Highly reliable cuprous oxide semiconductor sparking plug sealing method

A cuprous oxide and semiconductor technology, applied in high-energy electric ignition and low-voltage fields, can solve problems such as air leakage, poor transition layer quality, and low pass rate of product sealing, achieve high seal pass rate, solve poor quality, and improve sealing The effect of sexual eligibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

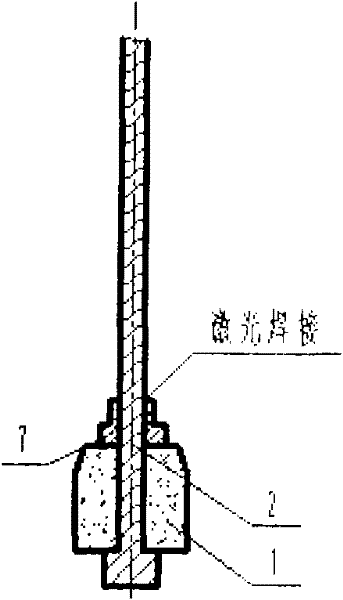

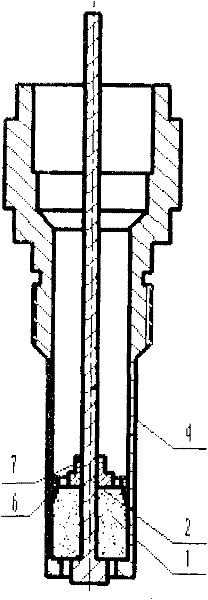

[0020] Figure 1 ~ Figure 4 Described is a cuprous oxide semiconductor electric nozzle composed of a semiconductor component 1, a central electrode 2, a sealing glass blank 3, an electric nozzle outer shell 4, a porcelain tube 5, etc., sequentially assembled. Wherein, the semiconductor component 1 is sandwiched between the center electrode 2 and the lock nut 7 . The semiconductor component 1 is an independent component that is pre-coated with semiconductor glaze and "sintered" at high temperature, and then put into the electric mouth shell 4 with sealing glass, etc., and the electric mouth glass is sealed. This process is called "sealing". The end of the central electrode 2 and the locking nut 7 are fixedly connected. The sealing glass blank 3 can be a pre-vitrified borosilicate glass material with a relatively high softening temperature.

[0021] The method for highly reliable sealing of the cuprous oxide semiconductor electric nozzle proposed by the present invention is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com