Infrared lock-in thermal wave non-destructive detection method based on image sequence processing

A technology of image sequence and infrared phase-locking, which is applied in the direction of material defect testing, etc., can solve the problems of false display, inability to detect porous materials, volatile test solution, etc., and achieve the effect of angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

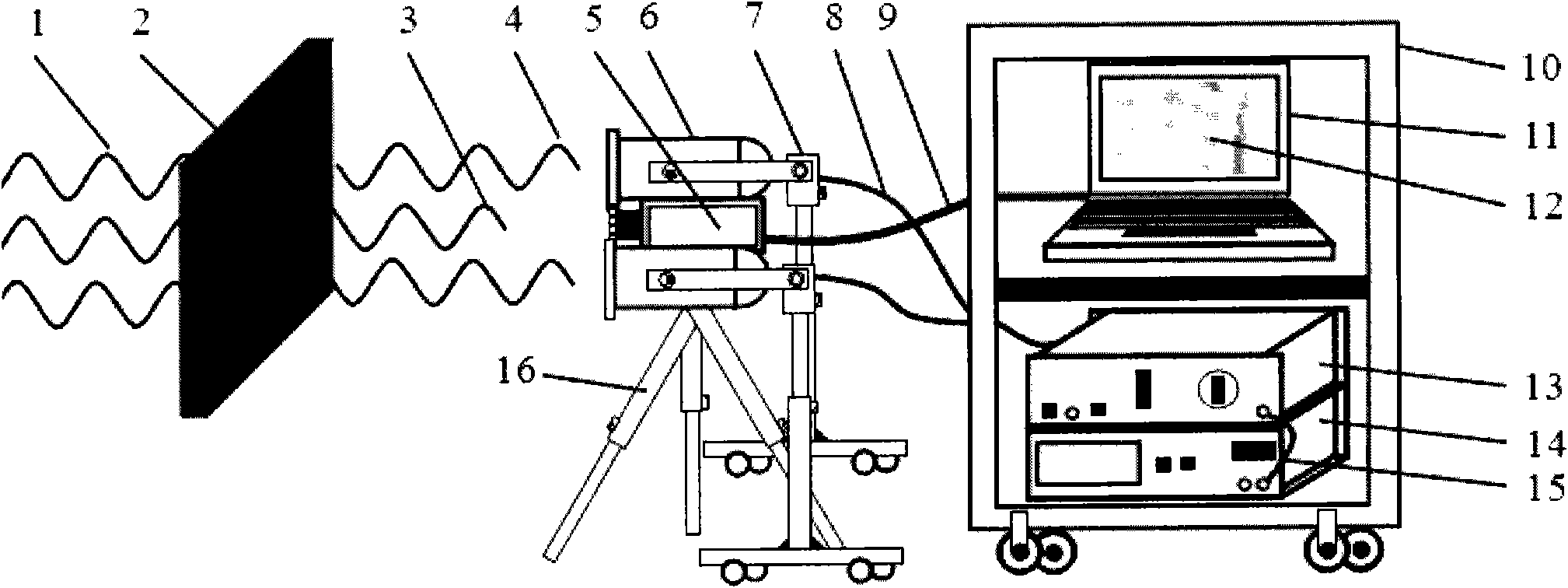

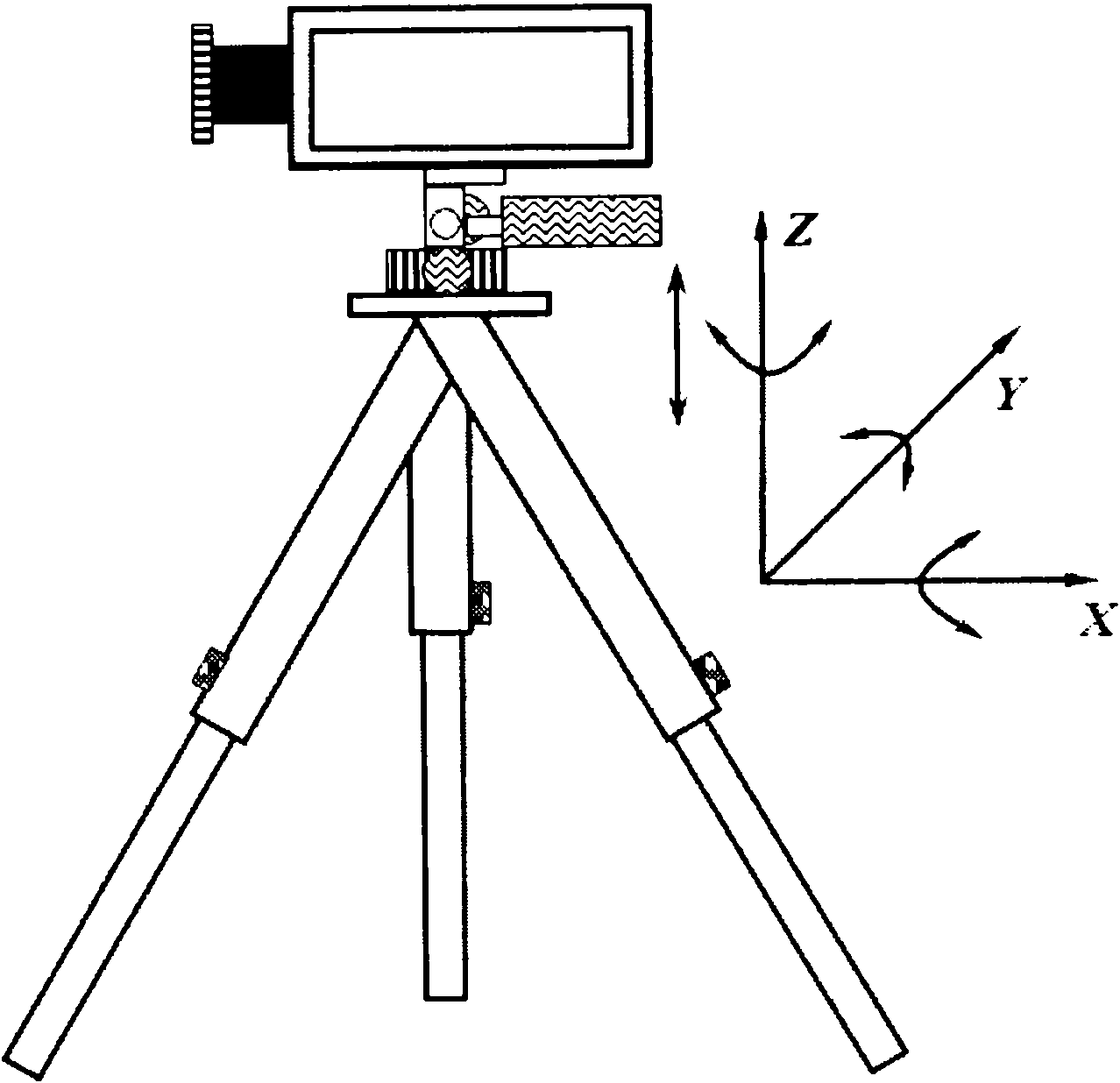

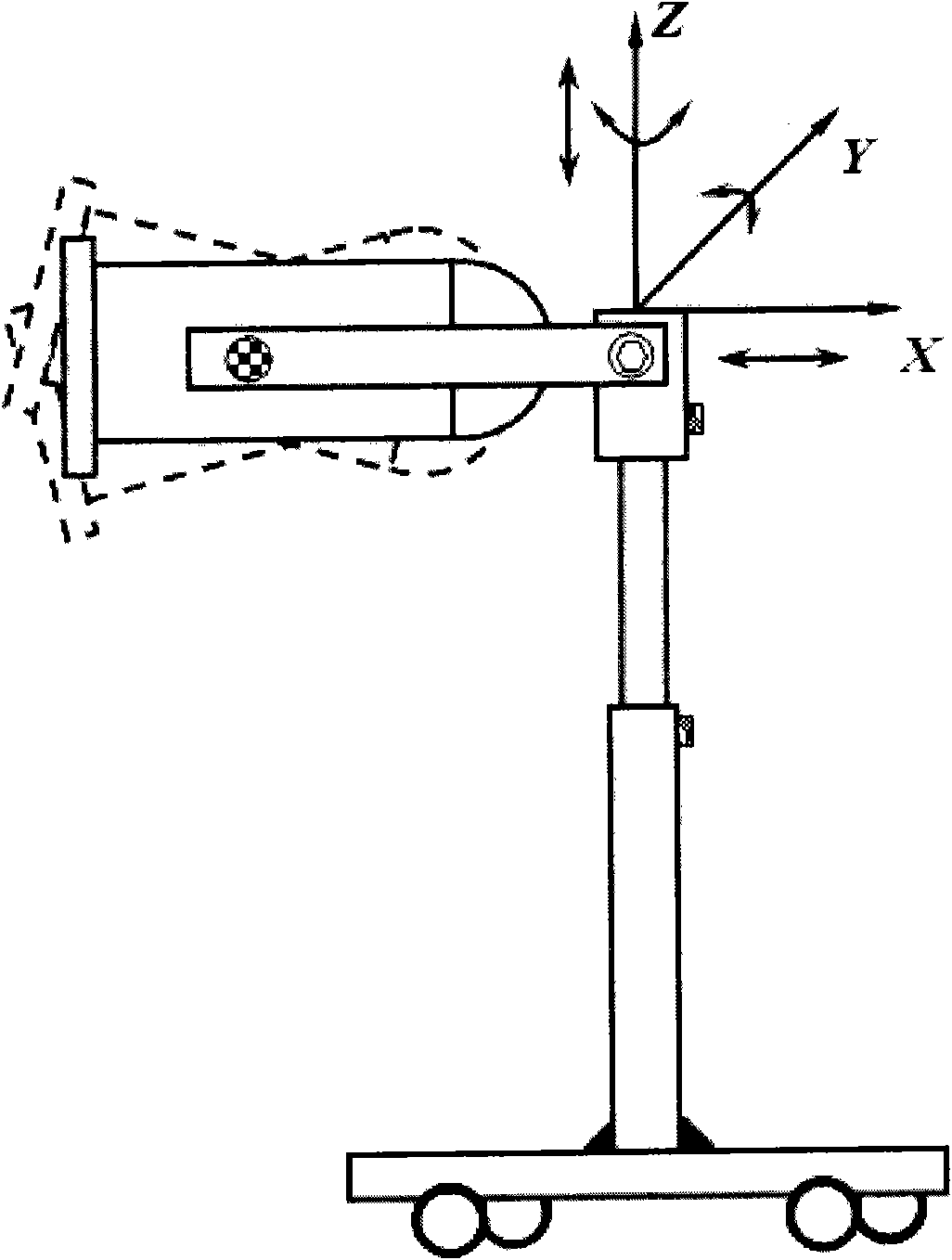

[0015] Such as figure 1 As shown, the infrared phase-locked thermal wave nondestructive testing method based on image sequence processing uses computer software to process infrared image sequences to realize the infrared phase-locked thermal wave nondestructive testing of internal defects of the sample. In the figure, the focal plane array thermal imaging camera 5 is fixed on a tripod 16, connected with the data acquisition card of the computer 11, and the initialization and image display of the thermal imaging camera are completed by using the infrared phase-locking processing software 12 based on the image sequence. The halogen light source 6 is fixed on the special support 7 to ensure that the incident light reaches the surface of the sample 2 as much as possible. The function generator 14 is connected to the light source power amplifier 13 through the signal line 15 to control the light intensity of the halogen light source 6 to change according to the sinusoidal law. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com