Patents

Literature

66results about How to "No glue overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die-cutting waste discharge device with inner frame die-cutting piece and die-cutting waste discharge method

InactiveCN106541449AGood waste discharge effectThe waste disposal process went smoothlyMetal working apparatusTectorial membranePunching

The invention relates to a die-cutting waste discharge device with an inner frame die-cutting piece and a die-cutting waste discharge method. The die-cutting waste discharge device comprises a first opposite-pressing roller, first-stamping die-cutting cutters, first waste discharge rollers, a second opposite-pressing mechanism, second-stamping die-cutting cutters and second waste discharge rollers which are arranged sequentially. The first opposite-pressing roller attaches a first single face gummed protective film to a first release film; indent inner frames are punched in first stamping by the first-stamping die-cutting cutters; the first waste discharge rollers is used to take up the first single face gummed protective films attached to wastes of the inner frames after the first-stamping punching; the second opposite-pressing mechanism attaches a second single face gummed protective film to the non-release surface of the first release film, and sequentially attaches double faced adhesive tape and a second release film to the release surface of the first release film; normal inner frames are punched in second-stamping by the second-stamping die-cutting cutters; the second waste discharge rollers are used to take up the second single face gummed protective films attached to wastes of the inner frames after the second-stamping punching; and the size of each normal inner frame is bigger than the size of each indent inner frame. Compared with the prior art, the die-cutting waste discharge device has the advantages that the effect of waste discharge is good, the product has no deformation, and efficiency is high.

Owner:YUANRANG IND SHANGHAI

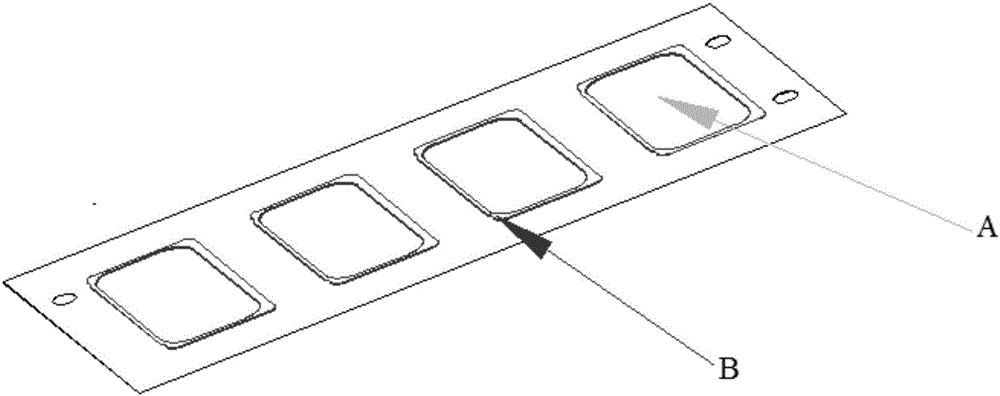

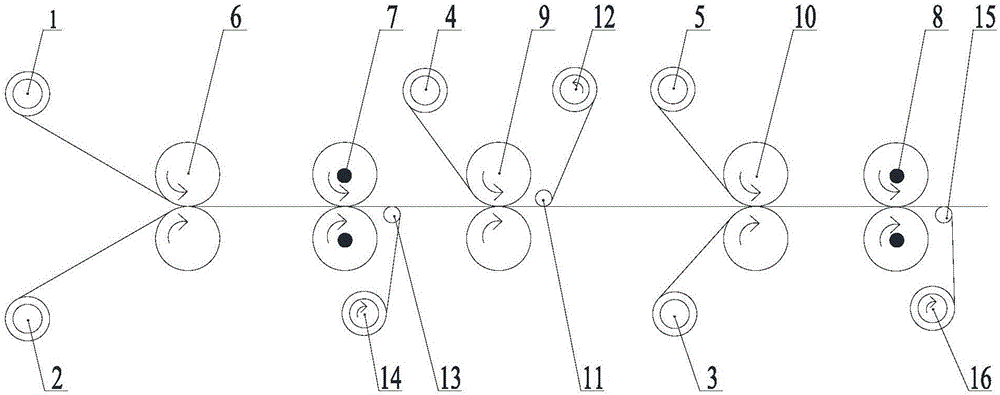

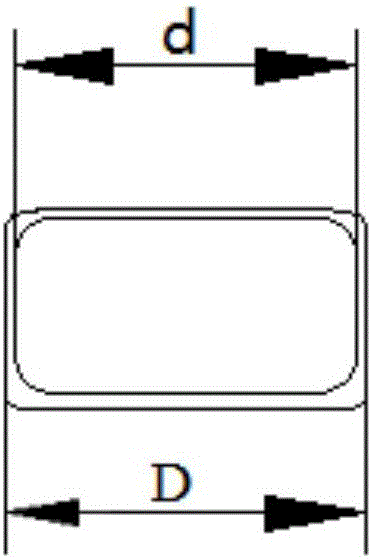

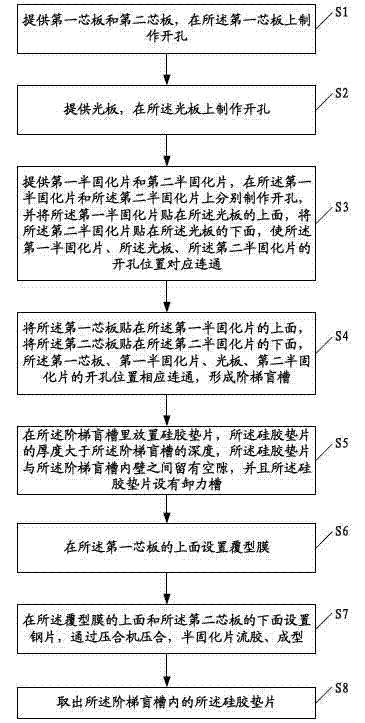

Machining method of printed circuit board (PCB) of step blind slot

ActiveCN102769996ANo glue overflowGood glue resistancePrinted circuit manufactureBlock effectSilica gel

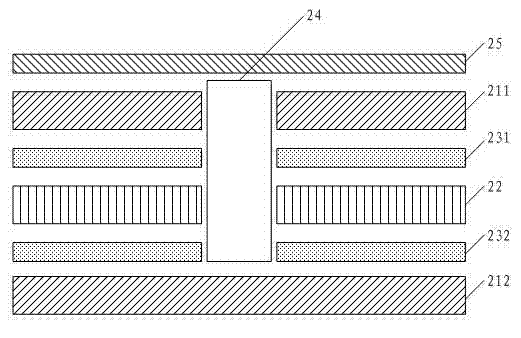

The invention discloses a machining method of a printed circuit board (PCB) of a step blind slot. The method includes that a first core board and a second core board are provided, and holes are arranged on the first core plate; a light panel is provided and holes are arranged on the light panel; a first semi-curing plate and a second semi-curing plate are provided, holes are arranged on the semi-curing plates, and the first semi-curing plate and the second semi-curing plate are attached to the upper surface and the lower surface of the light panel respectively; the core plates are arranged on the outer lateral sides of the semi-curing plates, and the holes of the first core plate, the first semi-curing plate, the light panel and the second semi-curing plate form the step blind slot; a silica gel gasket is placed in the step blind slot, the thickness of the silica gel gasket is larger than the depth of the step blind slot, a gap is reserved between the silica gel gasket and an inner wall of the step blind slot, and the silica gel gasket is provided with a relief groove; a film is arranged on the upper face of the first core plate; a steel plate is arranged on the upper face and the lower face of a lamination and pressed through a press machine, glue of the semi-curing plates flows, and the semi-curing plates are molded; and the silica gel gasket in the step blind slot is taken out. By means of an embodiment of the machining method, glue blocking effect is good and seam abnormality of the blind slot is effective reduced.

Owner:GCI SCI & TECH

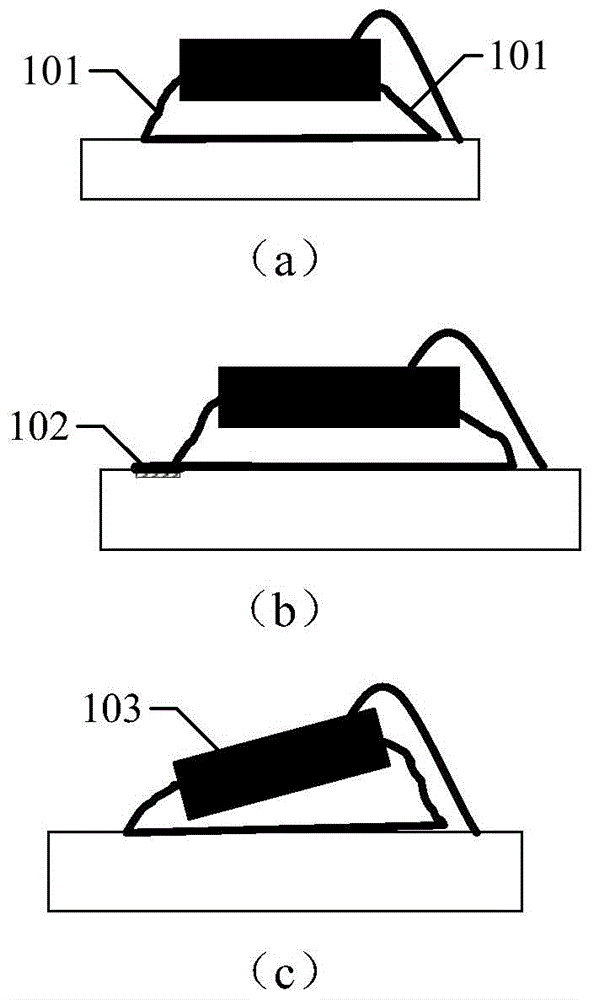

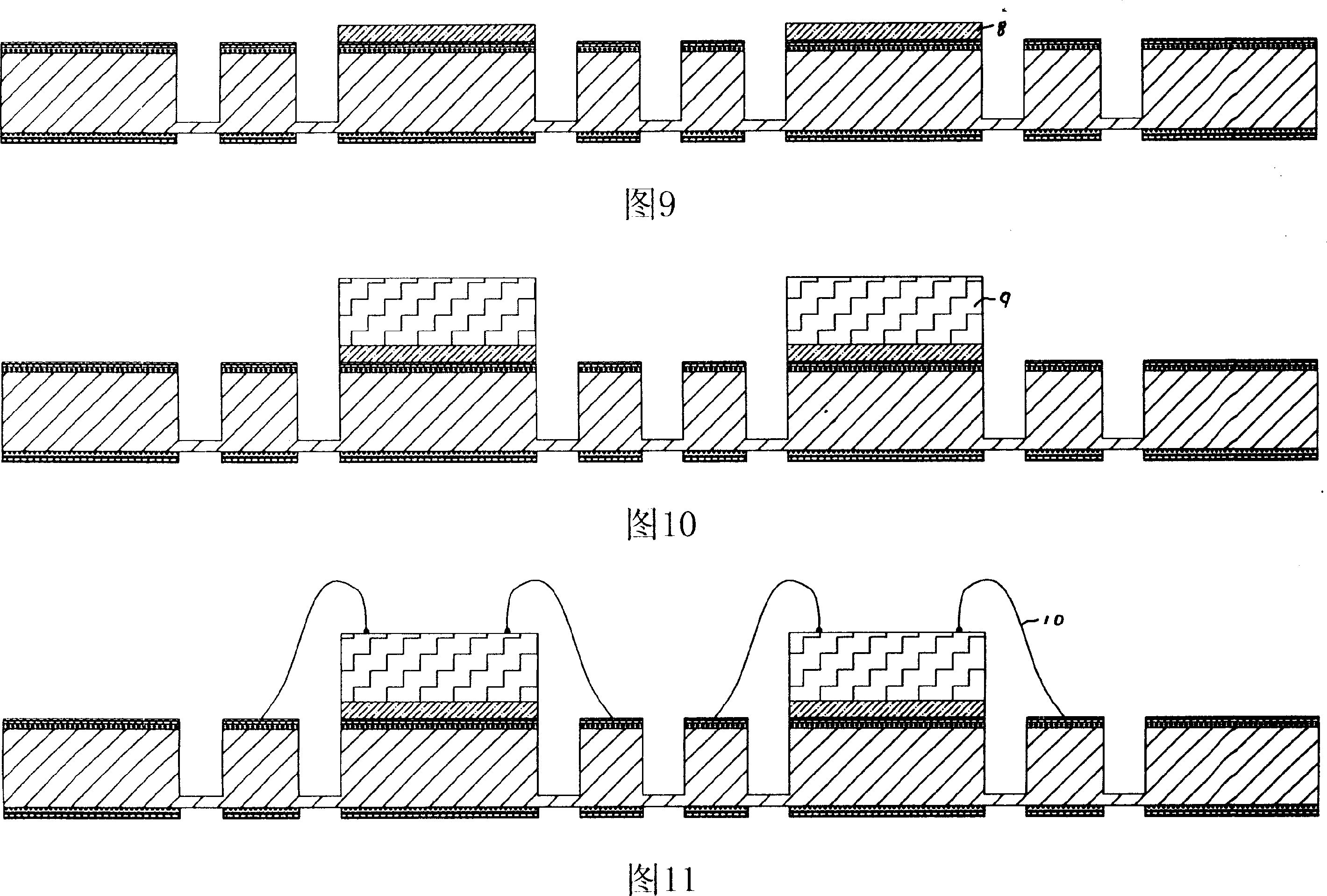

Plane button type packing technology of integrated circuit or discrete component and its packing structure

ActiveCN1725460ASmooth productionImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuitEngineering

This invention relates to a plane salient point encapsulation technology and its structure of IC or discrete components, among which, the technology includes: taking a base plate, dry-film layers are pasted to the front and back side of the base plate, removing part of the upper layer for the preparation of forming a basic island and pins, plating metal layers on the front, removing the rest dry film on the upper layer of the base plate, semi-etching it, removing the dry film on the back, implanting the chip, wiring, packaging with plastic capsule, pasting a dry film on the back of the base plate again, etching the dry film at the back and the rest of the metal of the semi-etched zone again so as to enable the back of the basic island and the pin projecting over the plastic capsule, removing the rest dry film, plating metal layers on the surface, pasting film on the front of the plastic capsule then cutting.

Owner:长电科技管理有限公司

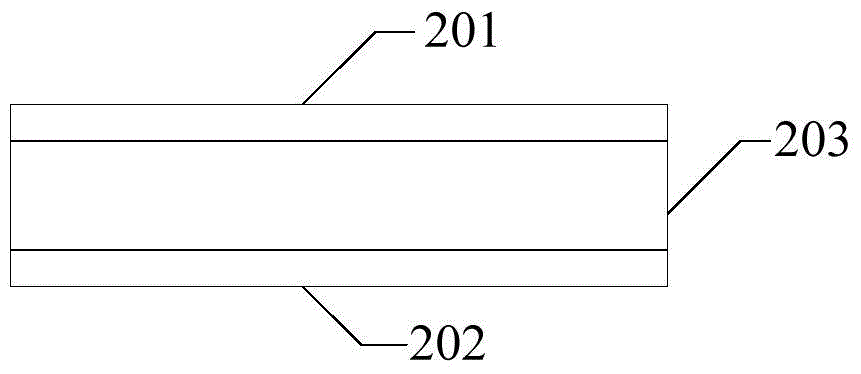

Conductive die bond glue solution, conductive die bond glue film, preparation methods and applications

ActiveCN104804687AGood workmanshipSimple processFilm/foil adhesivesNon-conductive material with dispersed conductive materialChemistryConductive materials

The invention discloses a conductive die bond glue solution which comprises components in parts by weight as follows: 2-10 parts of CTBN (carboxy-terminated butadiene nitrile liquid rubber) modified epoxy resin, 5-10 parts of a diluent, 2-10 parts of thermoplastic resin, 2-5 parts of a curing agent, 1-2 parts of a coupling agent and 70-90 parts of a conductive material. The invention further discloses a preparation method of the conductive die bond glue solution, an application of the conductive die bond glue solution in chip packaging, a conductive die bond glue film, a preparation method of the conductive die bond glue film and an application of the conductive die bond glue film in the chip packaging. The conductive die bond glue solution and the conductive die bond glue film prepared from the conductive die bond glue solution have excellent performance, avoid glue overflowing during application, have good manufacturability and can realize packaging of thinner and smaller chips. The processes for preparing the conductive die bond glue solution and the conductive die bond glue film with the methods are simple and easy.

Owner:深圳广恒威科技有限公司

Thermosetting rubber film for flexible circuit assembly and its preparing method

InactiveCN1580171AFast curingHigh peel strengthEpoxy resin adhesivesConjugated diene hydrocarbon adhesivesEpoxyPolymer science

It is about hot set rubber film for flexibility circuit assemblage and its preparation methods. This -can be used in ---circuit construction. It is made from epoxy resin, butadiene acrylonitrile rubber toughening agent, fixing tanning agents of imidazole derivates and solvent by form them into liquid cement and application. The binding strength and tenacity can be advanced by the combination of epoxy resin. The curing speed in the high temperature can be improved by the complex fixing tanning agents of aromatic polyamines and imidazole derivates. The whole process can finish within decades of seconds in temperature of 180 degree. So it is propitious to snap couple flexible electric. Compared with the exiting technique, the invention can keep the film of rubber stable in normal temperature and can fast set in high temperature and hot pressing without excessive glue and uncover.

