Patents

Literature

139results about How to "Prevent re-oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

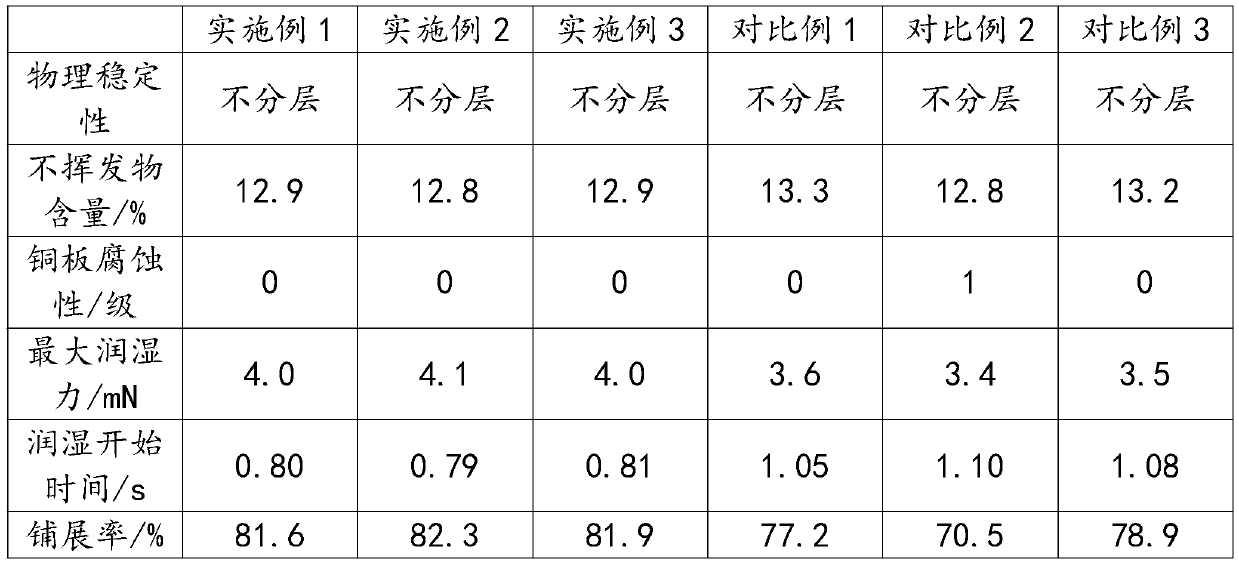

Copper base material cleaning agent and preparation method thereof

The invention provides a copper base material cleaning agent. The copper base material cleaning agent is composed of, by weight, 0.05%-2% of organic acid activators, 0.05%-1% of a nonionic surface activator, 0.01%-0.6% of an anion surface activator, 0.005%-0.2% of an antioxidant, 0.005%-0.2% of a chelating agent, and the balance deionized water. In addition, the invention discloses a preparation method of the copper base material cleaning agent. The copper base material cleaning agent is free of attenuation and controlling over the attenuation, can be directly used, does not contain heavy metal, is free of residues and can meet the processing requirements for copper before hot dipping; the surface of a copper base material processed by the cleaning agent is pure and is free of dark spots, oil contaminations, fingerprints and the like; accessories obtained after tinplating are free of exposed copper, dark spots and other defects, and the surfaces of the accessories are smooth.

Owner:THE NORTHWEST MACHINE

Process method for preparing cold brewing tea by ice crystallization cell wall breaking

InactiveCN101669553AInhibit peroxidationImprove solubilityPre-extraction tea treatmentData controlDrinking habits

The invention discloses a method for preparing cold brewing tea by ice crystallization treatment. The method comprises the following steps: putting fresh tea leaves in a low-temperature environment below 40 DEG C below zero for ice crystallization; putting the tea leaves subjected to the ice crystallization treatment into a vacuum container; slubbing the tea leaves in the vacuum container; heatingthe vacuum container at a heating temperature of between 70 and 100 DEG C; and stirring the tea leaves in the heated vacuum container until the tea leaves are dried. The ice crystallization process,which is adopted for replacing the conventional withering process, can change the conventional process depending on human experience control into data control and significantly improve the product consistency; the ice crystallization cooperated with the enzymatic oxidation of vacuum negative pressure isolated environment oxygen can avoid the problem of peroxided sensitive substances in the tea leaves; the adoption of an ice crystallization wall breaking process combined with vacuum evaporation dewatering drying can avoid the problem of reoxidation in the drying process; the tea prepared by theice crystallization wall breaking process has better solubility in cold water; the cold water brewing tea prepared by the ice crystallization wall breaking process can improve tea drinking habits ofhuman beings; and the adoption of the cold water brewing tea can save a large amount of energy for boiling water. The method can also be used for preparing cold water brewing beverages by using otherplants to conventionally be soaked in water for drinking, such as ginseng leaves, ginkgo leaves, chrysanthemums, green plums, olives and the like, thereby providing a new idea for enriching markets.

Owner:苏少宁

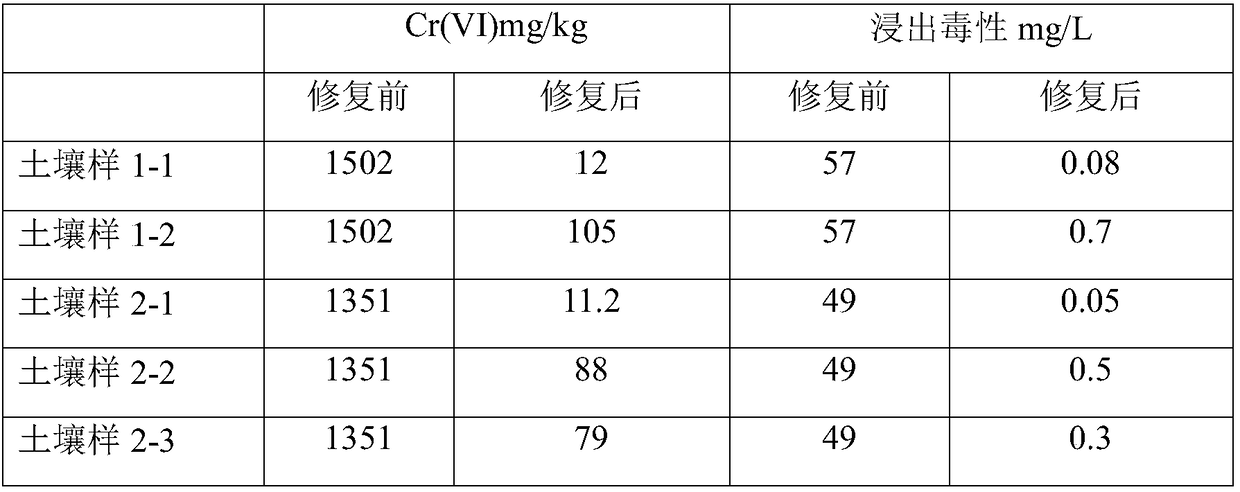

Method for reducing and stabilizing chromium-contaminated soil by chemical-biological coupling

InactiveCN104492802AImprove stabilityReduce leaching concentrationContaminated soil reclamationCouplingSulfate

The invention relates to a method for reducing and stabilizing chromium-contaminated soil by chemical-biological coupling. The method comprises the following steps: mixing chromium-contaminated soil and ferrous sulfate, uniformly stirring, adding water to control the water content, and maintaining until the concentration of hexavalent chromium in the chromium-contaminated oil is reduced to be lower than 500mg / kg to obtain chemically reduced soil; adding a microbial nutrient prepared from honey and soybean cake powder according to a certain proportion into the chemically reduced soil, uniformly stirring, regulating the water content, and isolating air to maintain for over 30 days to obtain the repaired soil. The method provides a new thought for repairing chromium-contaminated soil, has the advantages of low cost, good effect, small chemical reagent dosage, short repairing time, environmental friendliness, simple operation and the like, and has remarkable economic and environmental benefits.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

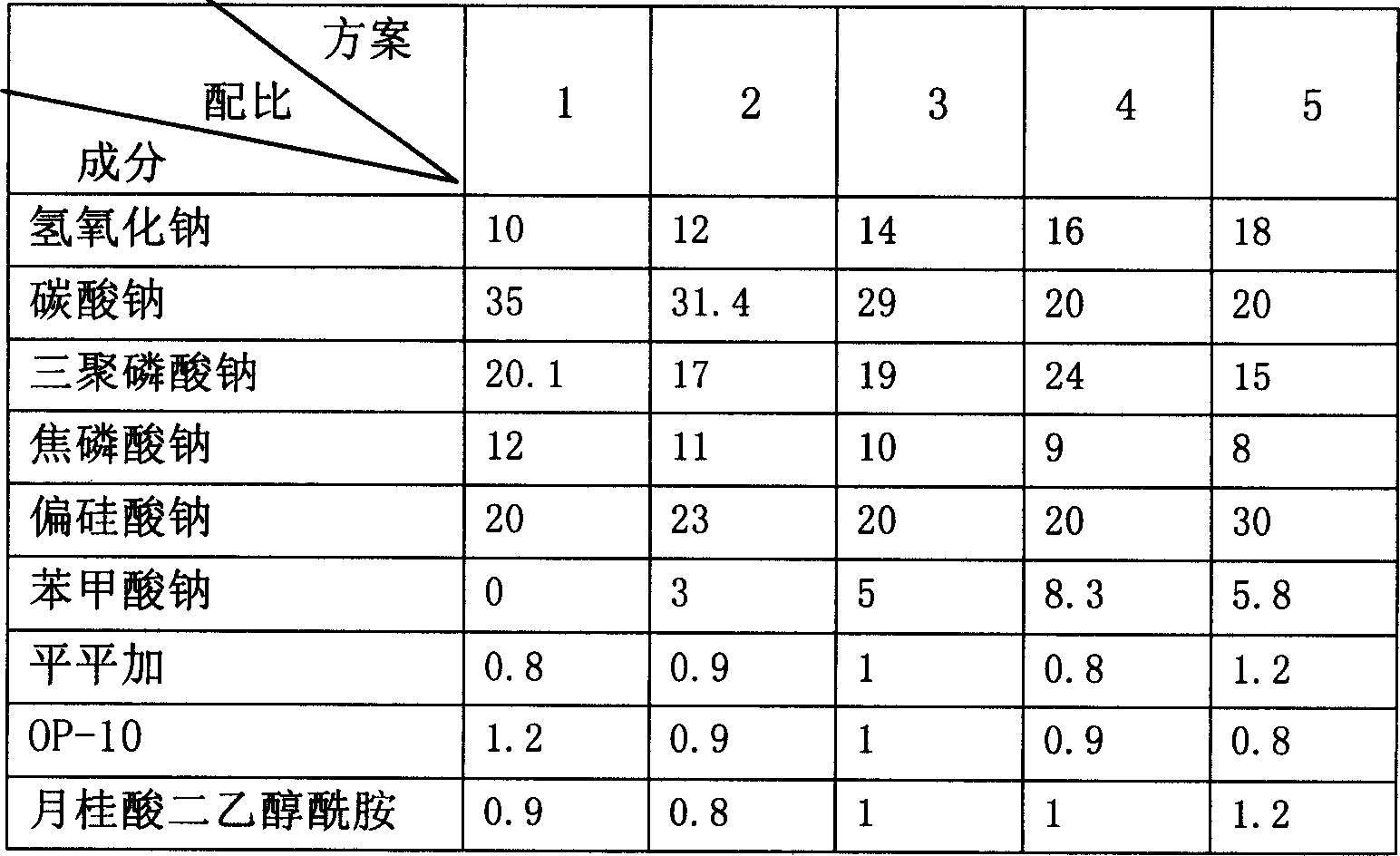

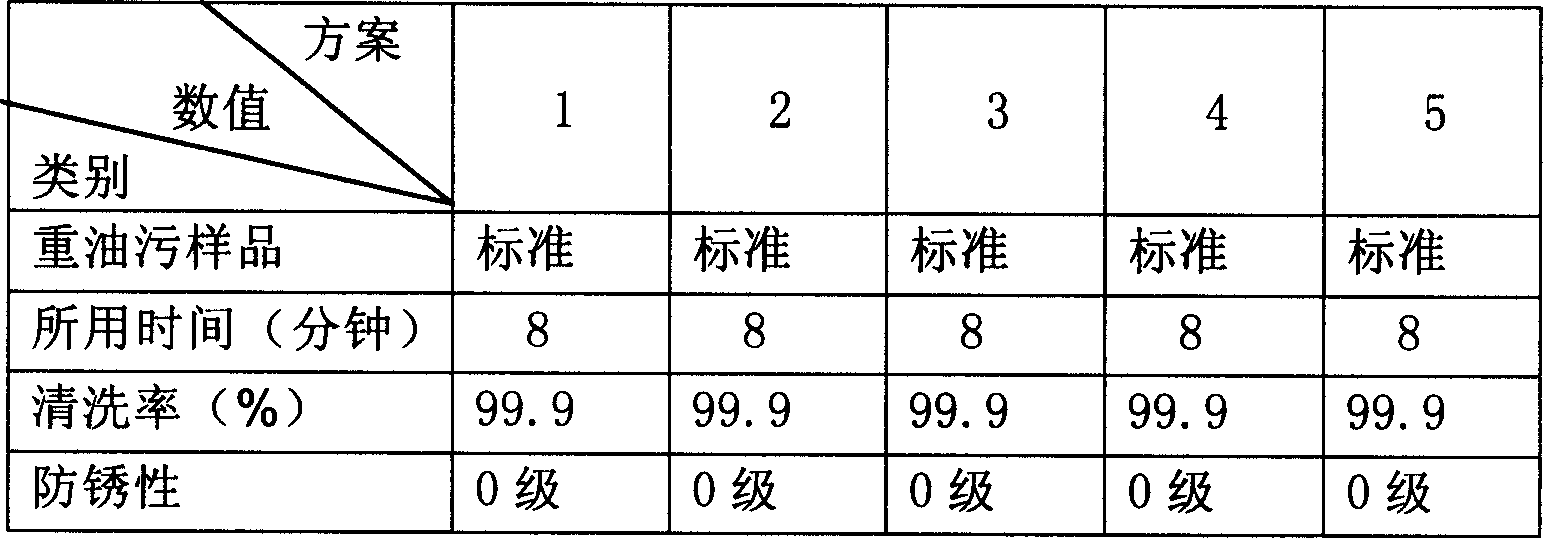

Metal greasy dirt cleaning agent and its production method

InactiveCN1570055AQuick washEasy to cleanInorganic/elemental detergent compounding agentsSurface-active detergent compositionsPyrophosphateSurface-active agents

The invention discloses a metal greasy dirt cleaning agent and its production method, wherein the metal greasy dirt cleaning agent comprises degreasing agent and surface active agent, while the degreasing agent comprises (by weight ratio) sodium-hydroxide 10-18, sodium carbonate 20-35, sodium tripolyphosphate 15-24, normal sodium pyrophosphate 8-12, sodium silicate 20-30, the surface active agent comprises leveling agent, OP-10 and lauric diglycollic amide 0.8-1.2.

