Air 3D printing material extruding and holding apparatus

A 3D printing and material support technology, applied in the field of 3D printing, can solve problems such as obstacles to the development direction of 3D printing large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

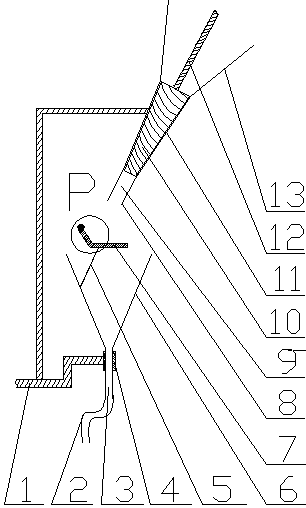

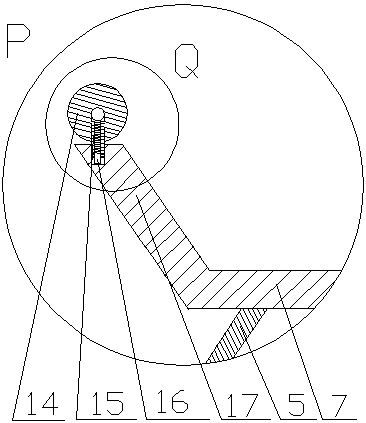

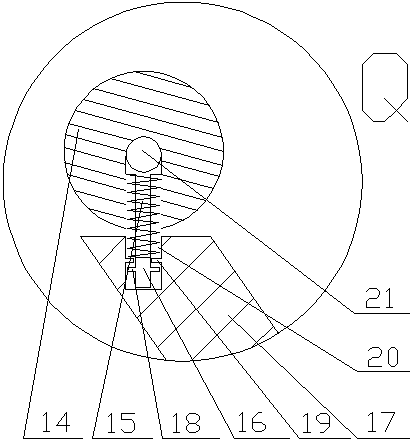

[0015] exist figure 1 In the embodiment shown in —3: the 3D printing extrusion and support device in the air, including the extrusion material composed of conical tube 11, conical extrusion screw 10, feeding hopper 13, square tube 9, connecting shaft 12, etc. device, and a material supporting device composed of a supporting plate 7, a powder scraping wheel 14, a hopper 6, and a straight pipe 3; The upper end is connected with a feed hopper with a larger tapered mouth, and a conical extruding screw 10 is installed in the conical tube 11. There is a connecting shaft 12 on the upper end of the conical extruding screw 10, and the connecting shaft 12 is connected to drive the conical extrusion. The motor for the rotation of the material screw 10, the small mouth end of the tapered pipe 11 faces down, and is connected with a section of square pipe 9. The end of the square pipe 9 and the tapered pipe 11, that is, the lower end, has a oblique square mouth 8, and the oblique square mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com