Method for injecting sealants into groove

A sealant and injection port technology, which is applied in the field of forming a sealant with a predetermined structure in a local area, can solve the problems of time-consuming, difficult, and the inability to form a sealant, and achieves the effect of reducing the manufacturing cost and the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

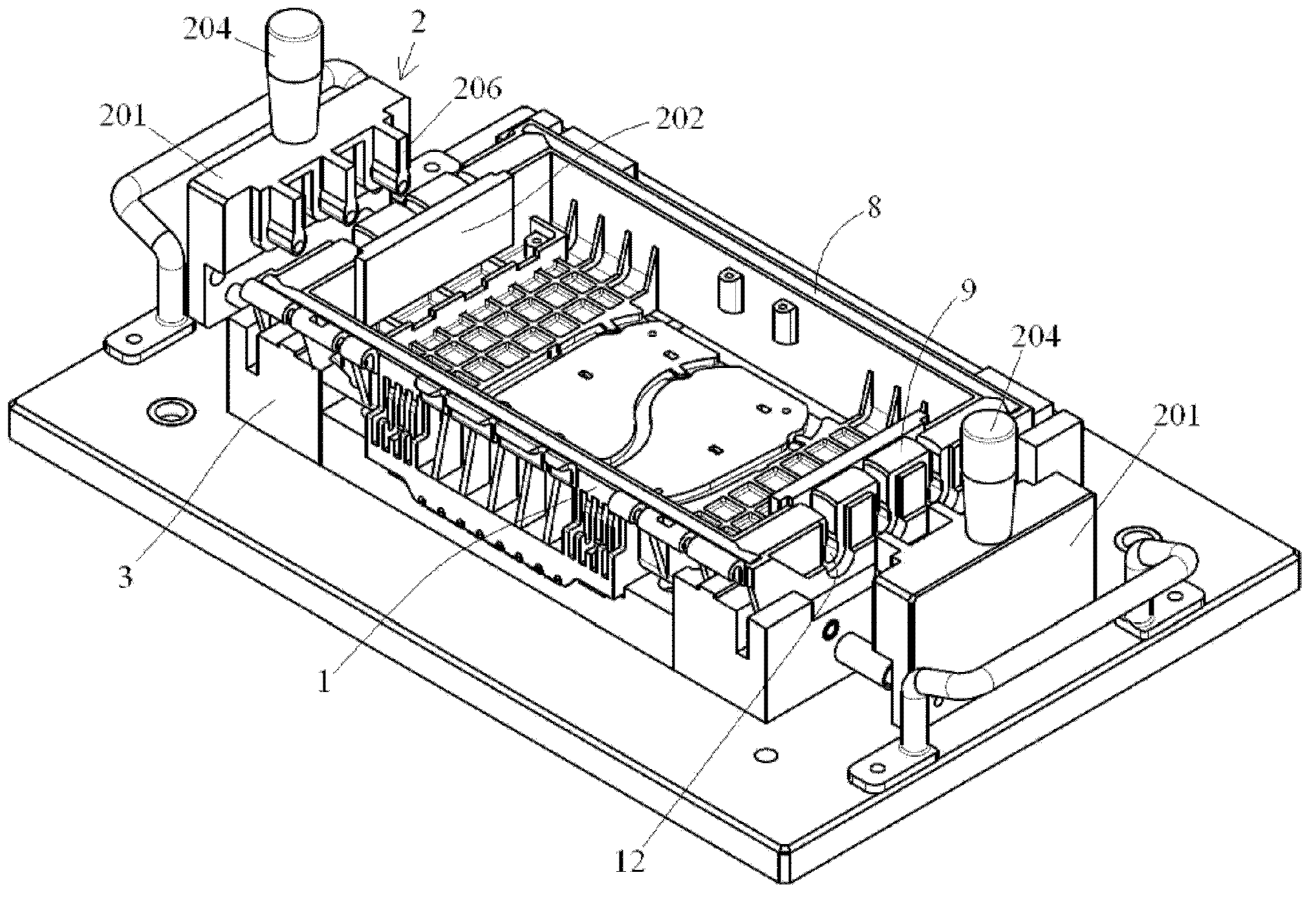

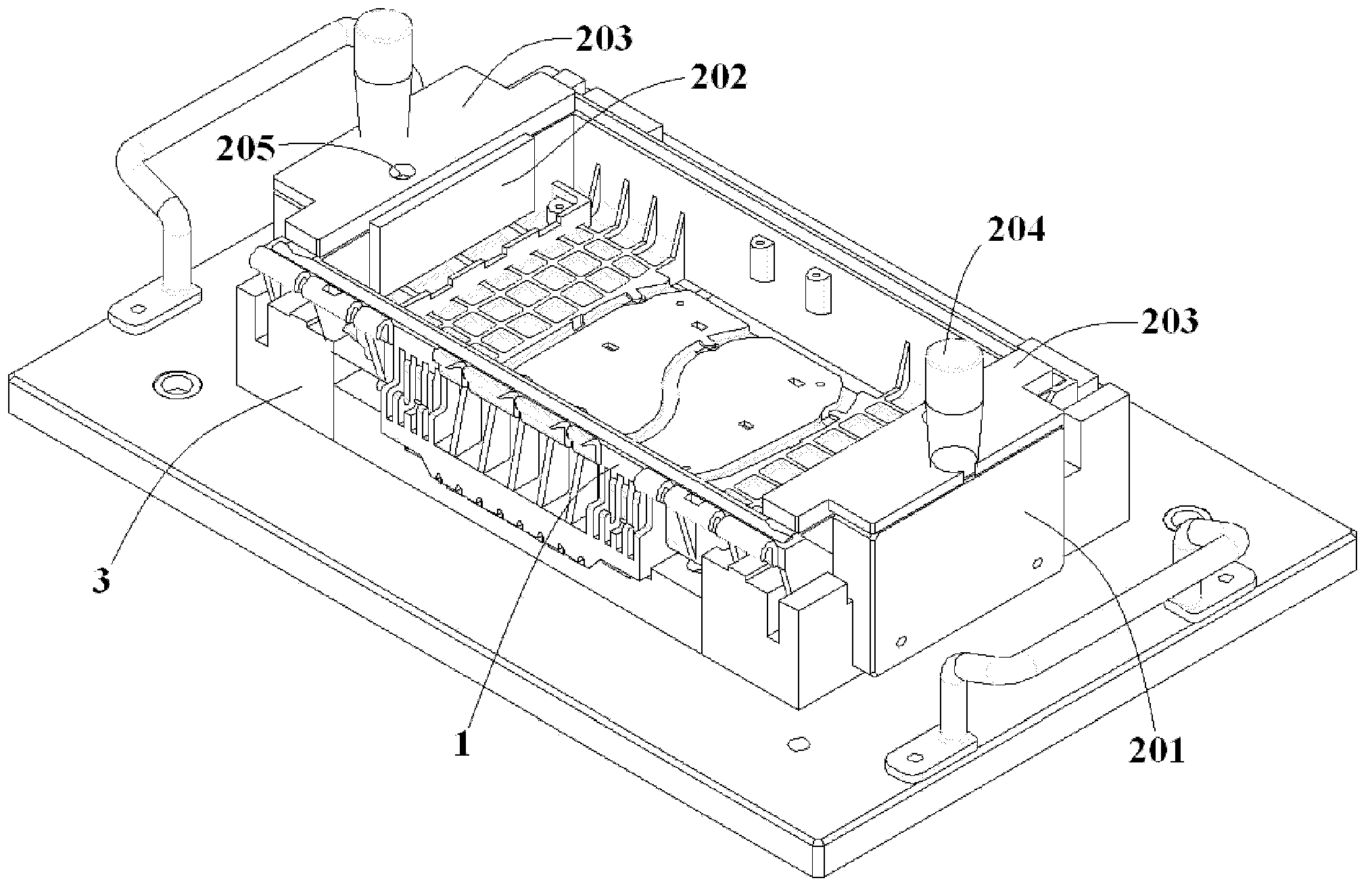

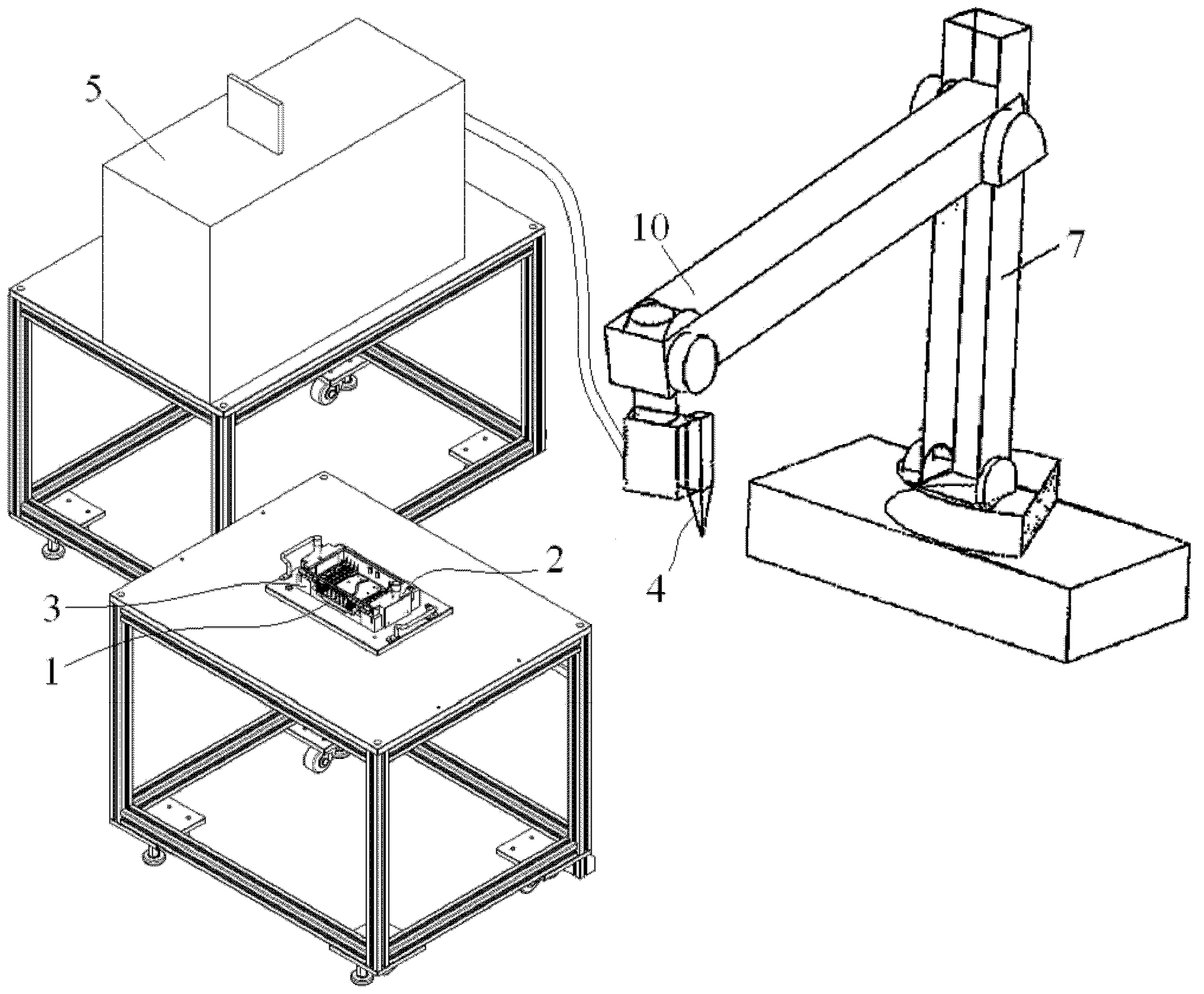

[0029] figure 1 A schematic diagram showing a plastic box body 1 fixed on a positioning member 3 according to an embodiment of the present invention, wherein a mold for forming a sealant with a predetermined structure 12 in a local area 9 of a groove 8 of the box body 1 is shown making tools.

[0030] Such as figure 1 As shown, a groove 8 is formed in the top surface of the surrounding side walls of the box body 1 , and the sealant will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com