Casting equipment

A casting equipment and casting machine technology, applied in casting equipment, foundry workshops, metal processing equipment and other directions, can solve the problems of increasing the oxidation of molten aluminum in the holding furnace, energy waste, uneven temperature of molten aluminum, etc., to improve the utilization rate, The effect of improving heating efficiency and avoiding re-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

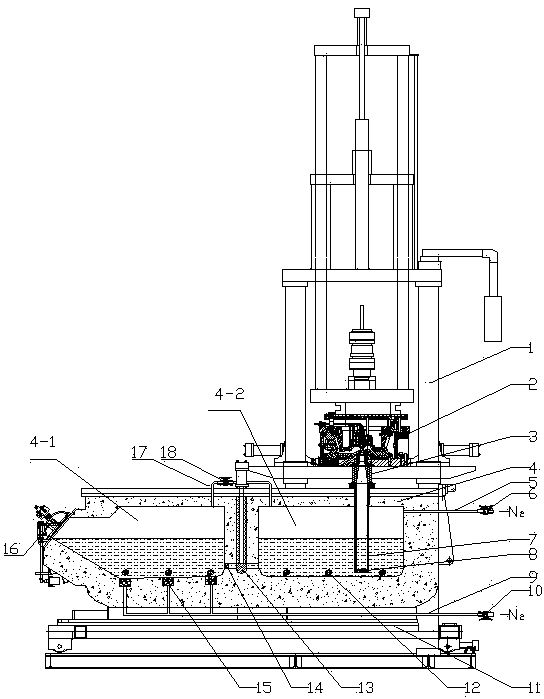

[0010] As accompanying drawing, the equipment of the present invention ( figure 1 ) is equipped with a mold (2) on the frame (1) of the low-pressure casting machine, and a holding furnace (4) is installed at the lower part of the frame (1) of the low-pressure casting machine. The holding furnace (4) is divided into two furnace chambers: a liquid-feeding refining chamber (4-1) and a pressurized casting chamber (4-2). The lower part of the two furnace chambers is connected by a channel with a gate valve (13); filter sheet (14). Three immersion-type electric heaters (12) are installed in the lower part of the two furnace chambers, and three air-permeable bricks (15) are evenly installed on the bottom of the liquid-feeding and refining chamber (4-1). It is connected with the compressed inert gas tank, and an electric proportional valve B (10) is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com