Owner:朱海亮

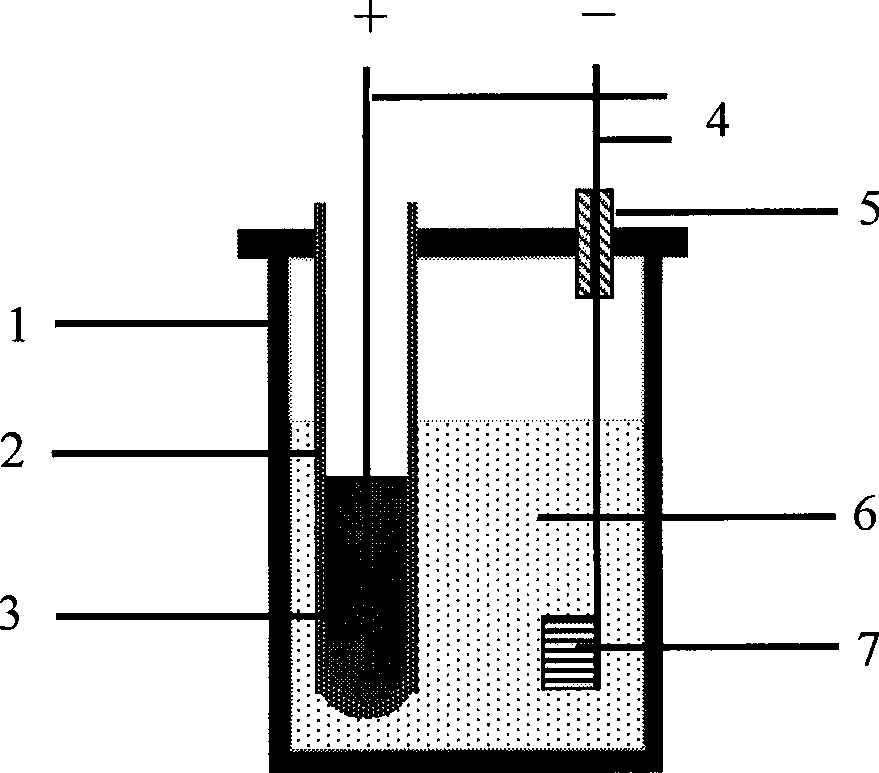

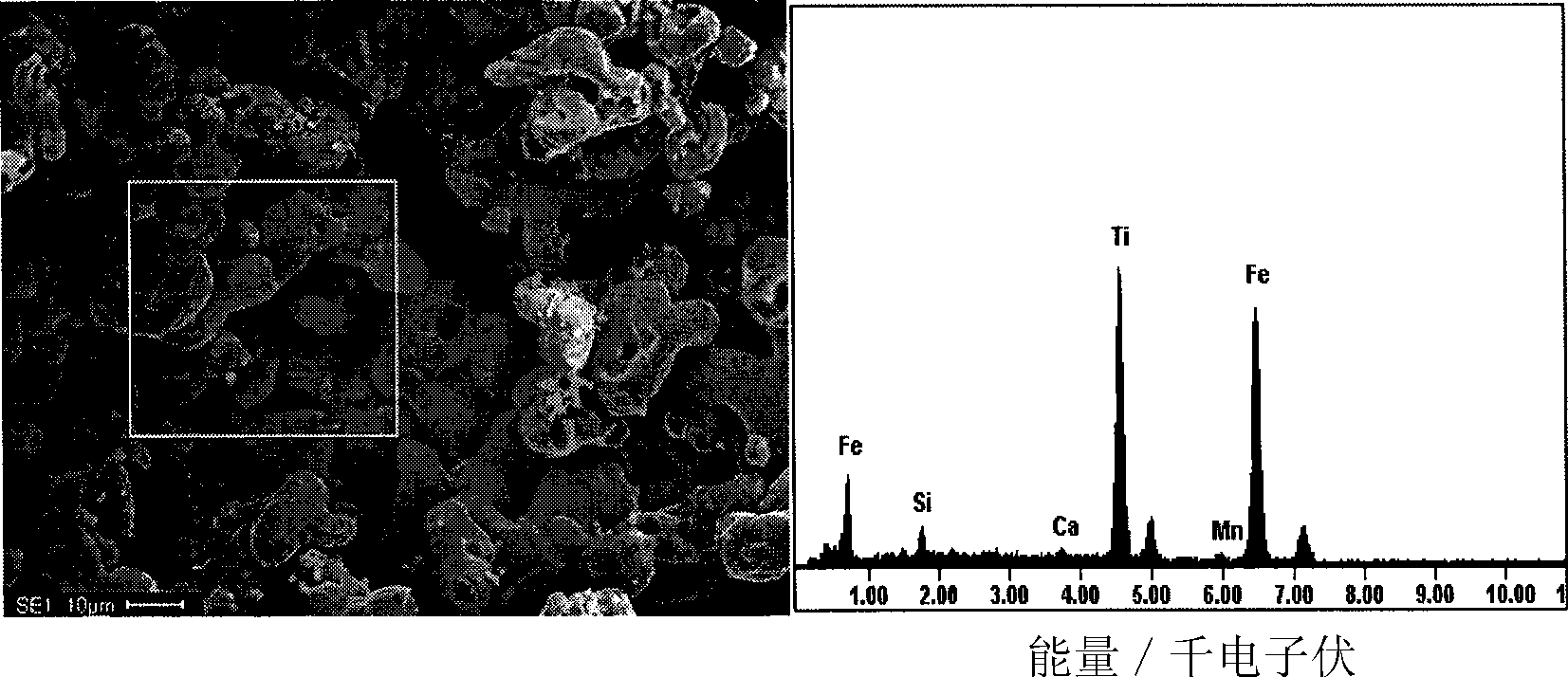

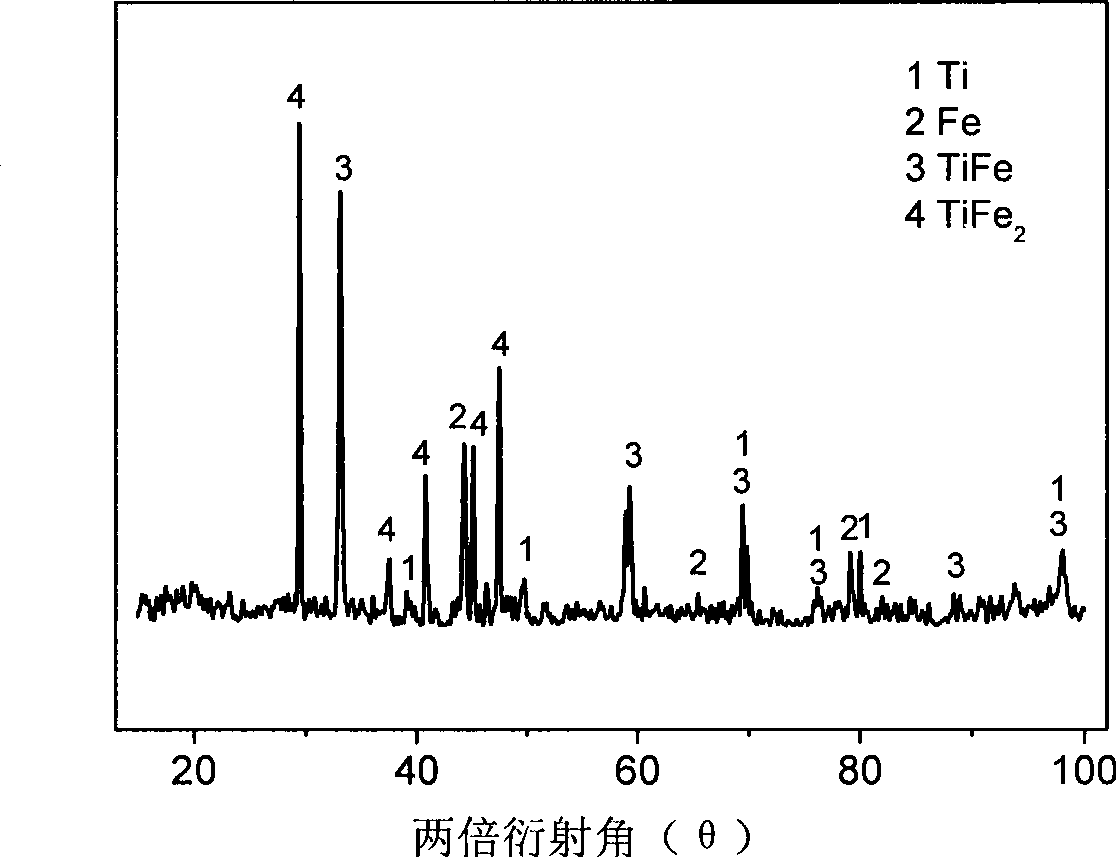

Method for directly preparing titanium and titanium alloy by titanium-containing waste residue

The invention relates to a method for directly preparing titanium and titanium alloy from titaniferous waste residues, and belongs to the technical field of electrochemical metallurgy. The method is characterized in that the titaniferous waste residues are made into an electrolysis electrode, and the electrolysis is performed in a crucible of an electrolytic cell by a solid oxygen permeable membrane in a specific molten salt electrolyte. The method comprises the following process steps: the titaniferous residues is processed by ball milling, then pressed and formed in a mould at 3-6MP, dried in the air, and then sinteredat the temperature of 1000-1100 DEG C for 2h to be made into an electrolysis cathode; molten salt is separated from an anode by an oxygen permeable membrane tube which only conducts oxyanion, the anode is liquid copper or copper alloy with saturated carbon powder, calcium chloride is taken as the molten salt electrolyte, the cathode and the anode are vertically arranged, the electrolytic temperature is 1000-1100 DEG C, the electrolytic voltage is 3.0-3.5V, the electrolysis time is 2-6h, and the cathodic products obtained by the electrolysis are metallic titanium and the titanium alloy. The method has the advantages of simple process, high electrolysis speed and high current efficiency.

Owner:SHANGHAI UNIV

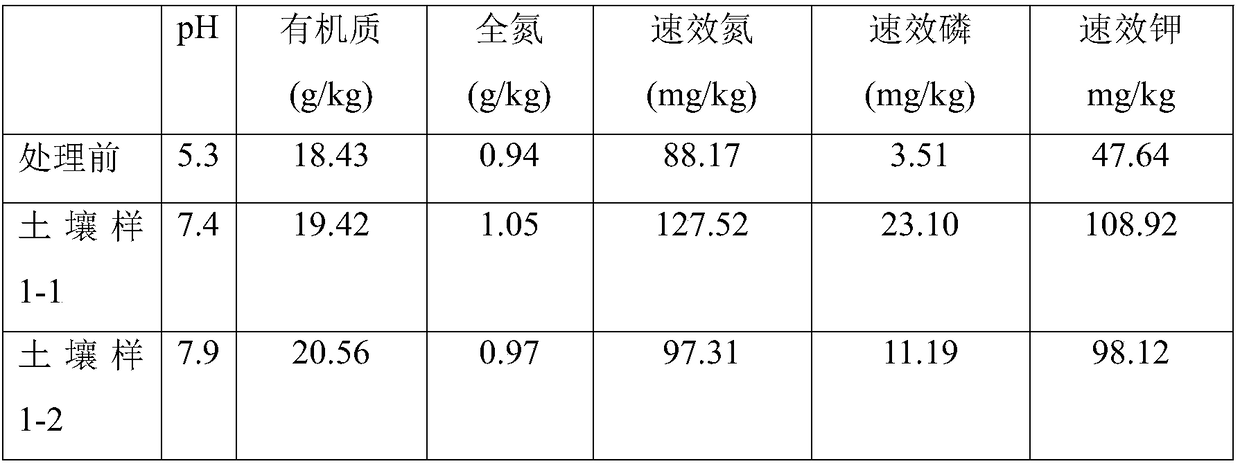

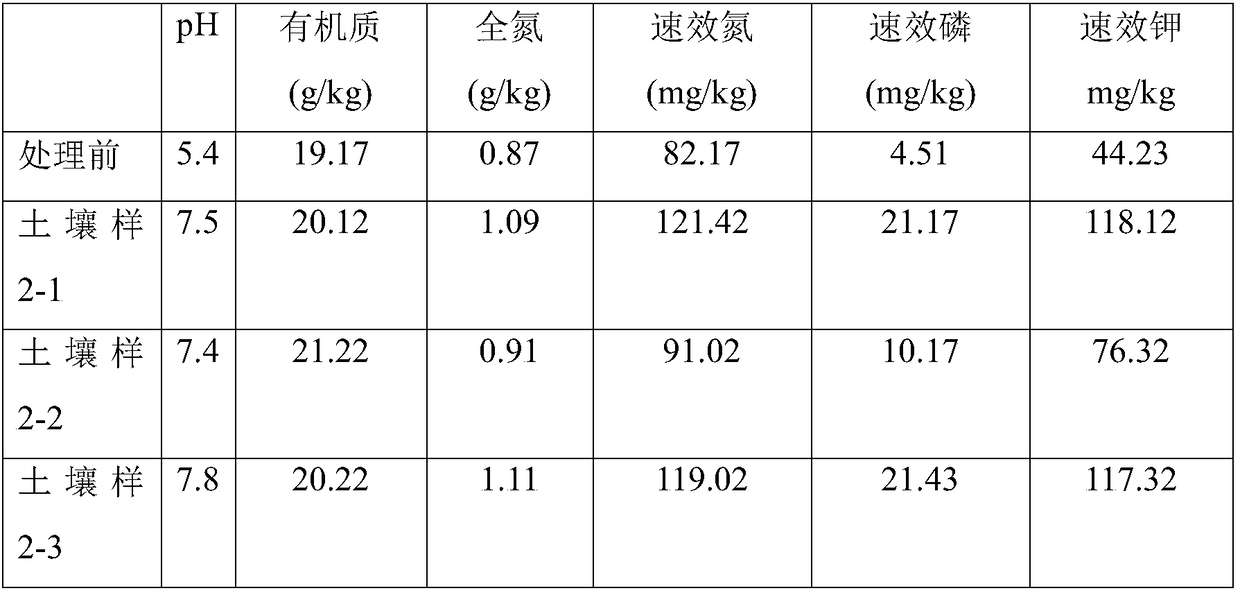

Fertilizer for Cr (VI) polluted soil remediation and improvement and preparation method of fertilizer

