Glue filling tool clamp mechanism

A tooling fixture and glue filling technology, applied in packaging and other directions, can solve the problems of large clamping tool volume, unstable glue filling speed, low degree of automation, etc., and achieve the effects of high production efficiency, reduced labor costs, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

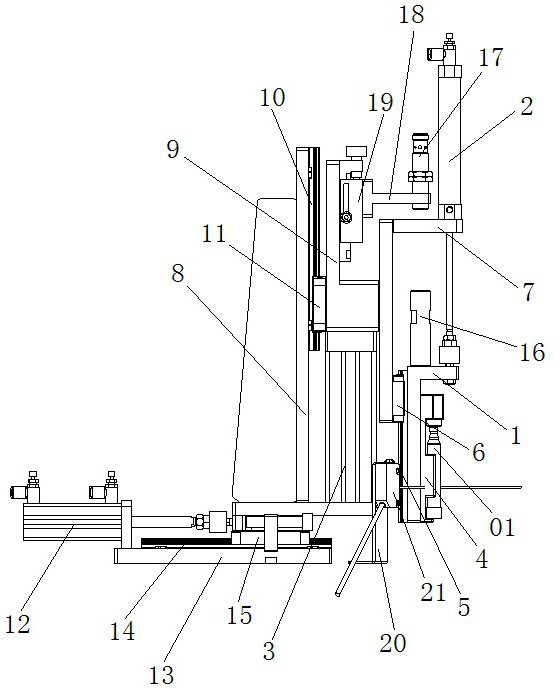

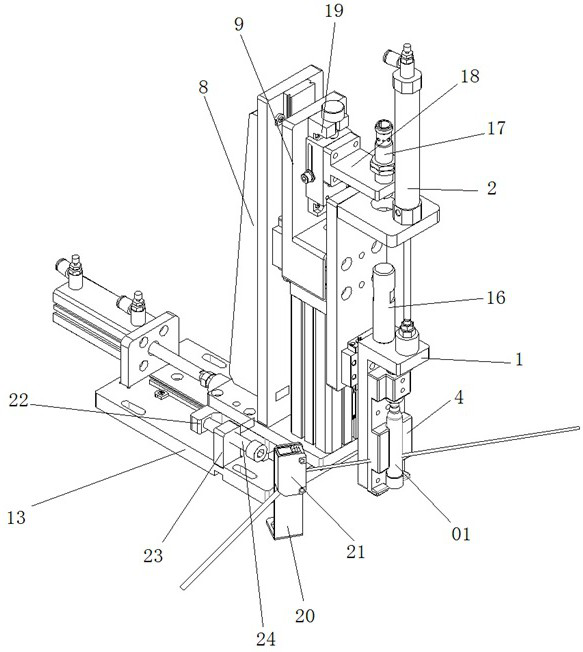

[0030] During use, the fixing seat 8 can be fixed on the machine table, and the syringe cylinder 01 can be clamped in the cylinder clamp by moving the syringe cylinder 01 . It is also possible to fix the mobile mounting seat on the machine table, extend the entire fixed seat by moving the cylinder, when the fixed seat is in place, the limit part contacts the buffer plunger, which is used to buffer the cylinder clamp and the syringe barrel Kinetic energy when the body 01 contacts, the syringe barrel 01 is clamped in the barrel clamp.

[0031] After the syringe barrel 01 is snapped into place, the nozzle of the automatic filling mechanism is inserted from the opening at the bottom of the syringe barrel, and the syringe barrel 01 is lifted up, and the nipple at the top of the syringe barrel 01 is snapped into the barrel fixture, and the start Glue filling, the colloid is squeezed into the nozzle by the automatic glue filling mechanism, and then enters the barrel of the syringe fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com