Owner:SHENZHEN DANBOND TECH

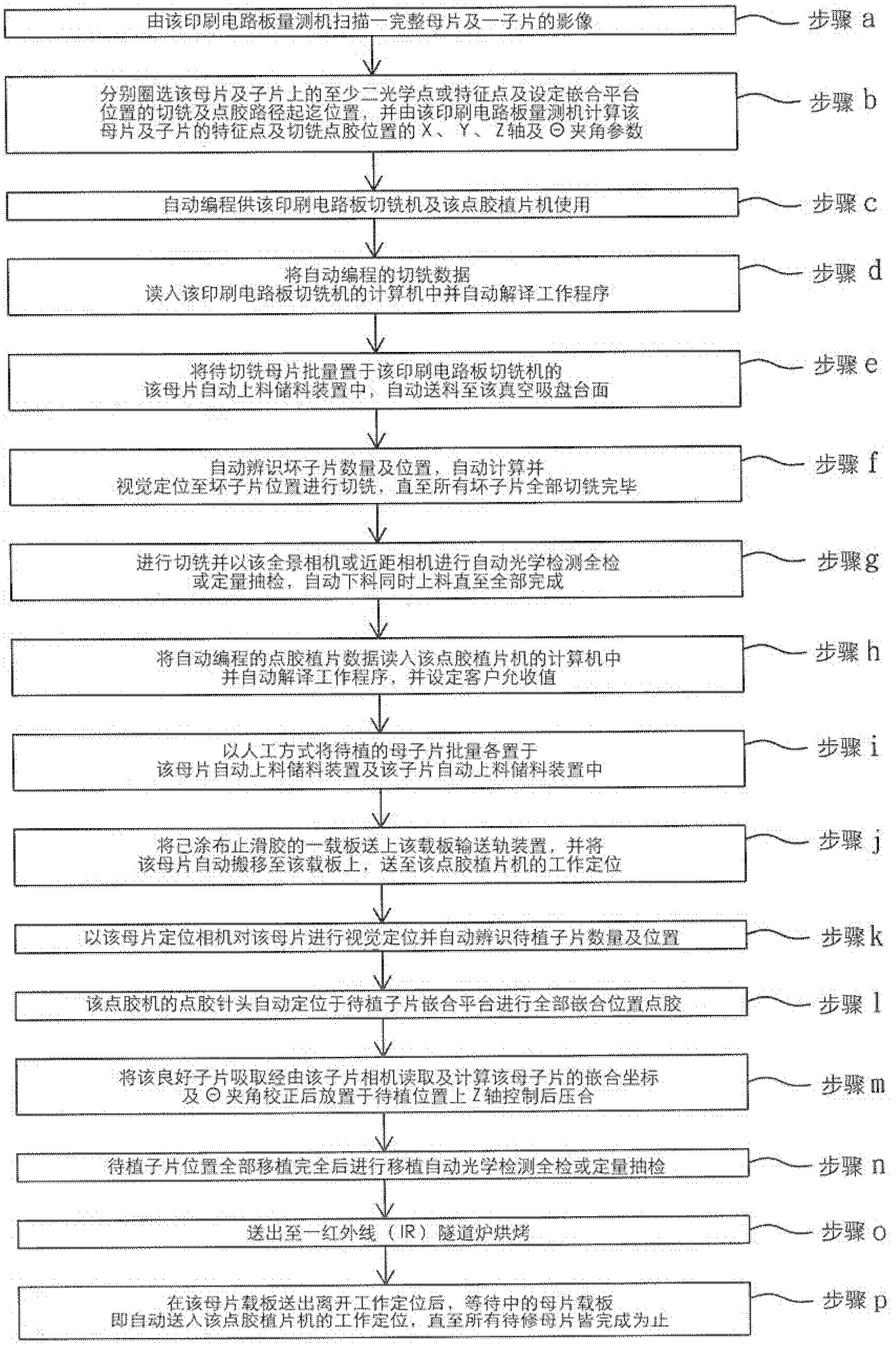

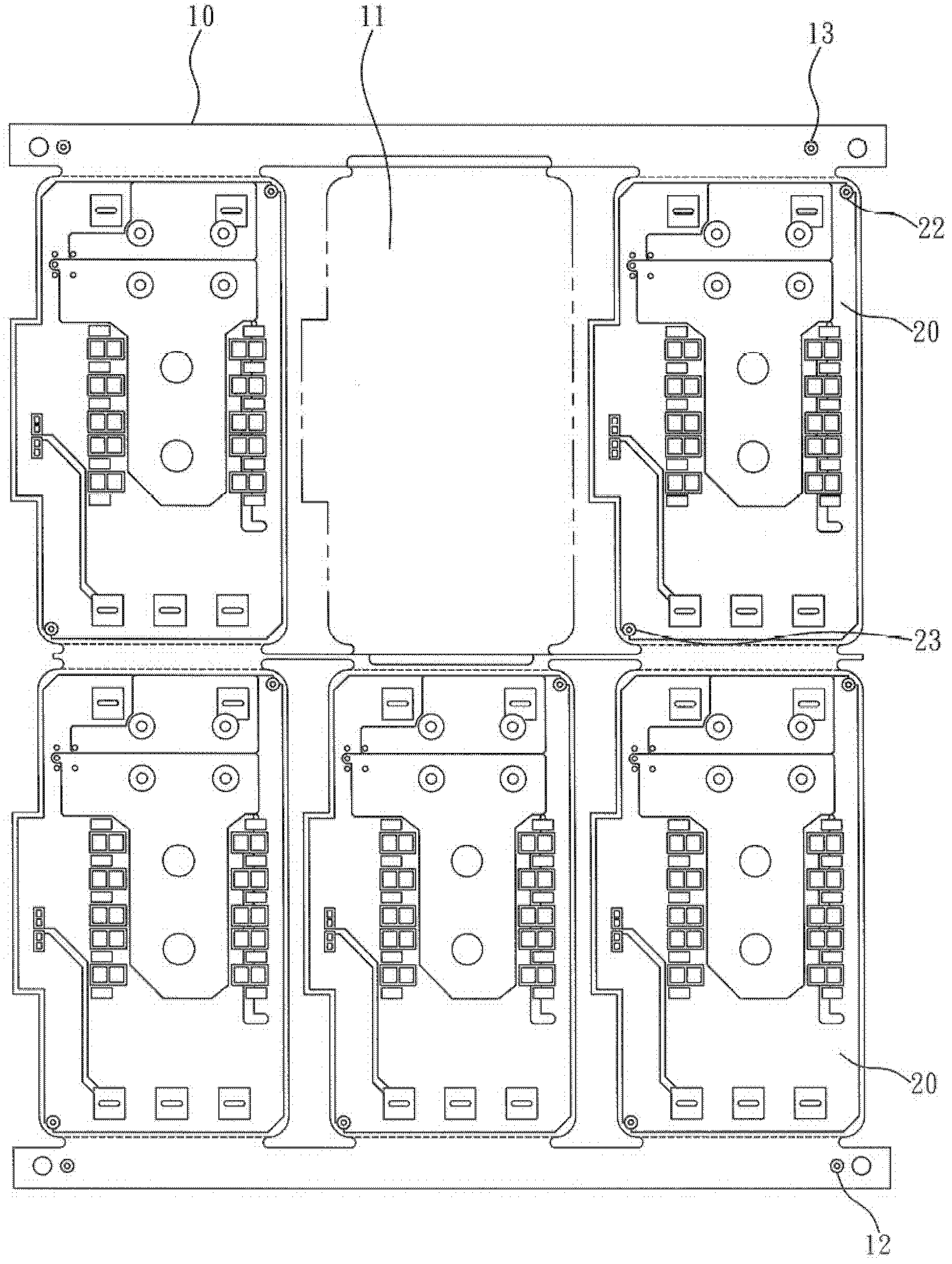

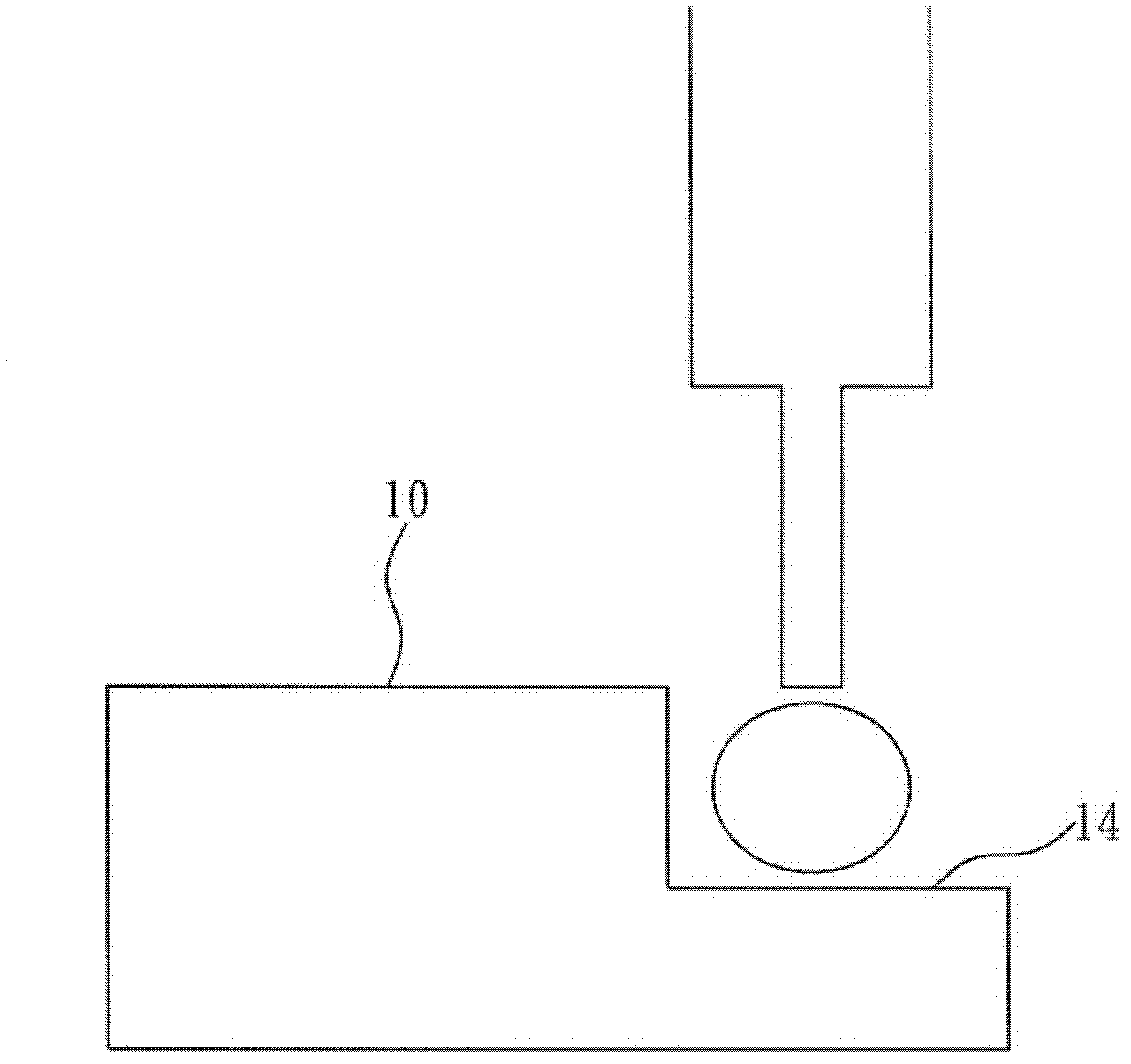

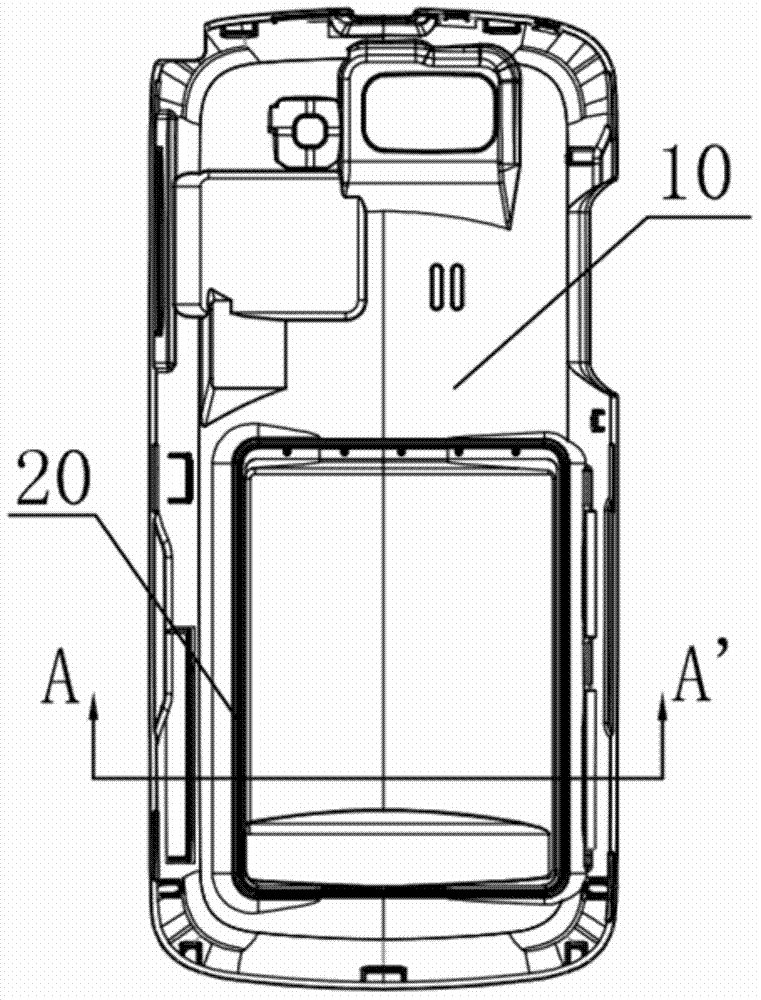

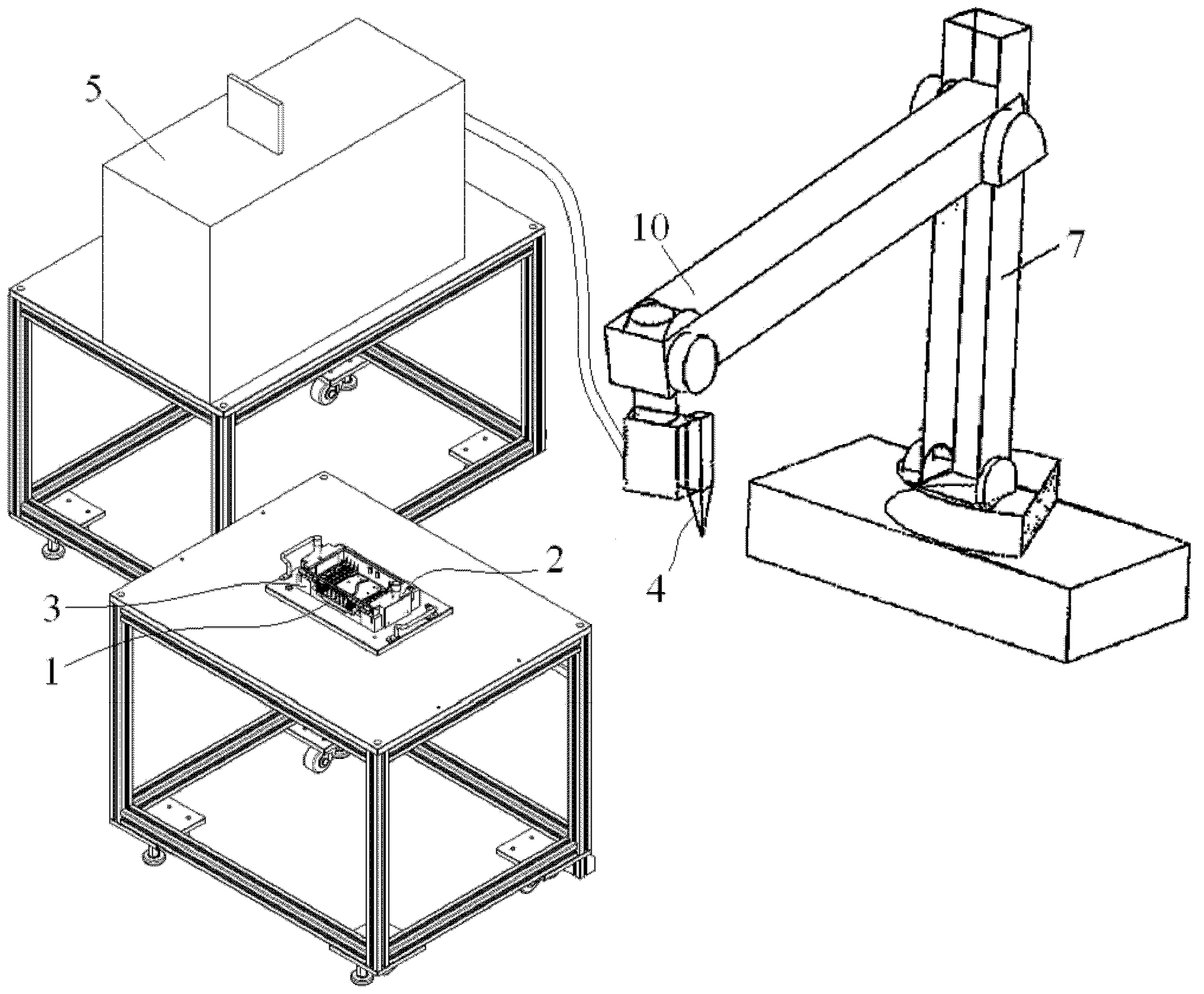

Flow line process method for automatic transplanting and repairing of printed circuit boards

The invention provides a flow line process method for automatic transplanting and repairing of printed circuit boards. Master slices and sub slices of the printed circuit board are embedded by concaves and convexes, a space for containing adhesive is reserved at each embedded part, the sub slices are embedded after dispensing adhesive and are vertically pressed down, and the adhesive overflows to fill the reserved embedded spaces to improve adhesiveness. The flow line process method for automatic transplanting and repairing of the printed circuit boards has such advantages that except the fact that the master slices and the sub slices are manually charged in batch in the end of a line and the middle of the line in the process of transplanting and repairing, the rest operations are automatically completed by a visual device instead of by manually placing the master slices and the sub slices slice by slice, adhesive tapes need not be stuck and torn, and different manufacturing devices need not be manufactured due to the fact that circuit modules of the circuit board are different.

Owner:何其俊 +1

Waterproof metal outer shell of electronic product and manufacturing method thereof

ActiveCN103929915AGood handle and heat dissipation performanceRelieve pressureMetal casingsHermetically-sealed casingsInjection molding processClosed cavity

The invention discloses a waterproof metal outer shell of an electronic product and a manufacturing method of the waterproof metal outer shell. According to the manufacturing method, a metal shell provided with a protrusive waterproof rib on the inner surface is formed, and the positions, spaced by a preset distance, on the two sides of the waterproof rib respectively protrude upwards to form a sealant boss; a mold is directly pressed on the sealant bosses, so that the sealant bosses deform, at least a part of each sealant boss is pressed in a containing groove, then a closed cavity is formed by the mold and the metal shell through the sealant bosses, then silica gel is injected to the cavity, the mold is opened after the silica gel is heated and vulcanized, a waterproof silica gel part integrated with the metal shell is formed on the waterproof rib, and the side surface or the top of the waterproof silica gel part is provided with a protrusive part. According to the waterproof metal outer shell, due to the design of the sealant bosses, when the waterproof metal outer shell is manufactured, silica gel overflowing and scratches on the surface of the metal product are not prone to occurring in the injection molding process, and compression or damage to the mold is also avoided.

Owner:宜宾市创世纪机械有限公司

Hot-melt pressure-sensitive structural adhesive film and preparation technique thereof

InactiveCN102153963AEasy to useImprove insulation performanceFilm/foil adhesivesThermoplastic elastomerHot melt

The invention discloses a hot-melt pressure-sensitive structural adhesive film which is composed of an epoxy adhesive film core material and hot-melt pressure-sensitive adhesive films which are respectively covered on both sides of the epoxy adhesive film core material, wherein the epoxy adhesive film core material is mainly composed of epoxy resin, and the hot-melt pressure-sensitive adhesive films are mainly composed of thermoplastic elastomer. The hot-melt pressure-sensitive structural adhesive film is very convenient to use, has pressure sensitivity at ordinary temperature, can generate a strong bonding function after being cured by heating, and can be directly used for structure bonding or substructure bonding.

Owner:CHANGZHOU TABANG NEW MATERIAL TECH

Low-flowability acrylic ester for multilayer flexible printed circuit

InactiveCN1837315AExtended shelf lifeLow curing temperaturePrinted circuit detailsPolyureas/polyurethane adhesivesPolyesterOrganic solvent

The invention discloses a low-liquidity acrylate adhesive on multiple flexible printing circuits, whose superior information: 2005100189758 CN 2005-6-23. The adhesive is composed of polybasic acrylate monomer, crosslinking modified monomer, organic solvent, reaction initiator and special polyester rubber macromolecular modifier. The preparing method of acrylate adhesive comprises the following steps: selecting polybasic acrylate monomer; crosslinking monomer; putting the monomers, organic solvent and initiator in the reactor at certain proportion; stirring the reaction to polymerize; blending the macromolecular compound and acrylate adhesive to constitute a new gel type with half-interpirecing network structure.