InactiveCN108276228AGuaranteed neutral and slightly alkalinePrevent acidificationCalcareous fertilisersBio-organic fraction processingMicrobial agentPollution

The invention discloses fertilizer for Cr (VI) polluted soil remediation and improvement and a preparation method of the fertilizer. The preparation method of the fertilizer comprises the following steps: spraying an EM microbial agent to the surfaces of bagasse and pig manures, then uniformly mixing the bagasse with the pig manures, and composting the mixture to obtain a cured material; adding anOneida silva microbial agent, the EM microbial agent and a desulfovibrio microbial agent into the cured material, uniformly mixing the microbial agents with the cured material, and composting the mixture to obtain a microbial compound; and mixing ferrous sulfate, modified coal ash, ground calcium carbonate and the microbial compound, and granulating the mixture to obtain the fertilizer. The fertilizer can improve the soil structure, improve the soil fertility and remediate and improve a microecological structure of the soil when effectively remediating chromium pollution, finally remetiates and improves the chromium-contaminated soil, and restores the ecological functions.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

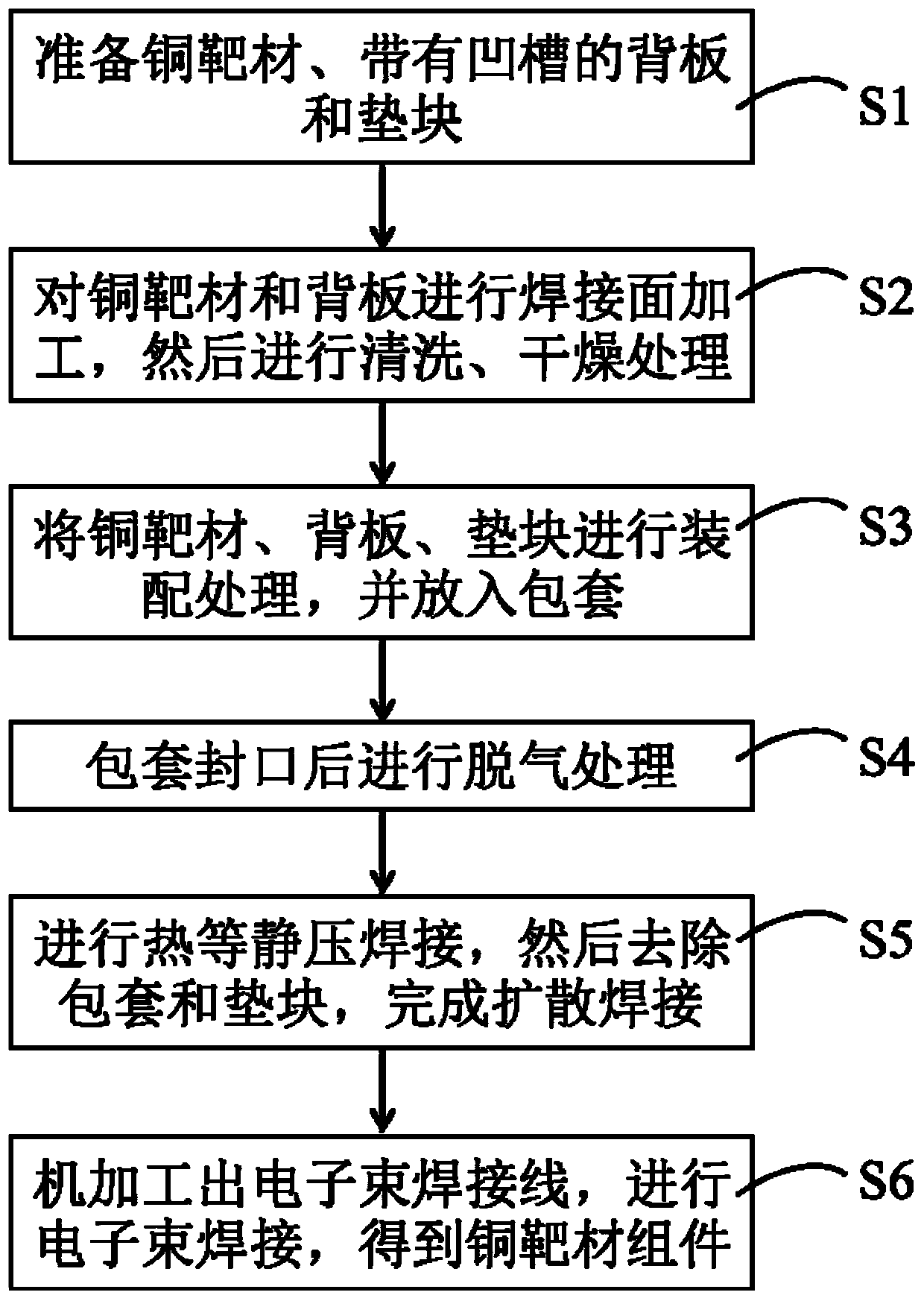

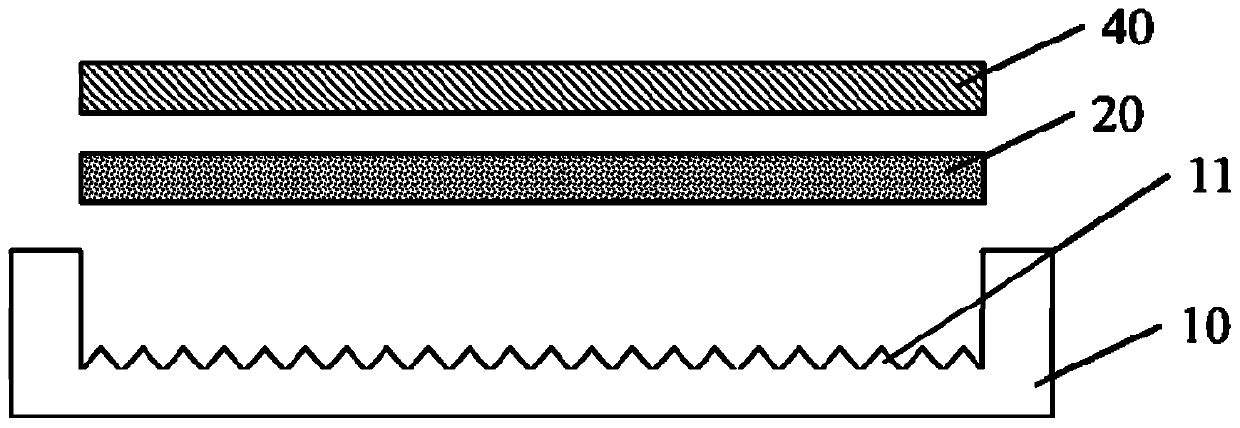

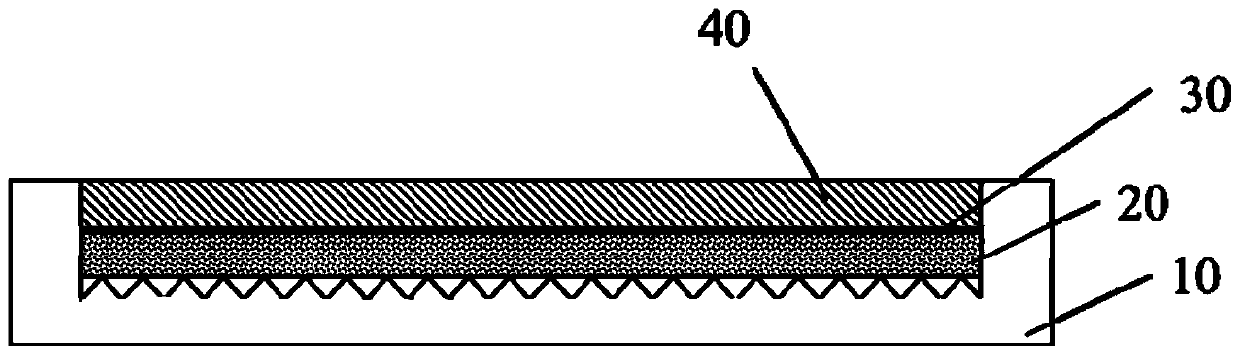

Diffusion welding method of copper target material and back plate

The invention relates to a diffusion welding method of a copper target material and a back plate. The diffusion welding method comprises the following steps that (1), the copper target material, the back plate and a cushion block, wherein the back plate is provided with a groove, and the areas of the copper target material and the cushion block are equal to the bottom area of the groove of the back plate; (2), the copper target material and the cushion block in the step (1) are sequentially put into the groove of the back plate to finish assembly treatment, and then a whole body is put into asheath; (3), the sheath obtained in the step (2) is sealed and then degassed; and (4), hot isostatic pressing welding is carried out on the sheath degassed in the step (3), and then the sheath and thecushion block are removed to finish diffusion welding of the copper target material and the back plate. According to the diffusion welding method, by improving an assembly structure of the copper target material and the back plate, the bonding degree of welding faces of the copper target material and the back plate is guaranteed, abnormal growth of crystal grains is effectively avoided, and particularly the phenomenon that the crystal grains are thick and large at the edge of the copper target material is avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Diffusion welding connecting method adopting Cu foil and Ti foil as composite interlayer

ActiveCN109014549AForm to avoidFully consider compatibilityWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureHeating furnace

The invention relates to a method for connecting a nickel-based superalloy with a Ti2AlNb alloy or a Ti3Al-based alloy, in particular to a diffusion welding connecting method adopting Cu foil and Ti foil as a composite interlayer. The diffusion welding connecting method comprises the steps that the nickel-based superalloy and the Ti2AlNb alloy or the Ti3Al-based alloy are processed into the neededsizes, ground and polished; the Cu foil and the Ti foil are subjected to oxidation film removing, and are placed into acetone with a welded base material to be subjected to ultrasonic cleaning; and the Cu foil makes contact with the nickel-based superalloy, the Ti foil makes contact with the Ti2AlNb alloy or the Ti3Al-based alloy, and thus a welded test piece with the structure of the Ti2AlNb alloy or the Ti3Al-based alloy / the Ti foil / the Cu foil / the nickel-based superalloy is obtained, a welded workpiece is placed into a vacuum heating furnace, the pressure is applied, and welding is completed after heating, heat preservation and cooling heat circulating. The welding temperature can be lowered, forming of a brittle phase of a joint is controlled, and the property of the joint is improved; and the obtained shearing strength of the joint at the room temperature reaches 240-310 MPa.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for producing active substance ferrous lithium phosphate as lithium-ion battery anode

ActiveCN1982208AEasy to operateEasy to controlCell electrodesPhosphorus compoundsPhysical chemistryLITHIUM PHOSPHATE

Production of lithium-ion battery positive active substance ferro-lithium phosphate is carried out by mixing polymer, phosphate-source compound with ferro-source compound and lithium-source compound in solution, sintering to obtain the mixed solution, removing solvent to obtain the gel and sintering. It's simple and convenient, the battery has excellent discharge capacity and circulation performance, and the ferro-lithium phosphate is solid, homogeneous and has better conductivity.

