Multifunctional colored toner and preparation method thereof and thermal transfer printing method

A color toner, multi-functional technology, applied in the field of digital printing, printer, copier toner, can solve the problems of expensive ink, large sewage discharge, easy nozzle clogging, etc., achieve flexible printing, fast printing operation, and low failure rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

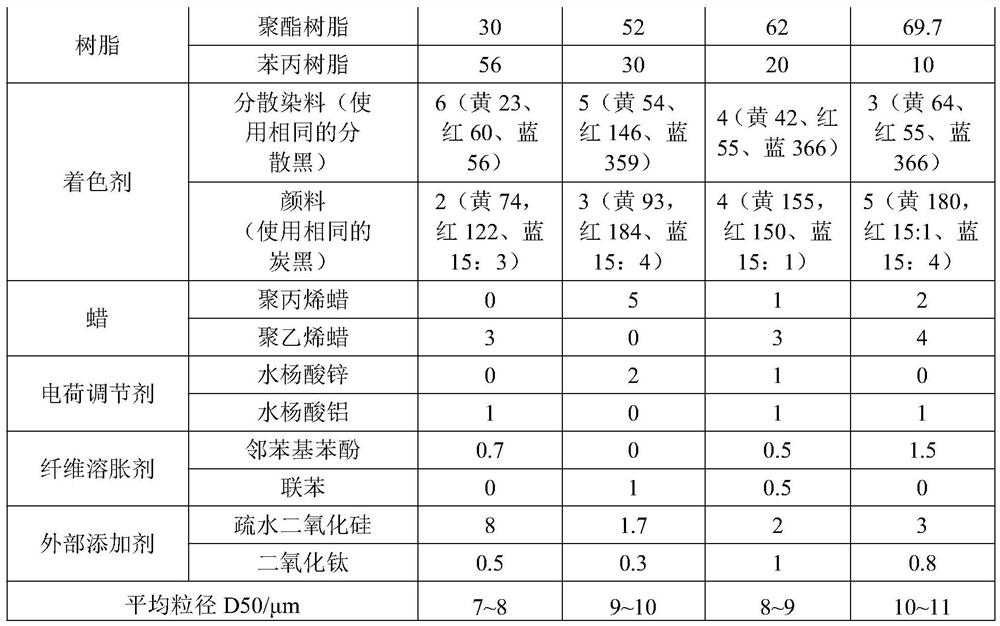

[0045] The preparation of black toner among the present invention comprises the steps:

[0046] (1) According to the formula ratio in Table 1, polyester resin, styrene-acrylic resin, disperse black, carbon black, wax, charge regulator, fiber swelling agent are mixed uniformly to form mixture A;

[0047] (2) After the mixture A is melted and mixed in a kneader (mixing temperature 100° C.), it is cooled and pressed into tablets to form flakes, and the flakes are then mechanically crushed to a particle size of 1 to 2 mm;

[0048] (3) The flakes that have been mechanically crushed enter the jet mill (pressure 0.9MPa, frequency 45Hz), ultra-fine crushing and grading system (speed 14000rpm, air volume 80Nm 3 / h), to obtain a graded product with a volume D50 of 7-8 μm;

[0049] (4) After mixing the graded product and the external additive, stirring for 10 min at a stirring rate of 30 m / s, a black toner was obtained.

[0050] Preparation of yellow, red and blue toner:

[0051] Usin...

Embodiment 2

[0058] The preparation of black toner among the present invention comprises the steps:

[0059] (1) According to the formula ratio in Table 1, polyester resin, styrene-acrylic resin, disperse black, carbon black, wax, charge regulator, fiber swelling agent are mixed uniformly to form mixture A;

[0060] (2) After the mixture A is melted and mixed in a kneader (mixing temperature 130° C.), it is cooled and pressed into tablets to form flakes, and the flakes are then mechanically crushed to a particle size of 1 to 2 mm;

[0061] (3) The mechanically crushed flakes enter the jet mill (pressure 0.7MPa, frequency 35Hz), ultra-fine crushing and grading system (speed 12000rpm, air volume 40Nm 3 / h), to obtain a graded product with a volume D50 of 9 to 10 μm;

[0062] (4) After mixing the classified product and the external additive, stirring was performed for 5 minutes at a stirring rate of 50 m / s to obtain a black toner.

[0063] Preparation of yellow, red and blue toner:

[0064...

Embodiment 3

[0071] The preparation of black toner among the present invention comprises the steps:

[0072] (1) According to the formula ratio in Table 1, polyester resin, styrene-acrylic resin, disperse black, carbon black, wax, charge regulator, fiber swelling agent are mixed uniformly to form mixture A;

[0073] (2) After the mixture A is melted and mixed in a kneader (mixing temperature 150° C.), it is cooled and pressed into tablets to form flakes, and the flakes are then mechanically crushed to a particle size of 1 to 2 mm;

[0074] (3) The mechanically crushed flakes enter the jet mill (pressure 0.8MPa, frequency 40Hz), ultra-fine crushing and grading system (speed 13000rpm, air volume 60Nm 3 / h), to obtain a graded product with a volume D50 of 8-9 μm;

[0075] (4) After mixing the classified product and the external additive, stirring was carried out for 8 minutes at a stirring rate of 40 m / s to obtain a black toner.

[0076] Preparation of yellow, red and blue toner:

[0077] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com