Owner:湖北省化学研究院

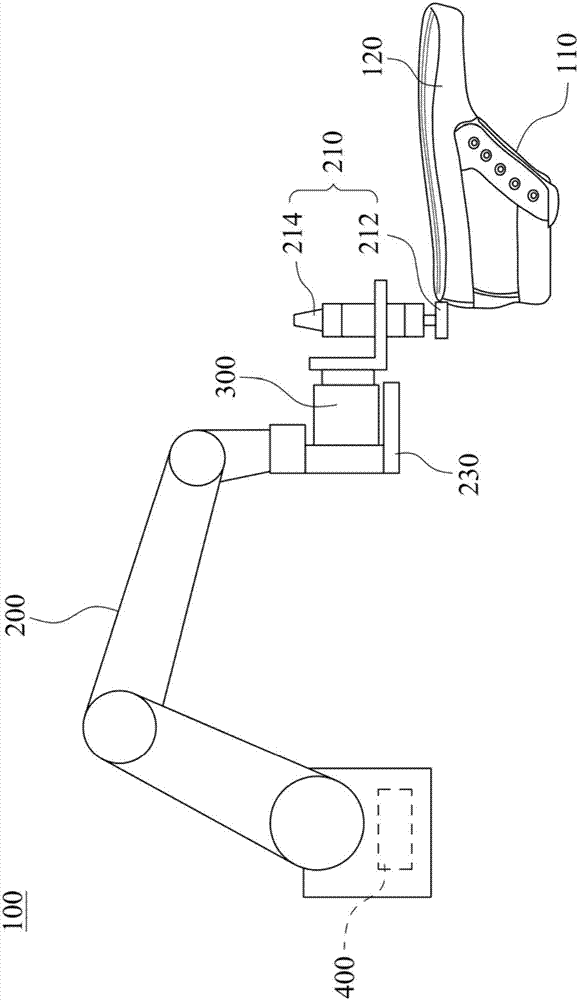

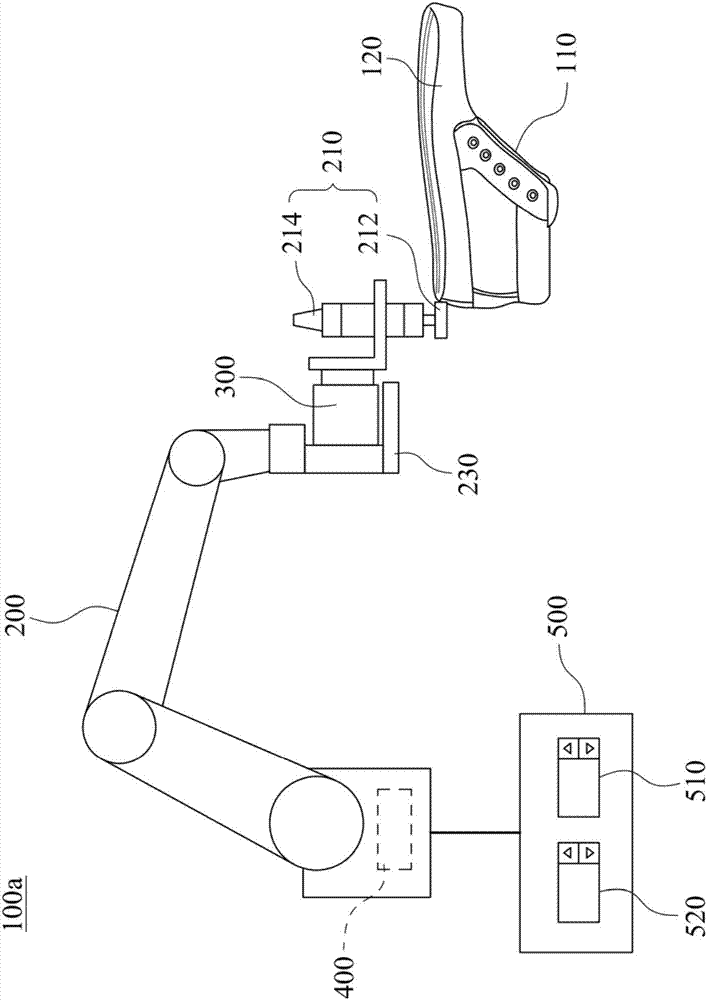

Outline measuring device and control method thereof

The invention provides an outline measuring device and a control method thereof. The outline measuring device is used for measuring an outline of a shoe upper, and the device comprises a mechanical arm, a feedback sensor, an outline path adjusting module. A measuring unit of the mechanical arm abuts against the shoe upper along an original outline path to shift, so that the shoe upper correspondingly generates displacement. The feedback sensor is connected with the measuring unit, and senses and records the displacement. The outline path adjusting module is connected with the mechanical arm and the feedback sensor, and the outline path adjusting module calculates and corrects the original outline path and generates a preset outline path according to the displacement, so that the measuring unit shifts along the preset outline path. Firstly the displacement of the shoe upper is read through the mechanical arm by combining with the feedback sensor, then the operation is conducted by using the displacement, the preset outline path is obtained, the different material is judged, and then the accuracy and efficiency of roughing are improved.

Owner:POU CHEN CORPORATION

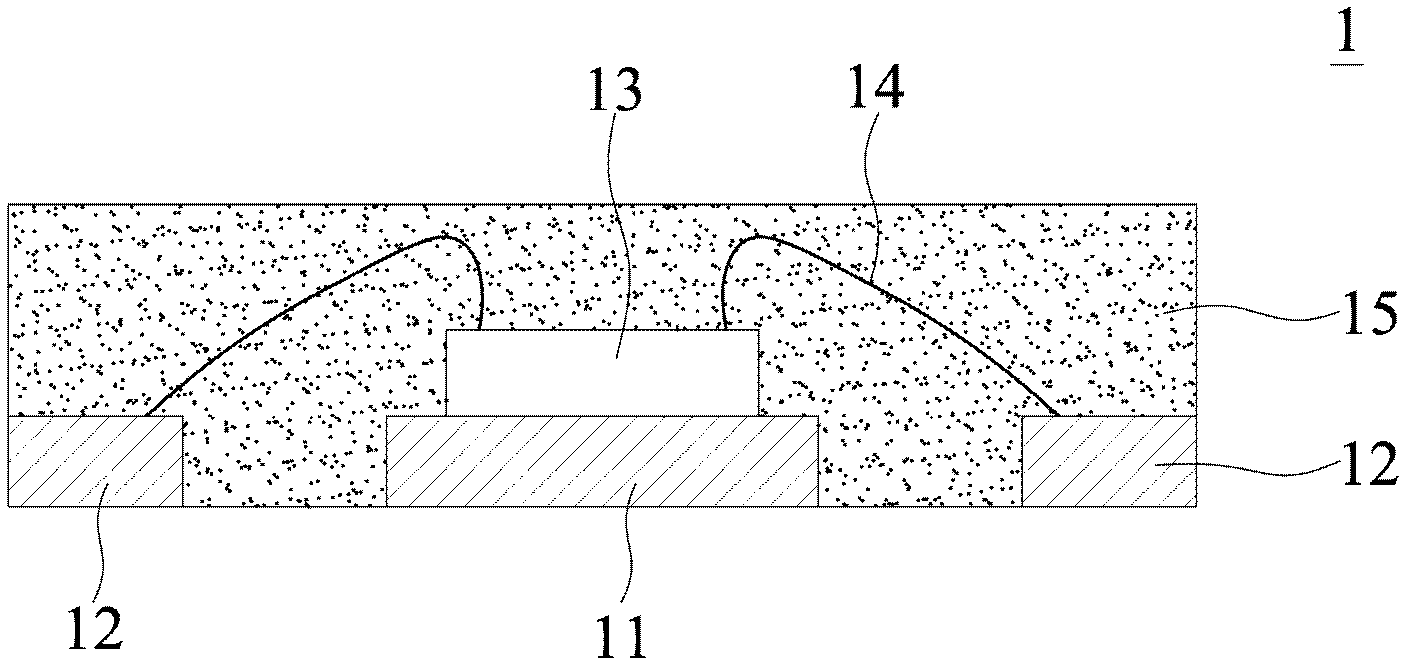

Semiconductor packaging piece, prefabricated lead frame and manufacturing method thereof

InactiveCN103107145AImprove reliabilityEasy to processSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

The invention provides a semiconductor packaging piece, a prefabricated lead frame and a manufacturing method thereof. The semiconductor packaging piece comprises packaging colloid; a plurality of guide pins partially embedded into the packaging colloid; surface processing layers formed on the top surface, the bottom surface and the recess of each guide pin; and a semiconductor chip embedded in the packaging colloid and used for being electrically connected with the guide pins.