Owner:BYD CO LTD

Continuous casting crystallizer casting powder for ultra-low-carbon steel

ActiveCN103817301ADoes not affect the melting rateAvoid the phenomenon of carbonizationActivated carbonMetallurgy

The invention discloses a continuous casting crystallizer casting powder for ultra-low-carbon steel. Active carbon is added in the casting powder, so that air can be made to pass through a casting powder layer to enable the carbon to be oxidized rapidly to generate carbon dioxide gas to be discharged; the active carbon itself has a powerful adsorption function and a part of air is stored, so that the oxidation rate is improved, it is guaranteed that the carbon is removed rapidly after the casting powder is melted rapidly and the casting powder does not contain the carbon, and therefore the recarburization phenomenon of the ultra-low-carbon steel is prevented from occurring from the source. After the active carbon is oxidized rapidly, gaps disappear due to consumption of the active carbon, and the casting powder enables steel billet to be sealed and isolated from the air rapidly so as to prevent the steel billet from being oxidized again. The continuous casting crystallizer casting powder for the ultra-low-carbon steel is low in cost, practical, good in effect and worthy of popularization and application.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

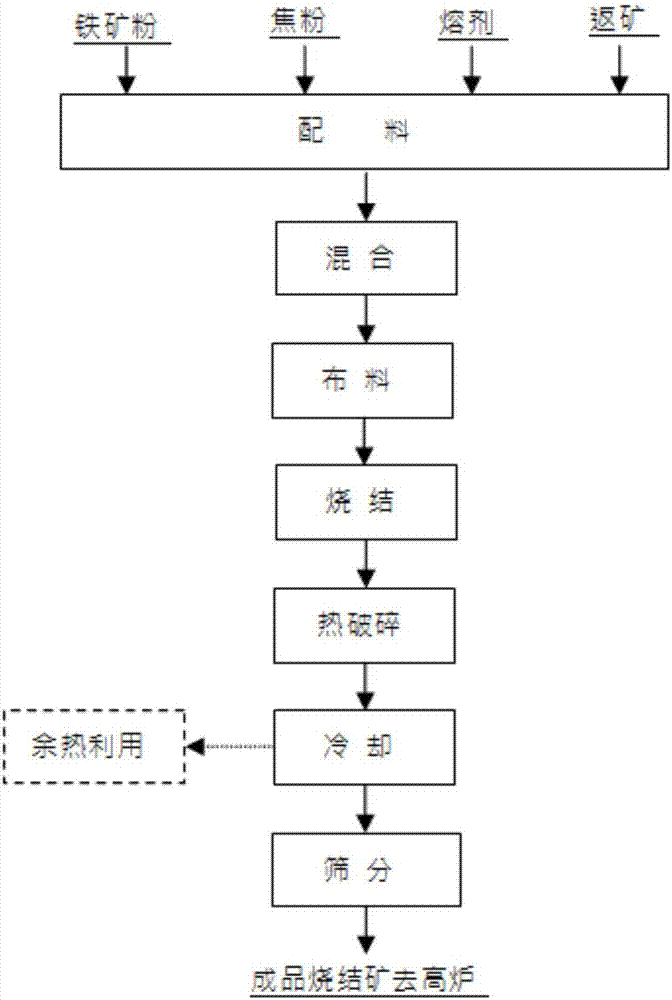

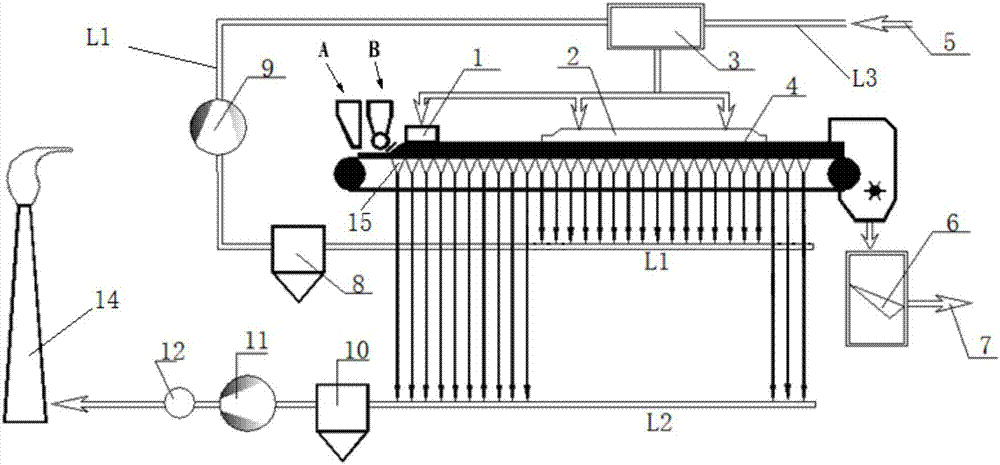

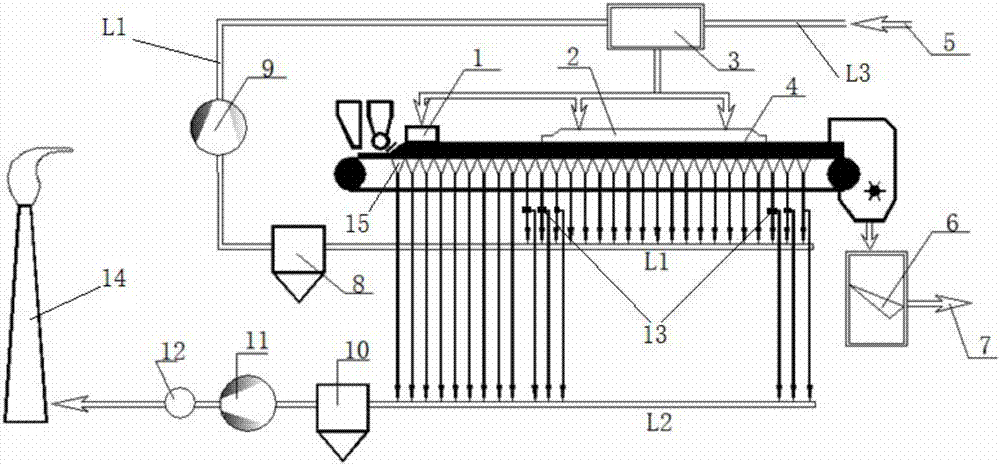

Iron ore pre-reduction sintering method and device

ActiveCN107304460AAchieve recyclingShort processIncreasing energy efficiencyWaste heat treatmentCombustionMaterial distribution

The invention provides an iron ore pre-reduction sintering method. The method comprises the steps that firstly, a traditional mixture is prepared, iron ore powder, a solvent and fuel are subjected to raw material matching, mixing and granulating are conducted, and the traditional mixture is obtained; secondly, a pre-reduction mixture is prepared, after the iron ore powder, an additive and the fuel are evenly mixed, pelleting is conducted, carbon-burdened pellets are obtained and placed in a cylinder mixer, fuel fine powder and quick lime or slaked lime are added for wrapping and granulating, and the pre-reduction mixture is obtained; thirdly, material distribution is conducted, a double-layer material distribution manner is adopted, the pre-reduction mixer prepared in the second step is placed on a sintering machine trolley in advance, and the traditional mixture prepared in the first step is placed on the pre-reduction mixture; and fourthly, sintering is conducted, ignition is conducted, and the traditional mixture and the pre-reduction mixture are subjected to smoke circulation type sintering on a sintering machine. The problem that CO smoke is hard to treat is solved, secondary oxidization in the pre-reduction sinter reducing process is reduced, the combustion atmosphere between material layers is improved, the material temperature is increased, and generation of the iron ore material reducing reaction is accelerated.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

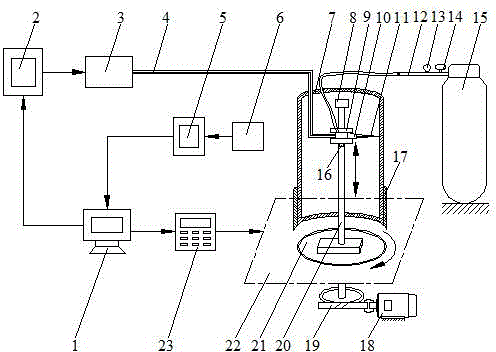

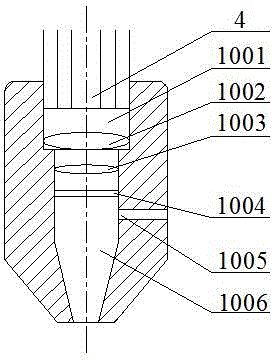

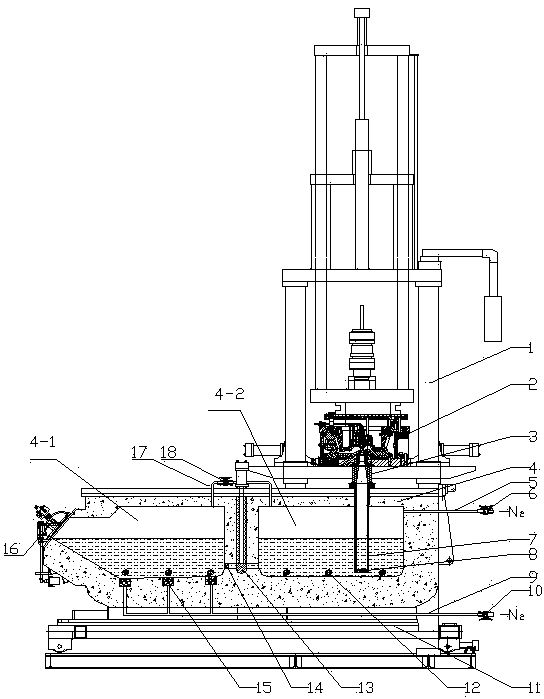

Device and method for removing rust corrosion of inner cavity of plastic rolling mould

ActiveCN104550134ANo pollution in the processImprove cleanlinessCoatingsCleaning processes and apparatusNanosecond laserControl system

The invention relates to a device and a method for removing rust corrosion of an inner cavity of a plastic rolling mould. The device comprises a laser loading system, a cleaning system, a control system, a real-time feedback system and an auxiliary system, wherein the laser loading system is composed of a nanosecond laser device, a laser controller and a flexible optical fiber; the cleaning system is composed of a cleaning work head; the control system is composed of a computer, a reacting type stepping motor, a screw guide rail, a rotating platform and a platform controller; the control system is used for controlling the work state of the nanosecond laser device and the motion state of the rotating platform and displaying a collected acoustic signal; the real-time feedback system is composed of a signal processing board, a pre-amplifier and an acoustic emission sensor; the auxiliary system is composed of a gas conveying pipe, a gas flow meter, an adjusting valve and an inert gas source. The device provided by the invention can be used for effectively removing the rust corrosion of the inner cavity of the plastic rolling mould and increasing the forming precision of products; the mould is irradiated by the laser, so that the surface performance is improved and the cleaning is modified; two effects are achieved through one operation.

