Nondestructive detecting system and method for automatic tracking thermal wave imaging

A non-destructive testing and imaging technology, which is applied in the online non-destructive testing system of thermal excitation infrared thermal wave imaging to detect objects in a non-stationary state, and can solve problems that affect the effective detection of the measured object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

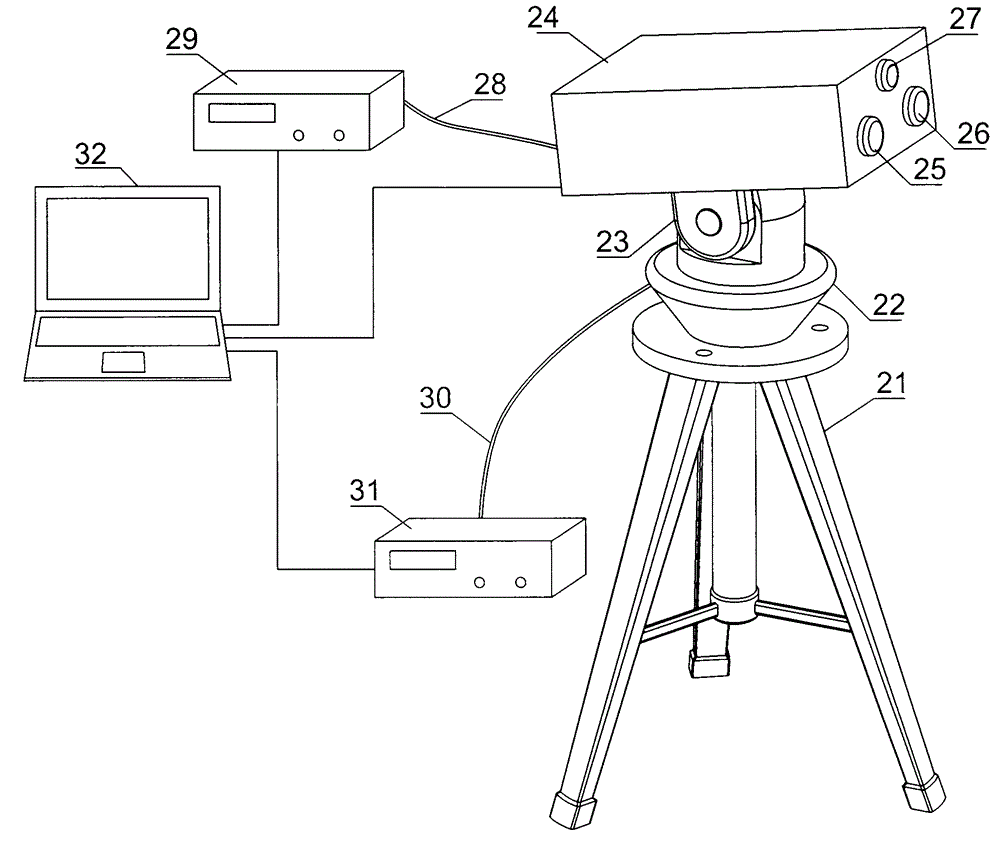

[0021] Such as figure 2 As shown, the system of the present invention includes a laser generator 29, a laser projection head 27, an infrared camera 25, a visible light camera 26, a pan-tilt 23 capable of horizontal rotation and pitch adjustment, a pan-tilt controller 31, a data acquisition processor 32, and the like. Wherein the laser projection head 27 , the infrared camera 25 and the visible light camera 26 constitute the optical detection module 24 of the system, and are connected to the supporting frame 21 through the pan-tilt 23 .

[0022] Such as figure 2 As shown, the laser generator 29 is used to heat the measured object, the laser beam is transmitted to the system optical detection module 24 through the optical fiber 28, and the beam is projected from the laser projection head 27 to the measured object after shaping. The infrared camera 25 is used to receive the infrared signal radiated from the measured object, and transmit the image to the data acquisition proces...

