Non-destructive detection method of pulse-excited infrared thermal wave phase of fixed viewing field

An infrared thermal wave and non-destructive testing technology, applied in the direction of material defect testing, etc., can solve the problems of lack of improvement measures, inconsistent with the actual situation, and restrictions on the application of fine-grained spectrum analysis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Below in conjunction with accompanying drawing, specific embodiment example of the present invention is described further:

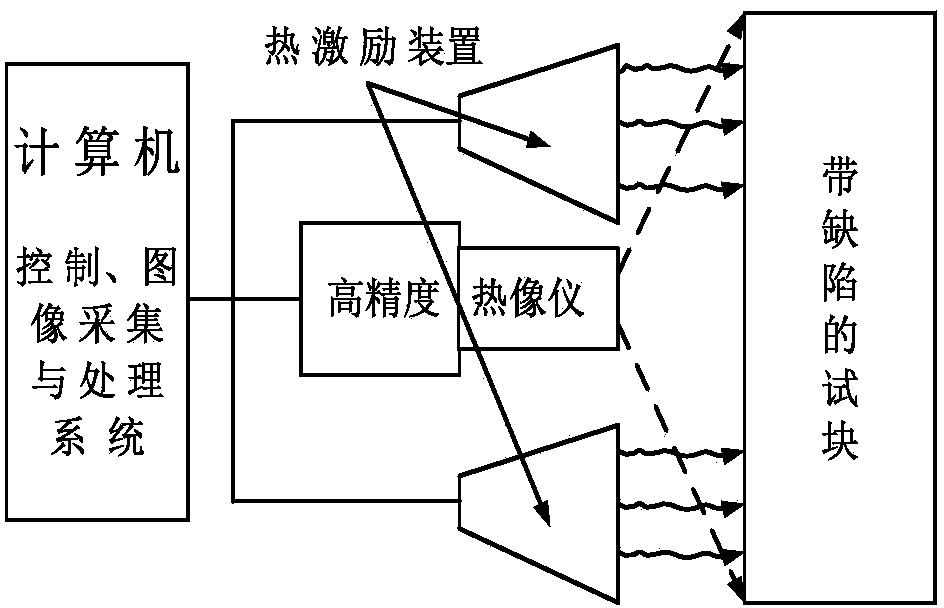

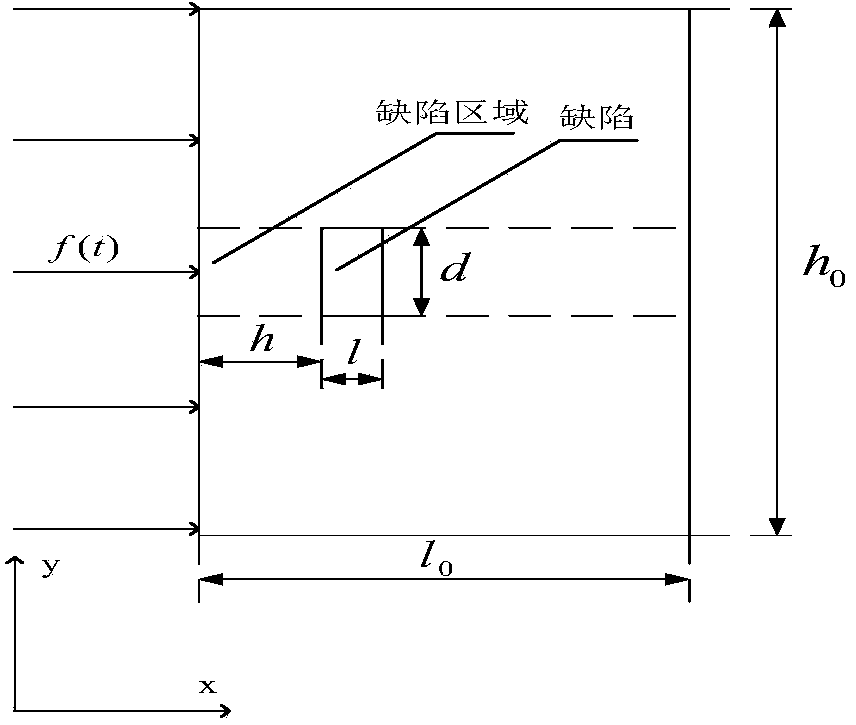

[0083] The implementation method of step 1 is as follows (see figure 1 , 2 , 4, 5, 6):

[0084] (1) The method of obtaining thermal wave images. The detection device of the pulse thermal imaging method is composed of a thermal imager, a computer, a display, a power supply and a thermal excitation source. During the detection process, the thermal excitation source sends a thermal excitation signal to heat the detection object instantaneously or for a short time, and the thermal imager collects the time and space distribution information of the surface temperature field of the measured object to form an infrared thermal wave image sequence. The sequence value is the infrared radiation density of the corresponding point, which can be converted into a temperature value. The thermal image sequence is analyzed by computer fitting, compression, recons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com