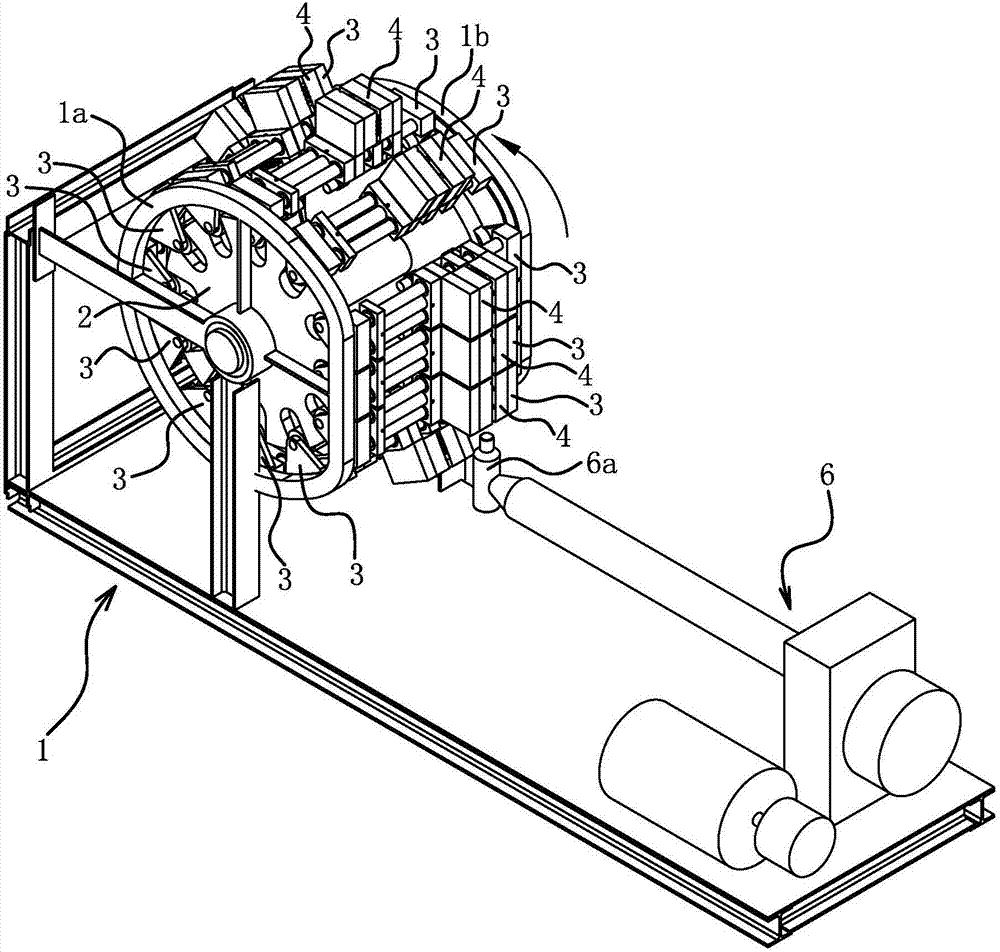

Blowing machine

A technology of blow molding machine and blow molding mold, which is applied in the field of plastic processing, and can solve the problems that the production efficiency is difficult to meet the needs of customers, and achieve the effects of smooth and stable movement, high product production efficiency, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