Owner:JIANGSU UNIV

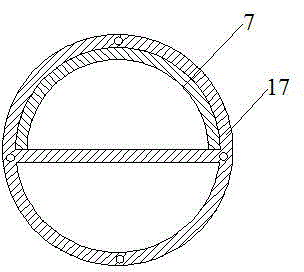

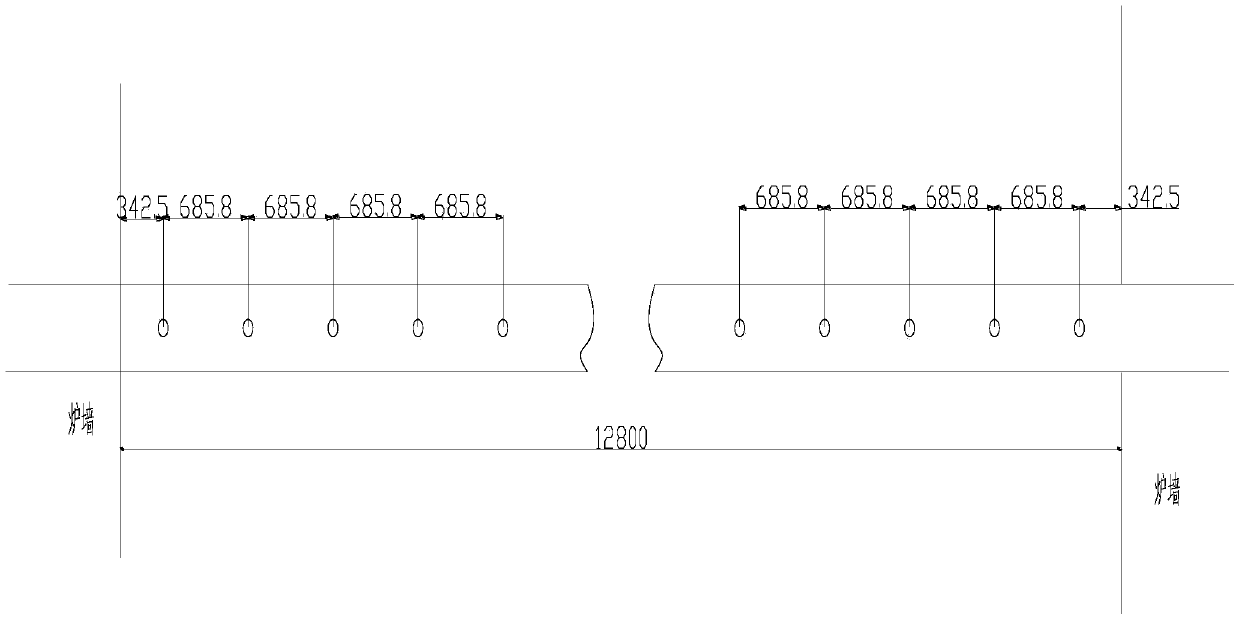

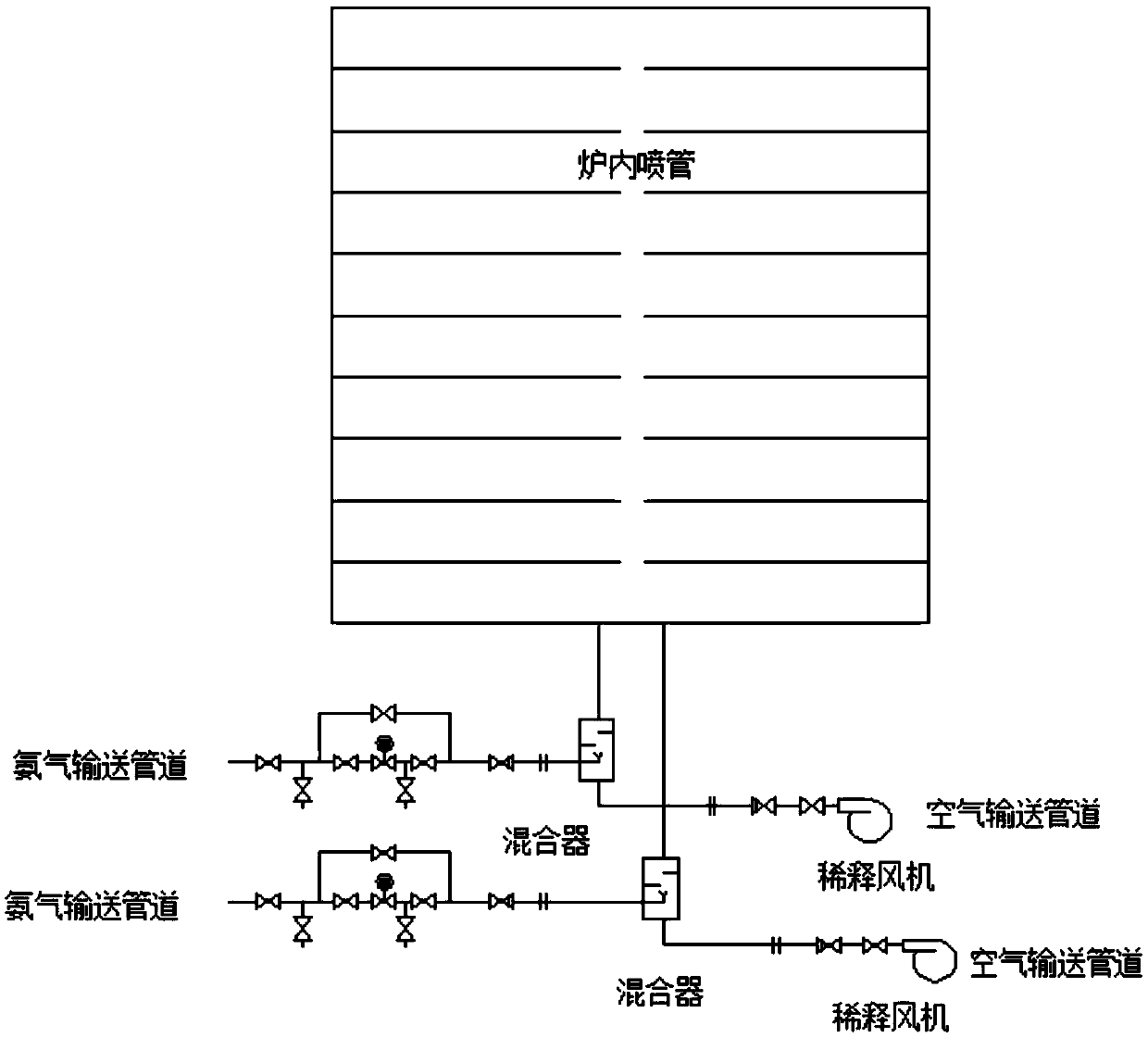

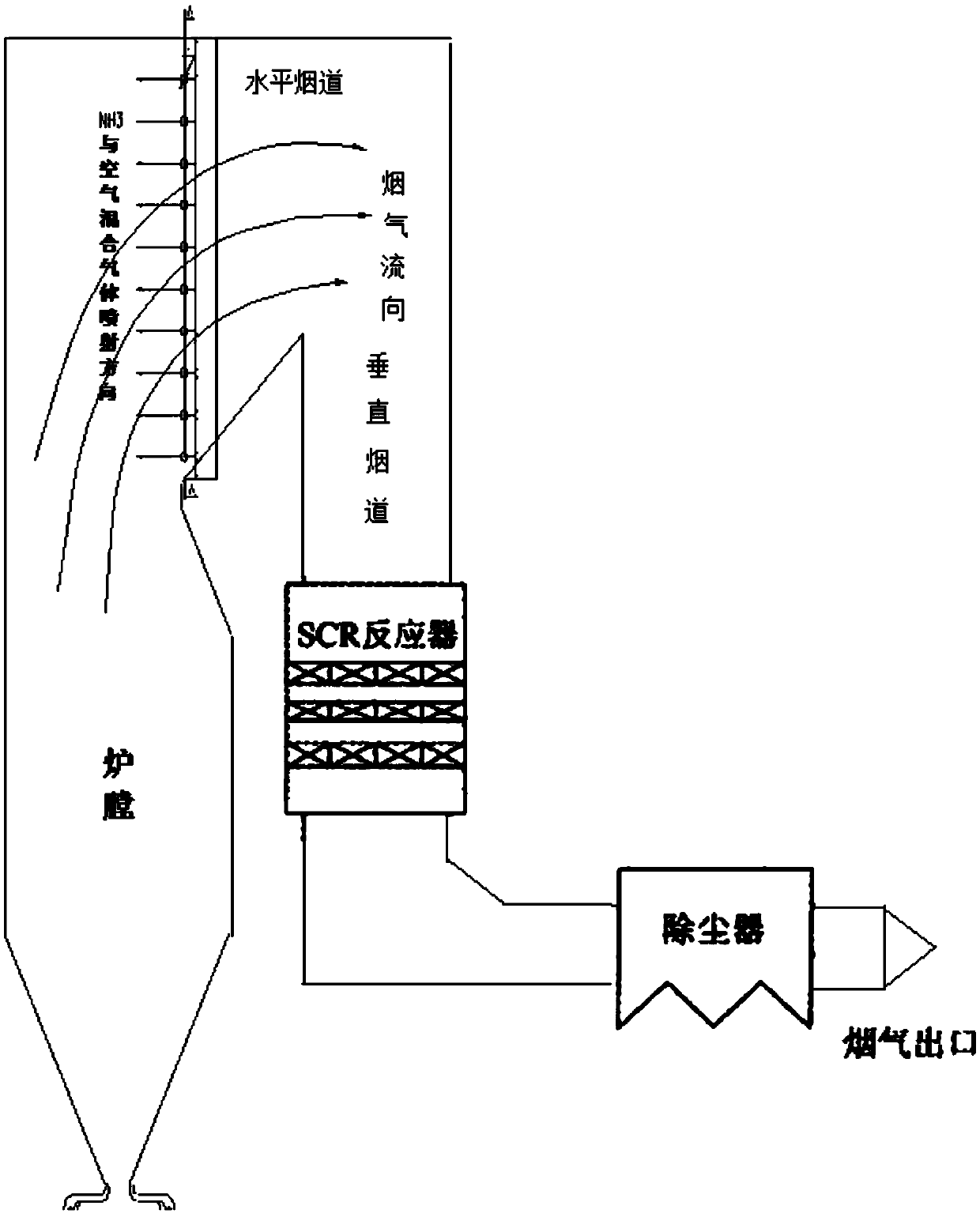

System and process for denitration by spraying ammonia gas in large-sized boiler high-temperature flue gas area

ActiveCN105509081AGuarantee the effect of denitrification onceGuaranteed denitrification effectGas treatmentEmission preventionFlue gasEngineering

The invention belongs to the technical field of flue gas denitration and relates to a system for denitration by spraying ammonia gas in a large-sized boiler high-temperature flue gas area. A boiler comprises a horizontal flue and a vertical flue. The system comprises an SNCR (selective non-catalytic reduction) system provided with a reducing agent injector, the reducing agent injector is a spray pipe disposed on the transverse section of the horizontal flue, an input end of the spray pipe is connected with a reducing agent conveyer, the other end of the spray pipe is closed, and the wall of the spray pipe opposite to flue gas is provided with a spray hole. The invention also discloses a denitration process for denitration treatment using the system, the denitration treatment with the system gives high denitration rate and low ammonia escape quantity as well as full flue gas purification, this product is applicable to present coal-consuming boilers for thermal power generation, iron and steel, chemicals, cements and the like, and satisfactory NOx emission index of these boilers can be ensured.

Owner:杜梦凡

Highly reliable cuprous oxide semiconductor sparking plug sealing method

InactiveCN102410124AHigh sealing pass rateReduce gapPiezo-electric ignitionElectrostatic ignitionOxide semiconductorAxial pressure

The purpose of a highly reliable cuprous oxide semiconductor sparking plug sealing method provided by the invention is to provide a sealing method which does not need to carry out oxidation treatment on metal parts in advance and has a high sealing percent of pass. The method is implemented by the following technical scheme: an enamel layer is coated on the lower end surface of a semiconductor part and then sintered, a pre-vitrified glass blank and a porcelain tube are coaxially mounted into a sparking plug shell, and the assembly is then put into a clamp, sent into a furnace along with the clamp and heated to be sealed under high temperature; the sealing process is carried out by two times of heating and pressurization, and in each time of heating process, the porcelain tube connected with the upper end in the sparking plug shell is utilized to apply axial pressure on the end surface of the melted glass blank, so that the melted glass blank can be sufficiently filled in the space of a sealed area. The method solves the problem that the quality of the transitional layer of the bonding interface between an oxidation film and the fused sealing glass is poor.

Owner:成都泛华航空仪表电器有限公司

Direct alloying steelmaking process for manganese oxide composite briquettes used for re-blowing revolving furnace

The invention relates to direct alloying steelmaking process for manganese oxide composite briquettes used for a re-blowing revolving furnace. The technical scheme comprises the following steps of: when the carbon content of molten steel in the revolving furnace is reduced to less than 0.1 percent and the molten steel reaches the temperature of between 1,650 and 1,750DEG C, and adding manganese oxide composite briquettes into the revolving furnace at one time, wherein the manganese oxide composite briquettes, which undergo cold pressing and mixed with carbon, are quickly heated to above 1,500 DEG C by the heat of the molten steel in the revolving furnace, the manganese oxide is quickly self-reduced in the manganese oxide composite briquettes which undergo cold pressing and mixed with carbon, so that the aim of the direct alloying of the molten steel is achieved. Oxygen blowing is stopped in the revolving furnace after the manganese oxide composite briquettes are added into the revolving furnace in order to avoid the re-oxidation of manganese, but the uniformization of manganese in the molten steel is enforced by the bottom-blowing strengthening molten pool stirring of the revolving furnace. The process of the invention has the advantages of simple process, easy operation and control, high manganese yield, great energy conservation, low CO2 emission and low production cost of the alloying of the manganese in the molten steel.

Owner:WUHAN UNIV OF SCI & TECH

Horizontal movement - fixed bed magnetization reduction roasting process

ActiveCN102268533AAvoid loopsSimple production processProcess efficiency improvementMagnetizationFixed bed

The invention relates to a horizontal moving-fixed bed type magnetization reduction roasting process, which comprises the following steps: (1) briquetting and pelletizing fine ore after sieving to obtain raw materials; (2) moving raw materials through horizontal moving-fixing The distribution machine of the ore bin in the bed type magnetization reduction roasting device distributes it to the horizontal moving bed, so that the lower layer is ore and the upper layer is balls; (3) The ore and balls on the horizontal moving bed are magnetized reduction roasted with gas or coal powder ;After the ore is fully reduced, the magnetization roasting process is completed; (4) The ore and balls roasted in step (3) are discharged by the scraper at the end of the bed surface, and discharged into the water cooling device. After cooling by water, the unloading machine moves out The ore is sent to the grinding and sorting process. The preheating, heating and reduction processes of powder ore magnetization reduction roasting in the present invention are all completed on the horizontal moving-fixed bed roasting device, which not only simplifies the production process, reduces investment costs, but also avoids the process similar to rotary kilns, etc. The ring formation problem of roasted fine ore.

Owner:JIUQUAN IRON & STEEL GRP +1

Surface passivation method for Ge

InactiveCN102005390APrevent re-oxidationElimination of Fermi level pinningSemiconductor/solid-state device manufacturingSemiconductorMaterials science

The invention belongs to the technical field of semiconductor manufacturing, and particularly discloses a surface passivation method for Ge. By adopting a thioacetamide (CH3CSNH2) solution to passivate a Ge sheet, the natural oxide on the surface of the Ge sheet can be removed, and an even and compact GeSx passivation layer can be generated to prevent the reoxidation of the surface of the Ge sheet and eliminate the Fermi level pinning. A layer of high-quality Al2O3 film is deposited on the passivated Ge sheet by adopting an atom layer deposition method to prevent the reoxidation of the surface of the Ge sheet, and therefore, a good Al2O3 / Ge interface can be obtained.

