Slm direct writer

一种空间光调制器、照射方向的技术,应用在光刻领域,能够解决回转时间消耗宝贵时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

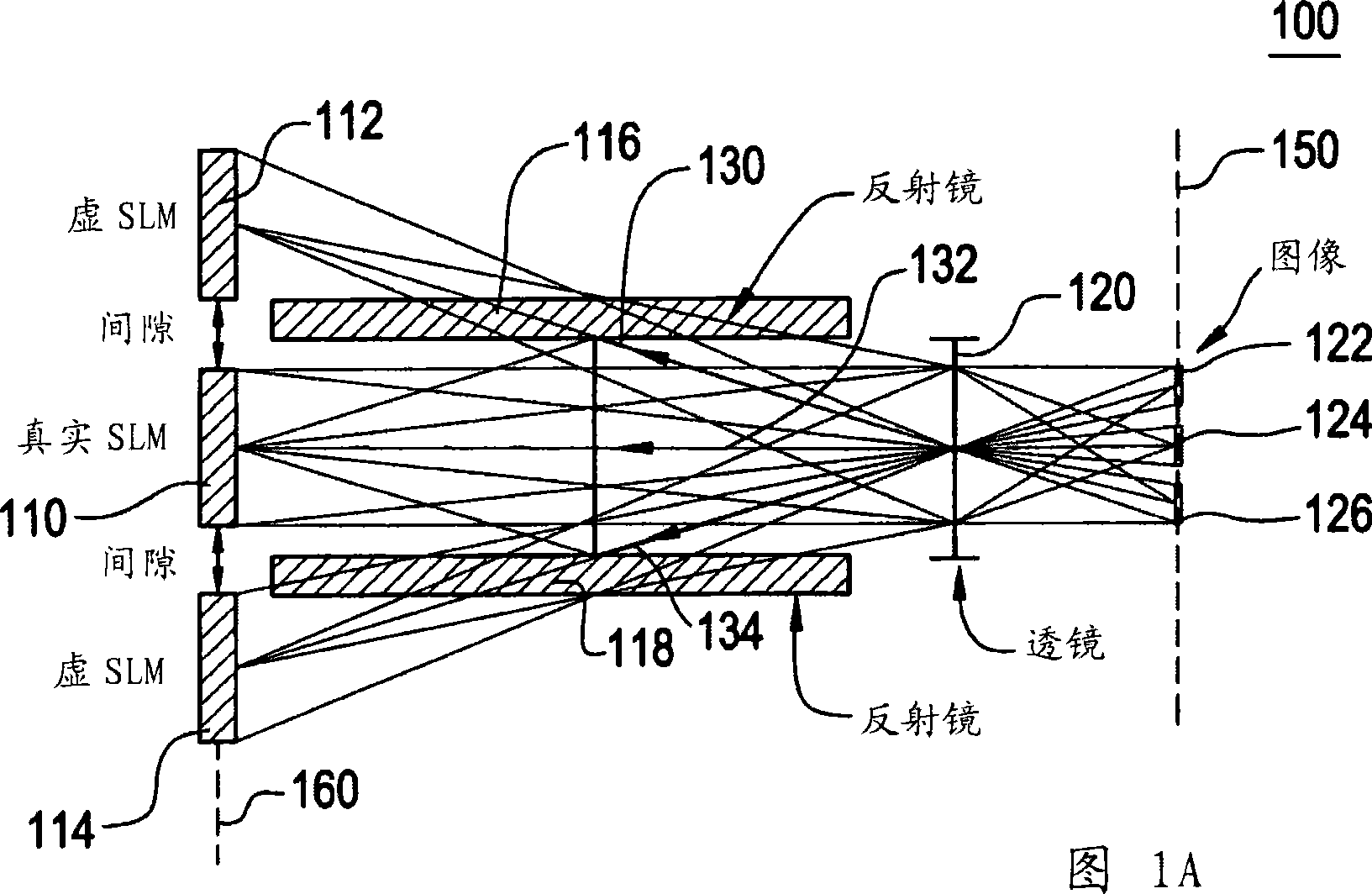

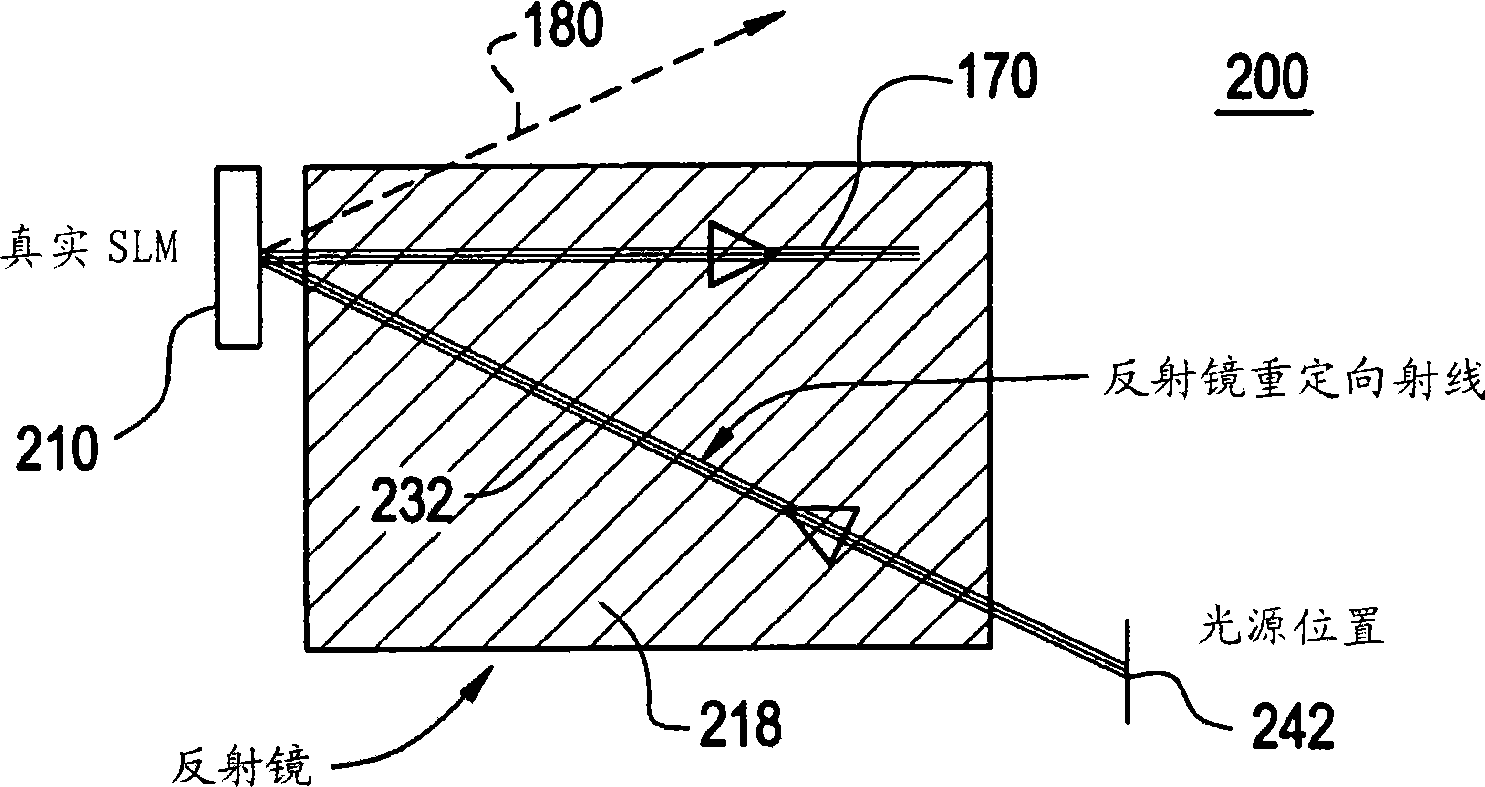

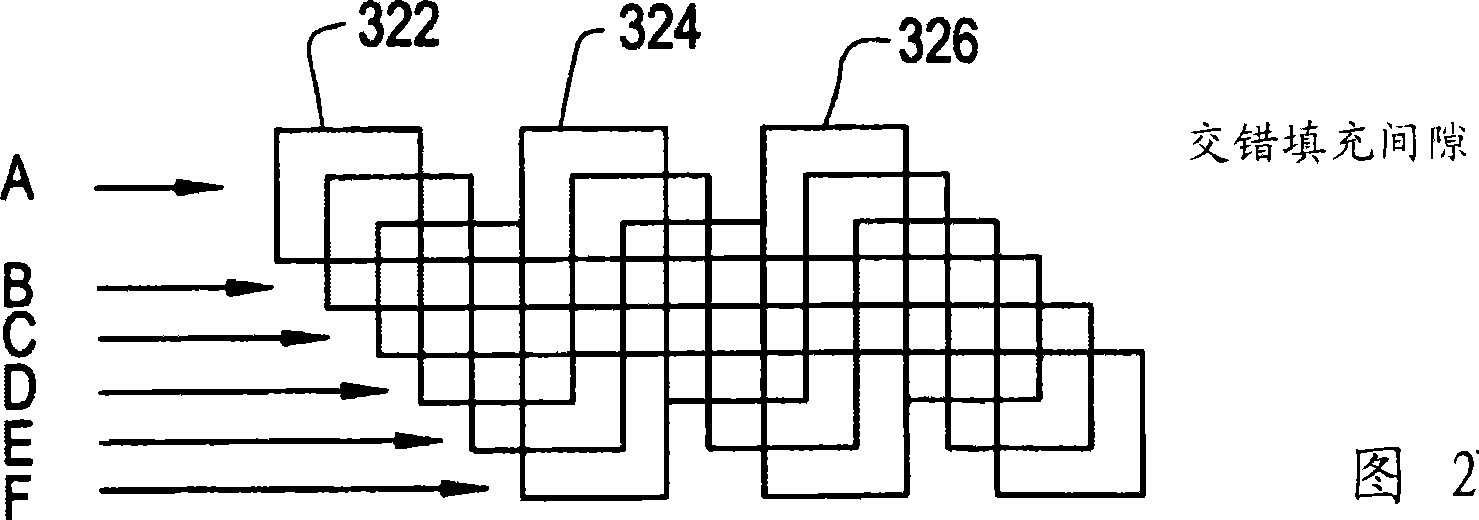

[0024] The following detailed description is made with reference to the accompanying drawings. The preferred embodiments are described to illustrate the invention, not to limit the scope of the invention, which is defined by the claims. Those skilled in the art will recognize many equivalent modifications from the following description.

[0025] Furthermore, the preferred embodiment is described with reference to an analog SLM, ie greater than or equal to one gray level between on and off. It will be clear to those skilled in the art that there are cases where other SLMs than analog SLMs are equally suitable; for example, digital SLMs like the Digital Micromirror Device (DMD) made by Texas Instruments. Still further, the preferred embodiment is described with reference to an excimer laser source. It should be clear to those skilled in the art that the method according to the present invention can use pulsed electromagnetic radiation sources other than excimer lasers, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com