Insulating adhesive film for flexible flat cable and preparation method of insulating adhesive film

An insulating film, flexible and flat technology, applied in the direction of adhesives, epoxy resin glue, film/sheet adhesive, etc., to achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Attached below figure 1 , 2 , and further illustrate the technical solution of the present invention through specific embodiments.

[0061] Unless specifically stated, various raw materials of the present invention can be purchased commercially, or can be prepared according to conventional methods in the art.

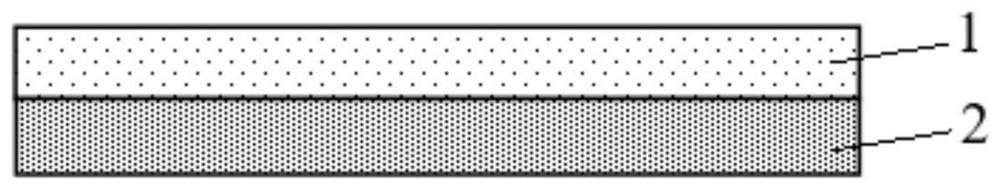

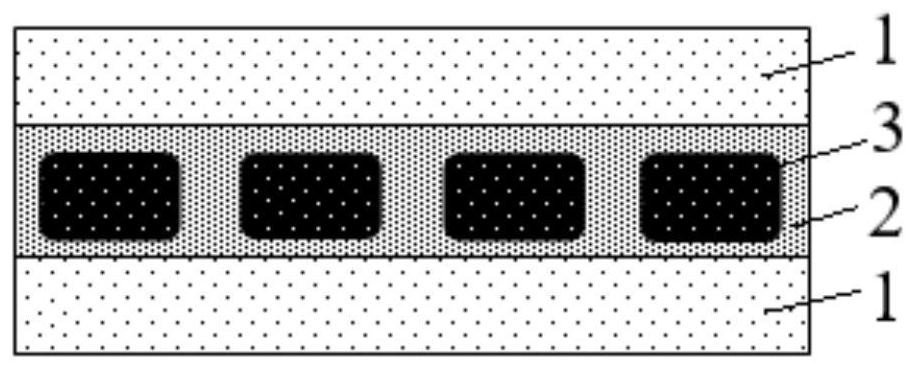

[0062] Such as figure 1 As shown, the insulating adhesive film for flexible flat cables of the present invention includes a substrate layer 1 and an adhesive layer 2, such as figure 2 As shown, the flexible flat cable made by using the insulating adhesive film of the present invention includes a plurality of conductors 3 arranged in parallel at intervals and insulating adhesive films attached to the upper and lower sides, wherein the adhesive layer 2 is used for bonding the conductors 3 .

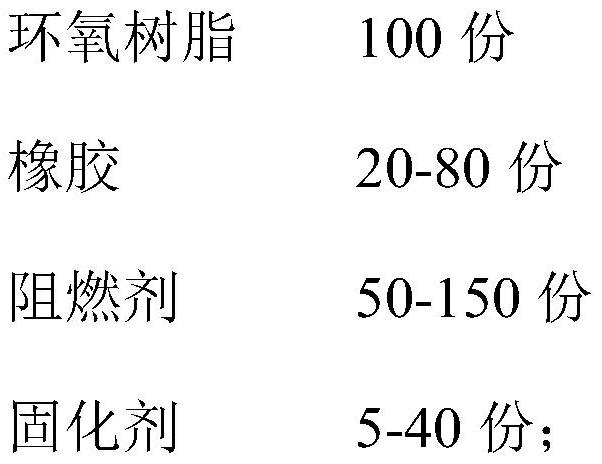

[0063] Insulating adhesive film of the present invention, by weight, the adhesive layer comprises the following components:

[0064]

[0065] Wherein, the epoxy resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com