Owner:FUDAN UNIV

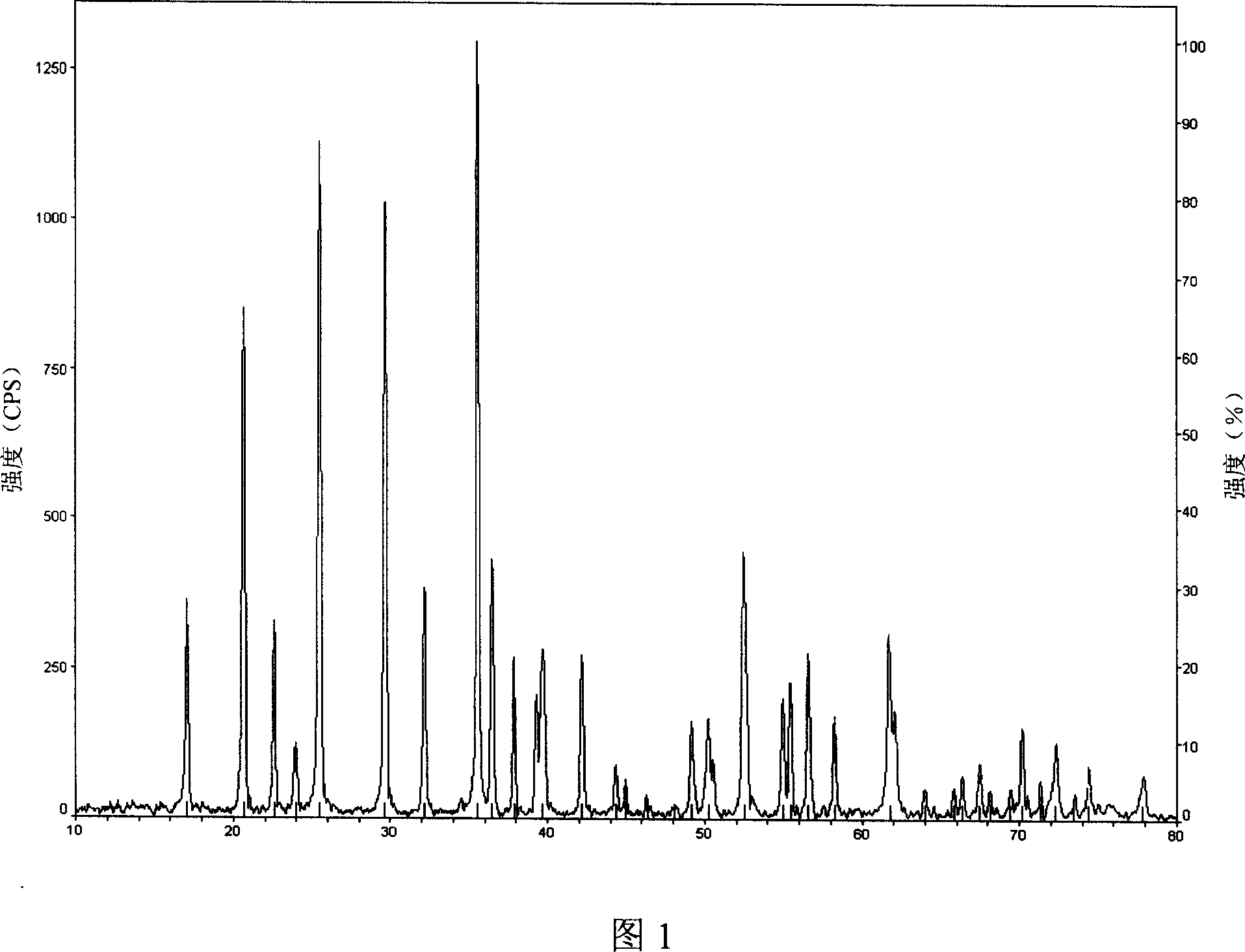

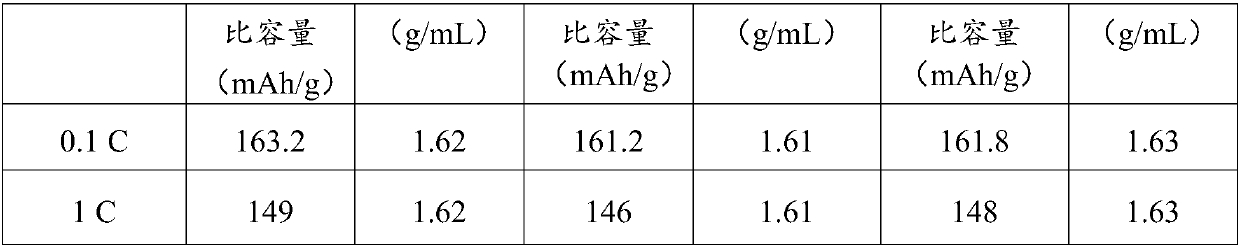

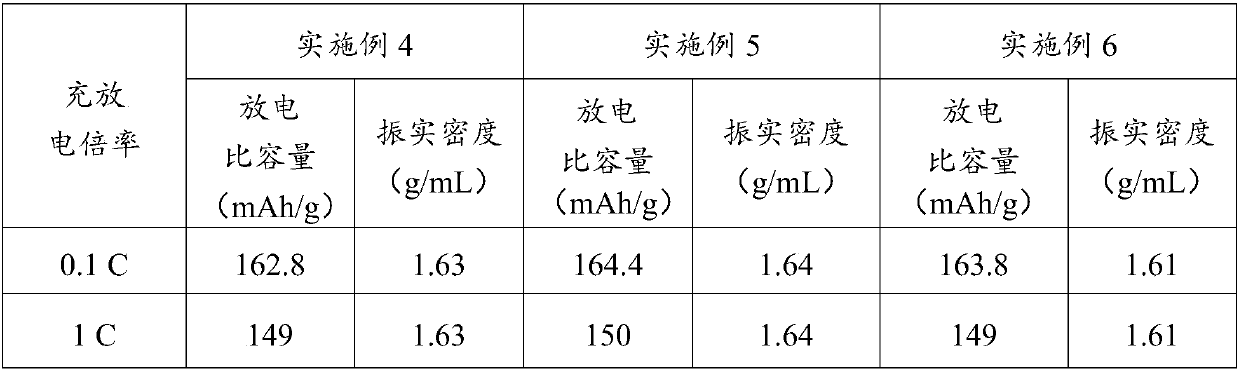

Preparation method of titanium-doped lithium iron phosphate cathode material

ActiveCN107611413AIncrease the kinetic energy of the reactionRapid responseCell electrodesSecondary cellsCarbon coatingElectron

The invention discloses a preparation method of a titanium-doped lithium iron phosphate cathode material. The preparation method comprises the following steps: by using a lithium source compound, a phosphorus source compound, an iron source compound and metallic titanium as raw materials, evenly mixing the raw materials and melting the mixture in a melting furnace at high temperature to obtain a mixture; performing water quenching on the mixture into particles; grinding and dispersing the particles and a carbon source compound together to ensure that the particle size reaches the Fineness index of D90 being less than or equal to 0.2 micron; making powder in a spray drying method, and calcining the powder for 40 to 300 minutes in an atmosphere furnace of 600 to 800 DEG C; performing coolingto obtain the lithium iron phosphate cathode material. By adopting a high-temperature melting method, the uniformity of the lithium iron phosphate cathode material is improved; by introducing metallic titanium powder, Fe<3+> in a melt solution is reduced into Fe<2+> at high-temperature melting state, and generated Ti<4+> is doped into a lithium iron phosphate structure, and the electron conductivity of the lithium iron phosphate cathode material is improved through formation of vacant positions; the specific surface area is reduced by means of grinding and dispersion as well as carbon coating, and the tapping density of the lithium iron phosphate cathode material is improved. According to the preparation method disclosed by the invention, crushing and integration are not needed, so that the original sphericity can be maintained and technological processes are also simplified.

Owner:威远县大禾陶瓷原料有限公司

Martensite stainless steel smelting process

ActiveCN103114244AGuaranteed contentPrevent re-oxidationRecovering materialsElectric furnaceSmelting processMartensitic stainless steel

The invention discloses a martensite stainless steel smelting process which is characterized in that the process adopts non-VOD (vacuum oxygen decarbufization) smelting, secondary reduction processes of unstable oxides in and after the VOD or AOD (argon oxygen decarburization) process are reduced, and the oxidation products are removed through continuous slagging, so that the steel ladle is positioned in a high-temperature state for a long time, and erosion loss of the steel ladle is accelerated; the contents of C and P in final components are reduced; the martensite stainless steel comprises the following raw material components in percentage by weight: 0.09-0.12 percent of C, 8-9.5 percent of Cr, 0.85-1.05 percent of Mo, 0.030-0.060 percent of N, less than or equal to 0.02 percent of P and the balance of Fe; and the smelting process comprises the following steps of: A, performing EAF (electric arch furnace) crude refining; B, performing LF (ladle furnace) refining, C, performing VD refining, D, adding chromium nitride and E, discharging to obtain the martensite stainless steel product. According to the process, the smelting time is shortened, the contents of C and P are guaranteed, and the re-oxidation of Cr and carbon is avoided.

Owner:TONGYU HEAVY IND

Powder for removing surface stains of silverware

The invention discloses a powder for removing surface stains of silverware, belongs to the technical field of silverware cleaning maintenance and aims at solving the problem of the surface stain removal of the silverware. The powder is prepared from the following components in parts by weight: 1-15 parts of thiourea, 1-15 parts of citric acid, 1-15 parts of tartaric acid, 1-3 parts of ethylenediamine tetraacetic acid disodium, 1-15 parts of sodium hypophosphite, 1-2 parts of sodium hexametaphosphate, 0.1-0.2 part of sodium methylene dinaphthalenesulfonate, 0.01-0.02 part of benzotriazole and 0.02-0.03 part of 2-mercaptobenzothiazole. In use, the powder is dissolved into water to obtain a 10-20% silver washing solution for soaking or scrubbing the silverware to remove the surface stains of the silverware. The powder is convenient to store and transport, capable of effectively treating silver-coated articles or the silverware with elaborate patterns, and also convenient and safe to operate.

Owner:HANDAN COLLEGE

Low-corrosivity soldering flux

InactiveCN110524139AGood film formingHigh reactivityWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a low-corrosivity soldering flux which is prepared from the following raw materials in parts by weight: 35-45 parts of modified rosin, 7-9 parts of an activating agent, 4-5 parts of a thixotropic agent, 0.8-1 part of a surfactant, 1.2-1.4 parts of other additives and 30-40 parts of a solvent. According to the soldering flux, the modified rosin is adopted as a film forming matter of the soldering flux, the modified rosin has good film forming performance, -COOH with high reaction activity and high metal oxide removing capacity, an oxidation film on the surface of a welded matter can be removed together with an activating agent in the welding process, and the welding effect is enhanced; organic acid and triethanolamine are compounded to serve as an activating agent, so that the acidity of the whole soldering paste system is reduced (the corrosivity is reduced), the stability is enhanced, triethanolamine and organic acid can be decomposed from a neutral product inthe high-temperature welding process, the spreading performance of the soldering paste is improved, the welding spot spreading rate is increased, and then the welding effect is improved.

