Tyre packing machine and packing method

A packaging machine and tire technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of easy damage, slow packaging, and high packaging costs, improve tightness and firmness, reduce the possibility of damage, and improve packaging. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

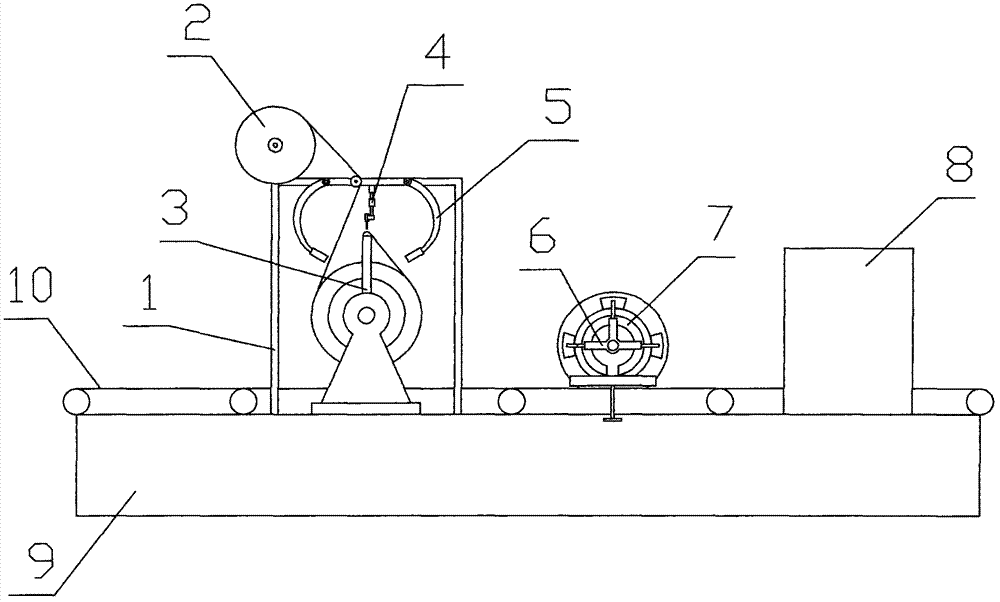

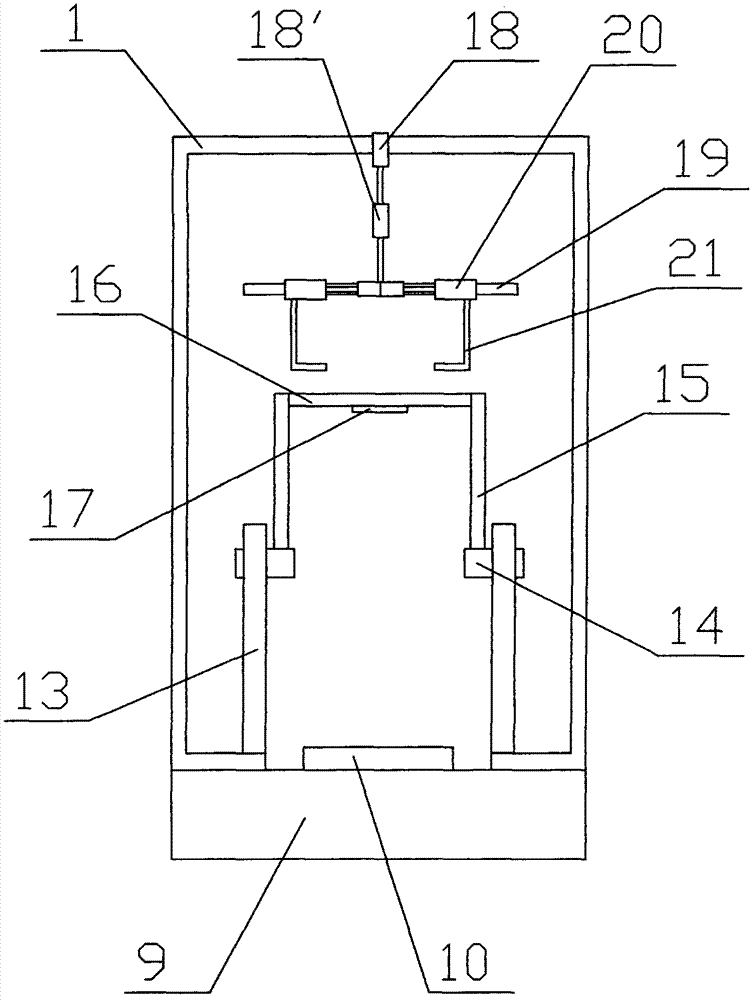

[0029] The tire packaging machine of the present invention, such as figure 1 As shown in the figure, a vertical tire feeding device is included, and a tire tread wrapping device, a tire inner ring bonding device, and a baking tightening device 8 are sequentially installed on the vertical tire feeding device along the tire feeding direction. The tire tread The wrapping device includes a frame 1. The frame 1 is provided with a feeding device 2, a tire wrapping device 3, a tire lifting device 4, and an outer ring bonding device 5. The feeding device 2 is located above the tire wrapping device 3. The tire inner ring The gluing device includes a flanging device 6 and an inner ring gluing device 7 , and the inner ring gluing device 7 is installed on the flanging device 6 .

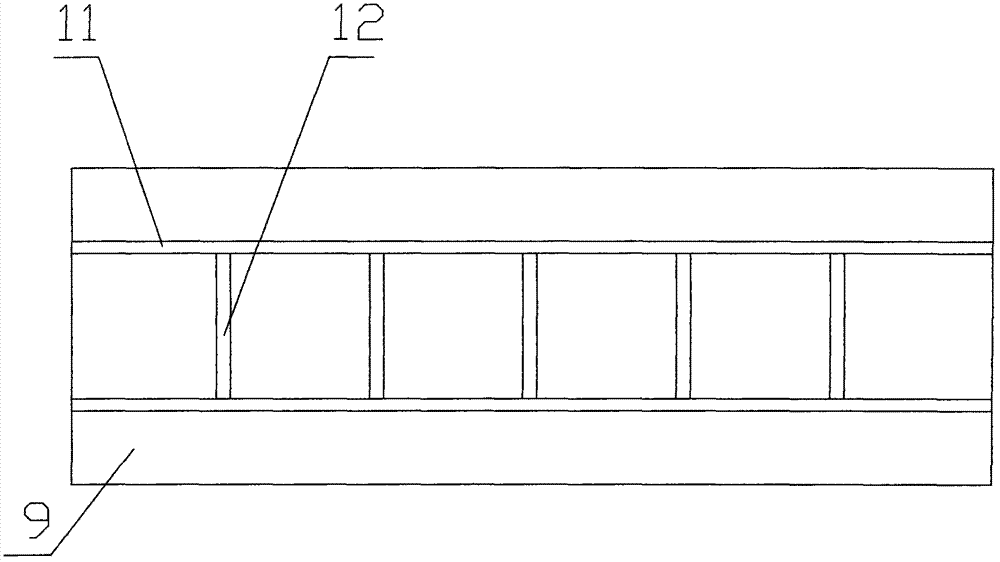

[0030] like figure 2 As shown, the vertical tire feeding device includes a base 9 and a conveying device 10 mounted on the base 9. The conveying device 10 includes two chains 11 parallel to each other, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com