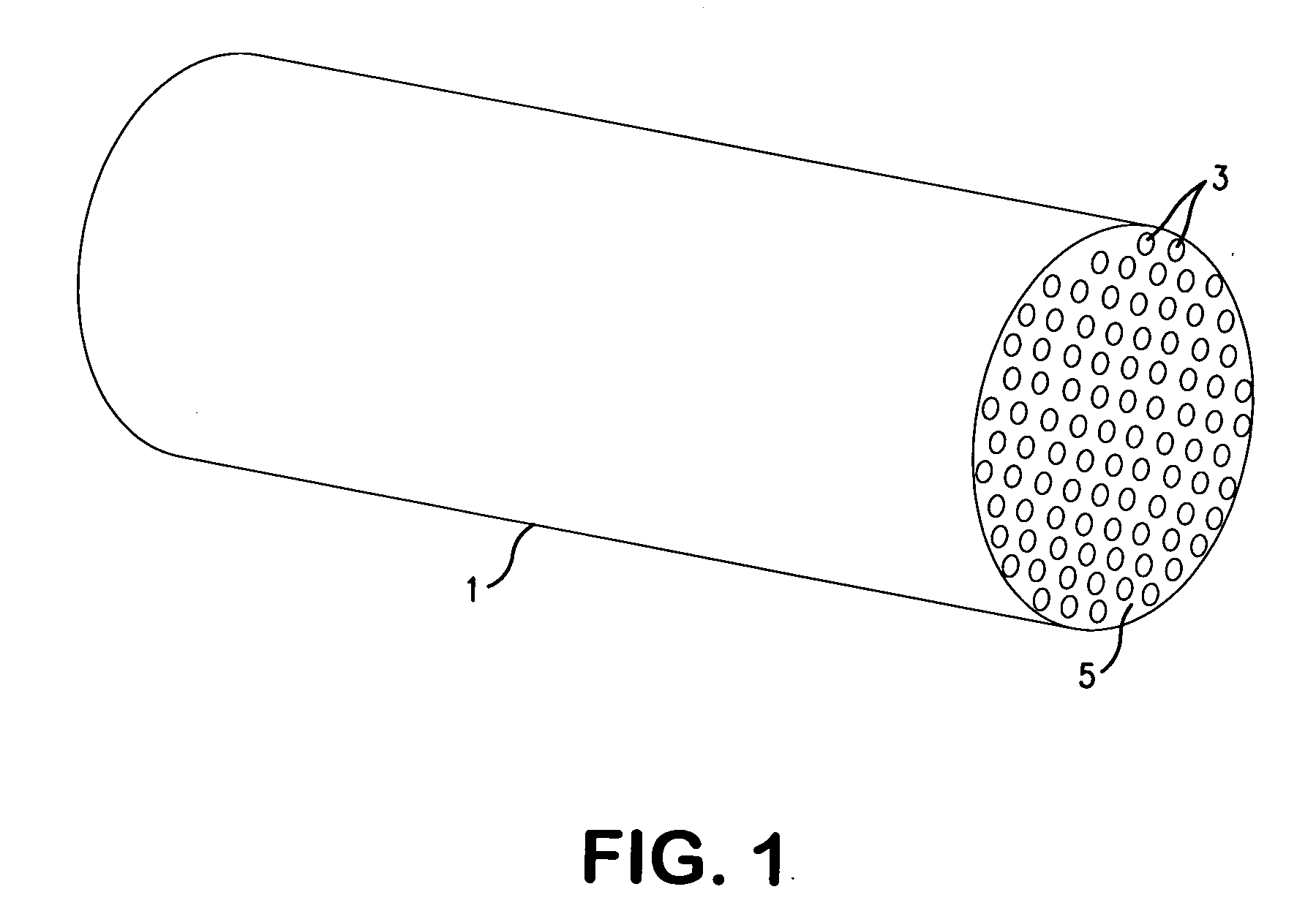

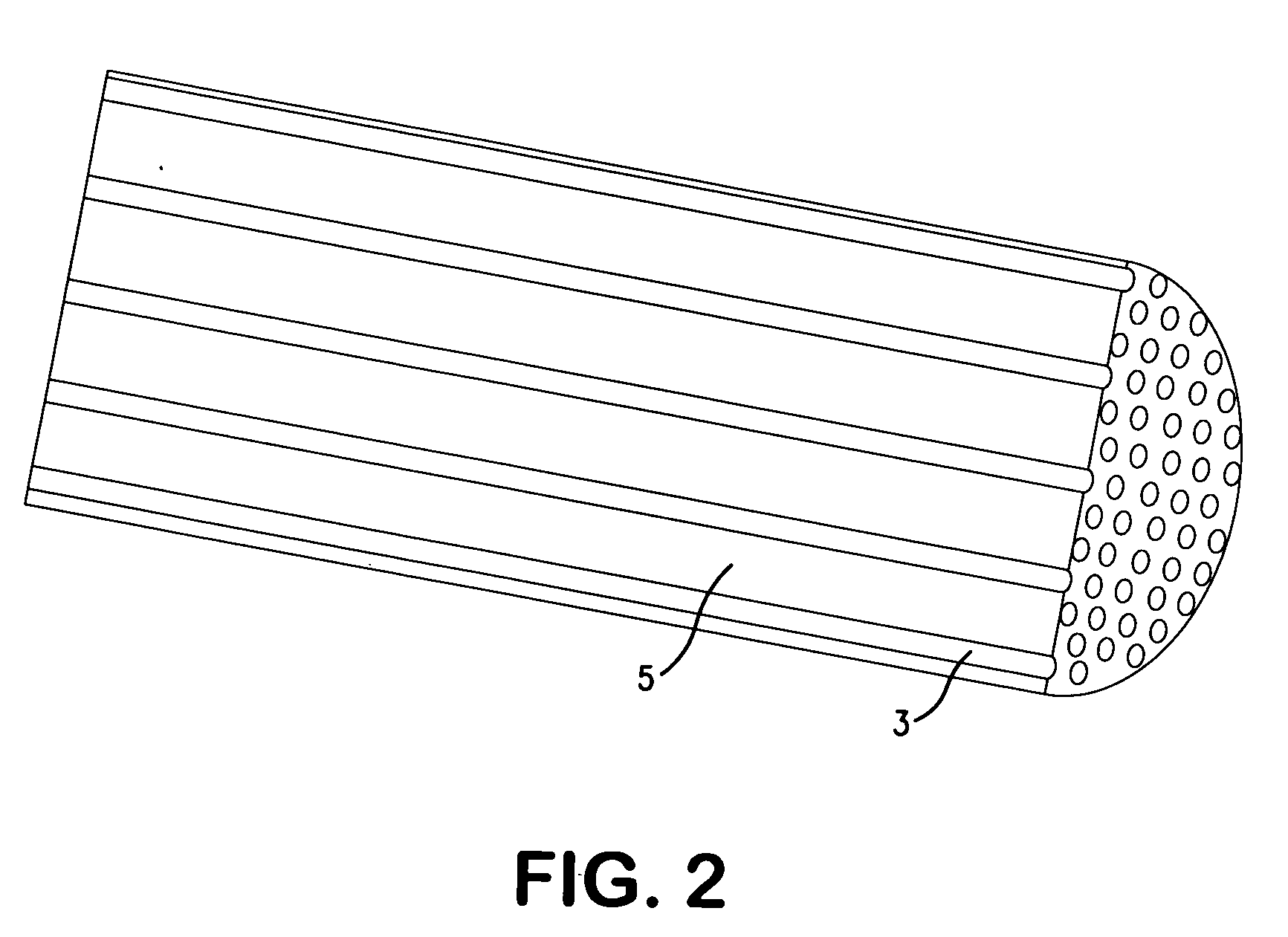

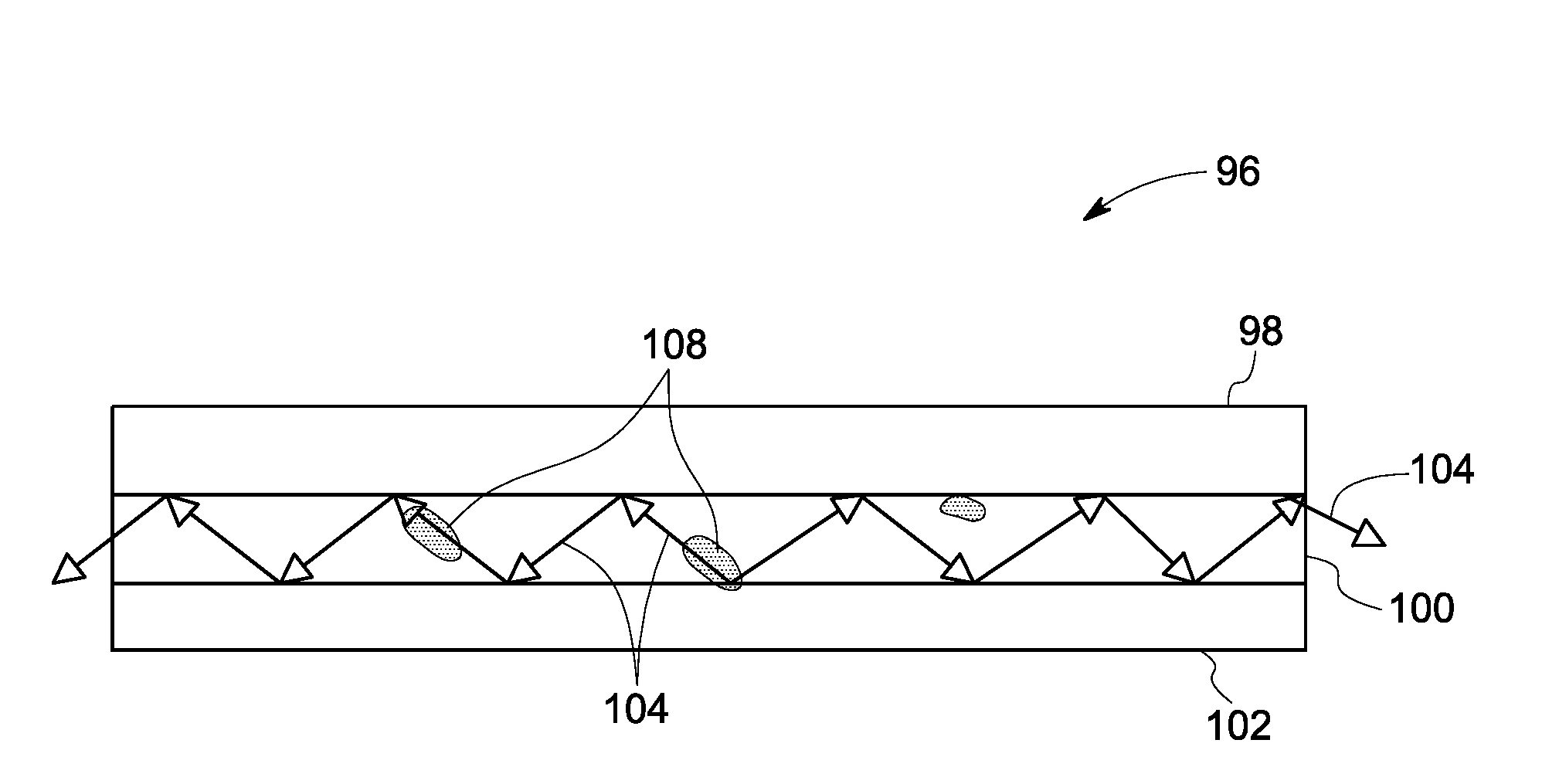

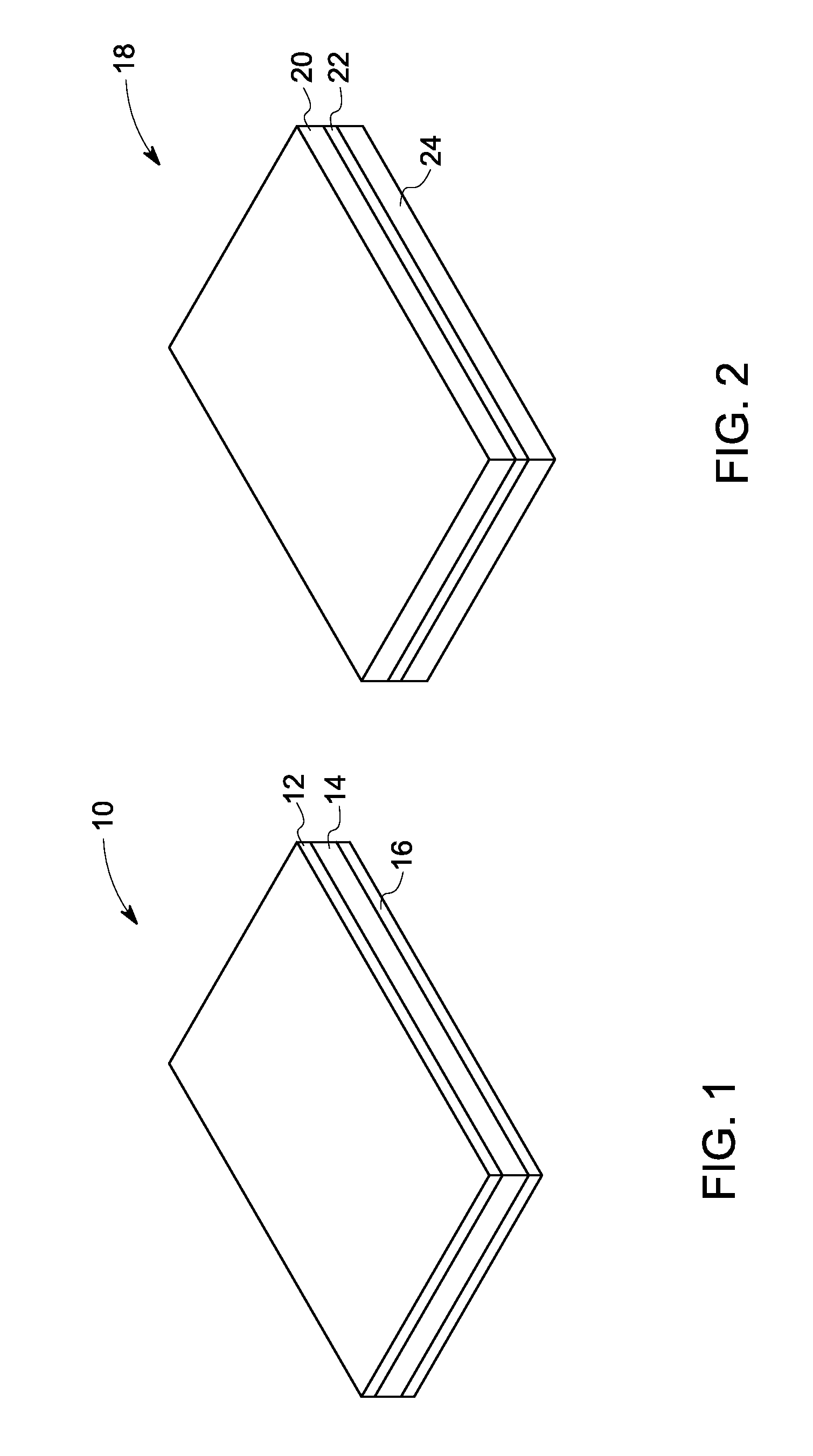

