A method for making a highly weather-resistant and fragile label material

A technology for label materials and manufacturing methods, which is applied to film/sheet adhesives, identification devices, film/sheet release coatings, etc., and can solve problems such as poor aging resistance and poor fragility of PVC fragile labels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

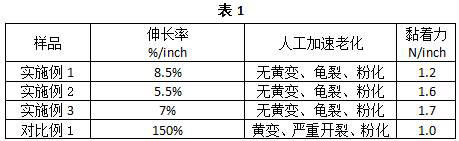

Examples

Embodiment 1

[0064] A method for making a highly weather-resistant and fragile label material, comprising the following steps:

[0065] Q1: Select a non-corona-treated PET substrate with a thickness of 36 μm, apply a weather-resistant layer coating on the surface of the PET substrate, place it at a temperature of 70 ° C for 2 minutes, and then dry it at 100 ° C for 3 minutes Form weather-resistant layer, make composite membrane A and wind up;

[0066] Q2: Coat the color layer paint on the surface of the weather-resistant layer of composite film A, place it in an environment with a temperature of 60°C to dry for 3 minutes, and then dry it in an environment with a temperature of 100°C for 3 minutes to form a color layer to obtain a composite film B and winding;

[0067] Q3: Form a covering layer on the surface of the colored layer of the composite film B, make a composite film C and wind it up;

[0068] Q4: Coat the pressure-sensitive adhesive layer paint on the grid-shaped release paper o...

Embodiment 2

[0109] A method for manufacturing a highly weather-resistant and fragile label material, comprising the following steps:

[0110] Q1: Select a non-corona-treated PET substrate with a thickness of 100 μm, apply a weather-resistant layer coating on the surface of the PET substrate, place it at 100°C for 3 minutes, and then dry it at 150°C for 5 minutes Form weather-resistant layer, make composite membrane A and wind up;

[0111] Q2: Coat the color layer paint on the surface of the weather-resistant layer of the composite film A, place it in an environment with a temperature of 100°C to dry for 5 minutes, and then dry it in an environment with a temperature of 150°C for 6 minutes to form a color layer to obtain a composite film B and winding;

[0112] Q3: Form a covering layer on the surface of the colored layer of the composite film B, make a composite film C and wind it up;

[0113] Q4: Coat the pressure-sensitive adhesive layer paint on the grid-like release paper or release...

Embodiment 3

[0154] A method for making a highly weather-resistant and fragile label material, comprising the following steps:

[0155] Q1: Select a non-corona-treated PET substrate with a thickness of 70 μm, apply a weather-resistant layer coating on the surface of the PET substrate, place it at a temperature of 85°C for 2.5 minutes, and then dry it at 125°C for 4 minutes Form weather-resistant layer, make composite membrane A and wind up;

[0156] Q2: Coat the color layer paint on the surface of the weather-resistant layer of the composite film A, place it in an environment with a temperature of 80°C to dry for 4 minutes, and then dry it in an environment with a temperature of 125°C for 4.5 minutes to form a color layer to obtain a composite film B and winding;

[0157] Q3: Form a covering layer on the surface of the colored layer of the composite film B, make a composite film C and wind it up;

[0158] Q4: Coat the pressure-sensitive adhesive layer coating on the grid-shaped release p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com