Semiconductor device and method of manufacturing the same

A semiconductor and device technology, applied in the field of semiconductor devices and their manufacturing, can solve the problems of increased cost, increased number of semiconductor device components, design changes, increased number of assembly steps, etc., and achieve the effect of improved manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

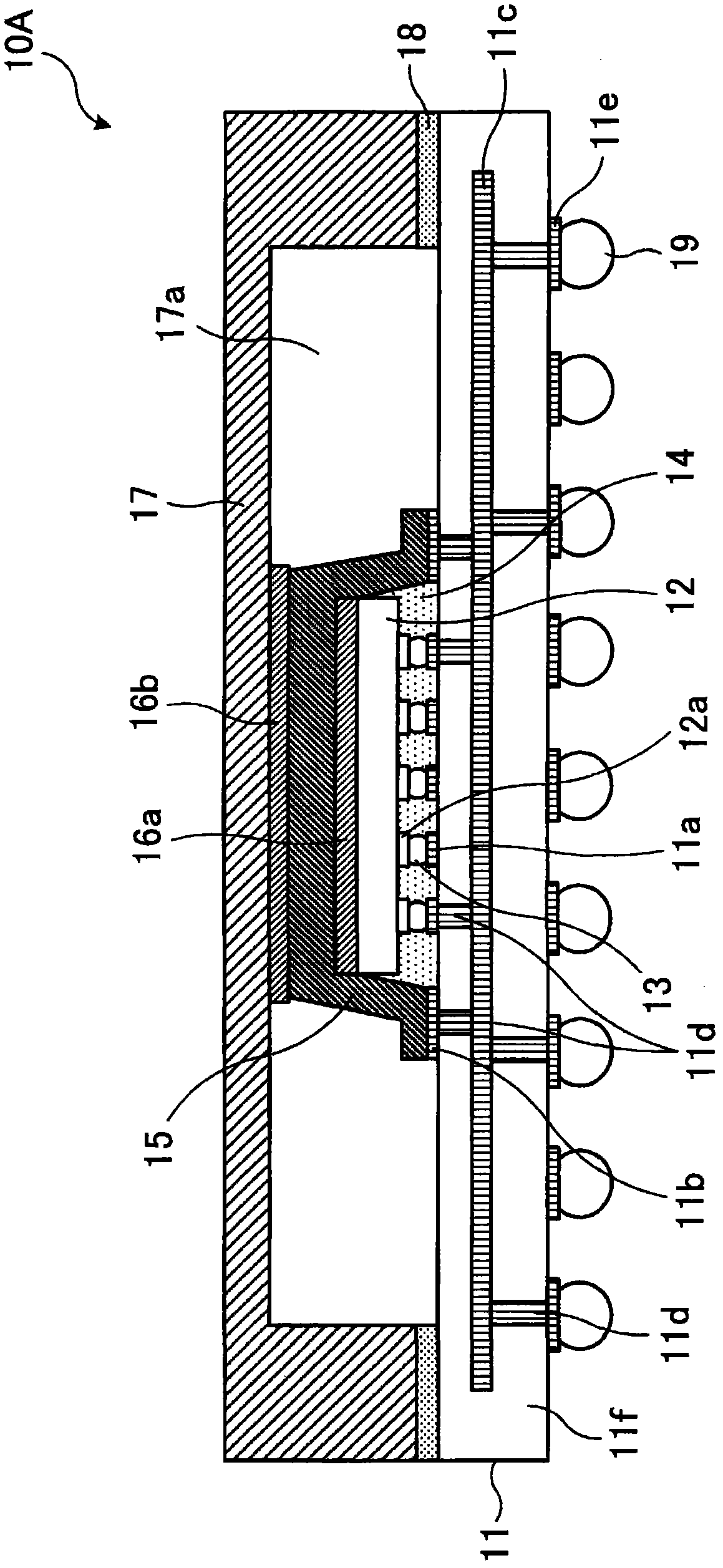

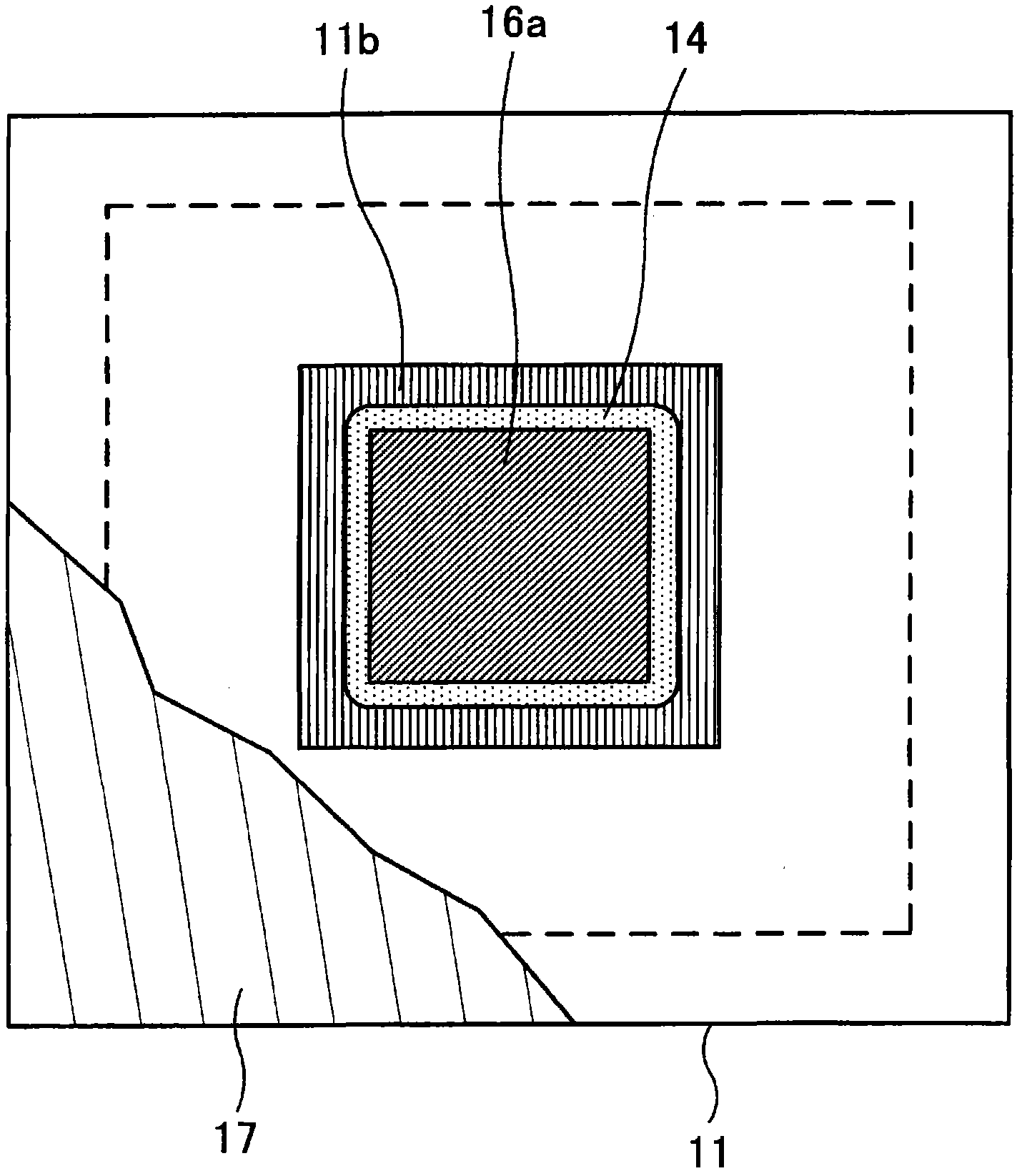

[0040] A first embodiment will now be described. figure 1 An example semiconductor device according to the first embodiment is shown.

[0041] A semiconductor device 10A according to the first embodiment includes a substrate (wiring board) 11 and semiconductor elements (semiconductor chips) 12 arranged on the substrate 11 .

[0042] The substrate 11 has an electrode portion (substrate electrode pad) 11 a arranged on a surface opposite to the semiconductor element 12 . The substrate electrode pad 11a is electrically connected to an internal wiring 11c at a ground (GND) potential and a signal line (not shown) arranged inside the substrate 11 through a via 11d.

[0043] The semiconductor element 12 has an electrode portion (chip electrode pad) 12a arranged on a surface opposite to the substrate 11 at a position corresponding to the substrate electrode pad 11a. The semiconductor element 12 is mounted (flip-chip mounted) on the substrate 11 via the chip electrode pad 12a connecte...

no. 2 example

[0105] A second embodiment will now be described. Figure 14A and Figure 14B An example semiconductor device according to the second embodiment is shown. Figure 14A is along Figure 14B A schematic cross-sectional view taken along the midline L8-L8, Figure 14B is a schematic floor plan.