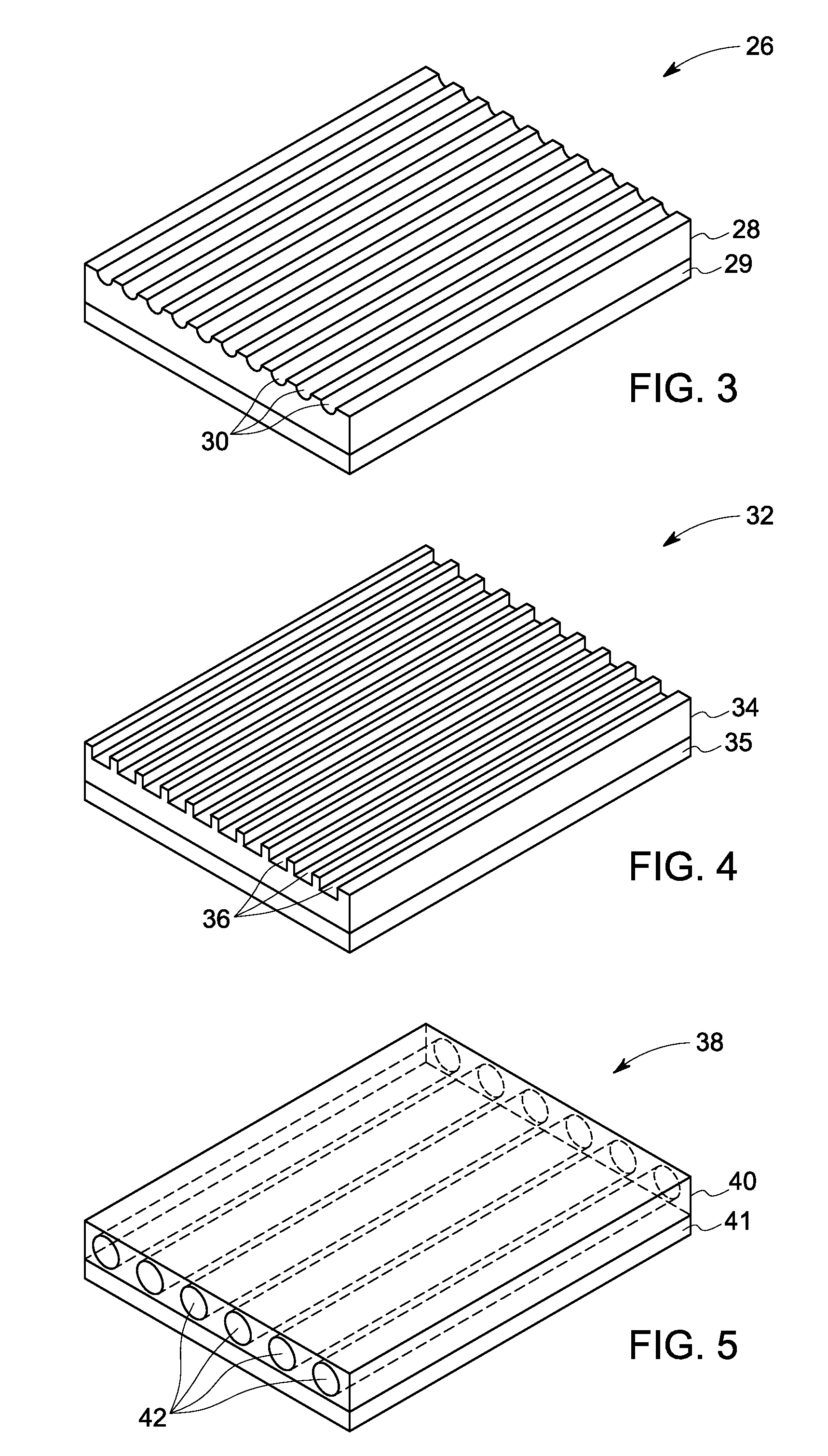

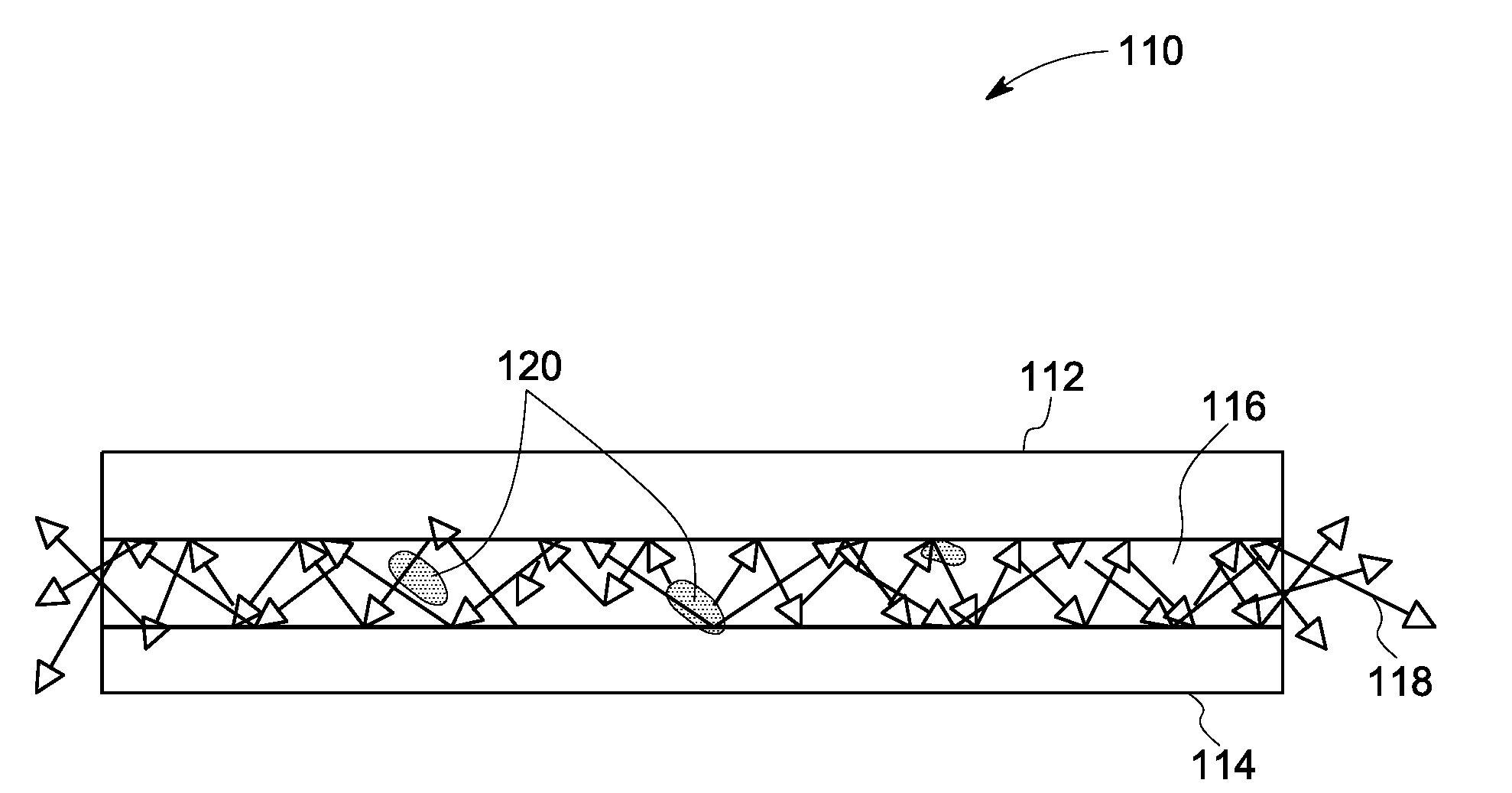

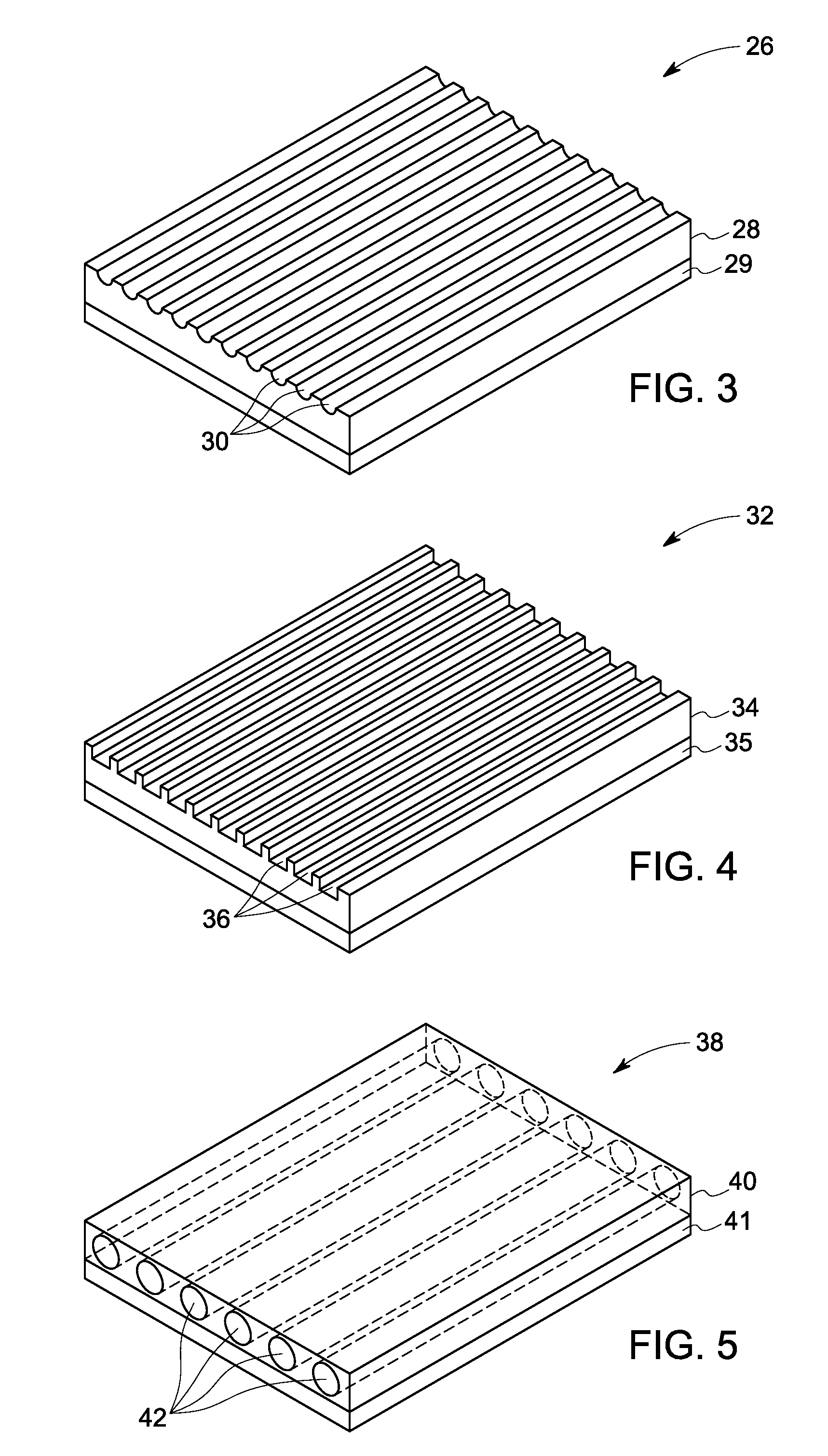

Thermal mangement article having thermal wave guide

