Automatic component glue filling device of LED driver

A LED driver and glue filling technology, which is applied in the direction of surface coating liquid devices, semiconductor devices, electrical components, etc., can solve the problems of different glue flow filling rates, excess glue, overflow glue or less glue, and accelerate the glue in the LED driver. Problems such as flow filling rate to achieve the effect of improving the degree of automation, avoiding excess glue, and speeding up the rate of flow and bottom sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

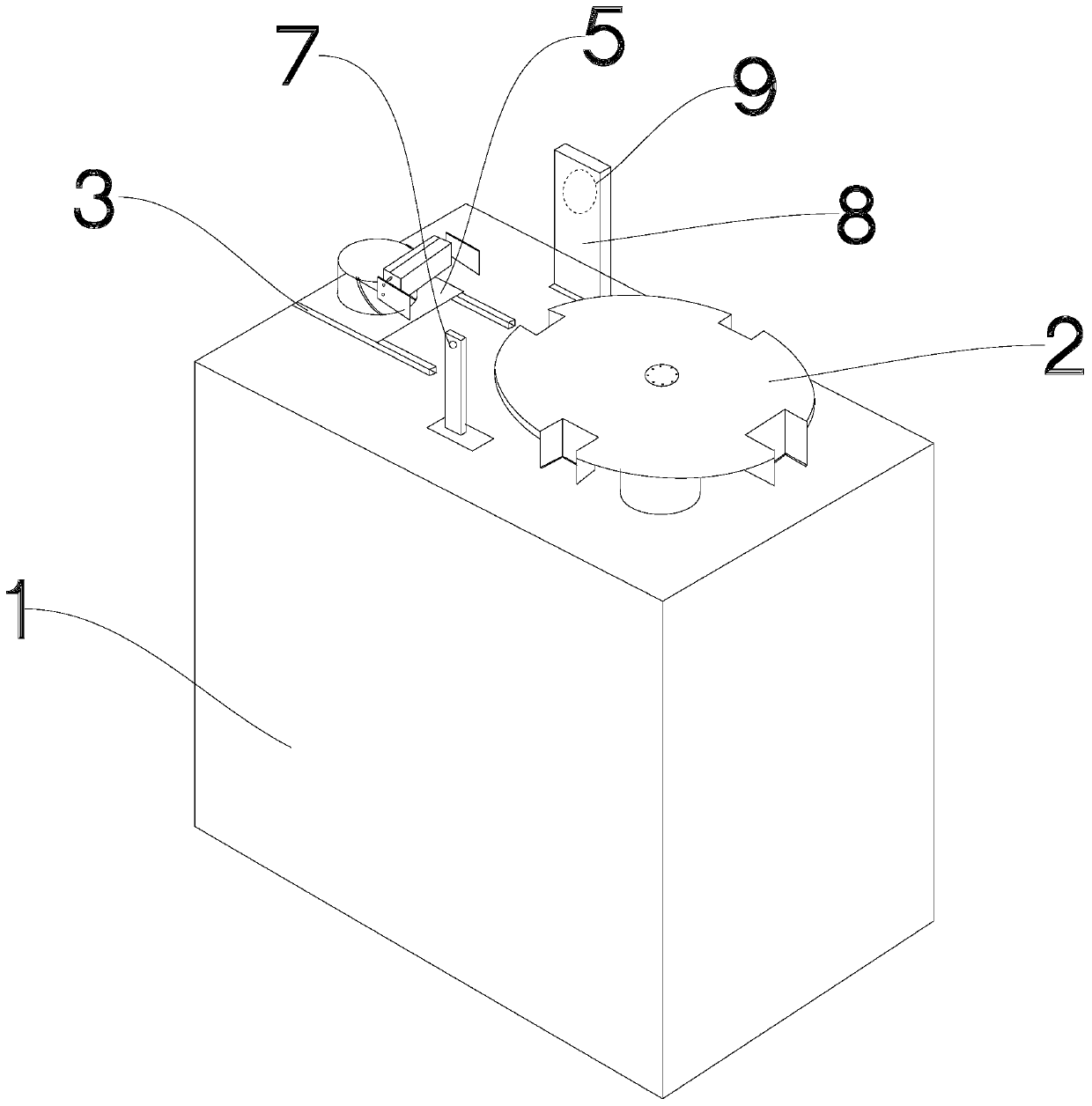

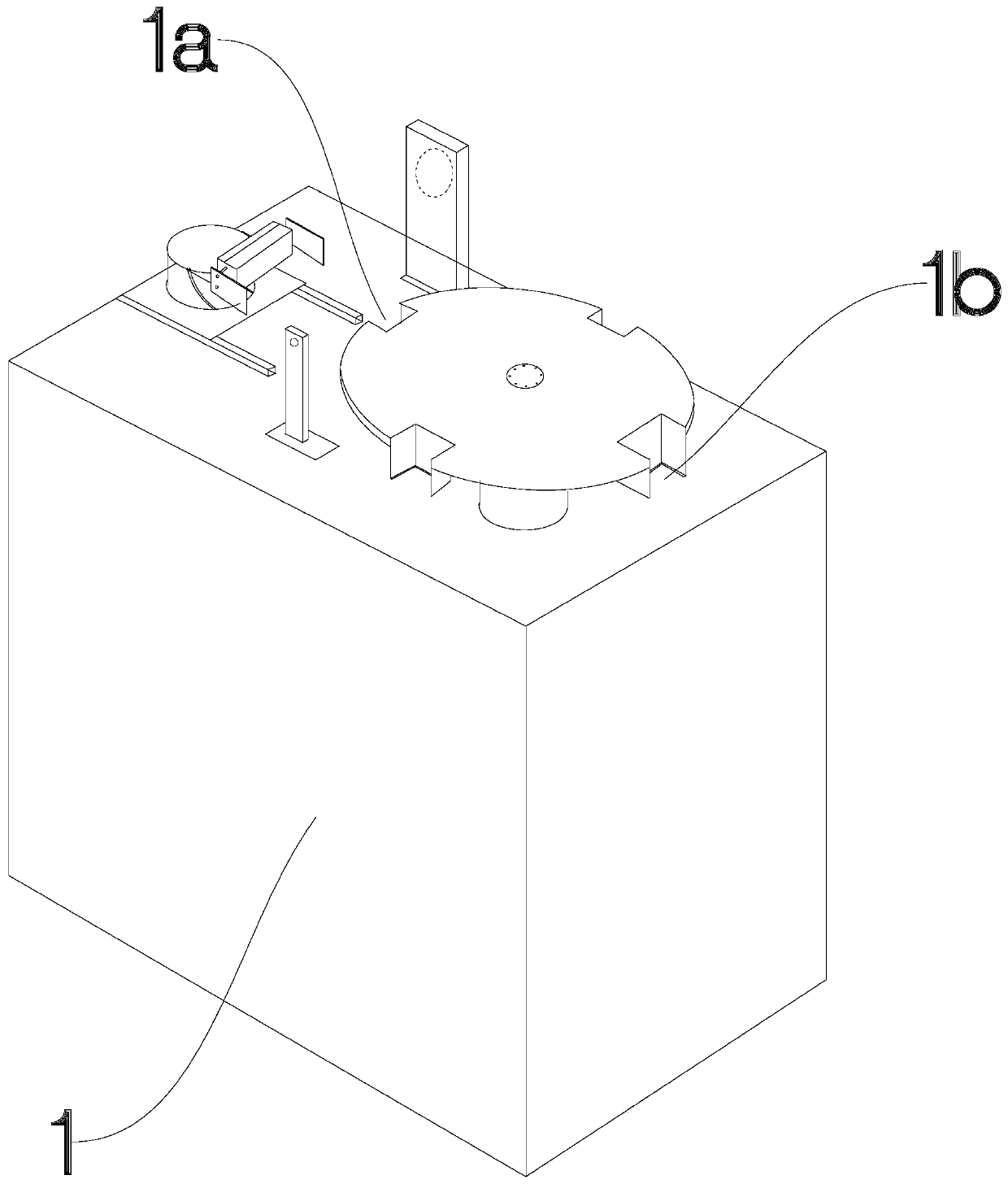

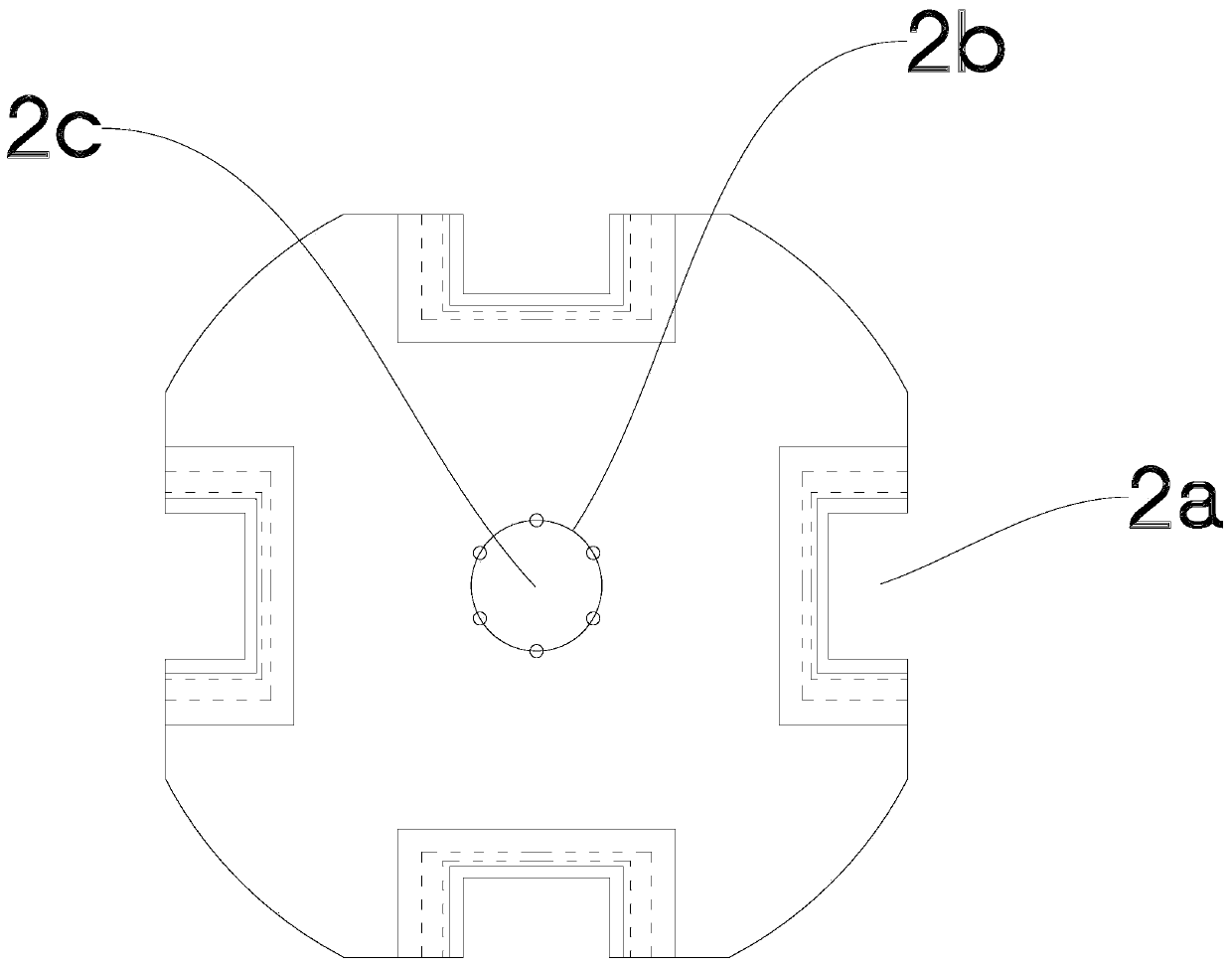

[0033] Such as Figure 1 to Figure 5 As shown, a component automatic glue filling device for LED drivers includes a workbench 1 on which an indexing turntable 2 is arranged. The radially symmetrical arrangement of the workbench is equipped with a linear movement module on the side close to the glue filling station. Driven by the power module, the linear movement module can move close to or away from the glue filling station. The linear movement module The upper part is provided with a vibration module 12 and a clamping module 13 for clamping the LED driver in sequence. The clamping module is located above the vibration module, and the indexing turntable is driven by the power module to drive the LED driver from loading and unloading. When the station turns to the glue filling station, the clamping module is driven by the linear movement module to approach the LED driver and clamp it. The liquid level detector on the side of the glue filling station monitors the liquid level o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com