Owner:SILICONWARE PRECISION IND CO LTD

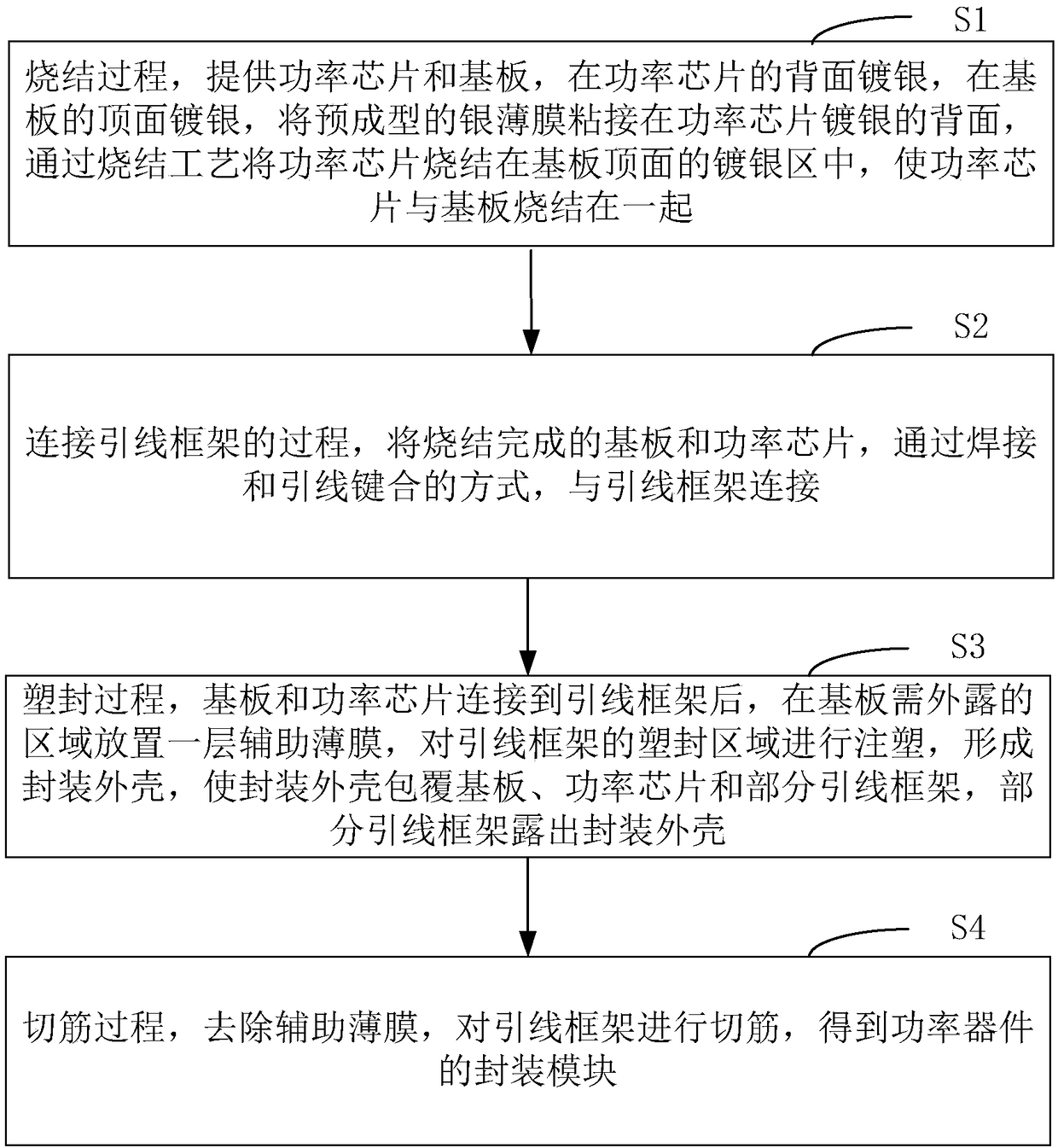

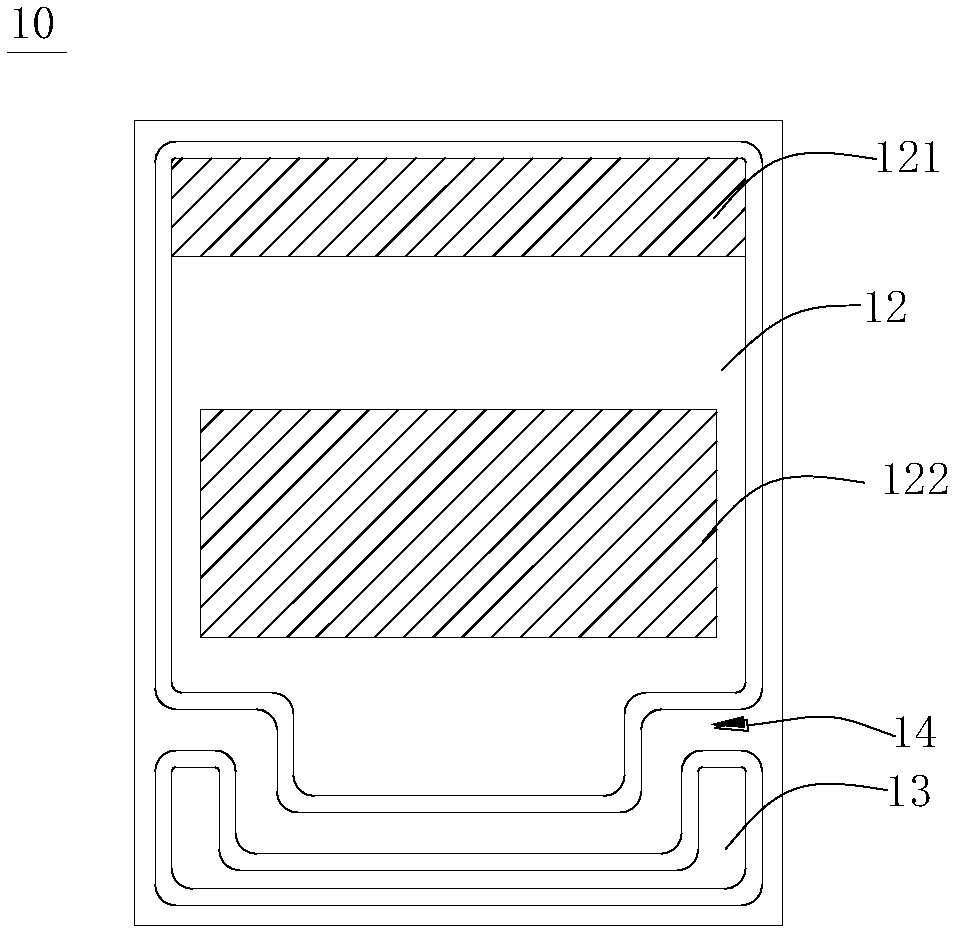

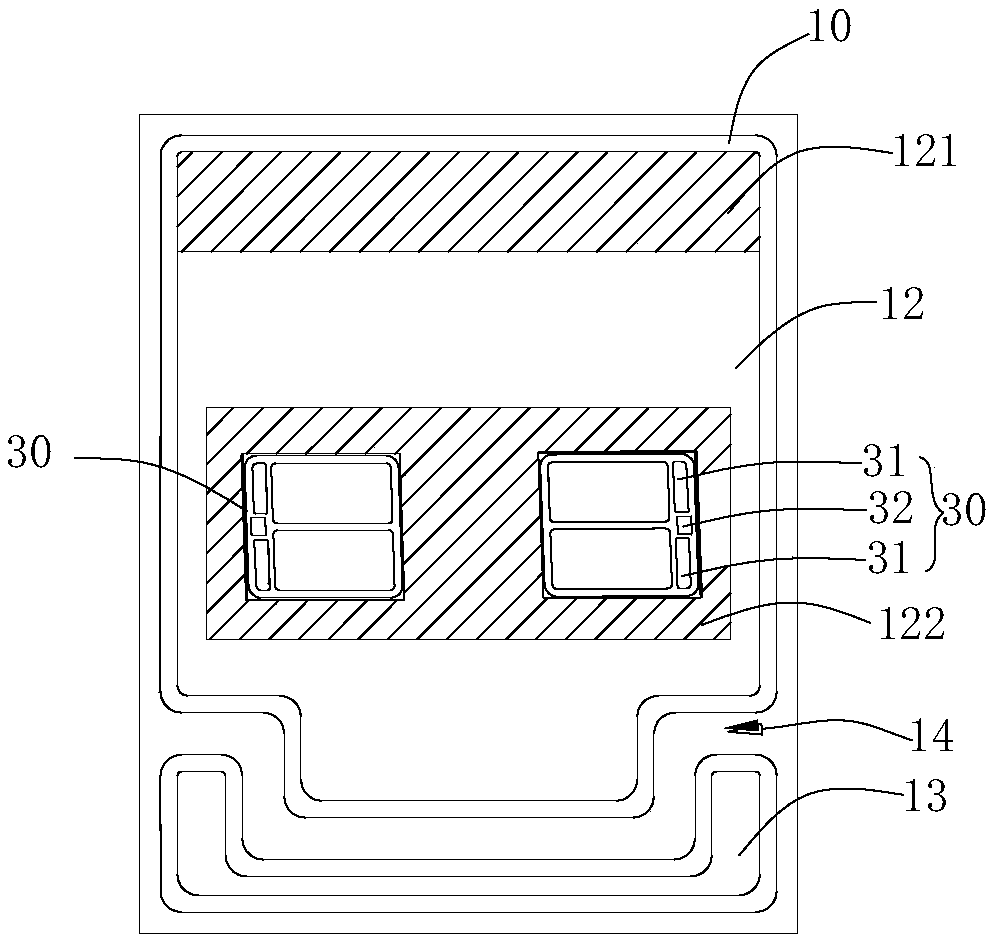

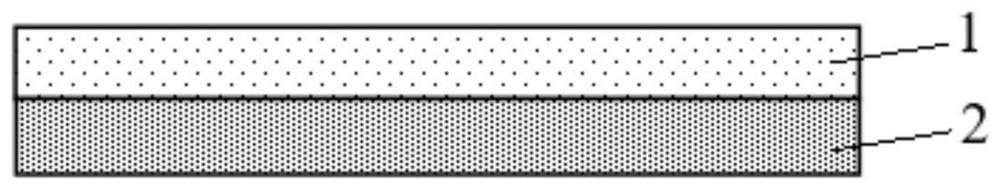

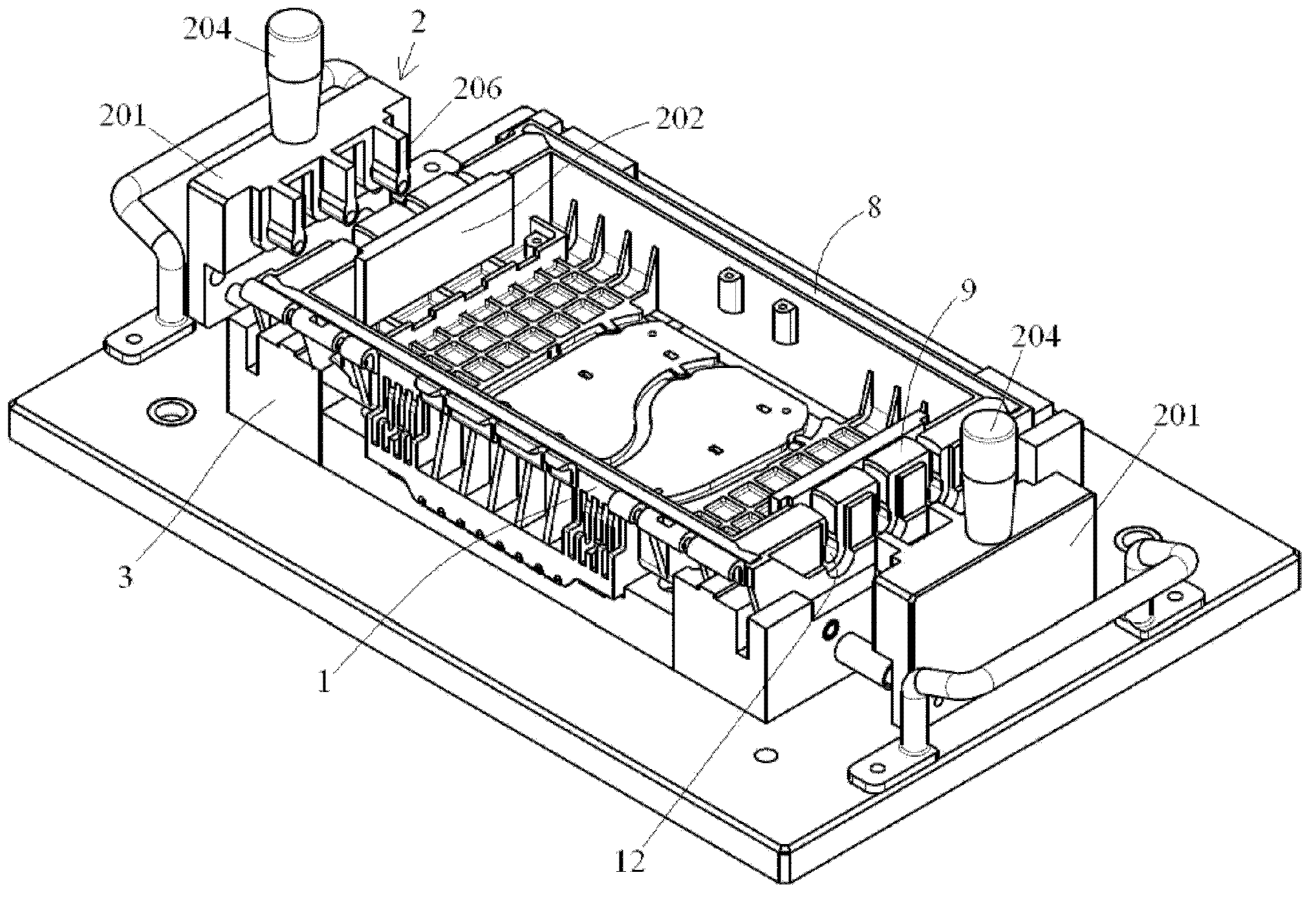

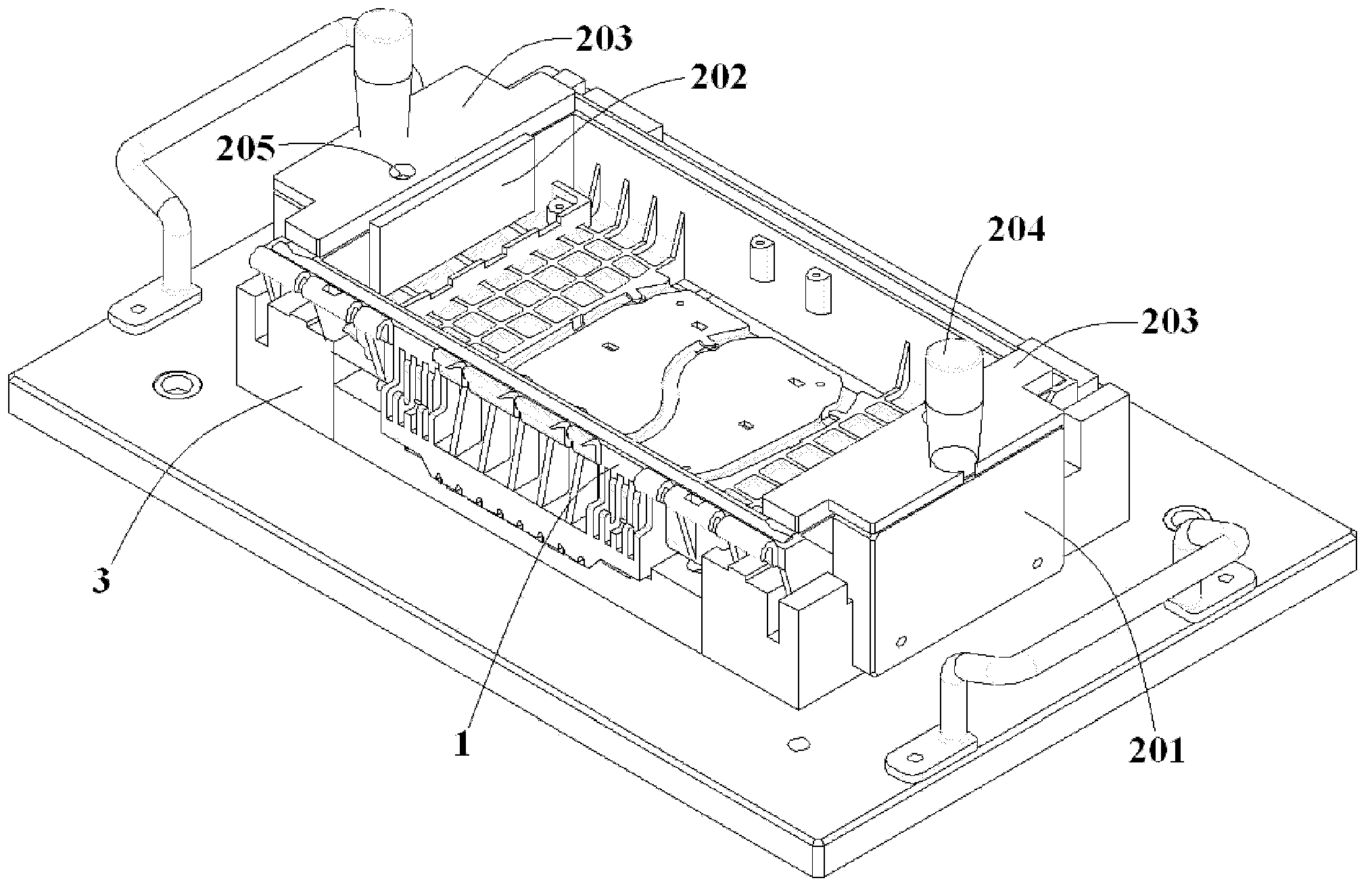

Power device packaging method as well as packaging module and lead frame thereof

PendingCN108321129AMeet the requirements of high thermal conductivityAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSilver plate

The invention discloses a power device packaging method as well as a packaging module and a lead frame thereof. The packaging method comprises a sintering process, a lead frame connecting process, a plastic packaging process and a rib cutting process. The sintering process comprises the steps: adhering a silver film onto the silver-plated back of a power chip, and sintering the power chip in a silver plating area on the top of a substrate by using a sintering process. The substrate and the power chip subjected to sintering are connected with the lead frame in a manner of welding and lead bonding. During plastic packaging, an auxiliary film is arranged in a to-be-exposed area of the substrate, and the plastic packaging area of the lead frame is subjected to injection molding so as to form apackaging shell. The auxiliary film is removed, and the lead frame is subjected to rib cutting, thereby obtaining the power device packaging module. The power device packaging module is obtained by adopting the packaging method. According to the packaging method and the packaging module, the heat conduction performance between the power chip and the substrate is enhanced, and the product reliability is improved. A connecting line is formed between first source pins of the lead frame, and the connecting stability is improved.

Owner:SHENZHEN STS MICROELECTRONICS

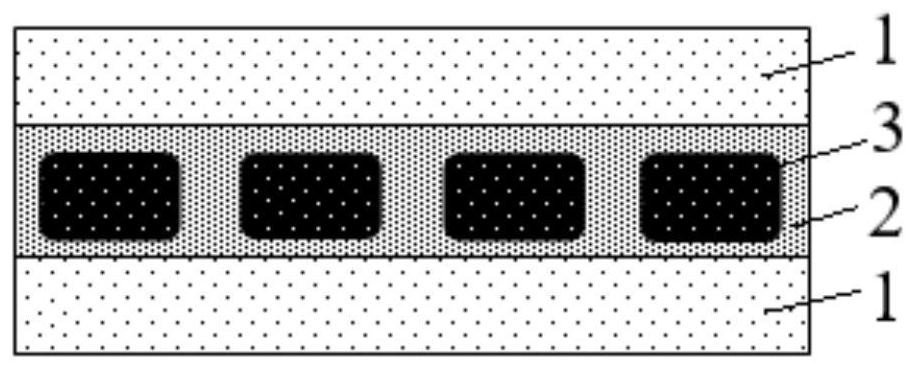

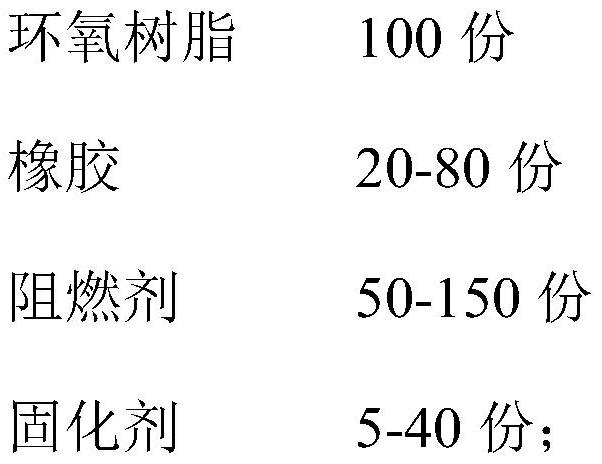

Insulating adhesive film for flexible flat cable and preparation method of insulating adhesive film

InactiveCN112760070AHigh bonding strengthExcellent heat and humidity resistanceFilm/foil adhesivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention provides an insulating adhesive film for a flexible flat cable and a preparation method of the insulating adhesive film. The insulating adhesive film for the flexible flat cable comprises a base material layer and an adhesive layer, and the adhesive layer comprises the following components in parts by weight: 100 parts of epoxy resin, 20-80 parts of rubber, 50-150 parts of a flame retardant and 5-40 parts of a curing agent, wherein the epoxy resin is epoxy resin with two or more epoxy groups, and the mass of the epoxy resin with the two or more epoxy groups accounts for 20% or more of the total mass of the epoxy resin. The insulating adhesive film for the flexible flat cable is a thermosetting insulating adhesive film, and has the properties of high bonding strength, humidity and heat resistance and adhesive overflow resistance.

Owner:CYBRID TECHNOLOGIES INC

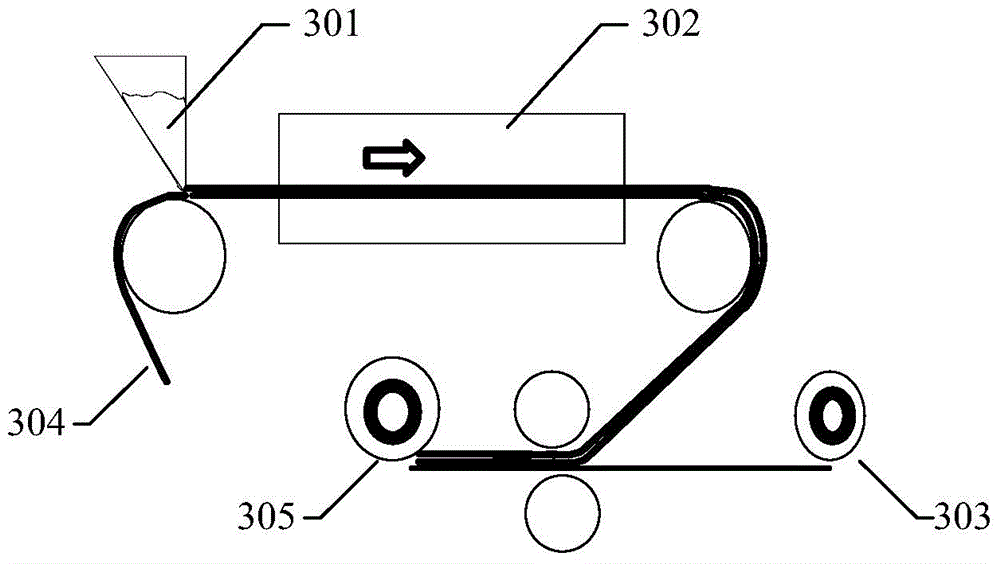

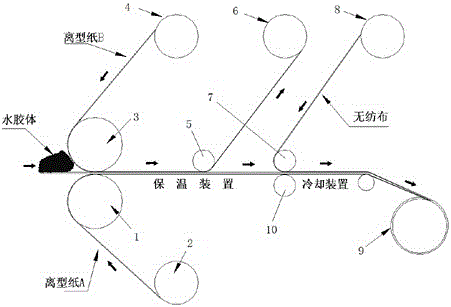

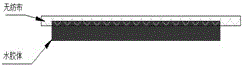

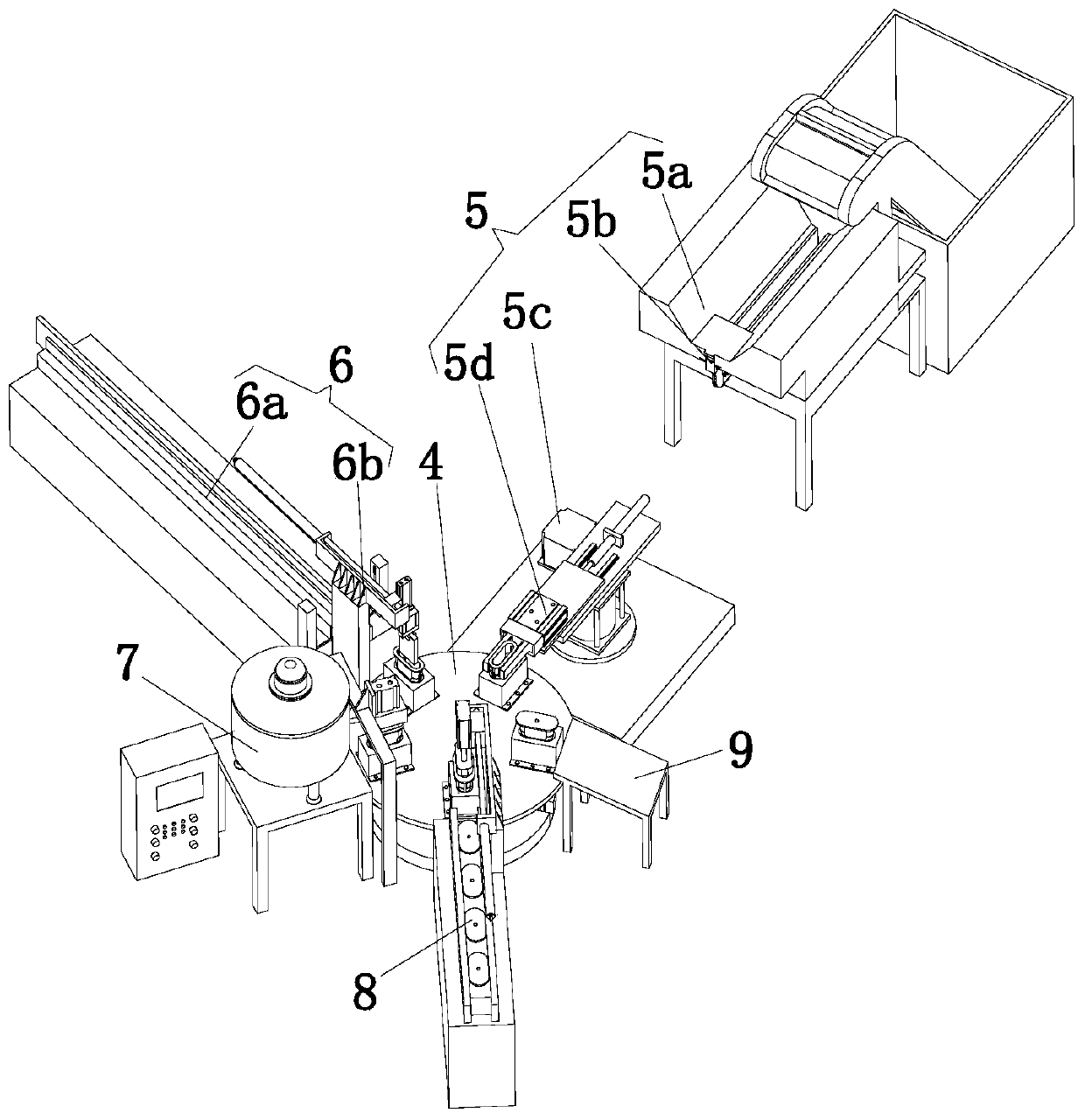

Non-woven fabric hot melt adhesive tape as well as coating method and coating device thereof

PendingCN107521213APrevent hot melt adhesive from seeping throughGuaranteed stickinessLamination ancillary operationsLaminationWoven fabricPolymer chemistry

The invention relates to a coating method of a non-woven fabric hot melt adhesive tape. The coating method comprises the following steps: (1) recombining for the first time: enabling release paper A and release paper B to be recombined together by utilizing hot melt adhesive, and preserving heat to enable the hot melt adhesive to keep a fluid state, wherein the release force between the release paper B and the hot melt adhesive is less than the release force between the release paper A and the hot melt adhesive; (2) peeling off the release paper B: peeling off the release paper B and the hot melt adhesive to enable one side of the hot melt adhesive to be exposed to become a to-be-recombined surface; (3) recombining for the second time: enabling non-woven fabric and the to-be-recombined surface of the hot melt adhesive to be recombined, cooling simultaneously to enable the hot melt adhesive to be solidified so as to obtain the non-woven fabric hot melt adhesive tape; and (4) rolling-up: rolling-up the obtained non-woven fabric hot melt adhesive tape. The invention further discloses a coating device of the non-woven fabric hot melt adhesive tape, and the obtained non-woven fabric hot melt adhesive tape has the following characteristics: (1) by enabling the hot melt adhesive and the non-woven fabric to be combined together, the dressing meets hydroscopicity and air permeability simultaneously; and (2) as the hot melt adhesive is recombined on the non-woven fabric, not only is the hot melt adhesive difficult to peel off, but also adhesive overflowing cannot happen.

Owner:ZHEJIANG HAICHUANG MEDICAL DEVICE CO LTD

Planar salient point type technique for packaging intergrate circuit or discrete component

ActiveCN1728352APrevent spillageNo pollution problemSolid-state devicesSemiconductor/solid-state device manufacturingMetalIntegrated circuit

The invention includes following technical steps: pasting dry film layer on both sides of metal base plate; removing part of dry film layer for preparing basic island and pins to be formed; plating metal layer at place, where basic island and pins are to be formed, on both sides, then removing remanent dry film layer on front face; carrying out half etching so as to form concave half etched area including basic island and pins, and removing remanent dry film layer on back face; embedding chip on metal layer of basic island on front face, making metal wire, enveloping plastic package, printing at front face; etching remanent partial metal at half etching area, and pasting rubber film onto plastic package and incising. Features are: good weldability, low cost, high adaptability, flexible to arrange multiple chips, and avoiding infiltration of material of plastic package.

