Guitar humidifier automatic assembling process

A technology for automatic assembly and humidifier, which is applied in the direction of device, material gluing, connecting components, etc. for coating liquid on the surface, which can solve the problems of inability to realize automatic assembly of guitar humidifier, physical injury of workers, and high labor cost. Significant economic benefits, increased production speed, and ingenious effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

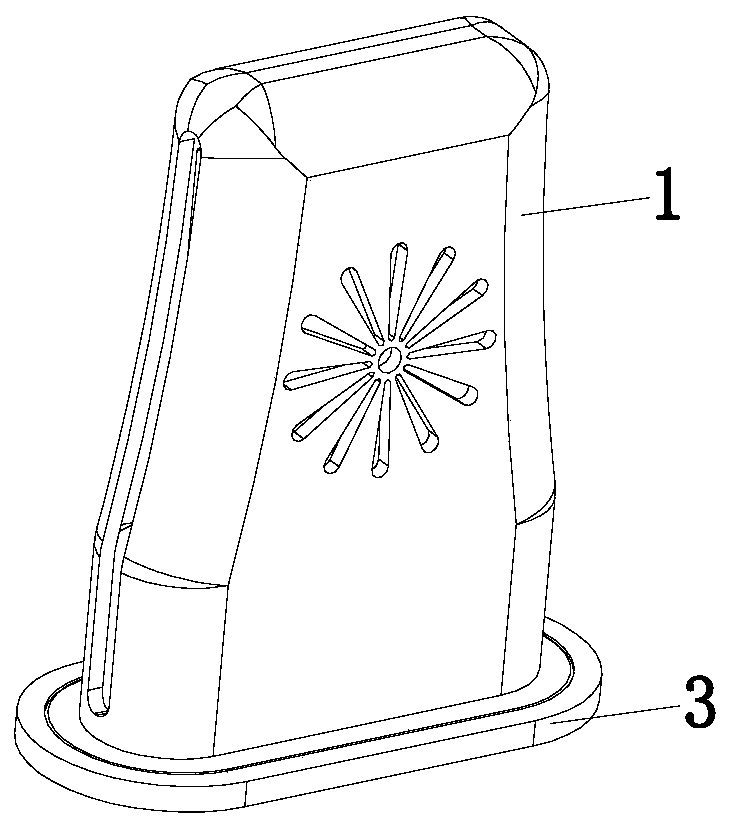

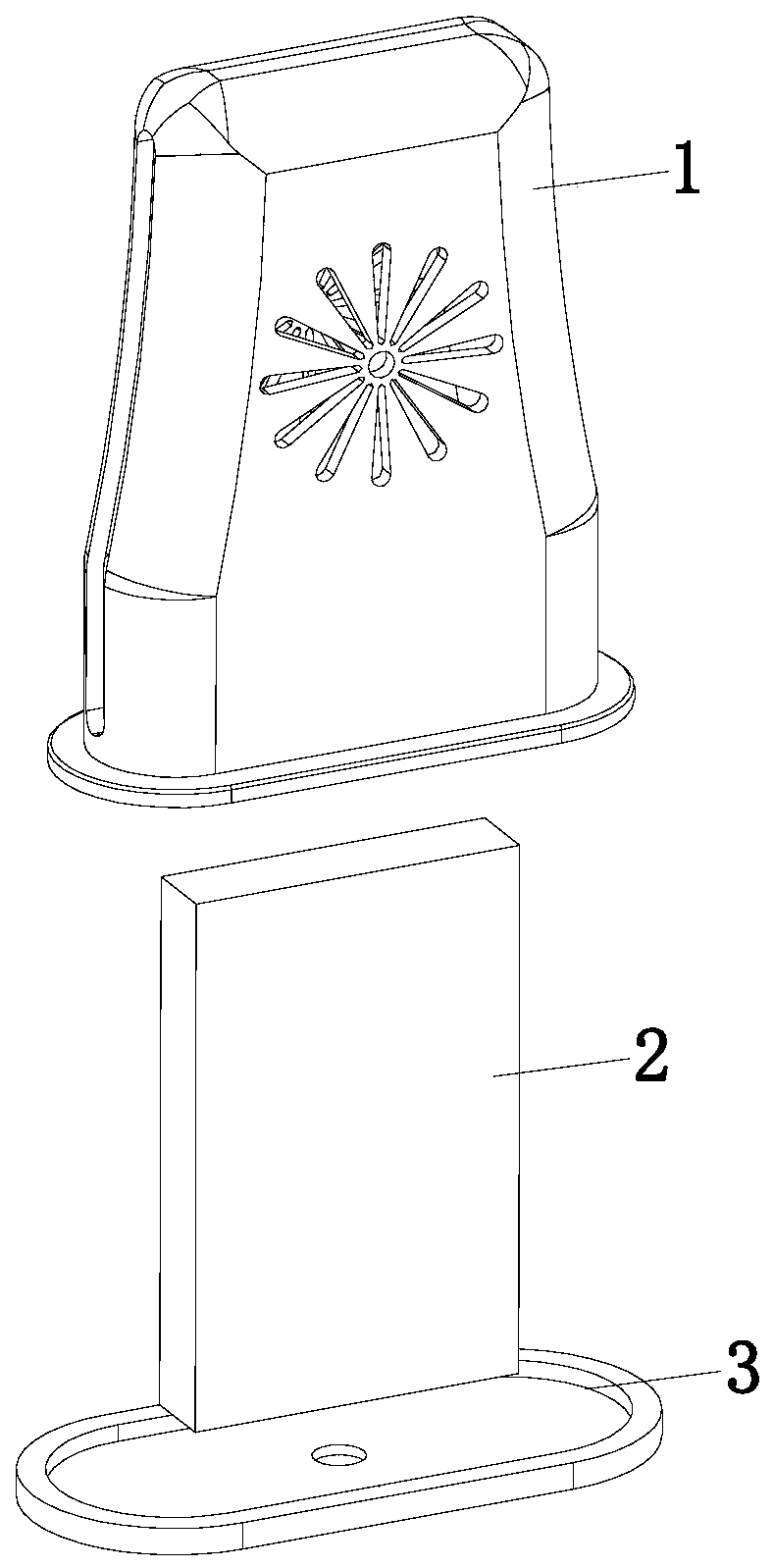

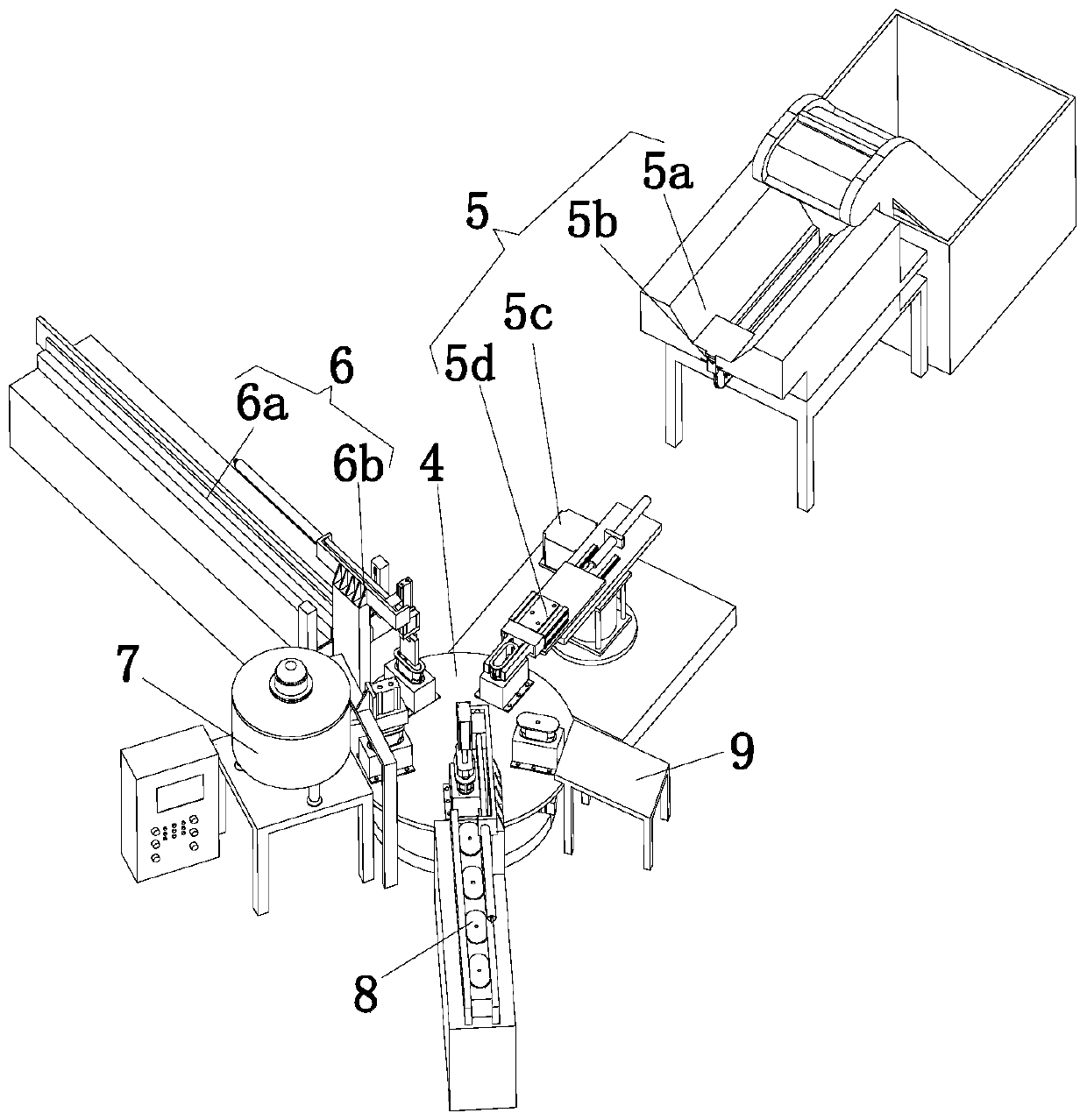

[0050] Such as Figure 1-Figure 18 As shown, a guitar humidifier automatic assembly process includes the following steps:

[0051] Step 1. Automatic feeding of the casing: the casing feeding mechanism 5 includes a feeding assembly 5a, a limiting assembly 5b, a driving assembly 5c and a transfer assembly 5d, and the transfer assembly 5d is located between the feeding assembly 5a and the rotating mechanism 4, The limiting assembly 5b is installed at the end of the feeding assembly 5a, the driving assembly 5c is installed below the transfer assembly 5d, and drives the feeding plate 5a5 to move through the work of the first conveyor belt 5a2, and the feeding plate 5a5 drives the material in the material box. The casing 1 moves together with the first conveyor belt 5a2 to the top of the feeding block 5a4, the casing 1 falls into the feeding chute 5a6 and hangs on the suspension groove 5a7, and the vibration motor 5a3 works so that the casing 1 moves along the suspension groove 5a7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com