Embodiment 2

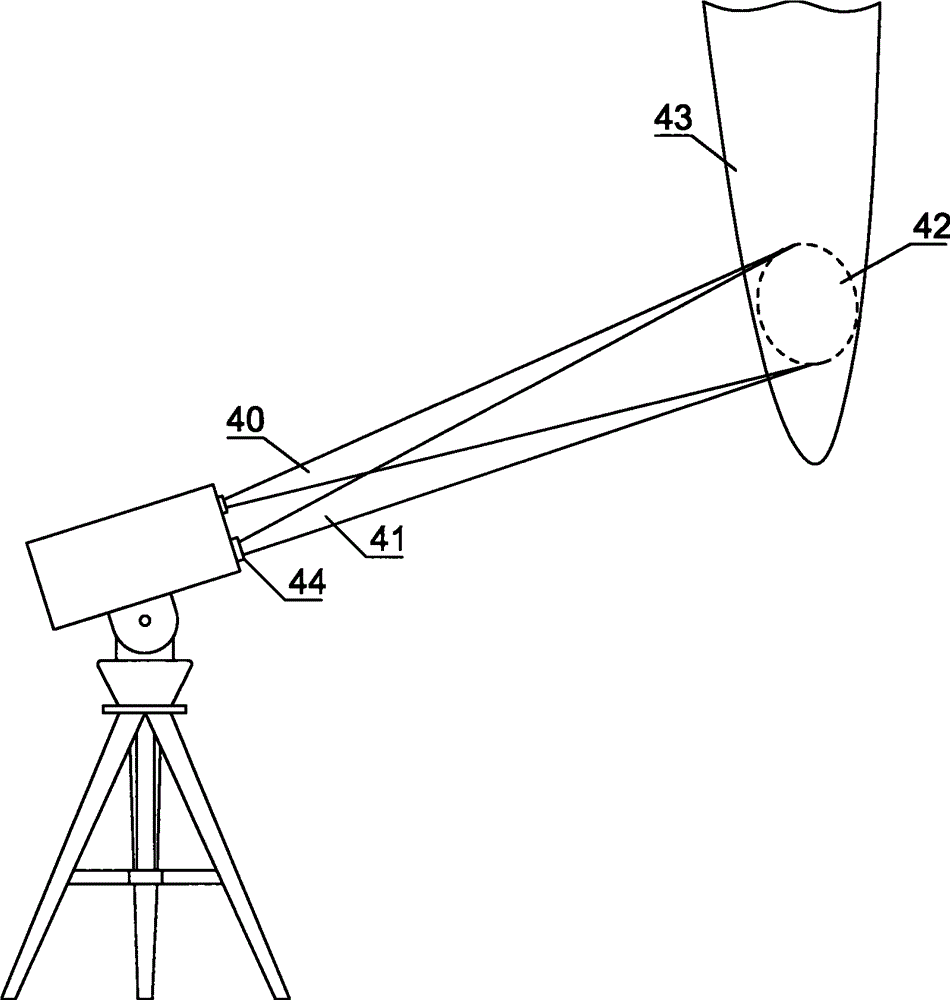

[0032] The design solution in Embodiment 1 has the advantage of a large tracking range, but the volume and weight of the optical detection module 24 are relatively large, which makes the pan-tilt automatic tracking system more complex and bulky. For the case where the moving range of the measured object is small, that is, when the measured part will not move out of the imaging range of the camera, the infrared camera and the visible light camera can be in a non-tracking state. Great simplification. Due to the limited power of the thermal excitation source, the laser beam still needs to be tracked, but the deflection of the beam is easy to achieve mechanically.

[0033] Such as Figure 4 As shown, the system omits the automatic tracking pan-tilt and its controller, and adopts the laser beam deflection device 29. Under the control of the data acquisition processor 32, the outgoing direction of the laser beam 33 can be deflected, so that the heating part remains at the measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com