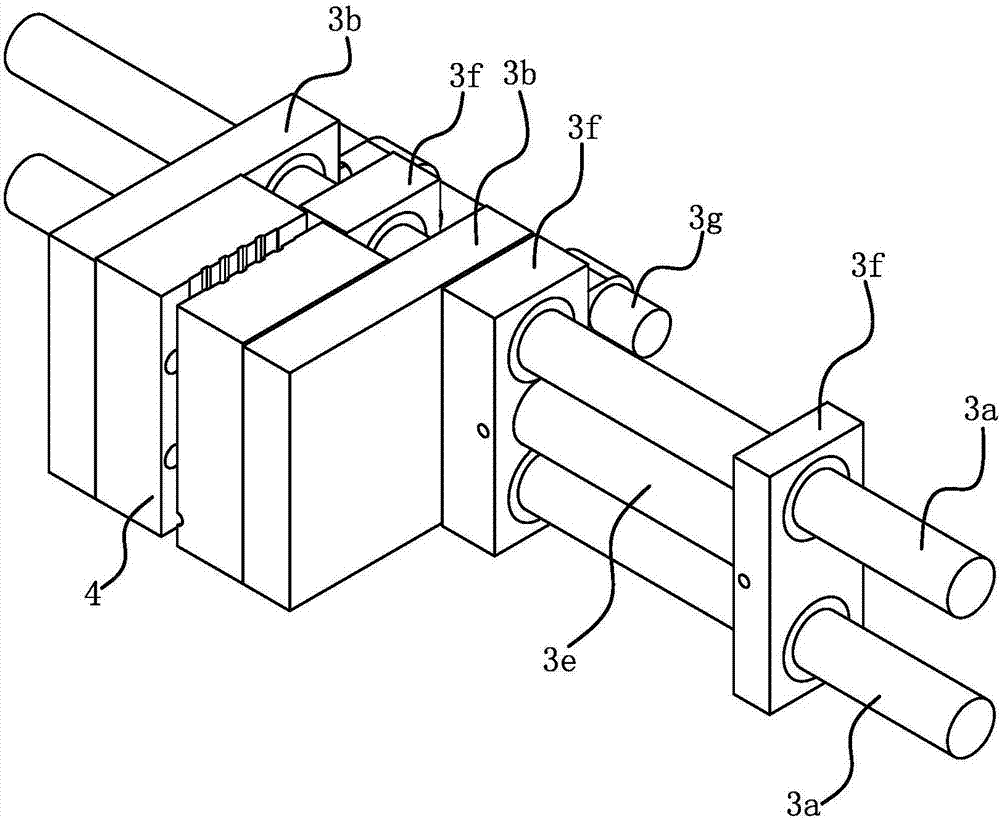

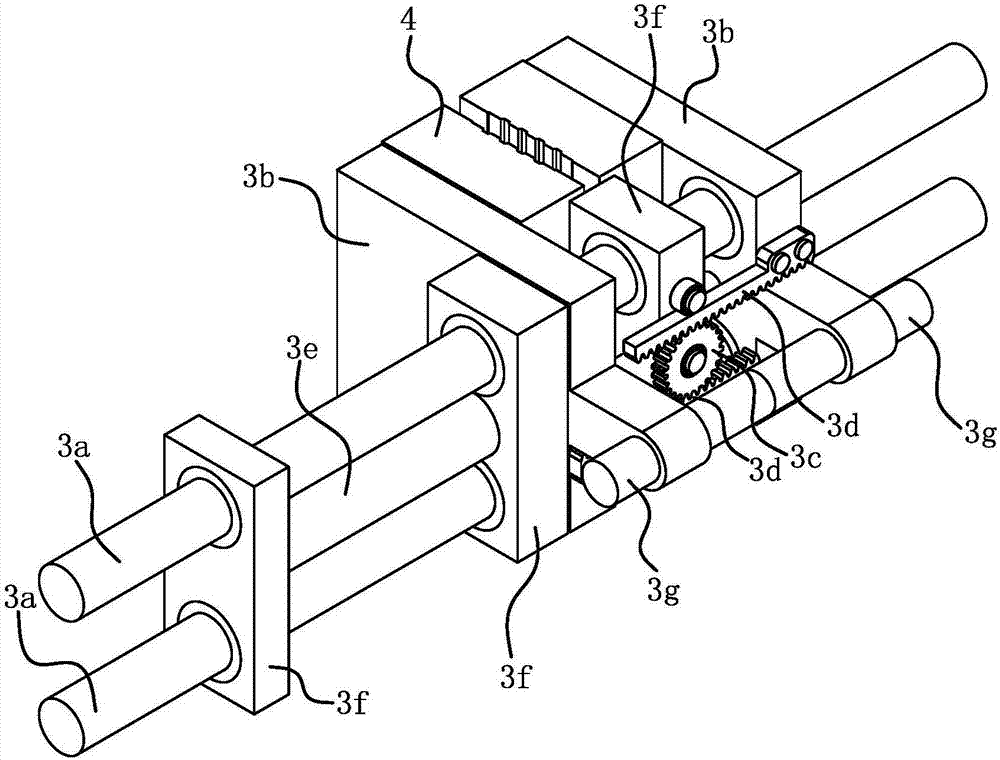

Method used

Image

Examples

Embodiment 2

[0048] The structure and principle of this embodiment are basically the same as those of the first embodiment, and the basic similarities will not be described redundantly. Only the differences are described, and the differences are that the turntable 2 is arranged horizontally.

Embodiment 3

[0050] The structure and principle of this embodiment are basically the same as that of the first embodiment. The basic similarities will not be described redundantly. Only the differences are described. The differences are: the cylinder body 3e1 of the oil cylinder 3e is fixed to one of the mold mounting plates 3b. Connected, the piston rod 3e2 is fixedly connected with another mold mounting plate 3b.

Embodiment 4

[0052] The structure and principle of this embodiment are basically the same as those of the first embodiment. The basic similarities will not be described redundantly. Only the differences are described. The differences are: the radial guide structure includes a guide post fixed on the turntable 2 and a guide The axis line of the column coincides with the radial line of the turntable 2. The number of guide posts is the same as that of the blow mold opening and closing device 3. The guide post is covered with a sliding sleeve, and the sliding sleeve is in the blow mold opening and closing device 3. The mounting bases 3f are rotationally connected one-to-one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com