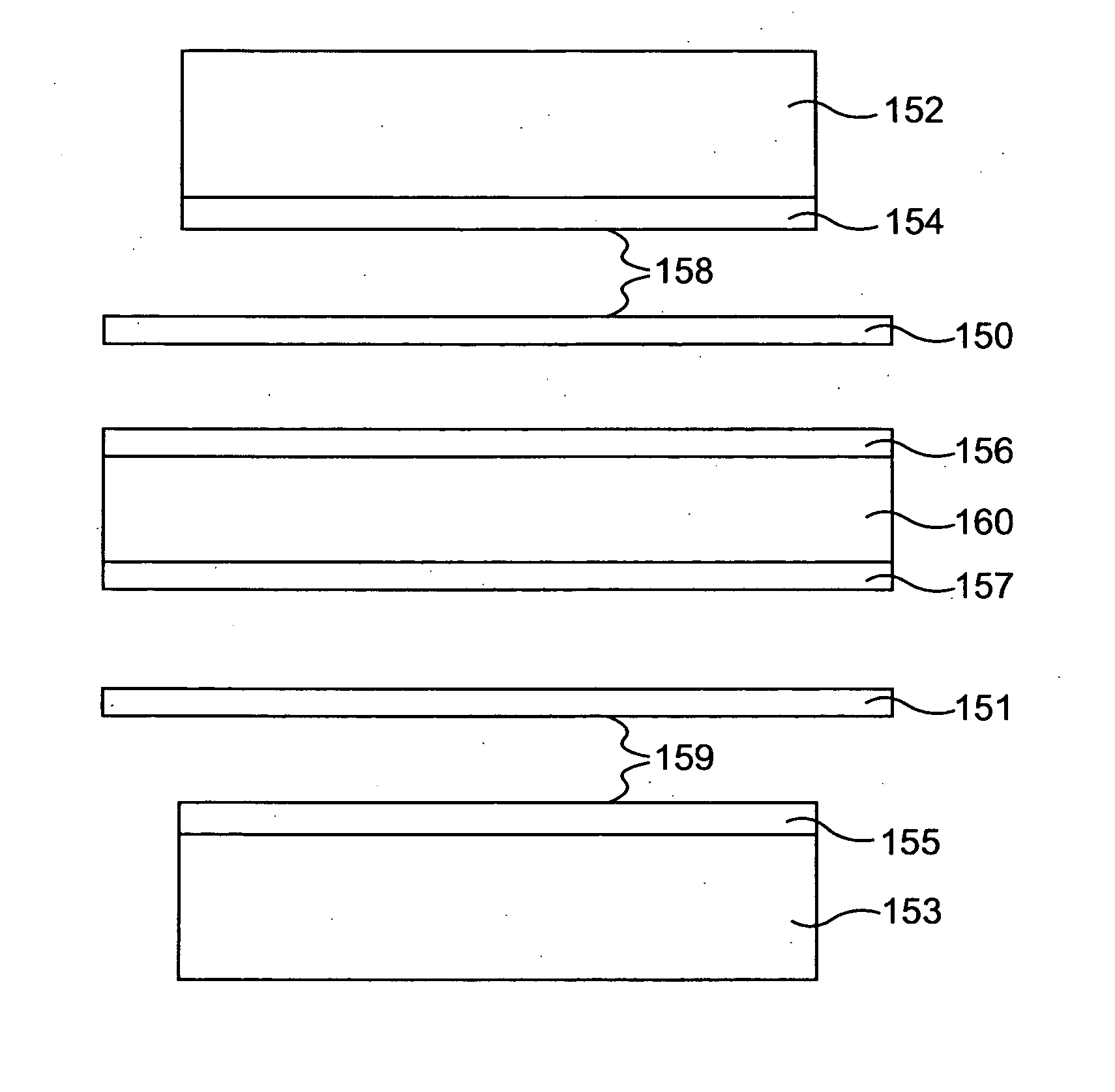

An article includes a stack of display layers including a display layer having a high-shear modulus that is sandwiched between two display layers having a low-shear modulus. The display layers include a light-emitting device that generates heat and light during use. The heat generated by the display layers may form localized heat-sources in the stack. The display layer with the high-shear modulus is a thermal transport layer through which the localized heat-sources-induced guided elastic waves propagate along an acoustic waveguide plane and can transport the heat generated by the light-emitting device away from the light-emitting device. Alternately, a display layer having a high refractive index may be sandwiched between two display layers having a low refractive index. The display layers with low shear modulus or low refractive index may be replaced with thermal transport layers having low shear modulus or low refractive index respectively.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com