Structure for raising highly reflective material LED light source luminous flux output

A technology of LED light source and luminous flux, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as affecting product quality, conductive vias overflowing, and achieve the effect of improving luminous flux output, improving quality, and preventing re-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

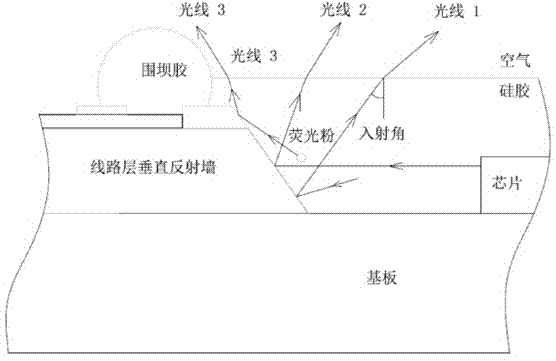

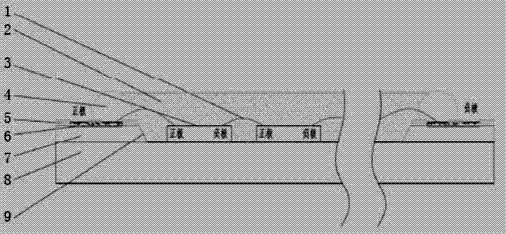

[0018] A structure for improving the luminous flux output of a highly reflective material LED light source, the structure comprising: a substrate 8; a circuit layer on the substrate 8; a GaN LED chip array 3 on the substrate 8; and between the GaN LED chip arrays 3, And there is a fluorescent powder silica gel layer 2 between the GaN LED chip array 3 and the wiring layer. The fluorescent powder silica gel layer 2 and the circuit layer are adjacent to the dam glue 4 . Wherein, the wiring layer includes the front wiring layer 5 on the upper surface of the substrate 8, the back wiring layer 7 on the lower surface of the substrate 8, and the inside of the conductive via hole on the substrate 8, and connects the front wiring layer 5 and the back wiring layer. The circuit layer 7 is electrically connected to the connection circuit layer 6, and the connection circuit layer 6 on the inner wall of the conductive via hole is filled with a plug, and the plug is preferably a rosin plug. ...

Embodiment 2

[0022] On the basis of the first embodiment, the front circuit layer 5 is a GBL circuit layer, and the back circuit layer 7 is a GBL circuit layer, and the thickness of the GBL circuit layer is 0.05mm larger than that of the GBL circuit layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com