Owner:JIESHOU HUAYU POWER SUPPLY

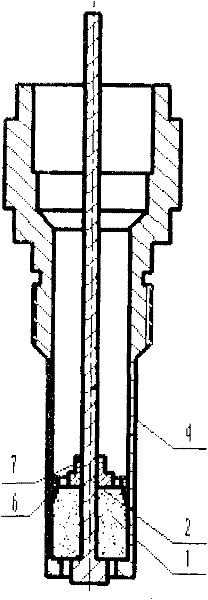

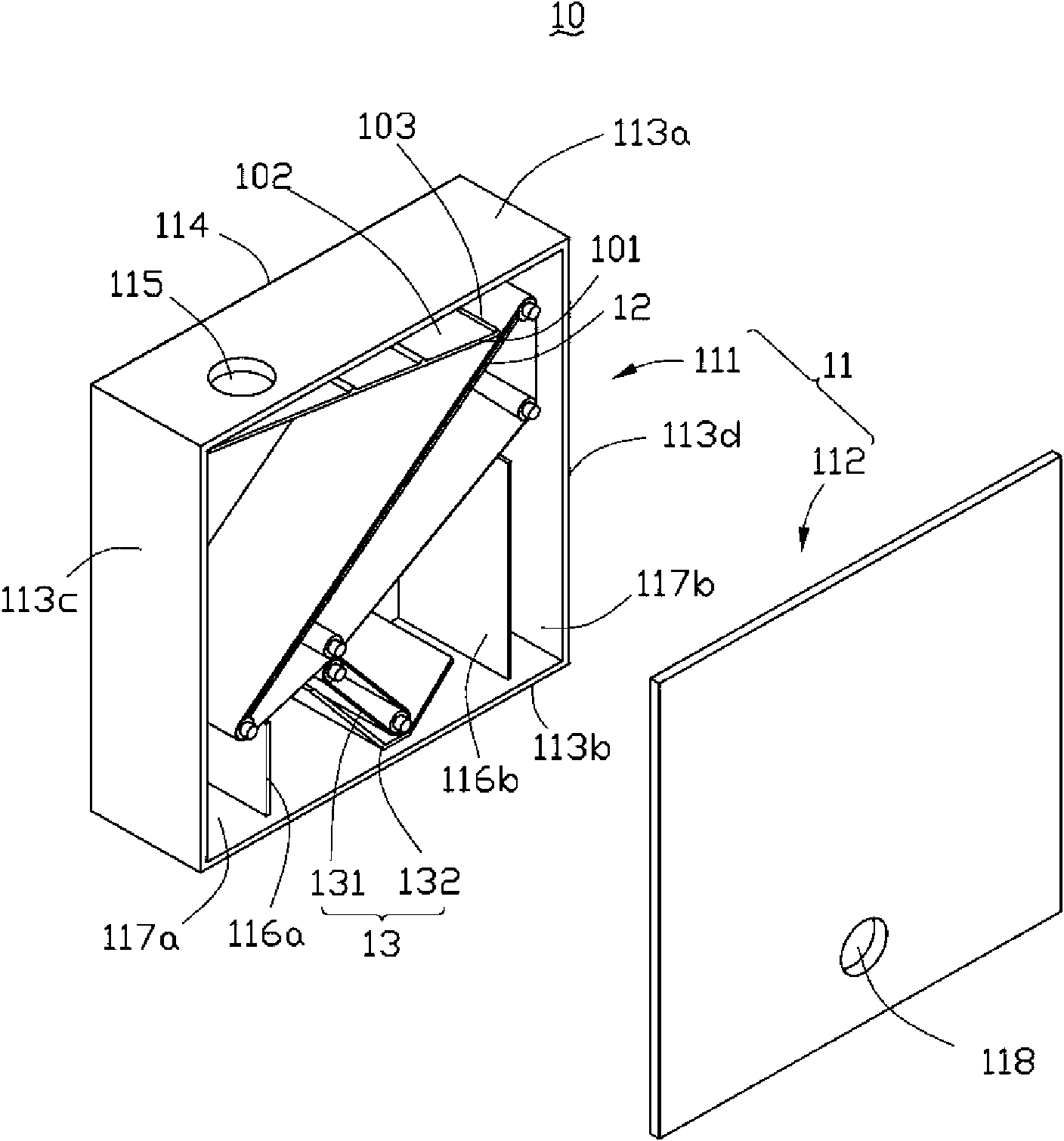

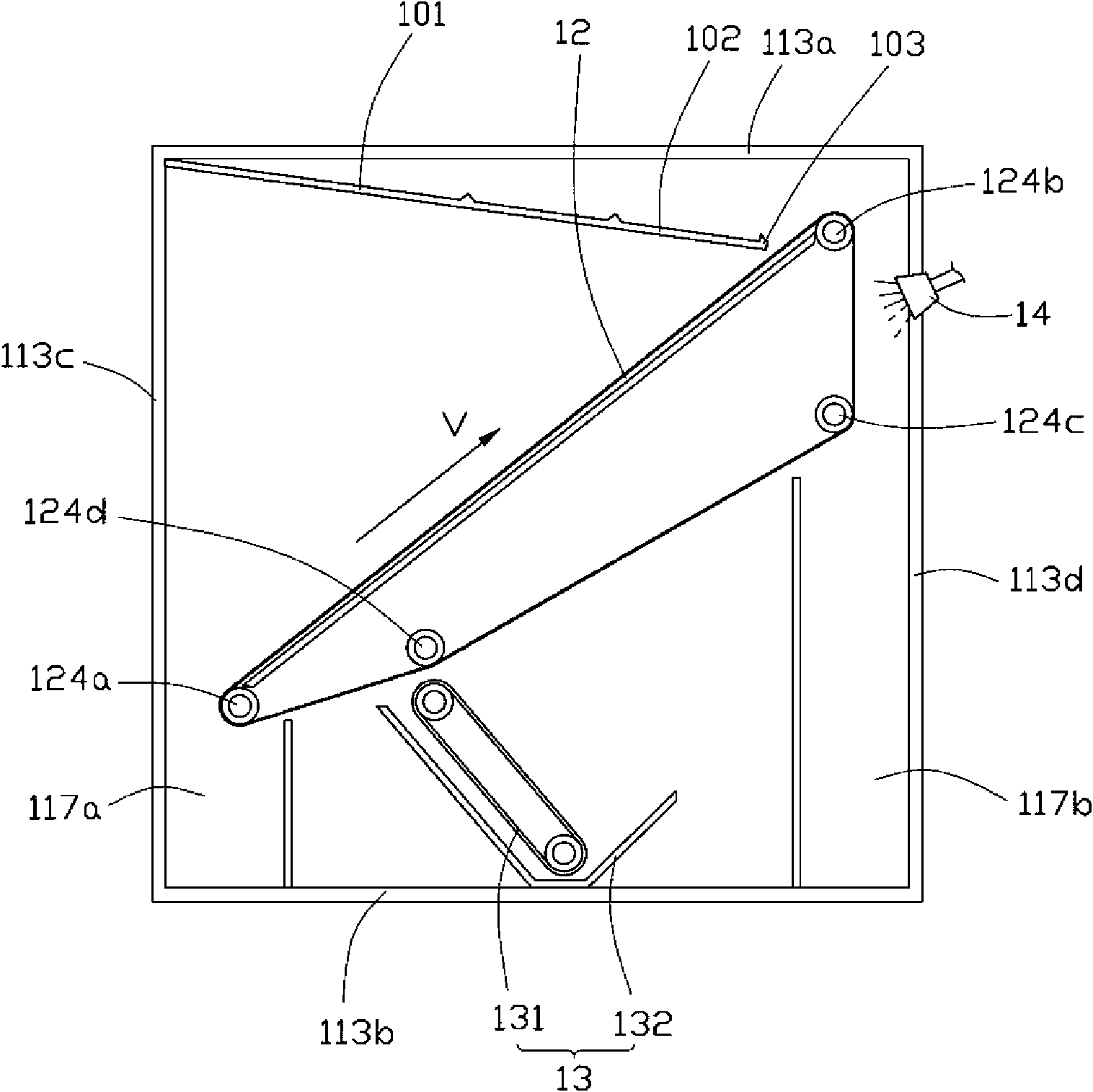

Casting equipment

InactiveCN103862023APrevent re-oxidationQuality improvementMelt-holding vesselsFurnace componentsPressure castingAluminum can

Owner:CITIC DICASTAL

Method for welding ultra-pure copper target material and back plate

PendingCN112122763AImprove welding strengthIntegrity guaranteedNon-electric welding apparatusVery large scale integrated circuitsWeld strength

The invention discloses a method for welding an ultra-pure copper target material and a back plate. The welding method comprises the steps that coating of a welding surface of the back plate with a thread is performed; then the back plate and the ultra-pure copper target material are assembled; the assembled ultra-pure copper target material and back plate are put into a sheath; the sheath is sealed and vacuumized; the vacuumized sheath is subjected to hot isostatic pressing treatment; and welding of the ultra-pure copper target material and the back plate is completed. According to the method, as the structure of the welding surface of the back plate is improved, threaded protrusions can be embedded into the target material, and then a combination effect of the target material and the back plate is enhanced, then diffusivity of a coating film is utilized, and the target material and the welding surface of the back plate are fully covered, so that the welding combination degree betweenthe target material and the back plate is improved, and the welding strength is high; the coating film is placed on the back plate, so that completeness of the coating film is ensured during welding,and damage caused to the coating film by the threaded protrusions is avoided. According to the welding method, a hot isostatic pressing process is adopted to control the size of crystal grains of thetarget material, so that the target material meets application requirements of a super-large-scale integrated circuit.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for recovering iron in low-iron Bayer process red mud

The invention discloses a method for recovering iron in low-iron Bayer process red mud. The method comprises the steps that de-alkalization treatment is conducted on the Bayer process red mud by adopting calcium oxide to mix the de-alkalization red mud with activated carbon; the mixture is mixed with a binding agent to be pressed into tablets; the tablets are placed into a graphite crucible, high-temperature treatment is conducted under the condition that argon is introduced all the time in a vacuum electromagnetic sensing furnace, the tablets are cooled down along with the furnace, grinding is conducted, and iron slags are separated through magnetic sorting. The method has the advantages that the recovery rate and grade of iron are higher than 80%, the processed Bayer red mud can be usedfor producing building materials, recovered iron is conformed to demands of industrial steel melting, the problem of excessively high red mud accumulation amount is effectively solved, and an excellent guiding meaning is achieved on the recovery of iron in the low-iron Bayer process red mud.

Owner:KUNMING UNIV OF SCI & TECH

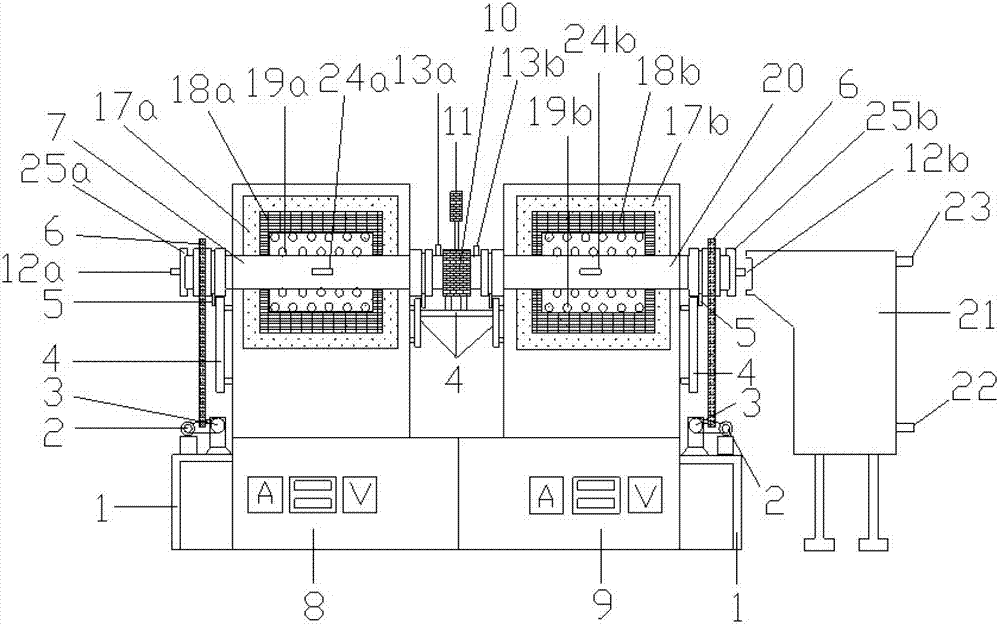

Atmosphere-adjustable double-temperature-control composite ceramsite sintering rotary furnace and working method thereof

InactiveCN103047855AAvoid temperature dipsAvoid re-oxidationRotary drum furnacesCeramic materials productionRotary furnaceContinuous production

The invention relates to an atmosphere-adjustable double-temperature-control composite ceramsite sintering rotary furnace and a working method thereof. The atmosphere-adjustable double-temperature-control composite ceramsite sintering rotary furnace comprises a tubular preheating furnace, a speed reducer, supports, a sectioning partition and a tubular sintering furnace, heaters are arranged outside a preheating furnace tube and a sintering furnace tube respectively, thermocouples are arranged in the preheating furnace tube and the sintering furnace tube respectively and are connected with automatic temperature controllers, the speed reducer drives the preheating furnace and the sintering furnace to rotate through linkage chains, and an atmosphere-adjustable ceramsite collector is further arranged outside the sintering furnace. The atmosphere-adjustable double-temperature-control composite ceramsite sintering rotary furnace integrates preheating and sintering and is capable of rotating at a uniform speed, adjustable in preheating and sintering atmosphere, reasonable in allocation and capable of achieving continuous production of ceramsite sintering.

Owner:SHANDONG UNIV

Continuous spot coating halogen-free solder paste and preparation method

InactiveCN102513738ASmall surface areaEasy to useWelding/cutting media/materialsSoldering mediaOrganic acidRosin

Owner:东莞优诺电子焊接材料有限公司

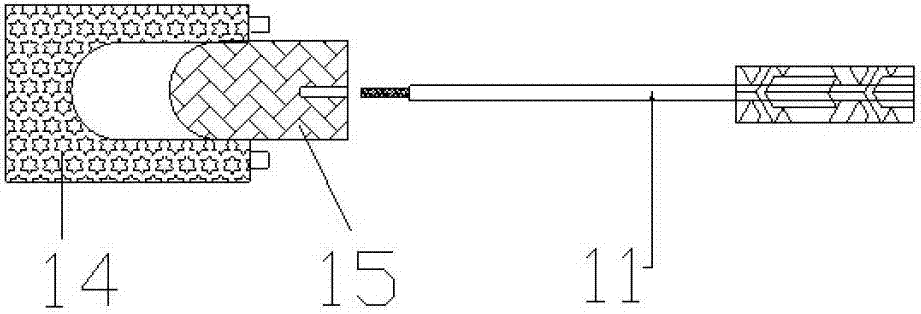

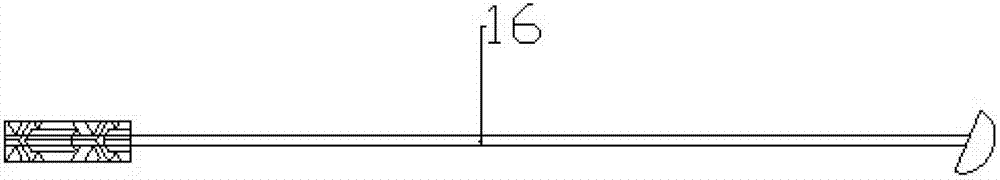

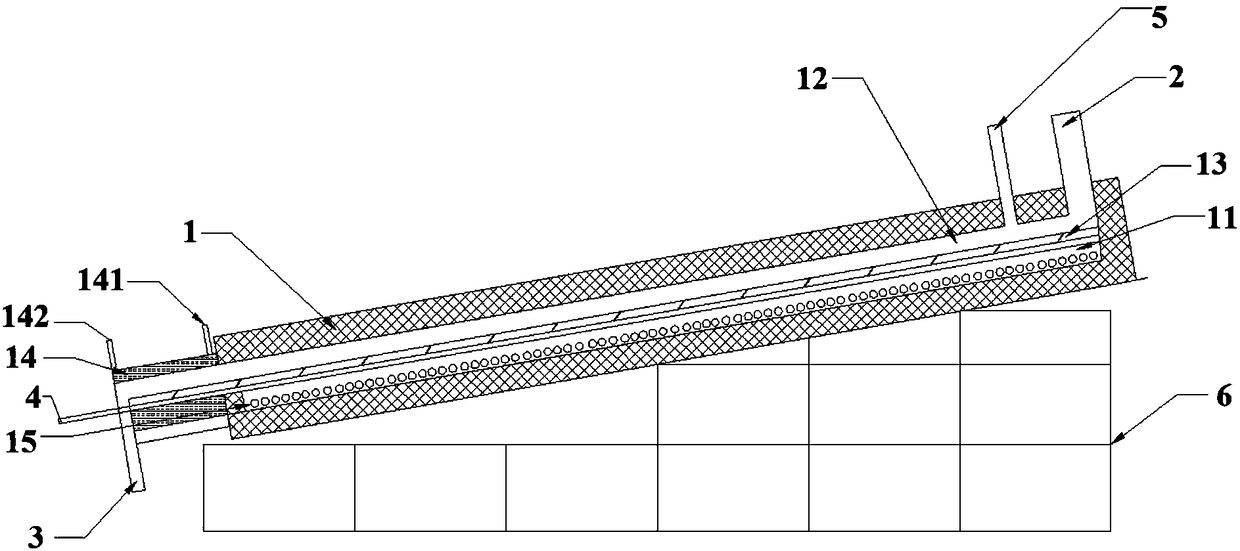

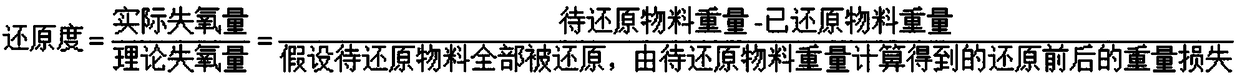

Bottom blowing reduction device and reduction method using device

The invention provides a bottom blowing reduction device. The bottom blowing reduction device comprises a furnace body, a feed port, a discharge port, a reduction gas inlet and a reduction gas outlet;the furnace body is transversely arranged, and forms a certain included angle with the horizontal direction; in the length direction of the furnace body, a gas cavity and a material cavity are formedin the furnace body; the gas cavity and the material cavity are separated by a porous plate; the feed port is formed in one higher end of the furnace body; and the reduction gas inlet and the reduction gas outlet both communicate with the gas cavity. The invention further provides a method for bottom blowing reduction by using the device; and materials to be reduced are fed in the material cavityfrom the feed port, slowly move downwards along the inclined furnace body under coaction of the gravity and the reduction gas, and are finally reduced and output from the discharge port. The method has no need to use a push rod or a conveying belt for driving a boat container to move, so that the boat container and a conveying device are omitted.