Owner:长电科技管理有限公司

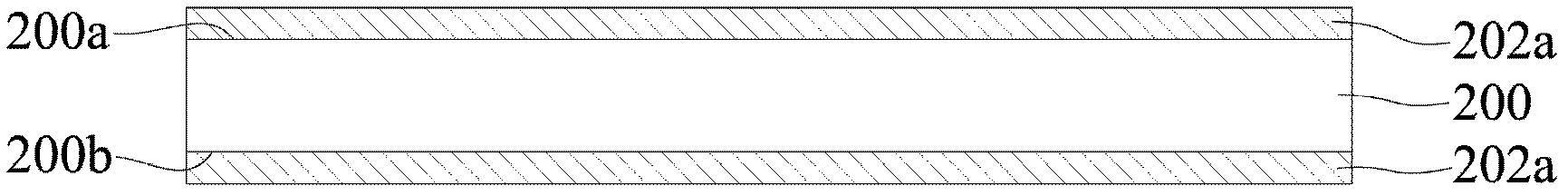

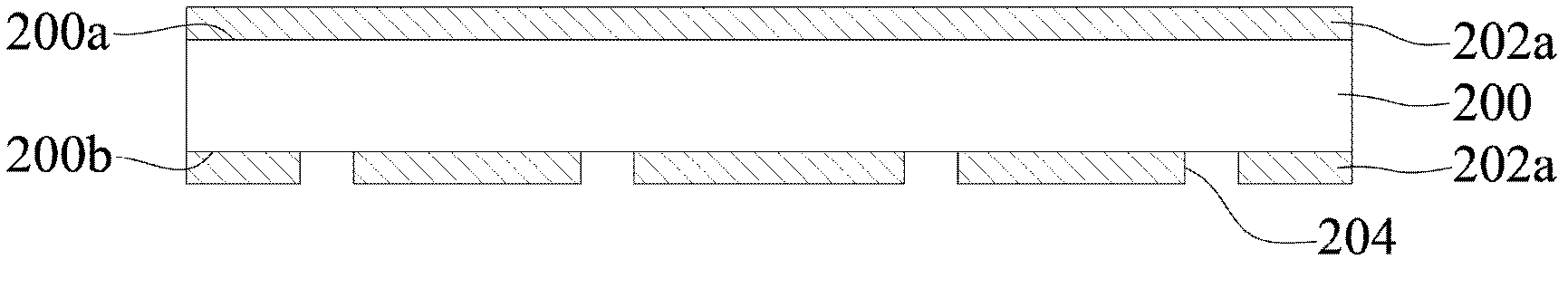

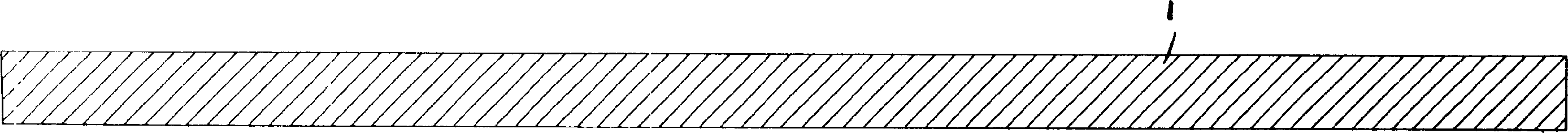

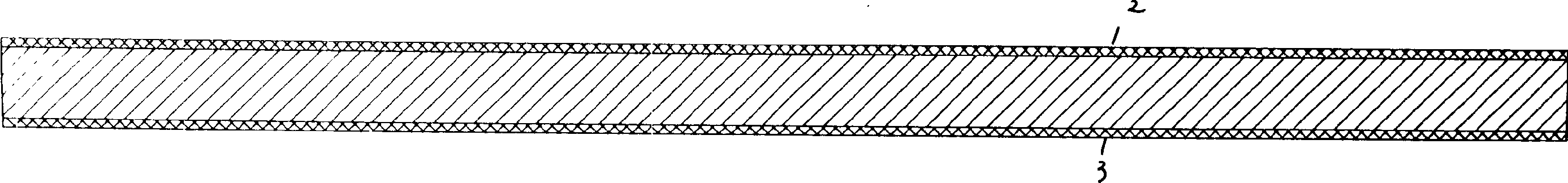

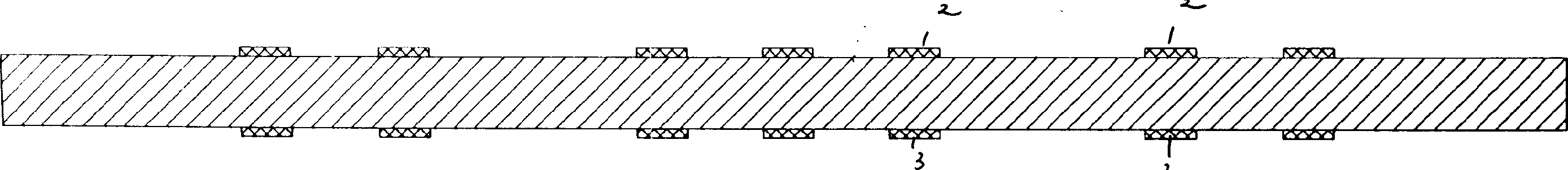

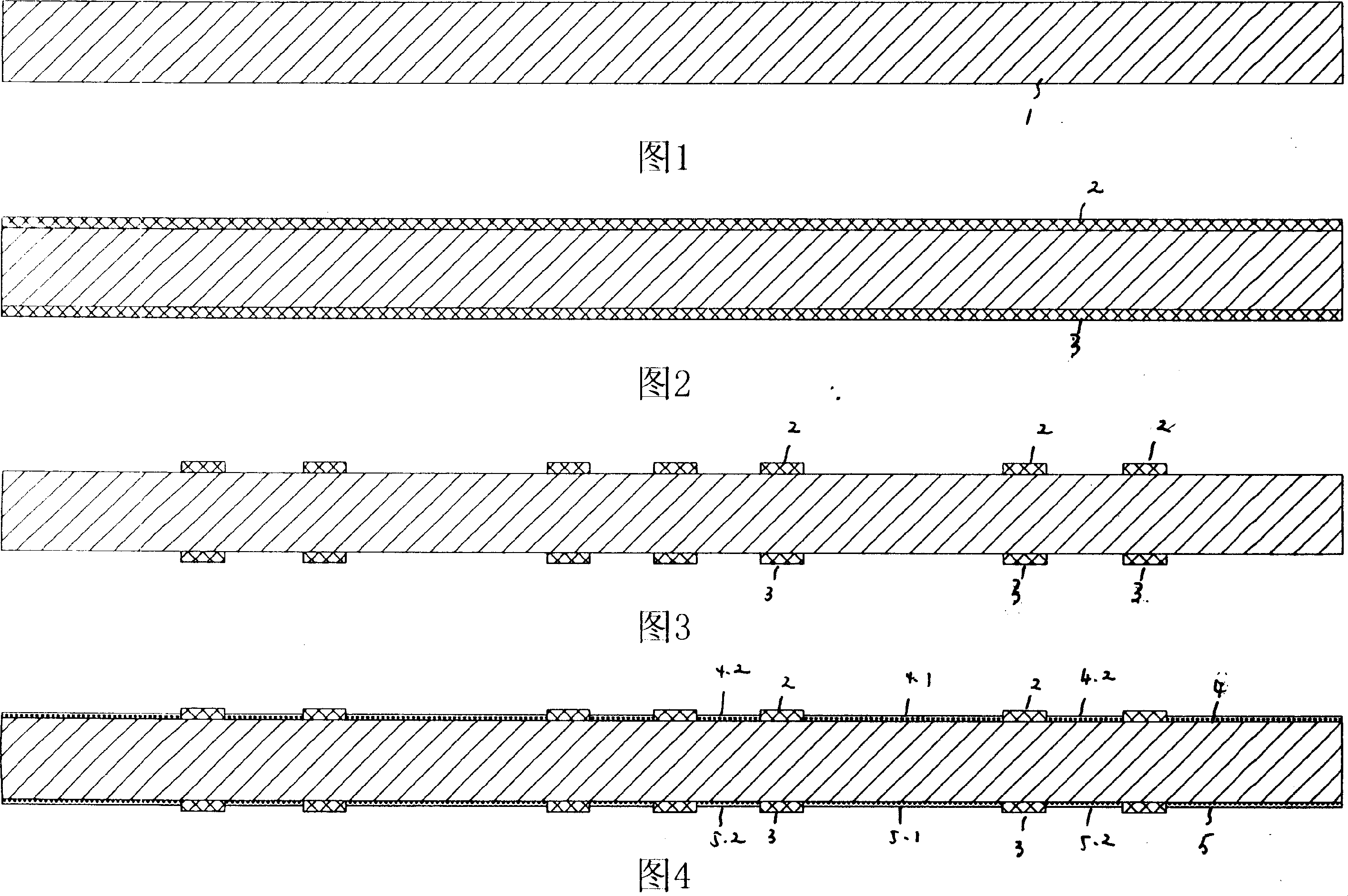

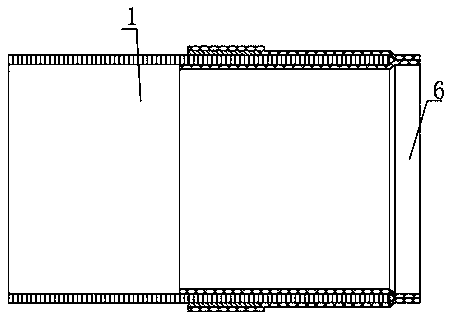

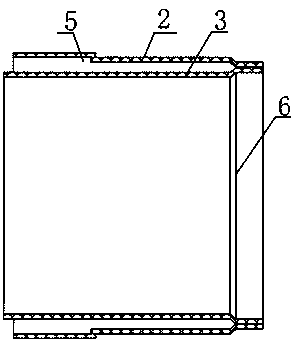

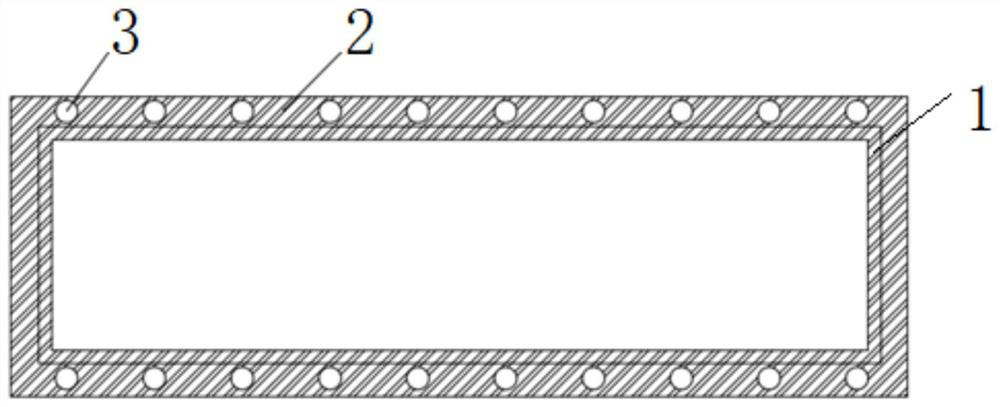

Novel integrated circuit or discrete component flat bump package technics and its package structure

ActiveCN1738015APrevent spillageNo pollution problemSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

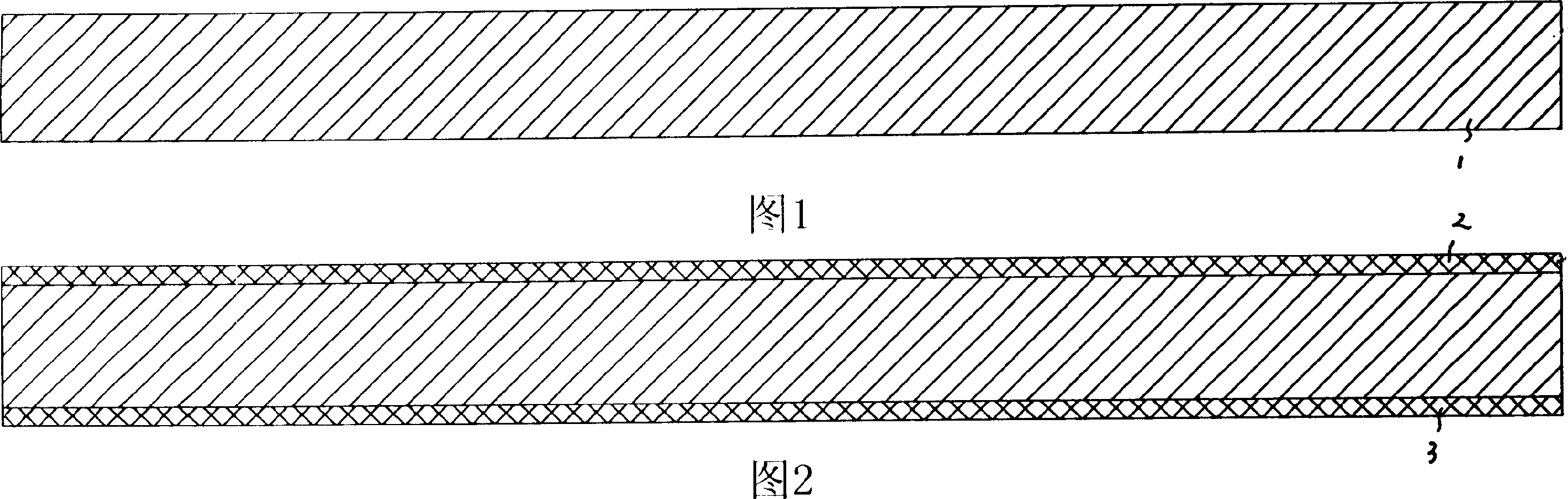

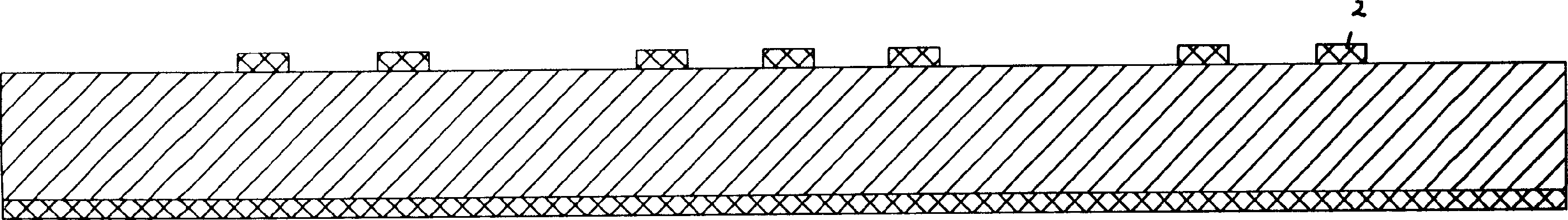

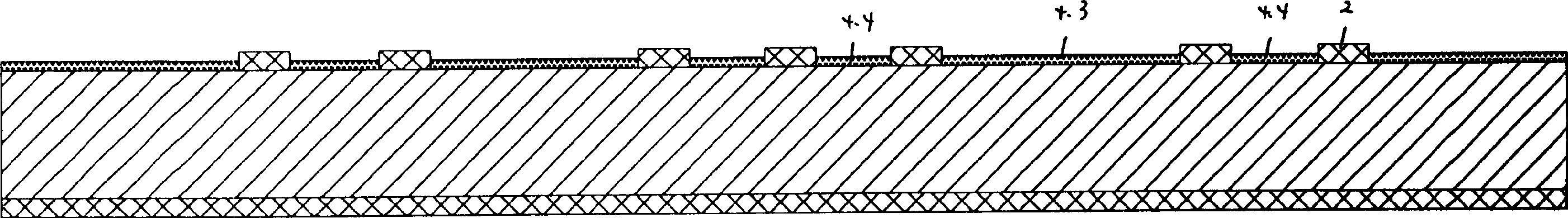

The invention relates to a plane point-protruded type packaging process and its structure of new integrated circuit or discrete component, comprising following steps: pasting dry films (2, 3) on the two surfaces of a metallic base plate (1) while removing some dry films of upper layer; preparing base island and pin; plating active compound (4.3, 4.4) and metallic layer (4.1, 4.2) on the face; removing the left dry film on the front of base plate; half etching, removing the dry film layer (3) left on the back of base plate; planting chip (6), tying metallic thread (7), packaging plastic packaging body (8), pasting dry film layer (10) again on the back of metal base plate (1); etching again on the metal of left part (1.4) and the dry film on the back of half etched region (1.3) to make the back surfaces of base island (1.1) and pin (1.2) protrude from plastic packaging body (8); removing left dry film and plating active compound (11.3, 11.4) and metallic thread (11.1, 11.2); pasting film (12) on the face of plastic packaging body, and slicing. Said invention has strong welding property, better quantity, low cost, good adaptability, reflex able arrangement of chips, while avoiding the problem of infiltration of plastic packaging material.

Owner:长电科技管理有限公司

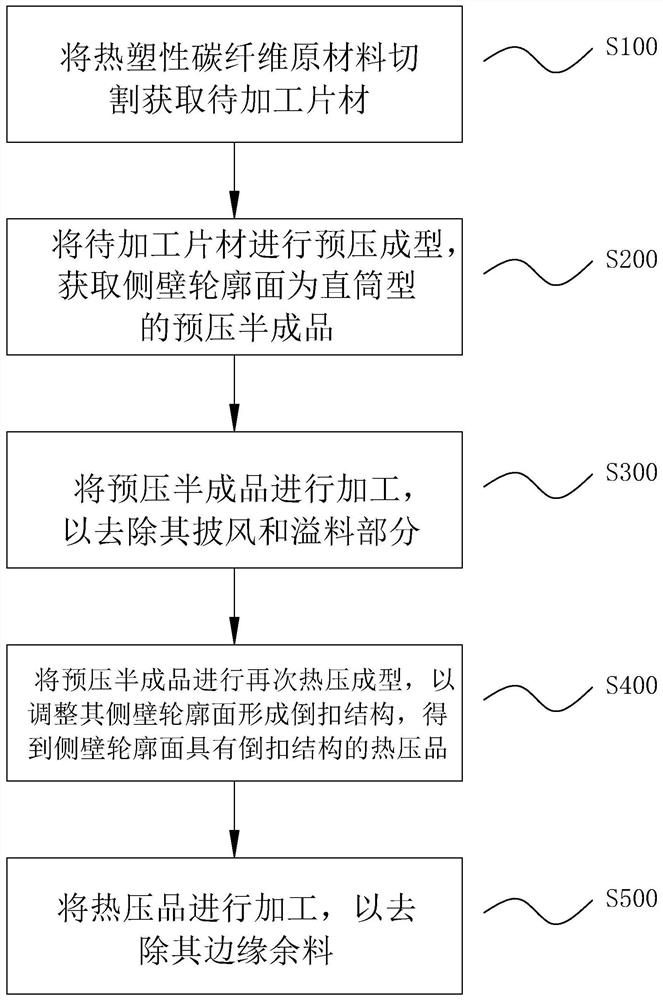

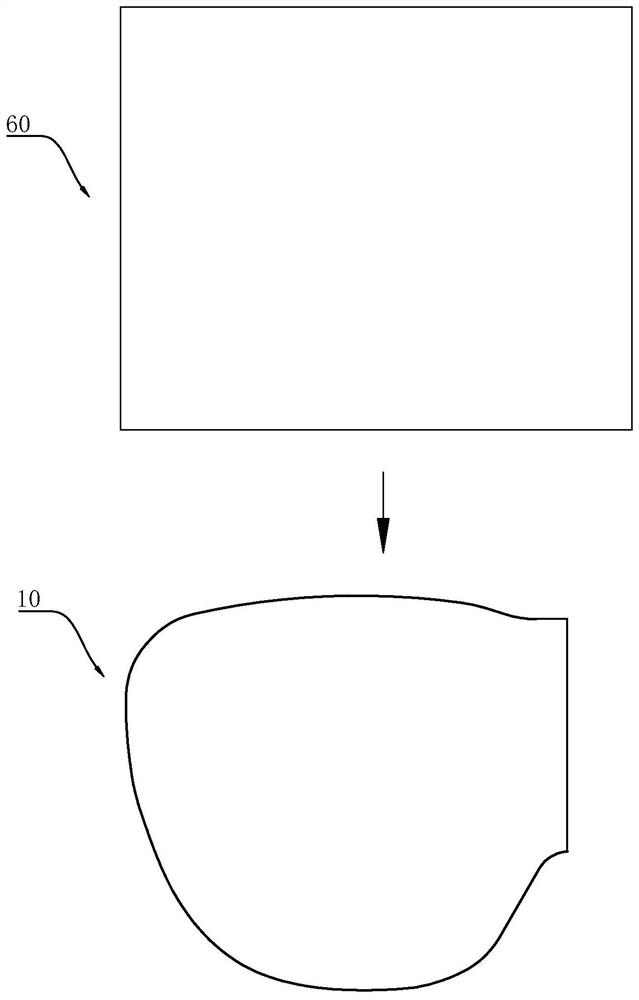

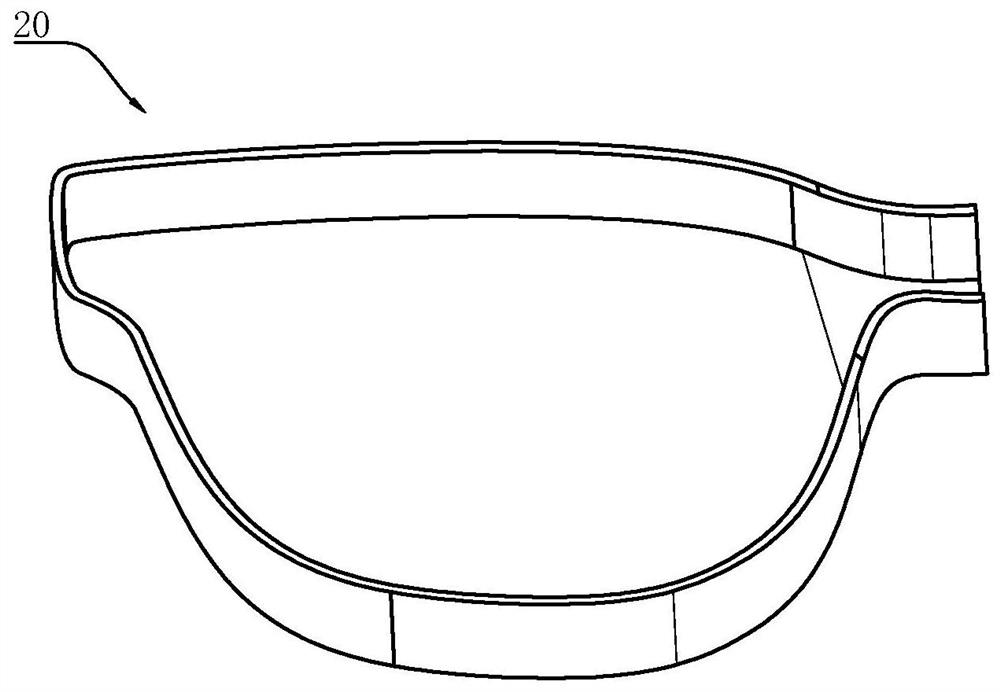

Thermoplastic carbon fiber product forming process

The invention discloses a thermoplastic carbon fiber product forming process. The thermoplastic carbon fiber product forming process comprises the following steps of cutting a thermoplastic carbon fiber raw material to obtain a to-be-processed sheet; performing pre-pressing forming on the to-be-processed sheet, and obtaining a pre-pressed semi-finished product with the side wall contour face being in a straight cylinder shape; performing hot press molding on the pre-pressed semi-finished product again so as to adjust the side wall contour surface of the pre-pressed semi-finished product to form an inverted buckle structure, and obtaining a hot-pressed product with the side wall contour surface having the inverted buckle structure; and processing the hot-pressed product to remove excess materials on the edge of the hot-pressed product. According to the thermoplastic carbon fiber product forming process, the problems of material clamping and glue overflowing of a thermoplastic carbon fiber product of a complex structure in the hot press forming process can be effectively solved, and therefore the product quality and the production efficiency are improved.

