Judgment method for detecting defects of wave absorption coating by using pulse infrared thermal waves

A technology of infrared thermal wave and wave absorbing coating, which is used in optical testing for flaws/defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

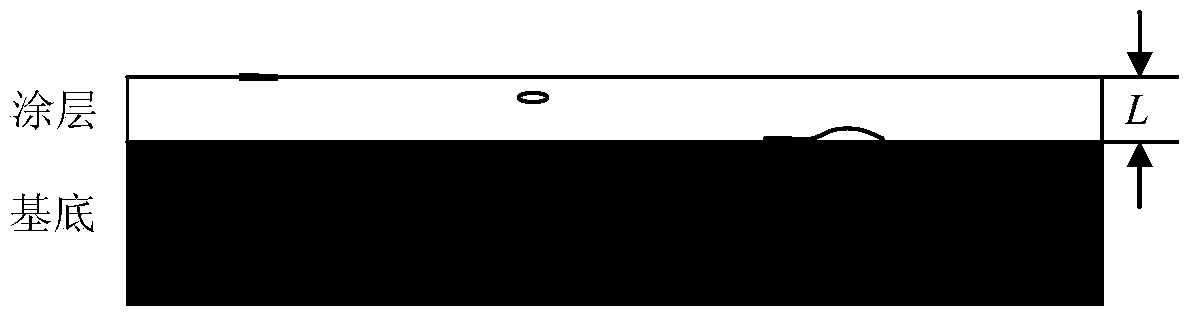

[0032] For coating structures, simply use figure 1 Indicated, the three main defect forms of the coating structure are depicted from left to right in the figure: surface damage, internal pores and debonding between the coating and the substrate.

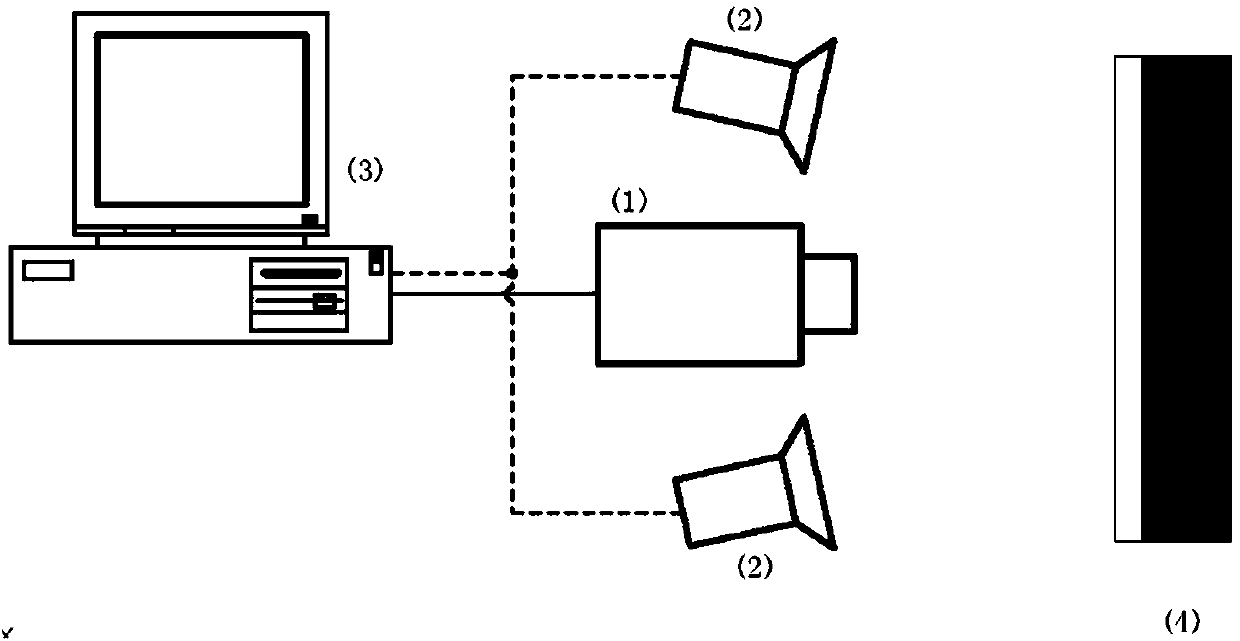

[0033] figure 2 It is a schematic diagram of the pulsed infrared thermal wave technology used in the detection of wave-absorbing coatings of the present invention, and it is also a structural schematic diagram of an actual system applying the method of the present invention.

