Debonding defect rapid detection line laser scanning thermal wave imaging method for TBC

A technology of laser scanning and thermal wave imaging, which is applied in the direction of material defect testing, etc., can solve the problems of not raising the sensitivity and resolution of detecting defects, and not mentioning the post-processing method of collecting images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

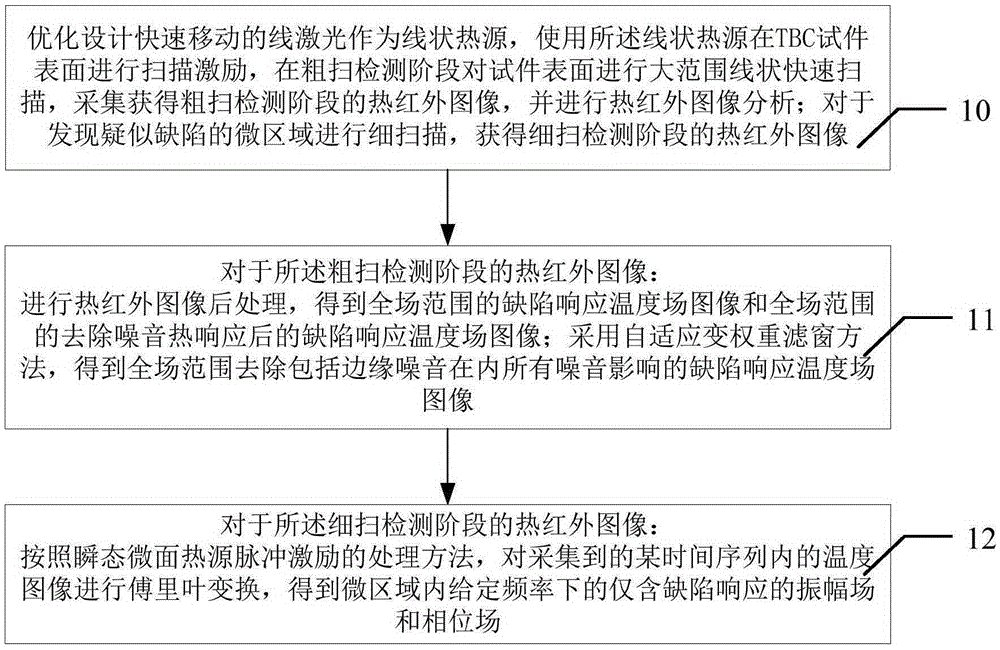

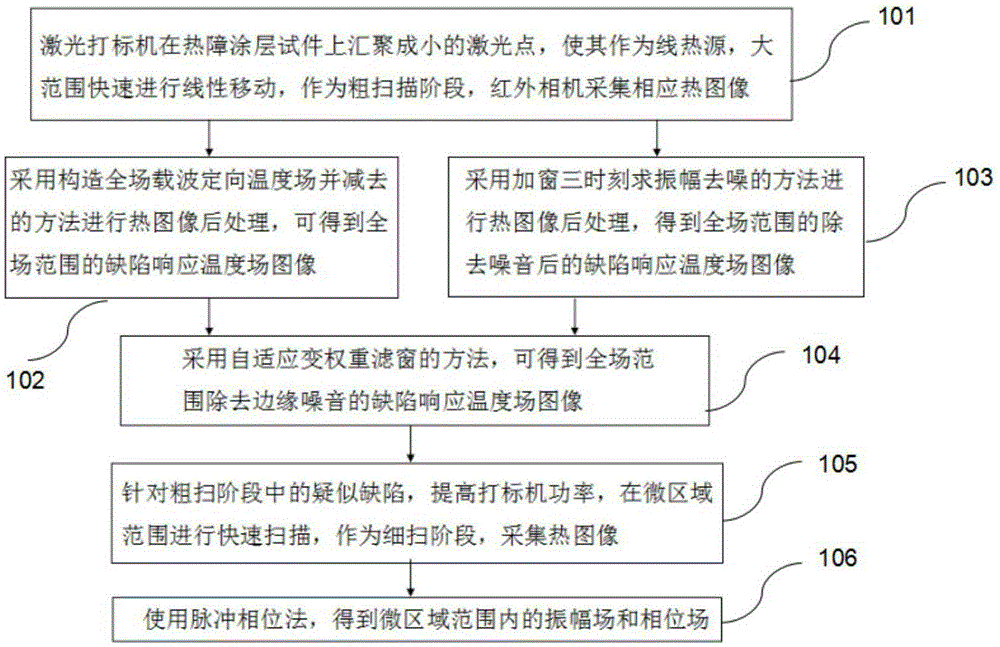

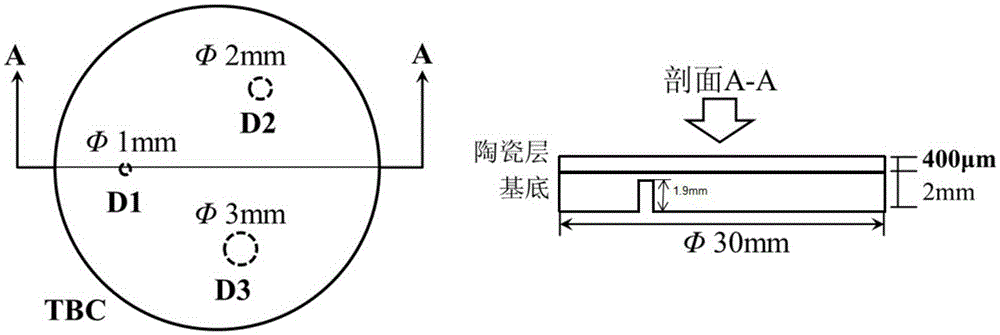

[0066] see figure 1 Shown is a specific embodiment of a line laser scanning thermal wave imaging method suitable for rapid detection of TBC debonding defects described in this application. The method in this embodiment includes the following steps:

[0067] Step 10. Optimize the design of the fast-moving line laser as a linear heat source, use the linear heat source to scan and excite the surface of the TBC specimen, and perform a large-scale linear rapid scan on the surface of the specimen during the rough scan detection stage, using an infrared thermal imager Acquisition of temperature images, acquisition of thermal infrared images in the rough scan detection stage, and thermal infrared image analysis; for micro-areas where suspected defects are found, use a higher power short-line laser to perform fine scanning in this area to obtain Thermal infrared image of the fine-scan inspection stage.

[0068] Step 11. For the thermal infrared image in the rough scan detection stage:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com