Owner:东莞市欧比迪精密五金有限公司

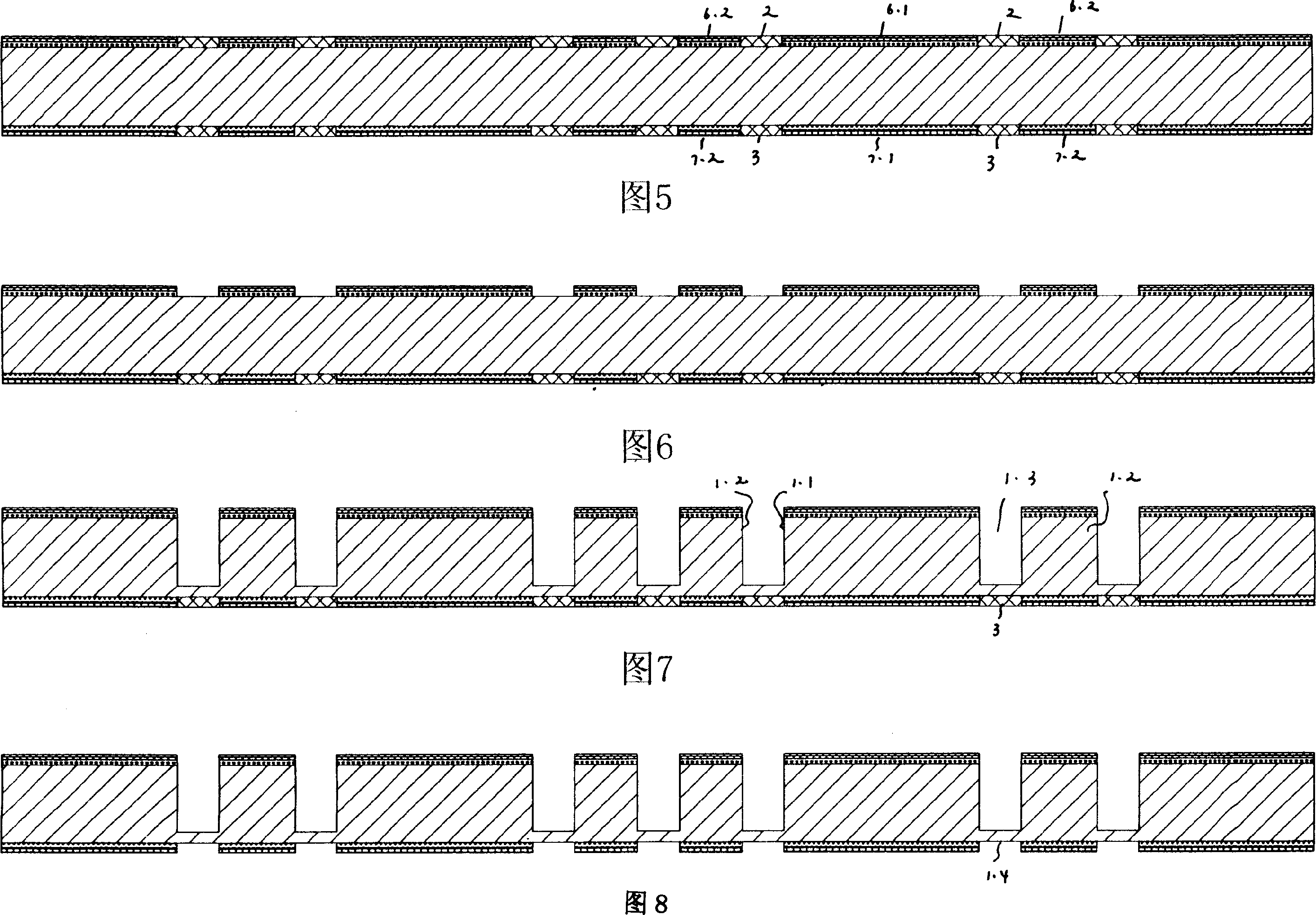

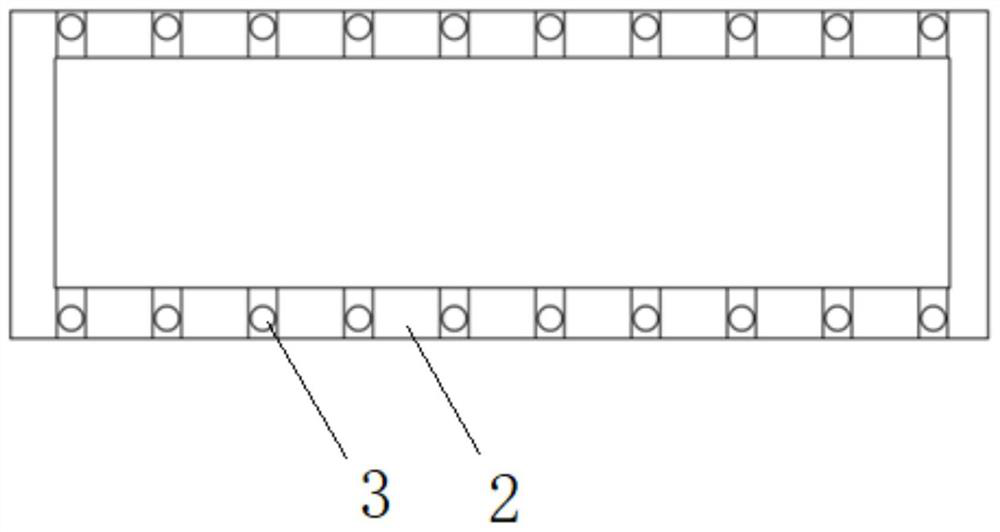

Flat bump package technics for integrated circuit or discrete component

ActiveCN100376021CPrevent spillageNo pollution problemSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a plane point-protruded type packaging process and its structure of integrated circuit or discrete component, comprising following steps: pasting dry films (2, 3) on the two surfaces of a metallic base plate (1) while removing some dry films relatively; plating active compound and metallic layer on the area of base plate for forming base island and pins; removing the left dry film on the front of base plate; half etching to form a depressed half etched region (1, 3), base island 1.1 and pin 1.2; removing the dry film left on the back of base plate; planting chip (9) into the front metal layer of base island, tie metallic thread (10), packaging plastic packaging body (11), front printing (12), and etching again on the left metal 1.4 of half etched region (1.3); pasting film (13) on the face of plastic packaging body, and slicing. Said invention has strong welding property, better quantity, low cost, good adaptability, reflex able arrangement of chips, while avoiding the problem of infiltration of plastic packaging material.

Owner:长电科技管理有限公司

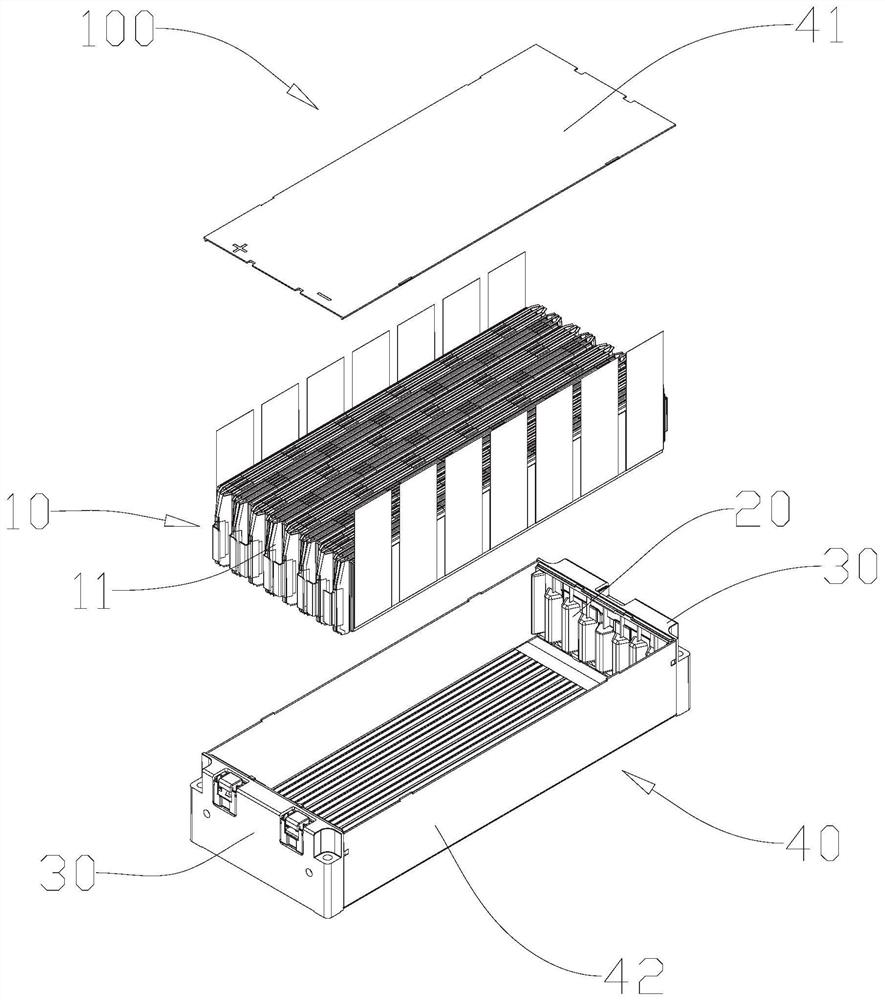

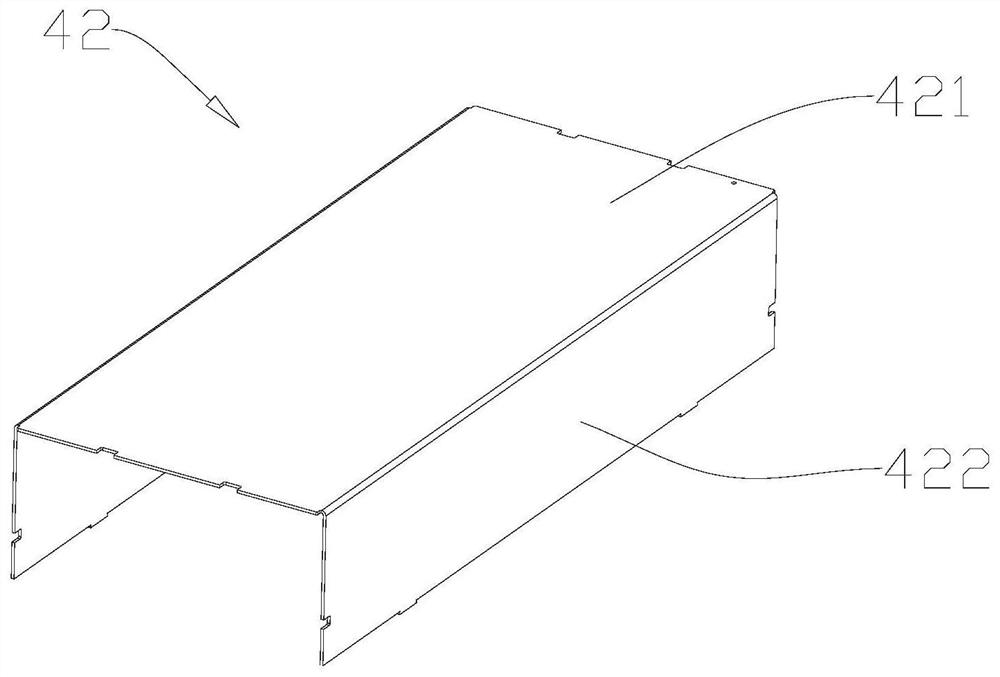

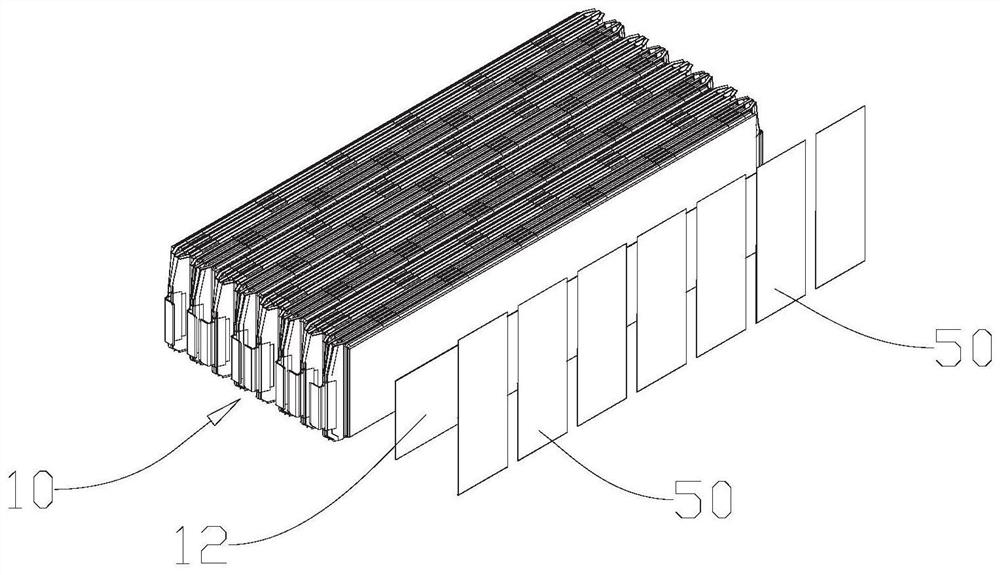

Battery module and assembling method thereof

PendingCN111785883AWill not polluteUniform thickness thicknessCell component detailsStructural engineeringMechanical engineering

The invention discloses a battery module and an assembling method thereof. The battery module comprises a battery cell assembly and a shell assembly, wherein the battery cell assembly comprises a plurality of battery cell units which are arranged side by side, the battery cell assembly is arranged in the shell assembly, the battery cell assembly is bonded with the shell assembly through a double-faced adhesive tape layer of an adhesive tape, the adhesive tape comprises an isolation layer and a double-faced adhesive tape layer, and the double-faced adhesive tape layer is bonded on one surface of the isolation layer. The battery cell assembly and the shell assembly of the battery module are bonded through the double-faced adhesive tape layer, the adhesive layer is uniform, other areas of themodule cannot be polluted in the assembling process, the battery module can be used immediately after being pasted, and adhesive overflowing is avoided.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD