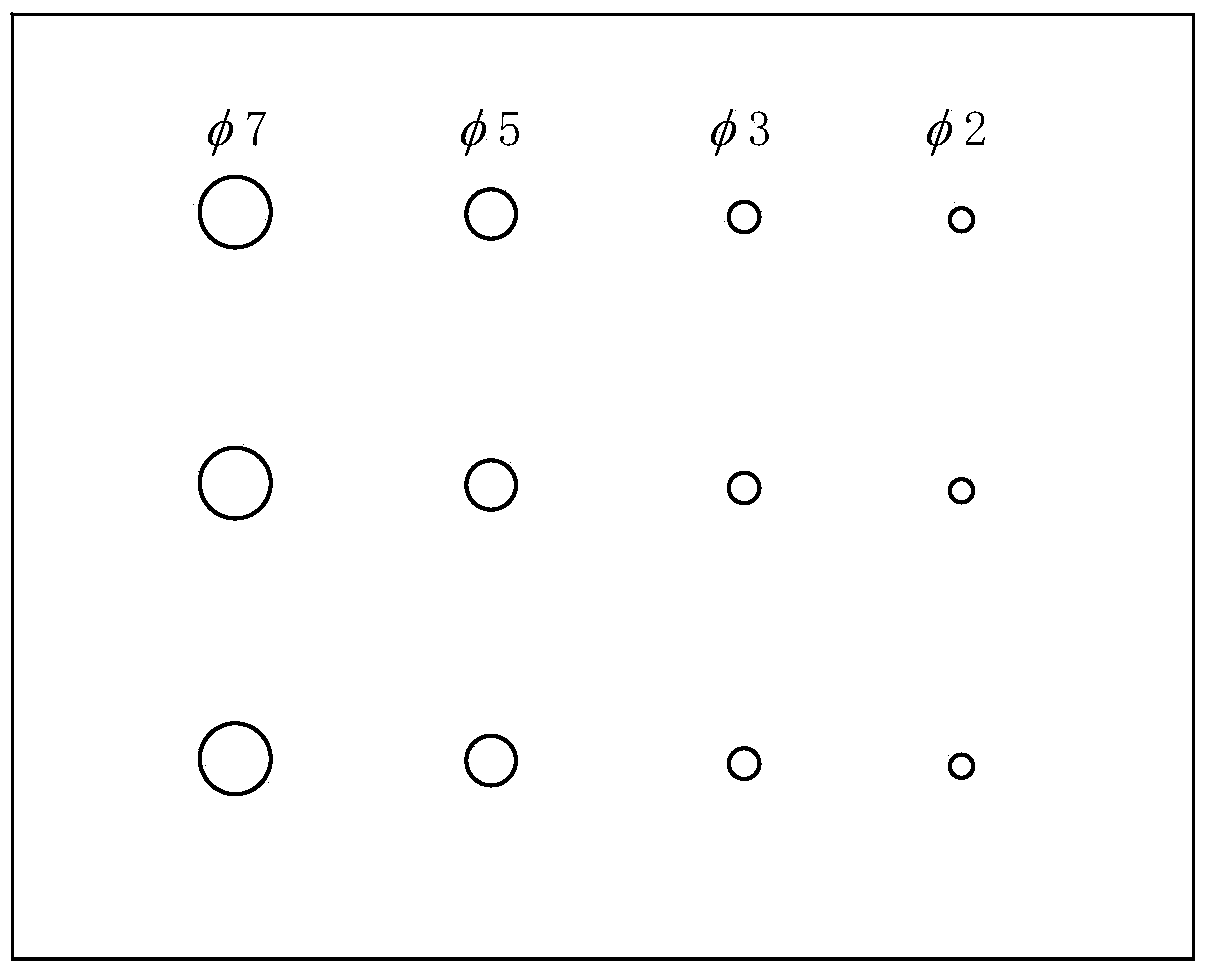

[0034]The process of using the pulse thermal imaging method to detect the wave-absorbing coating will be described below in conjunction with an embodiment. A standard sample of absorbing coating is used in this embodiment, its structure is as follows image 3 As shown, the coating thickness is designed to be 1mm, but the actual thickness is slightly larger than 1mm.

[0035] refer to image 3 , the high-energy flash lamp applies visible light energy to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com