Owner:孙院军 +2

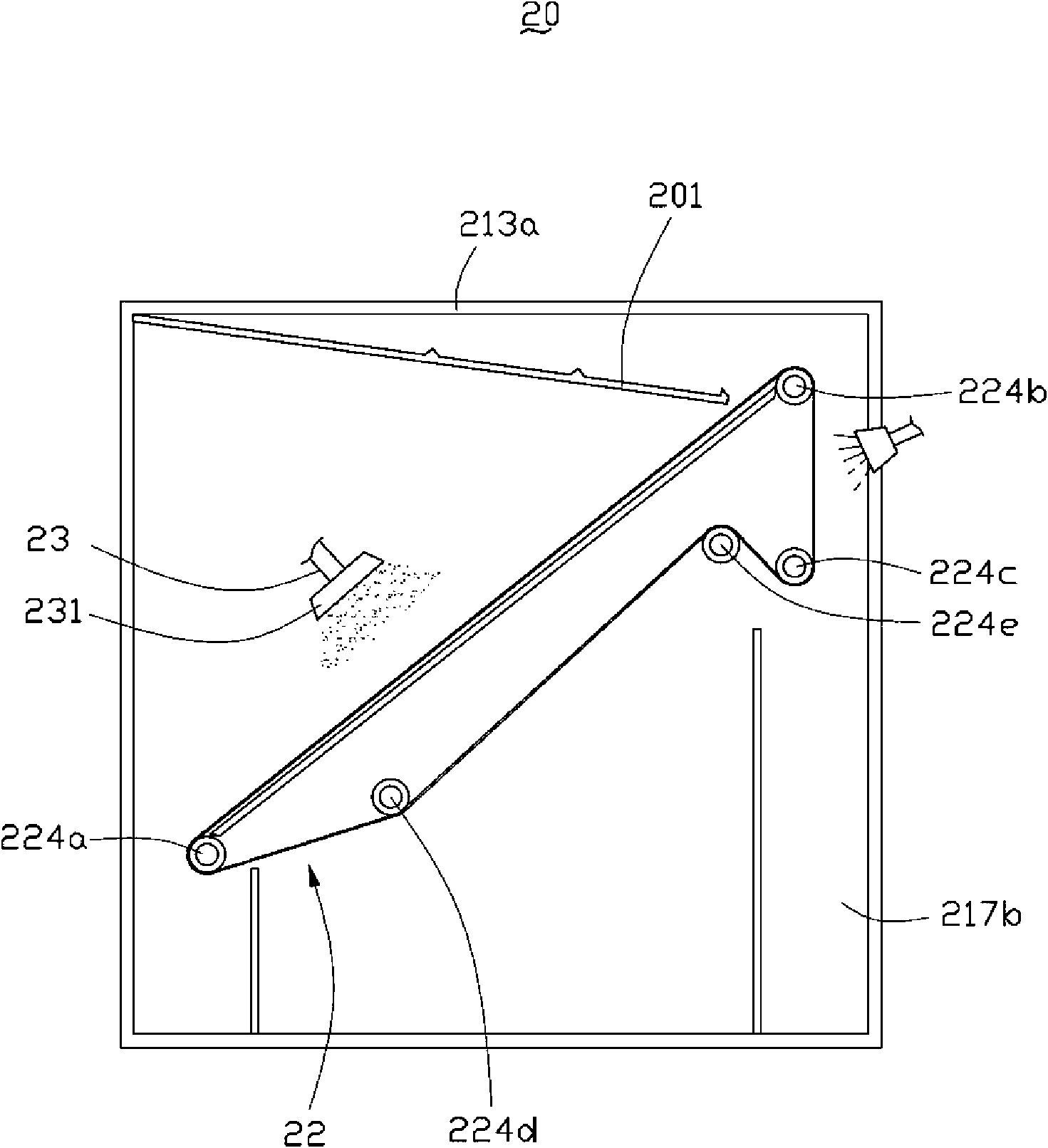

Waste liquor recovery device and method

InactiveCN101671075APrevent re-oxidationSeparation in timeWater contaminantsNature of treatment waterLiquid wasteRecovery method

The invention provides a waste liquor recovery device which comprises a reducing agent-supplying device, a waste liquor-guiding device and a conveyer belt, wherein the waste liquor-guiding device andthe conveyer belt are arranged opposite to the reducing agent-supplying device; the waste liquor-guiding device comprises an injection end for providing the conveyer belt with waste liquor; one end ofthe conveyer belt is close to the reducing agent-supplying device, and the other end is close to the injection end; the reducing agent-supplying device is used for providing the conveyer belt with areducing agent; the transmission direction of the conveyer belt enables the reducing agent to move towards one end of the conveyer belt close to the injection end; and the conveyer belt is obliquely arranged so that the flowing direction of the waste liquor on the conveyer belt is opposite to the transmission direction. The invention also provides a waste liquor recovery method.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Lipid aroma condensate prepared through fat thermal oxidation and preparation method thereof

InactiveCN102919806ALow peroxide valueLow acid valueEssential-oils/perfumesFood preparationFlavorFood additive

The present invention discloses a method for preparing a lipid aroma condensate by adopting fat as a raw material and by adopting a two step process of heating oxidation and degradation, and a product thereof. The specific method comprises: 1) in the presence of an antioxidant and water, introducing air to fat to carry out heating stirring oxidation, wherein an air flow rate is 0.1-2 m<3> / kg.h, a temperature is 100-180 DEG C, a time is 0.5-5 h, and a stirring speed is 200-1000 rpm / min; and 2) introducing nitrogen gas to the product obtained from the step 1) to carry out heating degradation, wherein a nitrogen gas flow rate is 0.1-0.5 m<3> / kg.h, a heating temperature is 100-180 DEG C, and a time is 0.5-6 h. According to the present invention, the obtained product has rich, harmonious and fruity lipid aroma, can be used as a thermal reaction flavor raw material, and can further be directly used in chicken essence, instant noodle condiments, soup sticks, sausages, cans, frozen dumplings and other seasonings or food as a natural food additive.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

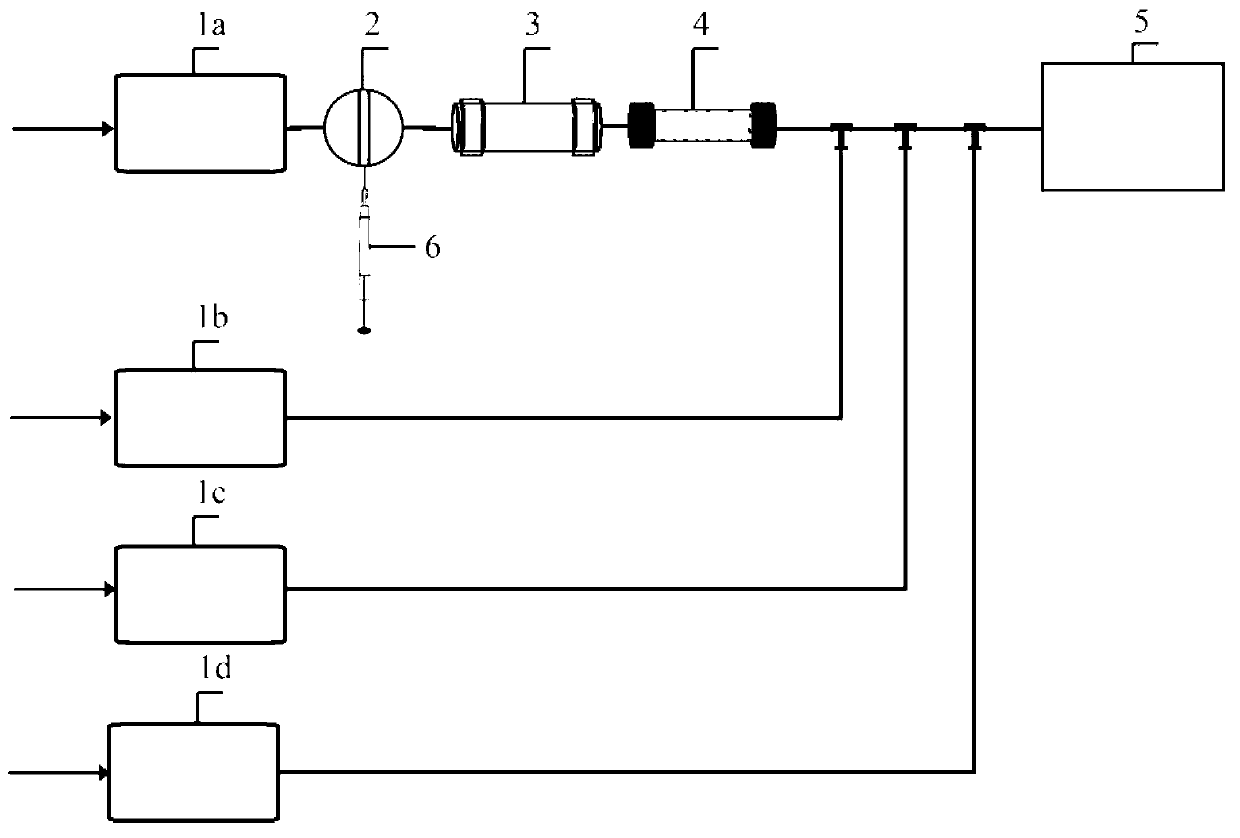

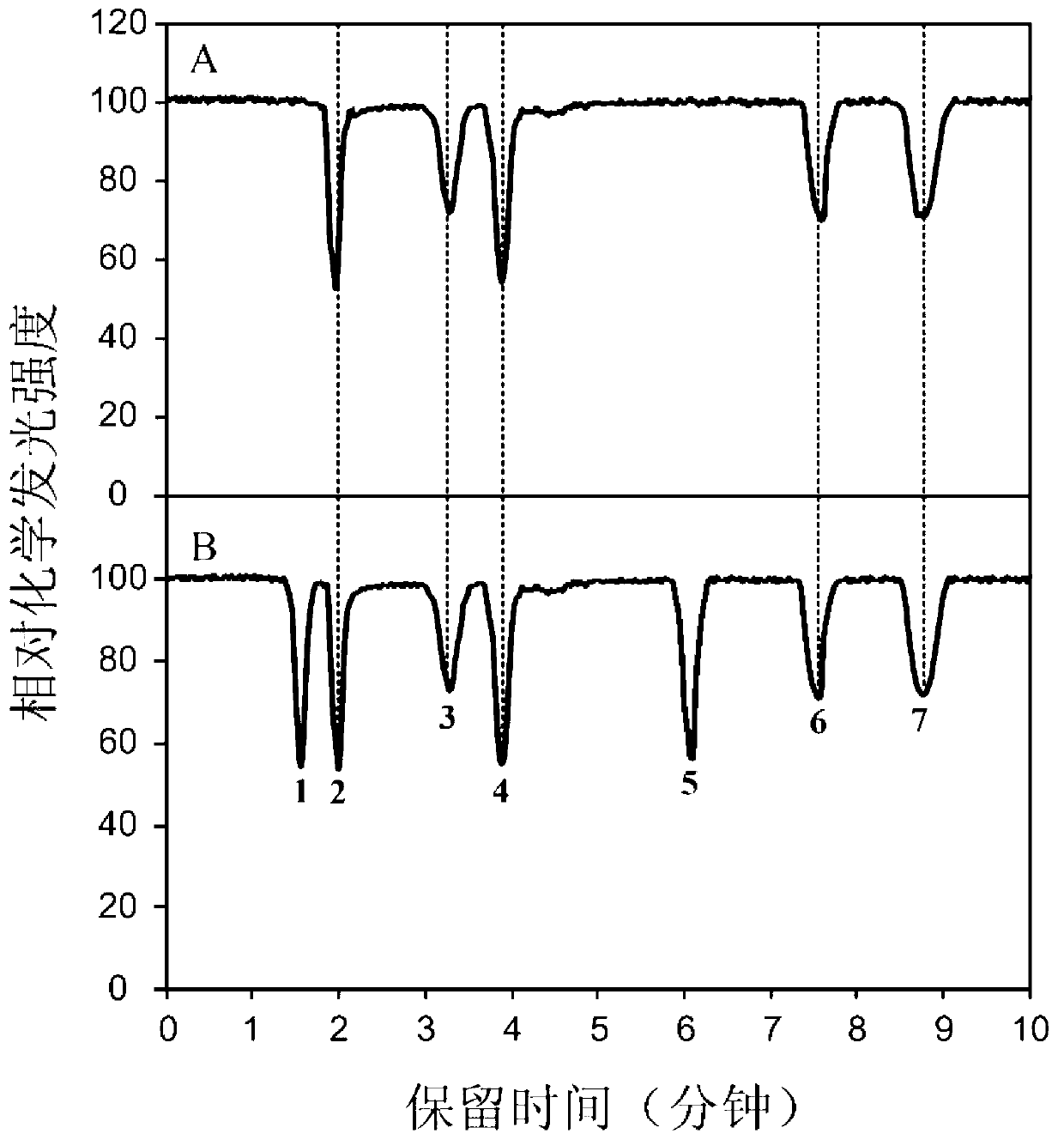

Device and method for online deduction of amino acid disulfide and determination of amino acid

InactiveCN102998155AEasy to makeThe restore process is fastComponent separationPreparing sample for investigationChromatography columnChemistry

The invention provides a device and a method for online deduction of amino acid disulfide and determination of amino acid. The device mainly comprises a high-pressure pump, a high performance liquid chromatographic column, an online reduction column, and a chemiluminescent detector. The basic technical route is as follows: a amino acid solution to be determined enters the online reduction column after being subjected to high performance liquid chromatographic column separation; and the amino acid disulfide in the solution is restored into corresponding mercaptoamino acid by tri(2-propyloic) phosphine complex crystal of zinc (II) in the online reduction column, and then enters the chemiluminescent detector to be subjected to online determination of the amino acid. The online reduction device is simple and convenient in detection method, rapid in reduction process, high in reduction efficiency, good in repeatability, and wide in application prospect, and newly restored mercaptoamino acid is prevented from being oxidized into the amino acid disulfide again in sample treatment and analysis processes.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com