Double-sealing-type socket press-fit pipe fitting and an assembling method thereof.

A technology for pipe fittings and pipe materials, which is applied in the field of double-sealed socket press-fit pipe fittings and assembly, which can solve the problems of easy generation of cavities and pores, unsaturated pressure pipe glue, and inability to achieve sealing, so as to reduce the amount of glue poured, High adhesiveness and the effect of preventing glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

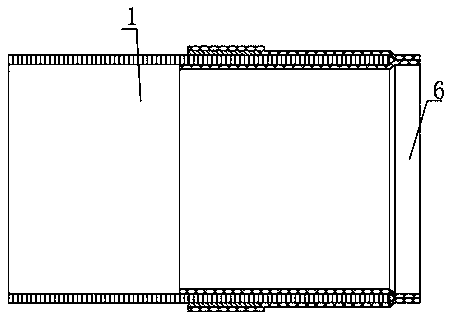

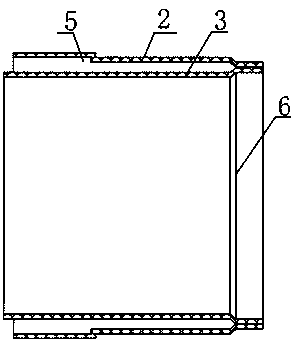

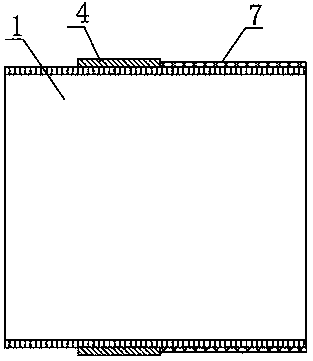

[0028] Embodiment 1: see Figure 1-Figure 4 , a double-sealed socket press-fit pipe fitting, including a pipe 1 made of stainless steel and a socket press-fit welded joint 6, the socket press-fit welded joint 6 includes an inner pipe body 3 and an outer pipe body 2, two They are arranged in parallel, one end is welded as the welding end, and the other end is used as the open end for the pipe 1 to be inserted into. part, the outer wall of the insertion part is sleeved with a ring of sealing tape 4, one end of the sealing tape 4 is flush with the open end, the other end is close to the welding end and the gap between the welding end and the welding end is filled with an anaerobic adhesive layer 7, the outer Corresponding to the sealing tape 4 on the pipe body 2, there is an annular groove 5 for the sealing tape 4 to be embedded in;

[0029] The pipe fittings and the socket compression welding joint 6 are tightly connected by the ring pressure of the hydraulic tool, and the two ...

Embodiment 2

[0038] Example 2: see Figure 1-Figure 4 , the sealing tape 4 is made of fluorine rubber, silicon rubber or nitrile rubber, with a thickness of 0.6mm-3.5mm and a width of 20-80mm, and the anaerobic adhesive standard is HG / T3737. All the other are identical with embodiment 1.

[0039] In this embodiment, on the existing clamping pipeline, increase the use of widened special sealing tape 4, such as about 70 mm, and the material is fluorosilicone rubber that is resistant to high and low temperatures and has a long service life. For more than 20 years, it can ensure the quality of pipeline engineering installation under extreme conditions such as high and low temperature areas and high pressure environments.

Embodiment 3

[0040] Embodiment 3: see Figure 1-Figure 4 In the present embodiment, the thickness of the sealing tape 4 is related to the diameter of the pipe 1. For example, the pipe 1 with a diameter of 15mm can use the sealing tape 4 with a thickness of 0.6mm, and the pipe 1 with a diameter of 400mm can use the sealing tape 4 with a thickness of 3.5mm. All the other are identical with embodiment 1.

[0041] The invention strengthens the sealing effect of the joints of the pipeline engineering, fills the existence of some small gaps caused by the springback when the stainless steel is pressed, and can adapt to the pipeline engineering in various regional environments. Through the test verification, this scheme is superior to the original technology. It can effectively reduce the overflow of anaerobic adhesives and reduce the amount of anaerobic adhesives, so that the sealing performance of pipeline engineering is stronger in high and low temperature climates and high pressure environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com