Manufacturing method and system of efficient heat dissipation PCB and PCB

A manufacturing method and high-efficiency technology, applied in the directions of multilayer circuit manufacturing, printed circuit manufacturing, circuit heating device, etc., can solve the problems of high manufacturing cost, high process difficulty, inability to meet high-efficiency and high-quality heat dissipation requirements, and reduce The effect of process cost and process difficulty, good planarity, and efficient heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

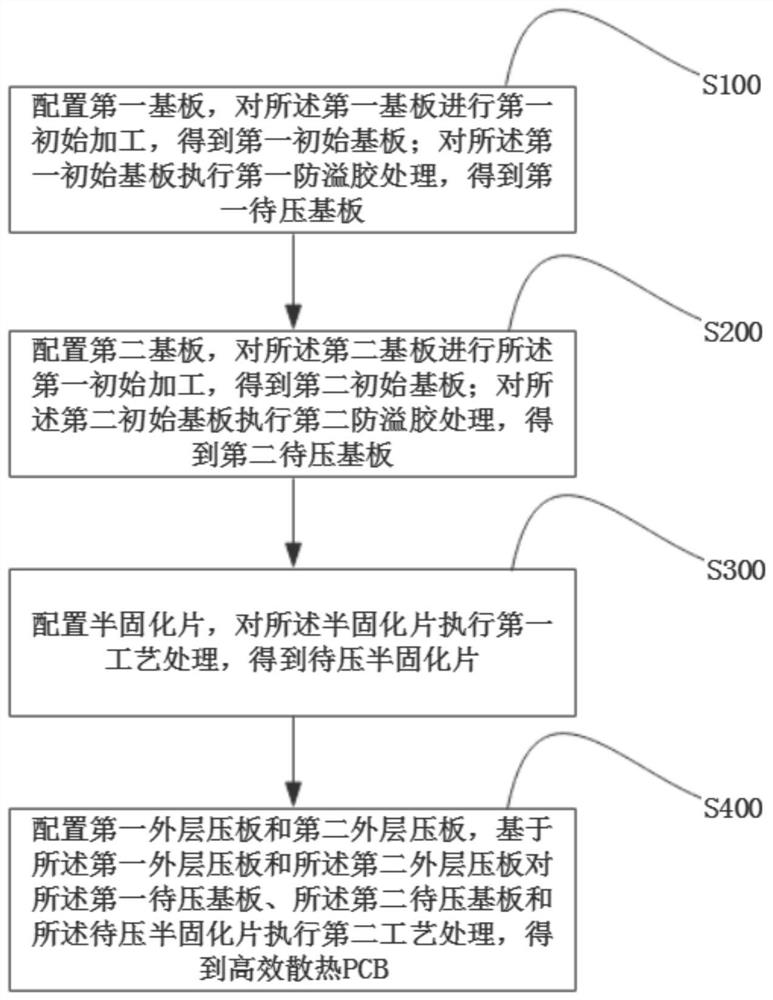

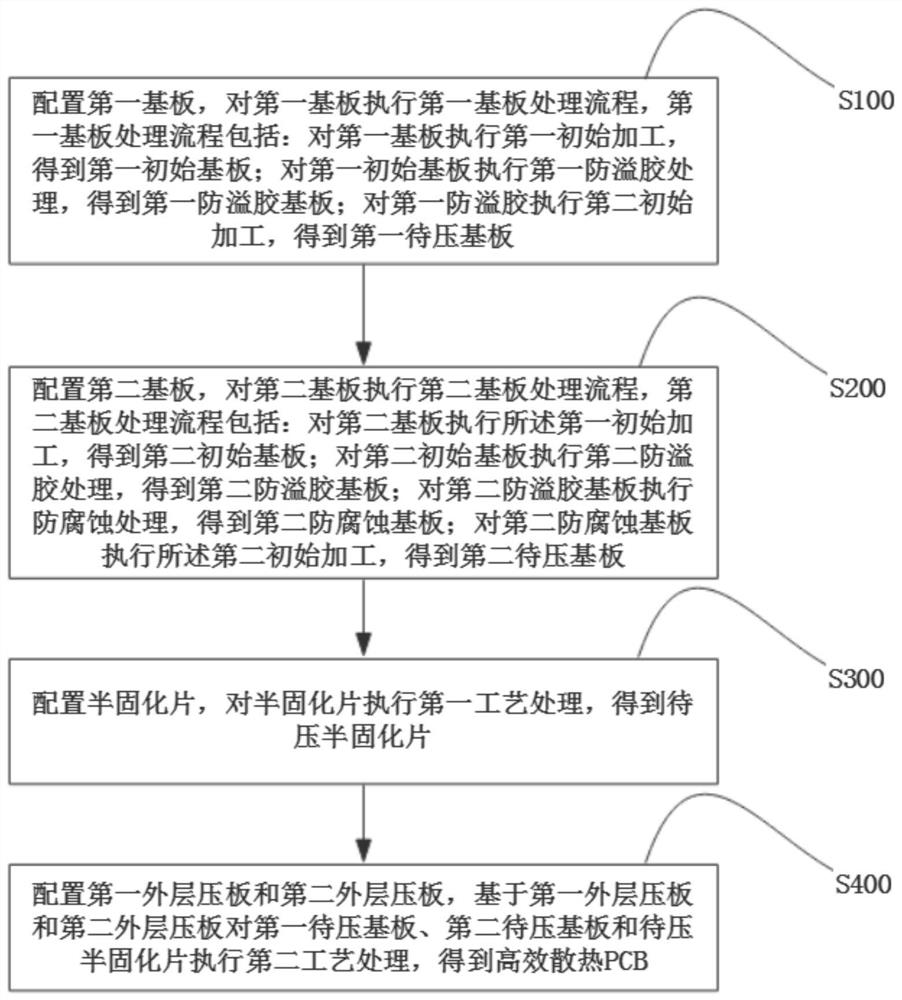

[0069] This embodiment provides a method for manufacturing a high-efficiency heat dissipation PCB, such as Figure 1 to Figure 3 shown, including the following steps:

