Waterproof metal outer shell of electronic product and manufacturing method thereof

A technology for waterproof shells and electronic products, applied in the direction of metal shells, sealed shells, etc., can solve problems such as mold and product damage, achieve pressure relief, good hand feeling and heat dissipation, and avoid damage to molds and/or shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

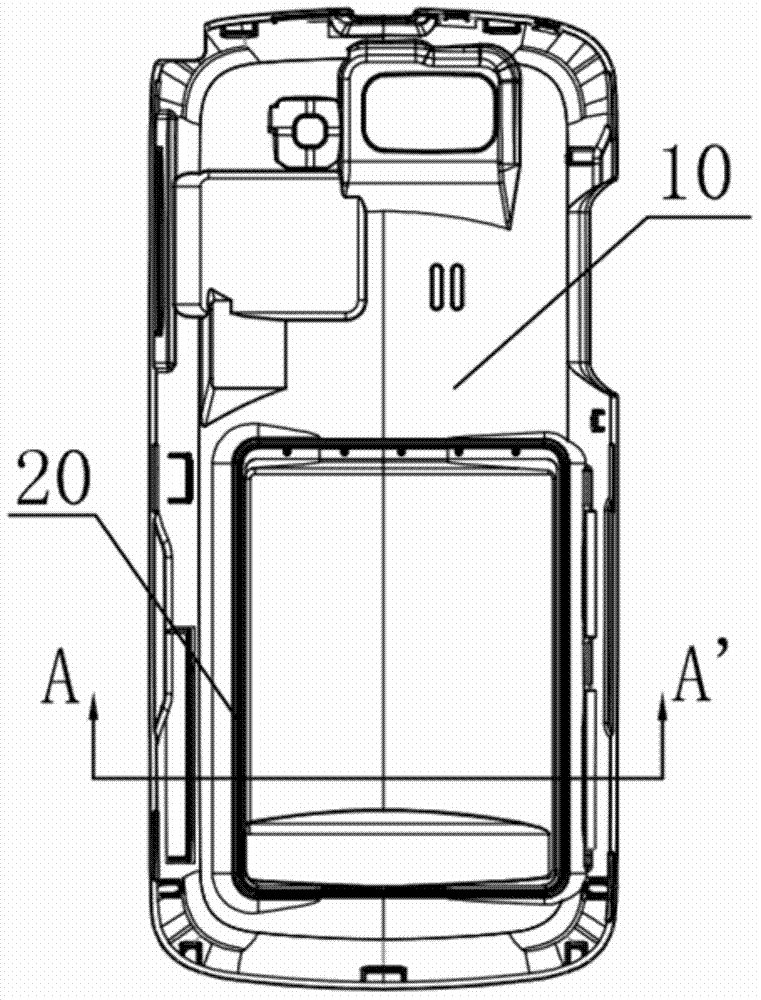

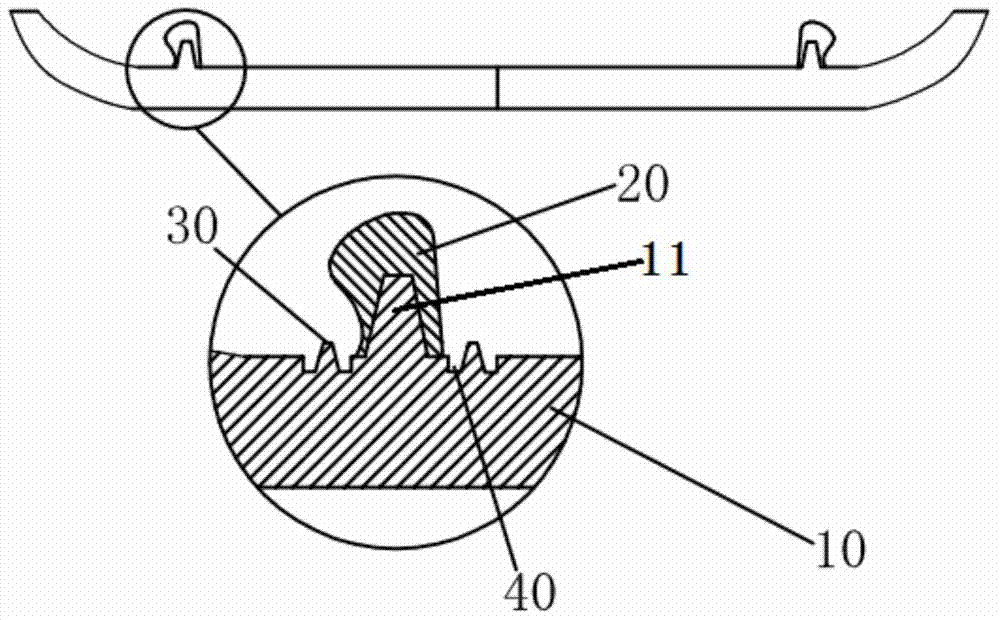

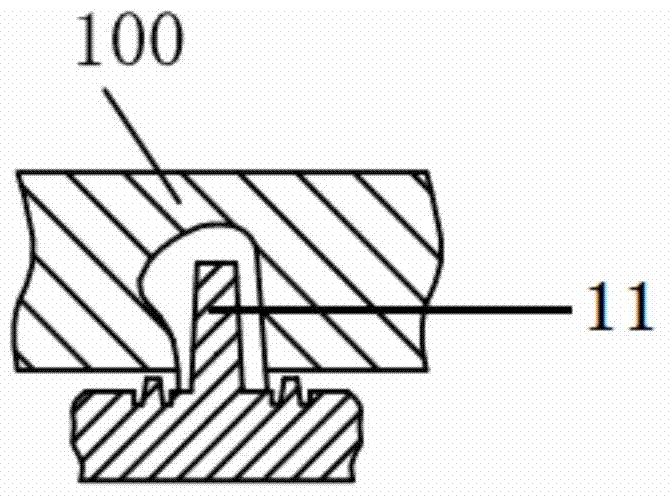

[0029] The specific embodiment of the present invention provides a kind of such as figure 1 The metal waterproof shell of the mobile phone shown includes a metal shell 10 and a silicone waterproof part 20 . Such as figure 2 As shown, the metal shell 10 includes a waterproof bone 11 protruding from its inner surface, and the inner surface of the metal shell 10 is formed by protruding upwards at positions on both sides of the waterproof bone 11 separated by a predetermined distance. The sealing boss 30, the inner surface of the metal shell 10 on at least one side of the sealing boss 30 is recessed to form an accommodating groove 40; the silicone waterproof part 20 is formed on the waterproof part by in-mold injection On the bone 11, and the side surface of the silicone waterproof part 20 has a convex part, such as Figure 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com