Infrared thermal wave radar imaging nondestructive testing method and system for defects of carbon fiber reinforced plastic (CFRP) plywood

A non-destructive testing and radar imaging technology, applied in the direction of material defect testing, etc., can solve the problems of slow detection speed, uneven heating, missed detection, etc., and achieve the effect of accurate non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

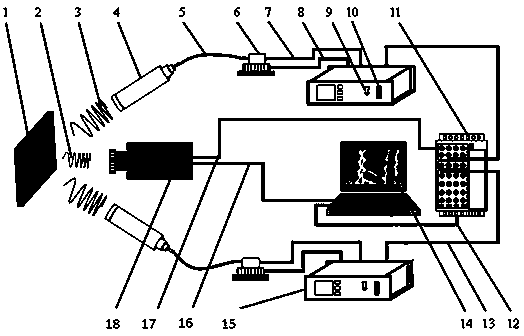

[0028] Such as figure 1 As shown, the infrared thermal wave radar imaging non-destructive testing method uses computer software to process infrared image sequences to realize the non-destructive testing of internal defects of the sample. In the figure, the focal plane thermal imager 18 is connected to the Ethernet interface of the computer 14, and the computer 14 is used to complete the initialization and image display of the focal plane thermal imager 18. The laser light source beam expander and shaping device 4 irradiates laser light onto the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com