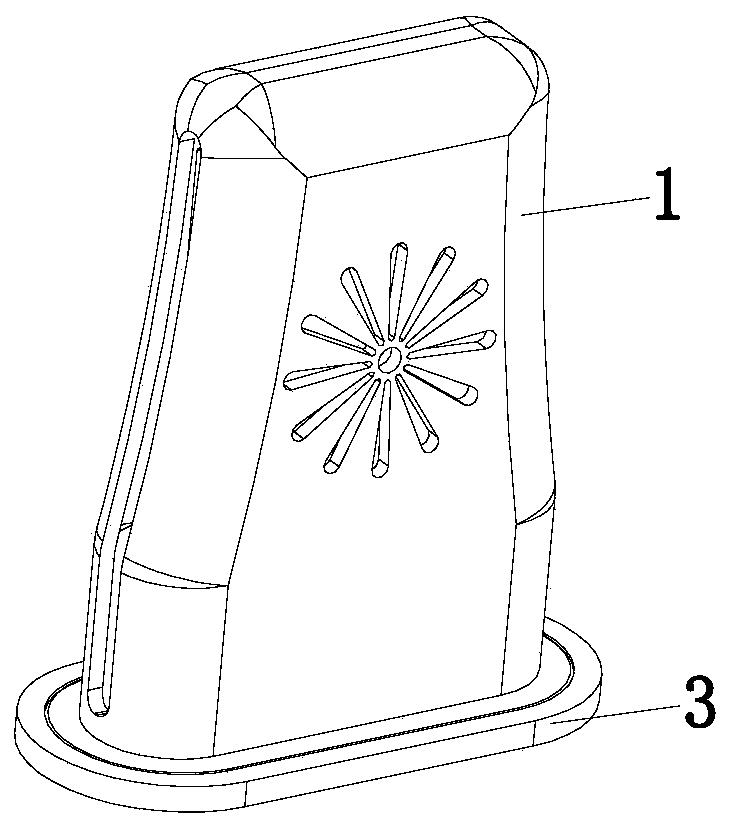

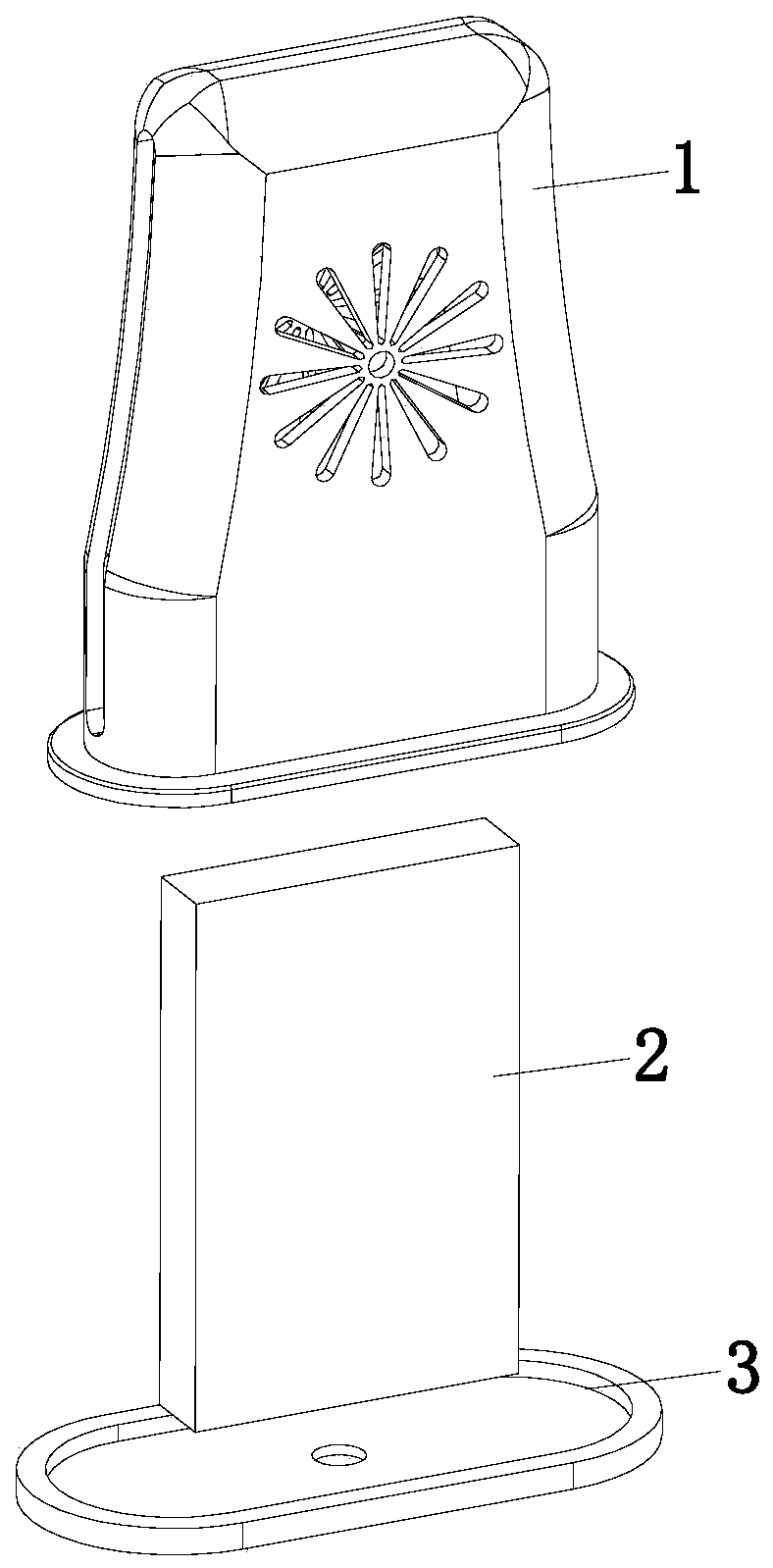

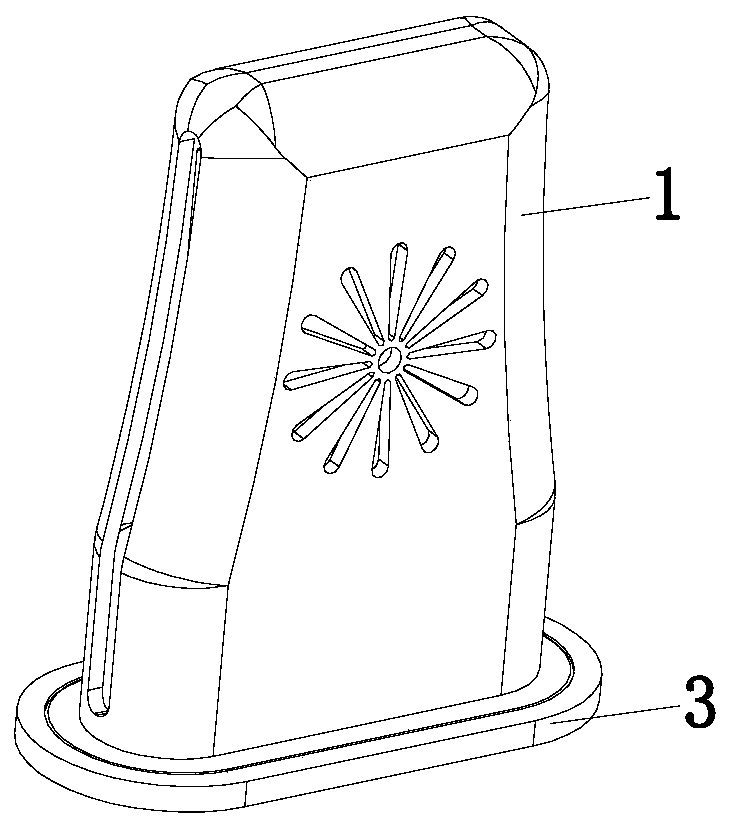

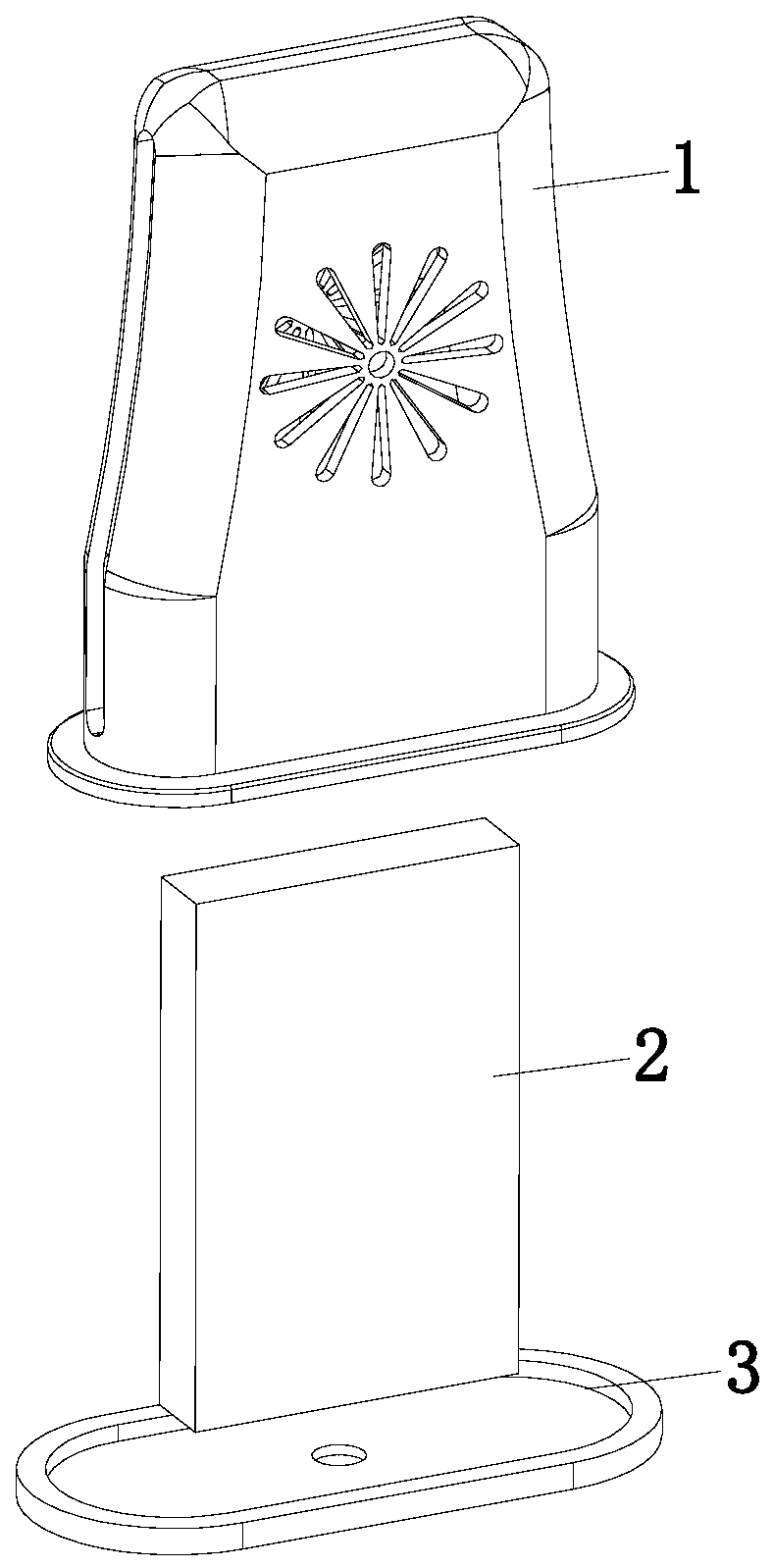

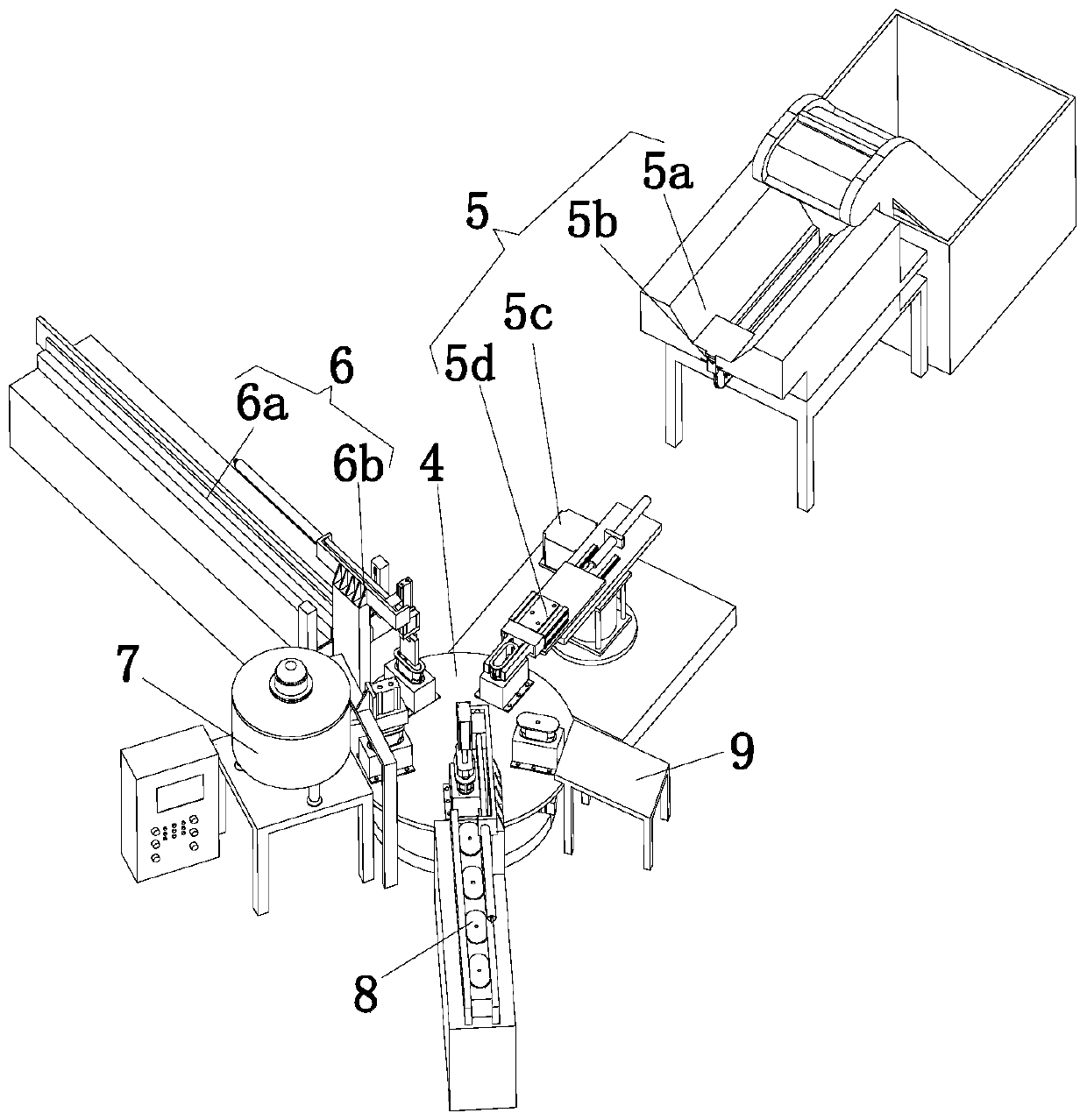

Automatic assembling mechanism for guitar humidifier and assembling technology thereof

ActiveCN110253287AImplement automatic assemblyReduce the amount of manual laborLiquid surface applicatorsAssembly machinesMechanical engineeringGuitar

The invention relates to the field of mechanism production, and specifically relates to an automatic assembling mechanism for a guitar humidifier. The mechanism comprises a rotating mechanism, a housing feeding mechanism, a sponge assembling mechanism, a gluing mechanism and a bottom cover assembling mechanism, wherein the housing feeding mechanism, the sponge assembling mechanism, the gluing mechanism and the bottom cover assembling mechanism are circumferentially distributed beside the rotating mechanism; the housing feeding mechanism comprises a feeding assembly, a limiting assembly, a driving assembly and a transferring assembly; the transferring assembly is positioned between the feeding assembly and the rotating assembly; the limiting assembly is mounted at the tail end of the feeding assembly; the driving assembly is mounted at the lower part of the transferring assembly; and the sponge assembling mechanism consisting of a sponge feeding assembly and a sponge assembling assembly is positioned between the sponge feeding assembly and the rotating mechanism. The mechanism has the beneficial effects that the guitar humidifier is automatically assembled, so that the labor workload is decreased; the production speed is increased; the production cost is decreased; and the damage of excessive volatilization of glue to workers can be avoided.

Owner:郭一帆

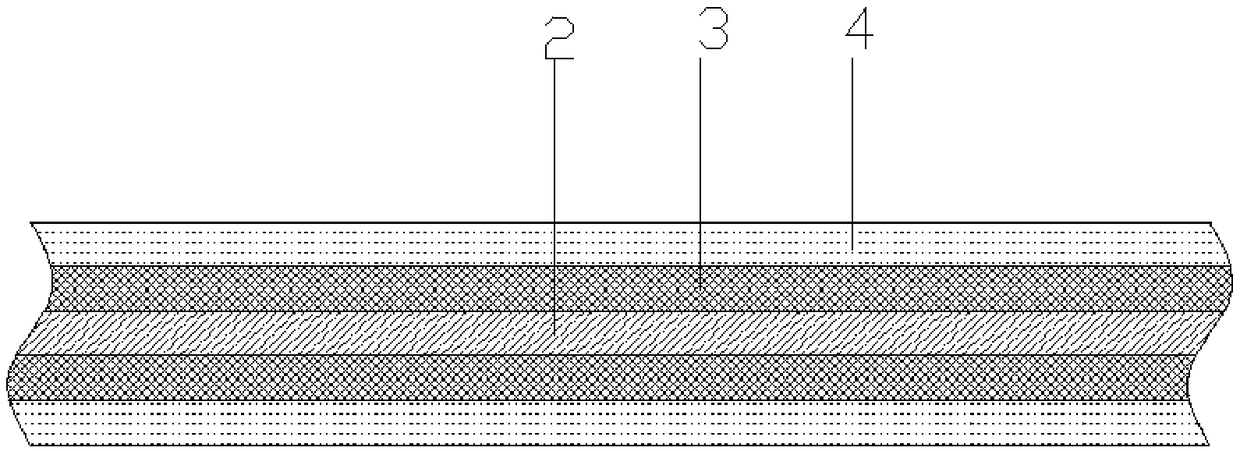

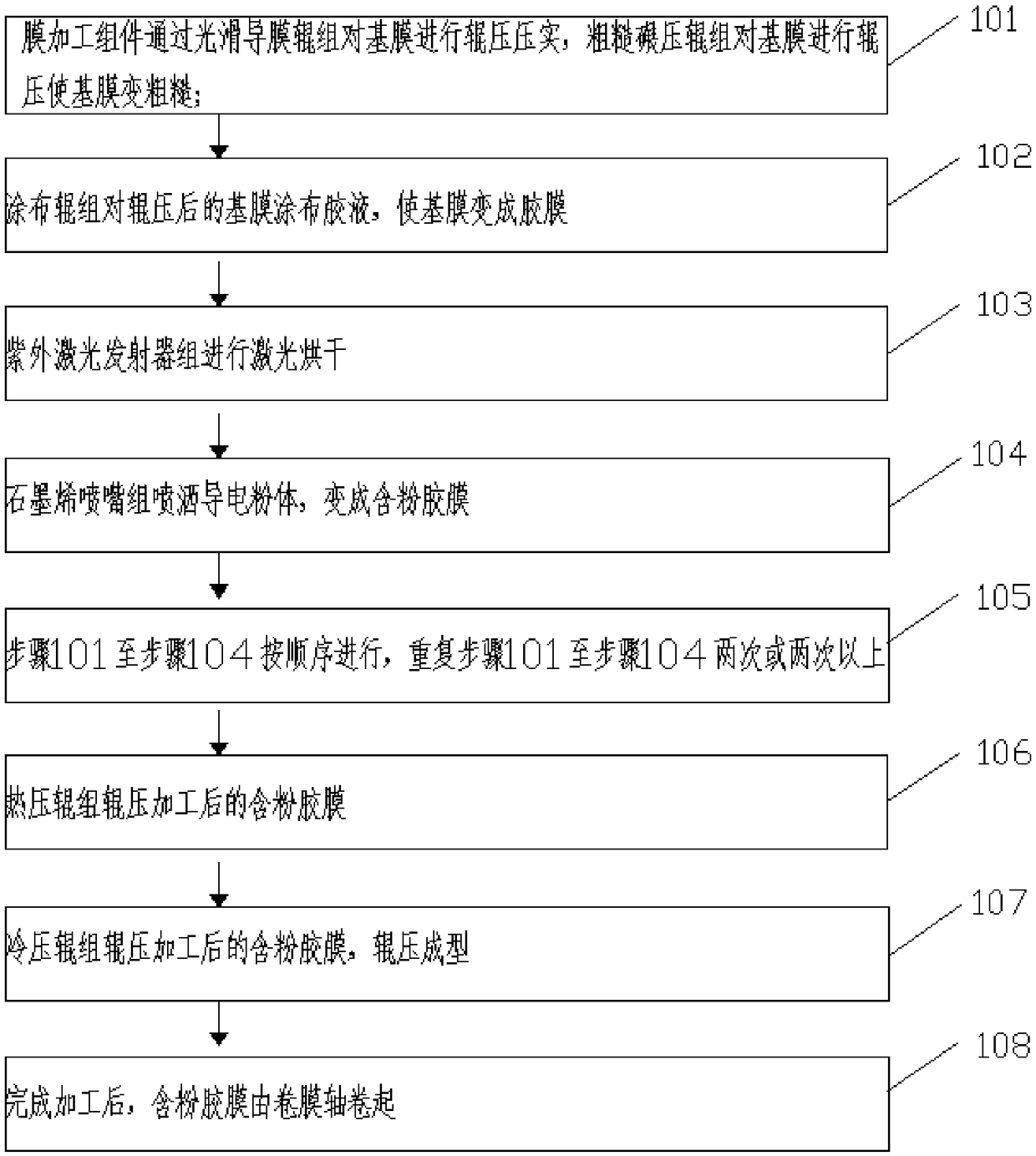

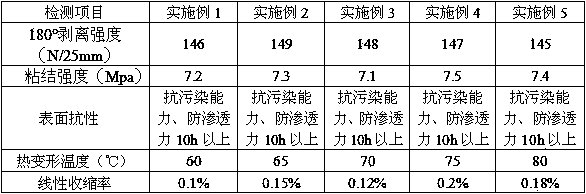

Double-side coated conducting film and preparation method thereof

InactiveCN109119184AImprove adsorption capacityInhibit sheddingConductive layers on insulating-supportsCable/conductor manufactureLaser transmitterGraphene

The invention discloses a double-side coated conducting film and a preparation method thereof. The double-side coated conducting film includes a film body, wherein the film body includes a base film,a graphene layer on both sides of the base film, and a sealant layer on both sides of the graphene layer; the base film can be prepared into a conducting film by a film processing device; and the filmprocessing device includes a film processing assembly, a hot press roll set and a cold press roll set; the film processing assembly comprises successively connected smooth rolling roll set, rough rolling roll set, coating roll set, graphene nozzle set, and ultraviolet laser emitter set. The preparation method of the double-side coated conducting film is simple in the process, satisfies the requirements of products with high adhesion requirements, enables the film body to be compact and strong through two or more times of rolling, and can effectively prevent the coated glue and the sprayed conductive powder from falling off and greatly improve the conductive performance of the conducting film through two or more times of coating the glue by means of the coating roll set, two or more timesof spraying conductive powder by means of the graphene nozzles, and two or more times of laser drying.

Owner:盐城美茵新材料有限公司

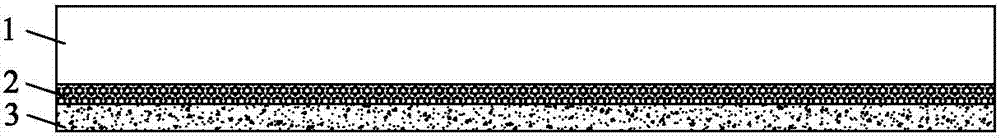

Paper-plastic edge banding with hot-melt adhesive and preparation process for paper-plastic edge banding

InactiveCN104207508AImprove adhesionReduce production processLamination ancillary operationsLaminationHot meltEdge banding

The invention relates to the technical field of paper-plastic edge bandings with hot-melt adhesives, in particular to a paper-plastic edge banding with a hot-melt adhesive and a preparation process for the paper-plastic edge banding. The paper-plastic edge banding with the hot-melt adhesive sequentially comprises a protective layer, a decorative layer, a paper-plastic substrate layer and a hot-melt adhesive layer from top to bottom, wherein the lower surface of the paper-plastic substrate layer is blade-coated with the hot-melt adhesive layer. According to the paper-plastic edge banding with the hot-melt adhesive, the hot-melt adhesive layer is combined, the paper-plastic substrate layer is adhered to and seamlessly connected with the hot-melt adhesive layer in a molten state, and the adhesion force of the hot-melt adhesive layer with the paper-plastic substrate layer and a product to be banded is high, so that the phenomenon of degumming is avoided; in addition, when the paper-plastic edge banding is used, adhesive overflow, the formation of an adhesive line and preparation work during the sticking of a conventional edge banding can be avoided, the effects of reducing the using amount of the adhesive and avoiding adhesive overflow during sticking, the adhesive line and tedious preparation are achieved, and the quality of a product and the production efficiency are greatly improved; a preparation method is simple, easy, high in production efficiency and applicable to industrial production.

Owner:DONGGUAN HUALI INDUSTRIES CO LTD

Plastic edge banding with 3D (Three Dimensional) effect and preparation process thereof

ActiveCN104323614AWith three-dimensional effectGood stereo visionCoatingsFittingMolten statePolymer science

The invention relates to the technical field of plastic edge bandings, in particular to a plastic edge banding with a 3D (Three Dimensional) effect and a preparation process thereof. The plastic edge banding with the 3D effect comprises a transparent substrate layer, a pattern layer and a hot melt adhesive layer, wherein the pattern layer is printed on the lower surface of the transparent substrate layer; the hot melt adhesive layer is scraped on the lower surface of the pattern layer. Since the pattern layer is arranged on the lower surface of the transparent protective layer, the pattern layer has the 3D effect when being seen through the transparent protective layer; a color can be matched for the pattern layer according to the color of a furniture plate applied by the edge banding; thus the edge banding has extremely excellent three-dimensional visual impression, richer aesthetic feeling of color, excellent product quality and a strong decoration effect; in addition, the hot melt adhesive layer and the pattern layer are seamlessly adhered together in a molten state and the adhesion force of the hot melt adhesive layer and a product to be subjected to edge sealing is high, the phenomenon of adhesive failure is avoided. The preparation method is simple and easy, has high production efficiency and is more suitable for industrial production.

