Device and method for removing rust corrosion of inner cavity of plastic rolling mould

A rotomolding mold and inner cavity technology, applied in cleaning methods and utensils, chemical instruments and methods, coatings, etc., can solve problems such as large pollution, impact on mold accuracy and life, achieve high cleanliness, improved surface performance, The effect of preventing re-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

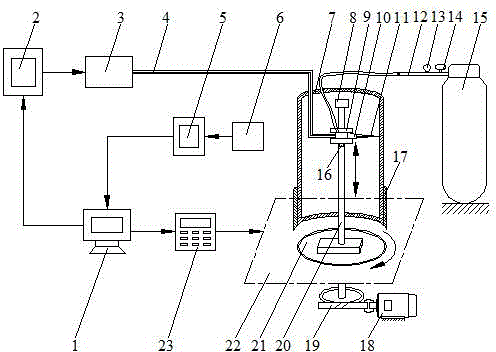

[0042] Such as Figure 1-3 shown.

[0043] A device for cleaning the inner cavity of a rotomolding mold, which includes five parts: a laser loading system, a cleaning system, a control system, a real-time feedback system, and an auxiliary system, such as figure 1 shown.

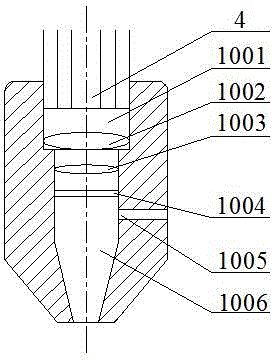

[0044] in:

[0045] The laser loading system consists of a laser controller 2 , a nanosecond laser 3 , and a bendable optical fiber 4 . The cleaning system consists of cleaning working heads 10 . Wherein, cleaning working head 10 internal structures such as figure 2 As shown, it is provided with a transmission fiber interface 1001 and a laser output channel 1006, and a beam expander input mirror 1002, a beam expander output mirror 1003 and a protective plane mirror 1004 are installed between the transmission fiber interface 1001 and the laser output channel 1006, and an inert gas The connecting port 1005 is vertically communicated with the laser output channel 1006 . After the laser beam 11 emitted...

Embodiment 2

[0052] A method for cleaning the inner cavity of rotomolding molds with a cleaning volume of 4 m 3 Take the semi-circular mold of the vertical flat-bottomed plastic storage tank (mold inner diameter D = 1600 mm, length 2000 mm, wall thickness 12 mm inner cavity corrosion as an example, the average thickness of the corrosion is 0.22 mm, and the corrosion surface area is 5.02 m 2 , the method steps are as follows:

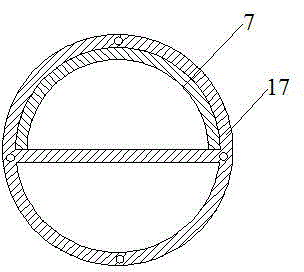

[0053] A. Place the rotomolding mold 7 to be cleaned above the workbench 22, make its axis coincide with the Z-direction rotation axis of the workbench 22, and fasten it with the bushing fixture 17, and then use the magnetic suction seat to place the acoustic emission sensor 16 Adsorbed on the bottom surface of the working head fixture 9.

[0054] B. Position the cleaning working head 10 completely on the working head fixture 9, and then adjust the height of the working head fixture 9 so that the cleaning working head 10 points vertically to the starting po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com