[0070] This embodiment is applied to the manufacturing process of PCB. When the existing PCB is manufactured, considering the problem of heat dissipation, buried copper block technology and blind groove design will be adopted. The use of these two technologies alone will have a certain adverse effect on the use of PCB. , the manufacturing method of high-efficiency heat dissipation PCB described in this embodiment combines these two technologies, and through the unique process technology involved in this method, the problems existing in the prior art are solved:

[0071] S100. Configure the first substrate, and perform a first substrate processing procedure on the first substrate. The first substrate processing procedure includes: performing a first initial processing on the first substrate to obtain a first ini...

Embodiment 2

[0106] This embodiment provides a manufacturing system for efficient heat dissipation PCB, such as Figure 4 and Figure 5 shown, including:

[0107] The first substrate processing module, the second substrate processing module, the prepreg processing module and the pressing processing module;

[0108] The first substrate processing module is configured to configure the first substrate, and execute the first substrate processing process on the first substrate to obtain the first substrate to be pressed, and the first substrate processing module sends the first substrate to be pressed to the pressing processing module;

[0109] Specifically, the operation of the first substrate processing module includes:

[0110] The first substrate processing module executes the first substrate processing process: the first substrate processing module sets the first size according to the server specification, and performs cutting processing on the first substrate according to the first size...

Embodiment 3

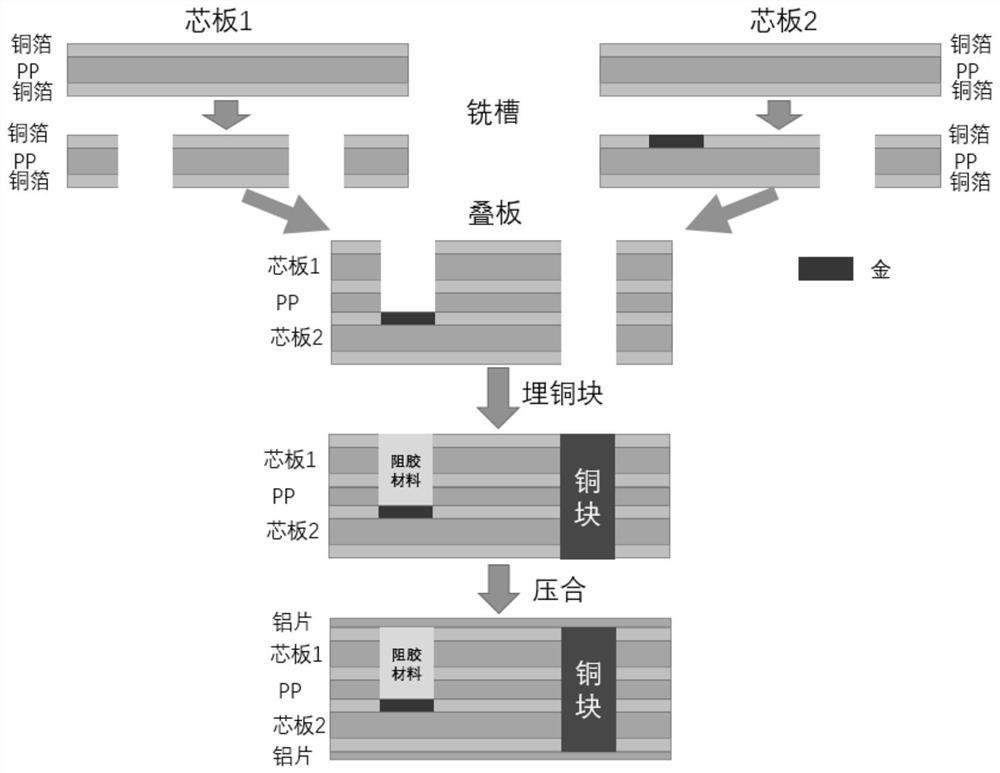

[0125] This embodiment provides a high-efficiency heat dissipation PCB, such as Figure 6 As shown, it includes: a first substrate, a second substrate, a prepreg, a first outer laminate and a second outer laminate;

[0126] The first outer laminate, the first substrate, the prepreg, the second substrate and the second outer laminate are sequentially pressed together; a copper block groove is provided between the first outer laminate and the second outer laminate, and a copper block groove is provided in the copper groove A copper block; a blind groove is provided between the first outer laminate and the second substrate, and a glue-resisting material is arranged in the blind groove; a metal material is plated between the bottom of the glue-resistant material and the bottom of the blind groove;

[0127] In this embodiment, the metal material is gold, the first outer laminate and the second outer laminate are aluminum sheets, the first substrate and the second substrate are both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com