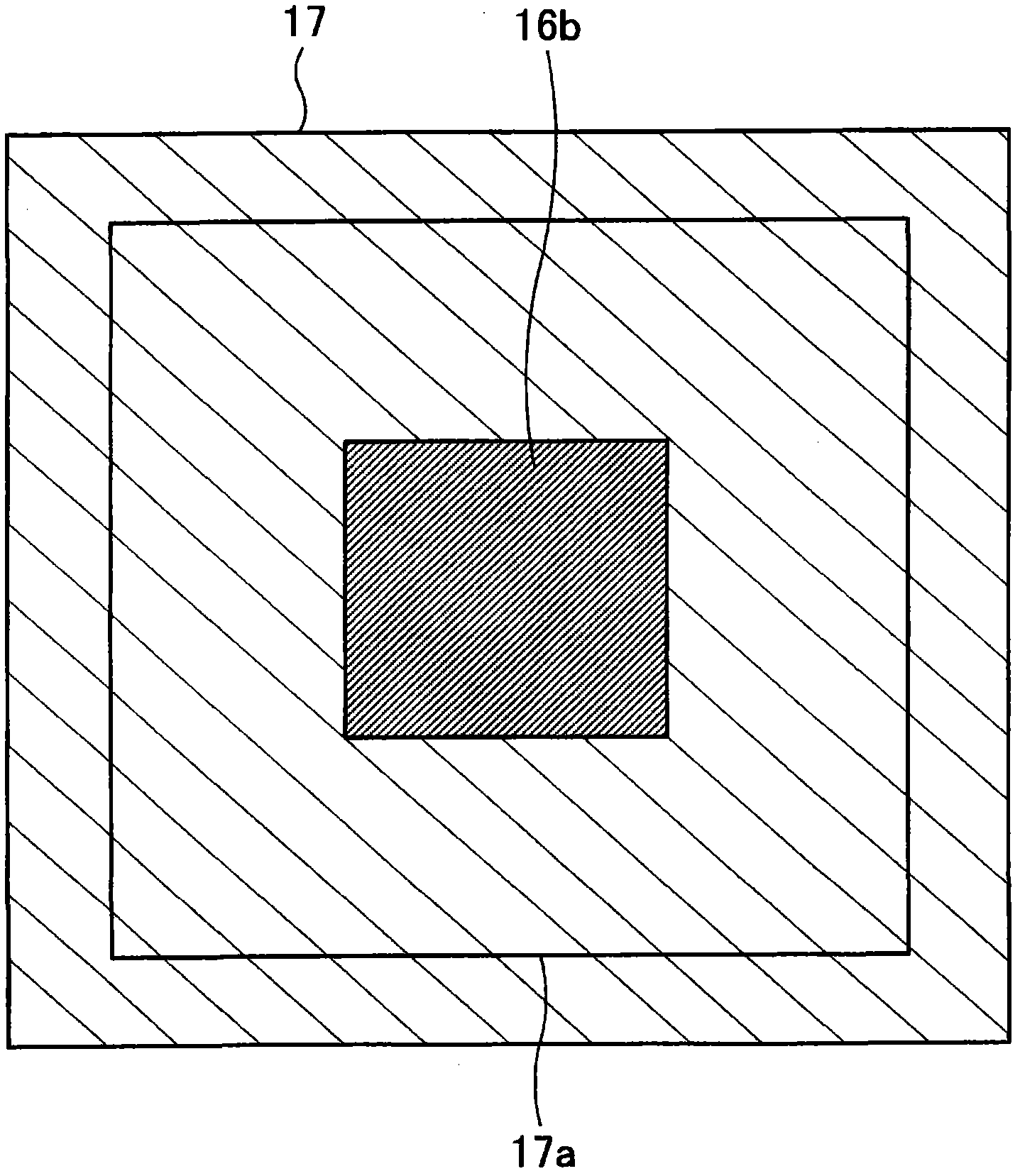

[0106] A semiconductor device 10B according to the second embodiment differs from the semiconductor device 10A according to the first embodiment in that the semiconductor device 10B includes a small-sized substrate 11 and a small-sized plate-shaped radiator 17 .

[0107] In the semiconductor device 10B, unlike the semiconductor device 10A according to the first embodiment, the heat sink 17 does not need to have a structure surrounding the periphery of the semiconductor element 12 and to be connected to the substrate 11 , that is, the concave portion 17 a. Due to the use of such a small plate-shaped heat sink 17, the substrate 11 does not need to have an area to which the heat sink 17 i...

no. 3 example

[0113] A third embodiment will now be described. Figure 15A and Figure 15B An example semiconductor device according to the third embodiment is shown. Figure 15A is along Figure 15B A schematic cross-sectional view taken along the midline L9-L9, Figure 15B is a schematic floor plan.

[0114] A semiconductor device 10C according to the third embodiment differs from the semiconductor device 10B according to the second embodiment in that the semiconductor device 10C includes a heat conduction member 15 having an opening 15c. The opening 15 c of the heat conduction member 15 can be used for application of an underfill resin 14 (described later).

[0115] A method of forming the semiconductor device 10C including the heat conduction member 15 having the opening 15c will now be described.

[0116] Figure 16A and Figure 16B Example substrate preparation steps according to the third embodiment are shown. Figure 16A is along Figure 16B A schematic cross-sectional view t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com