Owner:东莞市华富立装饰建材有限公司

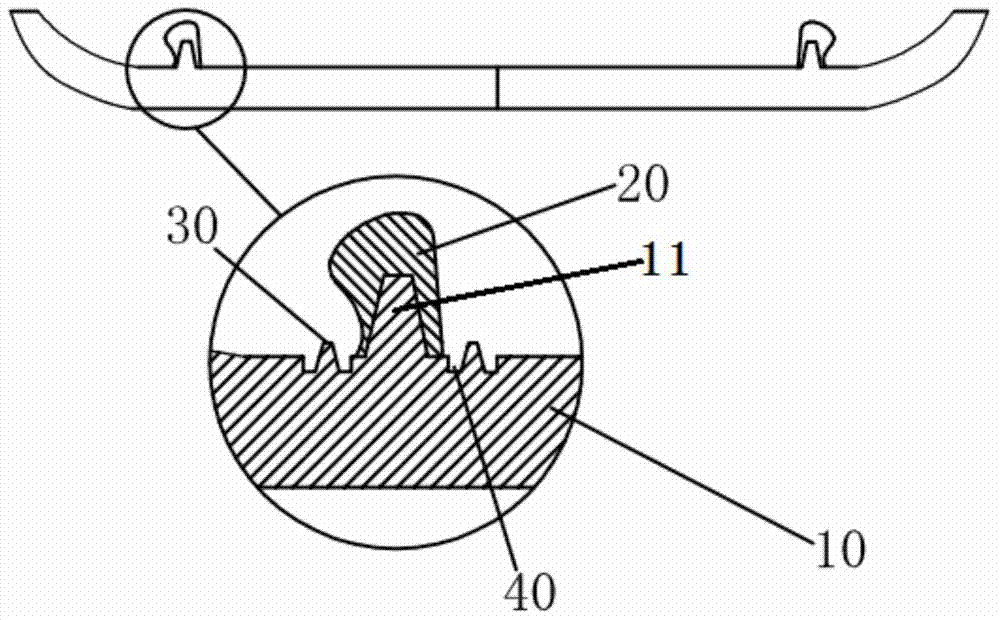

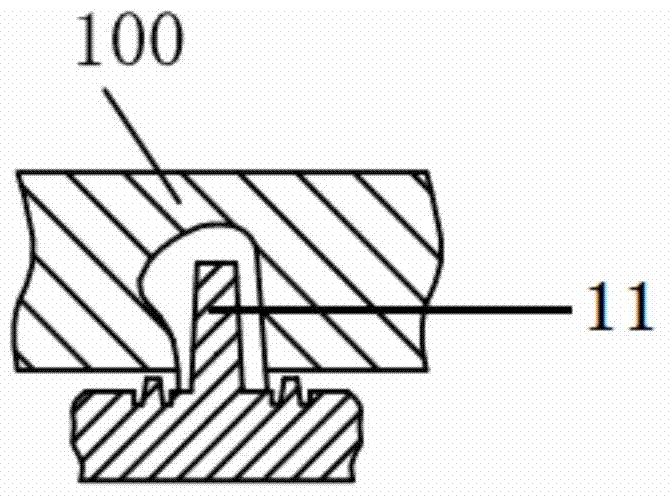

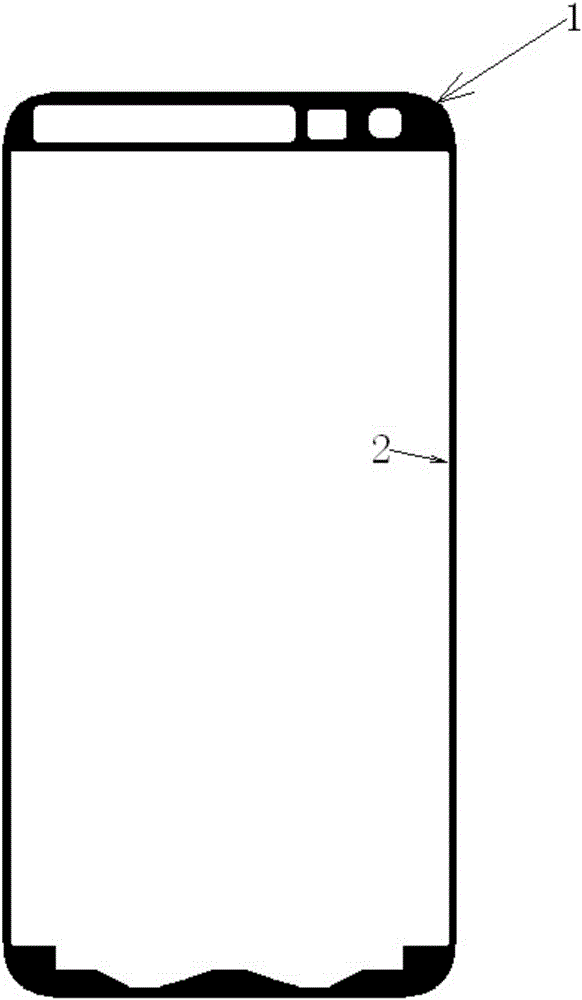

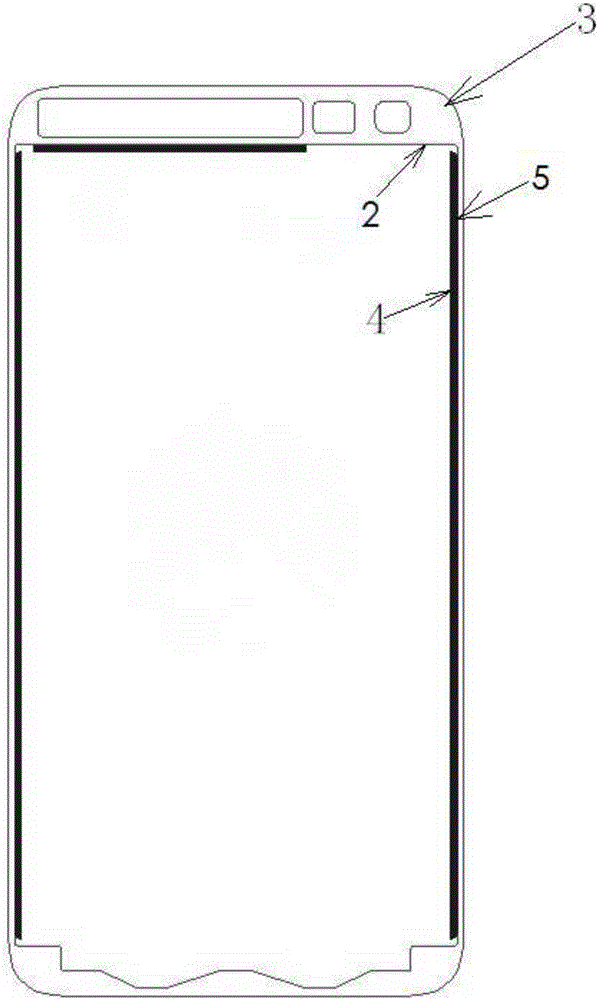

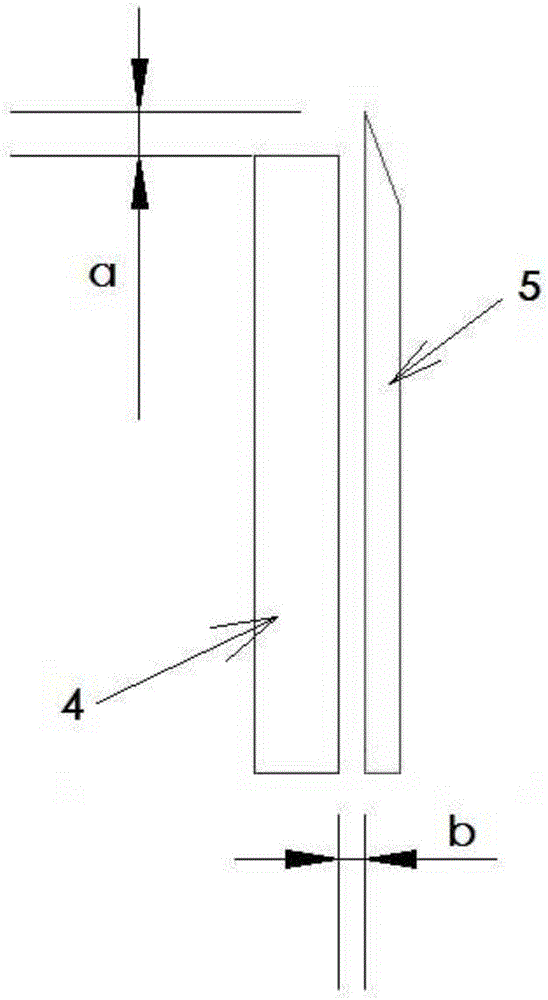

Die-cutting machining die structure

The invention provides a die-cutting machining die structure. A narrow-edge double-faced adhesive tape is attached to the lower bottom surface of a product; the product is attached to a die-cutting machining die; a stop strip is arranged along the side, which is required to be cut, of a frame of the die-cutting machining die; the stop strip and the inside position of the narrow-edge double-faced adhesive tape are positioned in the same horizontal line; the distance between the stop strip and the inside of the narrow-edge double-faced adhesive tape is 0.03 to 0.05 mm; the height of the stop strip is 0.03 to 0.05 mm lower than that of a cutting edge of the die. Due to the adoption of the technical scheme, the current common die structure of the die-cutting machining die structure provided by the invention is redesigned on the basis of not changing a material, and the same linear stop strip is added to the position which is 0.03 to 0.05 mm away from the narrow-edge double-faced adhesive tape, so that the product quality problems of glue overflowing and transformation after the narrow-edge double-faced adhesive tape is die-cut and stamped are avoided.

Owner:TIANJIN RIJIN TECH

Guitar humidifier automatic assembling process

ActiveCN110270477AImplement automatic assemblyReduce the amount of manual laborLiquid surface applicatorsMaterial gluingBiochemical engineeringEconomic benefits

The invention relates to the field of mechanical production, in particular to a guitar humidifier automatic assembling process. The process comprises the following steps that firstly, shells are automatically fed; secondly, sponge is automatically fed and cut; thirdly, the sponge is placed into the shells correspondingly; fourthly, the shells are coated with glue; fifthly, bottom covers are automatically fed and mounted on and fixed to the shells correspondingly; and sixthly, automatic discharging is performed. The process design is ingenious, the whole process is high in automation degree, and the production efficiency is improved by 10-15 times compared with that of a manual manner; in addition, glue coating is uniform, no glue overflows, the yield can reach up to 99.99% or above, and the product quality stability consistency is good; and in addition, manpower can be saved by 85% or more, the economic benefit is remarkable, the manual labor is reduced, and hurt of excessive glue volatilization to workers is avoided.

Owner:聊城国奥信息技术有限公司

Double-sealing-type socket press-fit pipe fitting and an assembling method thereof.

PendingCN111188953ASimple structureGuaranteed tightnessNon-disconnectible pipe-jointsPipe fittingEngineering

The invention discloses a double-sealing-type socket press-fit pipe fitting and an assembling method thereof. The double-sealing-type socket press-fit pipe fitting comprises a pipe material and a socket press-fit welding head, the pipe material is inserted from the open end to the welding end, after insertion, the part located in the socket press-fit welding head is an insertion part, a circle ofsealing tape are connected to the outer wall of the insertion part in a sleeving mode, one end of the sealing tape is parallel and level to the open end, the other end of the sealing tape is close tothe welding end, the gap between the other end of the sealing tape and the welding end is filled with an anaerobic adhesive layer, and an annular groove is formed in the position, corresponding to thesealing tape, of an outer pipe body; the pipe fitting and the socket press-fit welding head are subjected to confining pressure through a hydraulic tool and are connected with each other tightly, andtwo confining pressure positions of confining pressure are separately located on the sealing tape and the anaerobic adhesive layer. According to the double-sealing-type socket press-fit pipe fitting,the structure and assembling method of the socket press-fit pipe fitting are improved, the amount of adhesive filling is effectively reduced, and the phenomenon of adhesive overflowing is avoided; and meanwhile, the installation cost is greatly saved, the sealing performance can be increased, and the installation quality of pipeline engineering can be ensured under extreme conditions such as high-and-low temperature area and high pressure environment.

Owner:金品冠科技集团有限公司

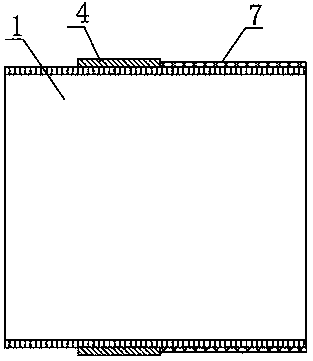

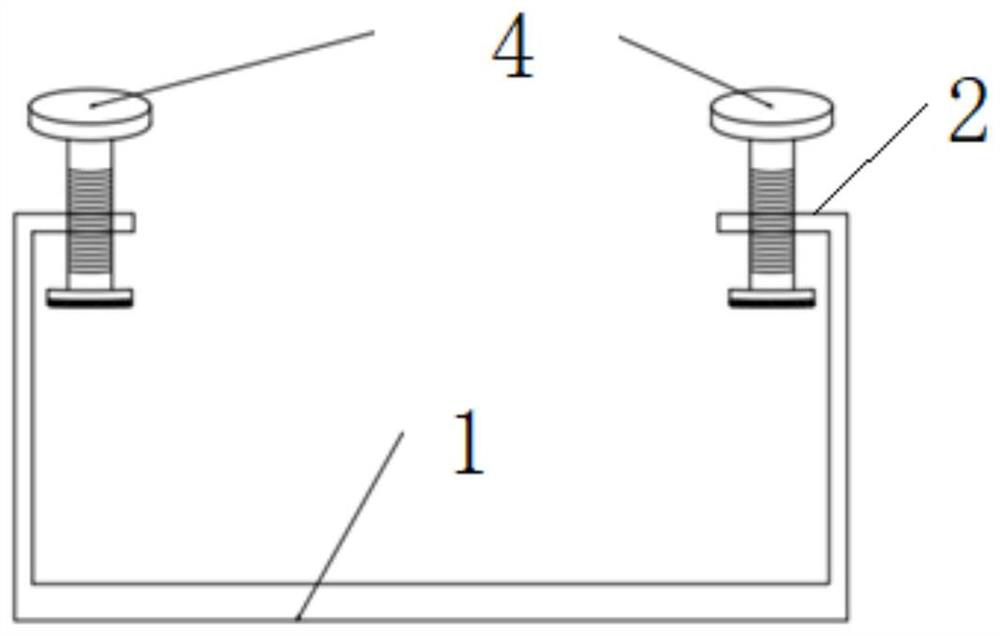

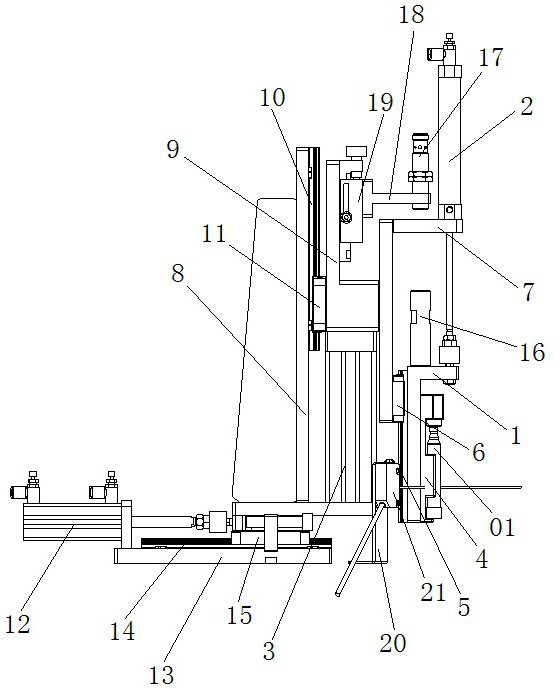

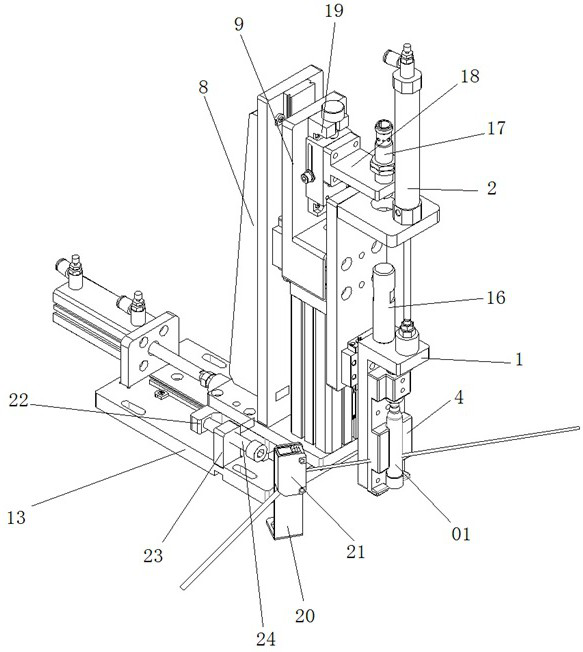

Clamping jig and glue filling system thereof

PendingCN114146875AHigh degree of automationAccurately adjust the clamping thicknessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a clamping jig and a glue filling system thereof, the clamping jig comprises a main body provided with a supporting part and a fastening part, a product to be clamped is located between the supporting part and the fastening part, and the fastening part is provided with a screw hole; the screw is matched with the screw hole, and a screw rod of the screw is provided with scale marks; wherein the screw is screwed into one end of the screw hole and penetrates through the fastening part, the distance between the screw and the supporting part is the clamping thickness, and the screw is screwed in or screwed out to adjust the clamping thickness to be the same as the thickness of the product to be clamped. According to the clamping jig and the glue filling system thereof, the clamping jig utilizes the screws with the scale marks to accurately adjust the clamping thickness, the clamping precision of products including curved screens is improved, the fixing effect is good, the thickness uniformity of the products can be guaranteed to the maximum extent, it is guaranteed that glue failure and glue overflowing do not occur in the follow-up process, the corresponding glue filling system is high in automation degree, and the production efficiency is improved. The product is not easy to damage.

Owner:越达光电科技浙江有限公司

Integrated circuit or discrete component flat bump package technics and its package structure

ActiveCN1738014APrevent spillageNo pollution problemSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a plane point-protruded type packaging process and its structure of integrated circuit or discrete component, comprising following steps: pasting dry films (2, 3) on the two surfaces of a metallic base plate (1) while removing some dry films relatively; plating active compound and metallic layer on the area of base plate for forming base island and pins; removing the left dry film on the front of base plate; half etching to form a depressed half etched region (1, 3), base island 1.1 and pin 1.2; removing the dry film left on the back of base plate; planting chip (9) into the front metal layer of base island, tie metallic thread (10), packaging plastic packaging body (11), front printing (12), and etching again on the left metal 1.4 of half etched region (1.3); pasting film (13) on the face of plastic packaging body, and slicing. Said invention has strong welding property, better quantity, low cost, good adaptability, reflex able arrangement of chips, while avoiding the problem of infiltration of plastic packaging material.

Owner:长电科技管理有限公司

Method for injecting sealants into groove

ActiveCN104324867APromote formationEasily and precisely formedLiquid surface applicatorsDomestic articlesSealantMechanical engineering

A method of injecting a sealing gel into a recess (8) of a work piece to form a predetermined structure defined by sealing gel at a local region (9) of the recess, comprising steps of: providing a molding tool (2) having an insertion structure complementary to the predetermined structure; enclosing the local region of the recess with the molding tool, and injecting a fluid sealing gel into the molding tool; and after the sealing gel has been cooled and solidified, dismantling the molding tool so that the predetermined structure defined by sealing gel is formed at the local region of the recess.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

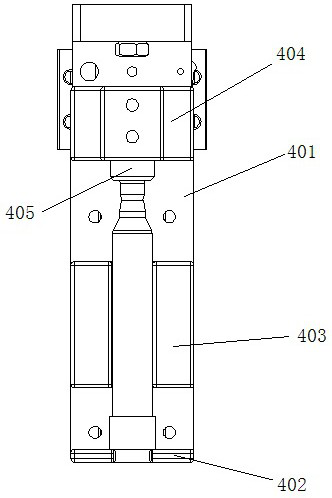

Glue filling tool clamp mechanism

The invention discloses a glue filling tool clamp mechanism. A barrel clamp is arranged on a clamp mounting seat, a first vertical guide rail is arranged on the clamp mounting seat, a first sliding block is arranged on the first vertical guide rail, the first sliding block is connected with a backpressure air cylinder mounting seat, a backpressure air cylinder is arranged on the backpressure air cylinder mounting seat, and a telescopic rod of the backpressure air cylinder is connected with the top of the clamp mounting seat. A jacking air cylinder is arranged on a fixing seat, a jacking installation seat is arranged on a telescopic rod of the jacking air cylinder, a second vertical guide rail is arranged on the side face of the fixing seat, a second sliding block is arranged on the second vertical guide rail, and the second sliding block is connected with the side face of the jacking installation seat. A movable air cylinder is arranged on a movable installation seat, a horizontal guide rail is arranged on the movable installation seat, a third sliding block is arranged on the horizontal guide rail, a telescopic rod of the movable air cylinder is connected with the third sliding block, and the top of the third sliding block is connected with the bottom of the fixing seat. The glue filling tool clamp mechanism is compact in structure, high in strength and capable of achieving continuous glue filling and accurately controlling the glue filling volume.

Owner:烽禾升医疗设备(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com